J Periodontal Implant Sci.

2013 Oct;43(5):221-226. 10.5051/jpis.2013.43.5.221.

The combined effect of dismantling for steam sterilization and aging on the accuracy of spring-style mechanical torque devices

- Affiliations

-

- 1Department of Prosthodontics, Dental School, Shahid Beheshti University of Medical Sciences, Tehran, Iran. A_Saboury@yahoo.com

- KMID: 2212030

- DOI: http://doi.org/10.5051/jpis.2013.43.5.221

Abstract

- PURPOSE

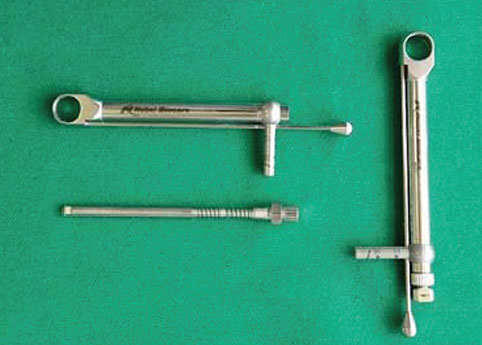

This study aimed to assess the combined effect of dismantling before sterilization and aging on the accuracy (+/-10% of the target torque) of spring-style mechanical torque devices (S-S MTDs).

METHODS

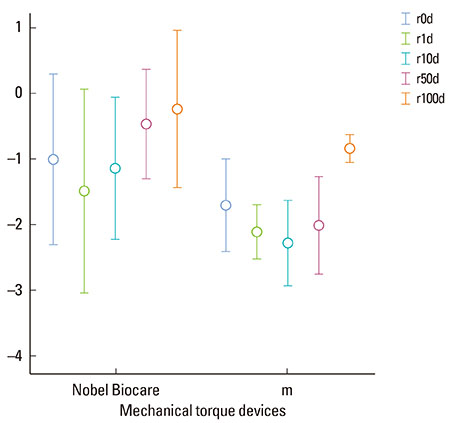

Twenty new S-SMTDs from two different manufacturers (Nobel Biocare and Straumann: 10 of each type) were selected and divided into two groups, namely, case (group A) and control (group B). For sterilization, 100 cycles of autoclaving were performed in 100 sequences. In each sequence, 10 repetitions of peak torque values were registered for aging. To measure and assess the output of each device, a Tohnichi torque gauge was used (P<0.05).

RESULTS

Before steam sterilization, all of the tested devices stayed within 10% of their target values. After 100 cycles of steam sterilization and aging with or without dismantling of the devices, the Nobel Biocare devices stayed within 10% of their target torque. In the Straumann devices, despite the significant difference between the peak torque and target torque values, the absolute error values stayed within 10% of their target torque.

CONCLUSION

Within the limitations of this study, there was no significant difference between the mean and absolute value of error between Nobel Biocare and Straumann S-S MTDs.

Keyword

Figure

Reference

-

1. Tsuruoka M. Tohnichi torque handbook. Tokyo: Tohnichi Mfj Co.;2008. Vol. 7.2. Haack JE, Sakaguchi RL, Sun T, Coffey JP. Elongation and preload stress in dental implant abutment screws. Int J Oral Maxillofac Implants. 1995; 10:529–536.3. Guda T, Ross TA, Lang LA, Millwater HR. Probabilistic analysis of preload in the abutment screw of a dental implant complex. J Prosthet Dent. 2008; 100:183–193.

Article4. Gutierrez J, Nicholls JI, Libman WJ, Butson TJ. Accuracy of the implant torque wrench following time in clinical service. Int J Prosthodont. 1997; 10:562–567.5. Santos GC Jr, Passos SP, Coelho Santos MJ. Accuracy of mechanical torque devices for implants used in Brazilian dental offices. Int J Prosthodont. 2011; 24:38–39.6. McCracken MS, Mitchell L, Hegde R, Mavalli MD. Variability of mechanical torque-limiting devices in clinical service at a US dental school. J Prosthodont. 2010; 19:20–24.

Article7. Cehreli MC, Akca K, Tonuk E. Accuracy of a manual torque application device for morse-taper implants: a technical note. Int J Oral Maxillofac Implants. 2004; 19:743–748.8. Mahshid M, Saboury A, Fayaz A, Sadr SJ, Lampert F, Mir M. The effect of steam sterilization on the accuracy of spring-style mechanical torque devices for dental implants. Clin Cosmet Investig Dent. 2012; 4:29–35.9. Vallee MC, Conrad HJ, Basu S, Seong WJ. Accuracy of friction-style and spring-style mechanical torque limiting devices for dental implants. J Prosthet Dent. 2008; 100:86–92.

Article10. Kreissl ME, Gerds T, Muche R, Heydecke G, Strub JR. Technical complications of implant-supported fixed partial dentures in partially edentulous cases after an average observation period of 5 years. Clin Oral Implants Res. 2007; 18:720–726.

Article11. Zurdo J, Romao C, Wennstrom JL. Survival and complication rates of implant-supported fixed partial dentures with cantilevers: a systematic review. Clin Oral Implants Res. 2009; 20:Suppl 4. 59–66.

Article12. Aglietta M, Siciliano VI, Zwahlen M, Bragger U, Pjetursson BE, Lang NP, et al. A systematic review of the survival and complication rates of implant supported fixed dental prostheses with cantilever extensions after an observation period of at least 5 years. Clin Oral Implants Res. 2009; 20:441–451.

Article13. Jung RE, Pjetursson BE, Glauser R, Zembic A, Zwahlen M, Lang NP. A systematic review of the 5-year survival and complication rates of implant-supported single crowns. Clin Oral Implants Res. 2008; 19:119–130.

Article14. Pjetursson BE, Bragger U, Lang NP, Zwahlen M. Comparison of survival and complication rates of tooth-supported fixed dental prostheses (FDPs) and implant-supported FDPs and single crowns (SCs). Clin Oral Implants Res. 2007; 18:Suppl 3. 97–113.

Article15. Gratton DG, Aquilino SA, Stanford CM. Micromotion and dynamic fatigue properties of the dental implant-abutment interface. J Prosthet Dent. 2001; 85:47–52.

Article16. Standlee JP, Caputo AA, Chwu MY, Sun TT. Accuracy of mechanical torque-limiting devices for implants. Int J Oral Maxillofac Implants. 2002; 17:220–224.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Accuracy of spring-style and friction-style mechanical implant torque wrench

- Comparative analysis of accuracy of how to use the implant torque controllers

- The Influence of E-beam Irradiation on POLY(ETHER-BLOCK-AMIDE) (PEBA, Pebax)

- Cyclic fatigue of the sodium hypochlorite treated and/or steam autoclaved nickel-titanium endodontic files

- A study on the torque effect of orthodontic wires