J Korean Acad Prosthodont.

2012 Apr;50(2):128-134. 10.4047/jkap.2012.50.2.128.

Evaluation of reverse torque value of abutment screws on CAD/CAM custom-made implant abutments

- Affiliations

-

- 1Department of Prosthodontics, Graduate School of Clinical Dental Science, The Catholic University of Korea, Seoul, Korea.

- 2Department of Prosthodontics, Samsung Medical Center, College of Medicine, Sungkyunkwan University, Korea. seokgyu_k@yahoo.com

- KMID: 2195507

- DOI: http://doi.org/10.4047/jkap.2012.50.2.128

Abstract

- PURPOSE

The purpose of this study was to compare the screw joint stability between the CADCAM custom-made implant abutment and the prefabricated implant abutment by measuring the reverse torque value after cyclic loading.

MATERIALS AND METHODS

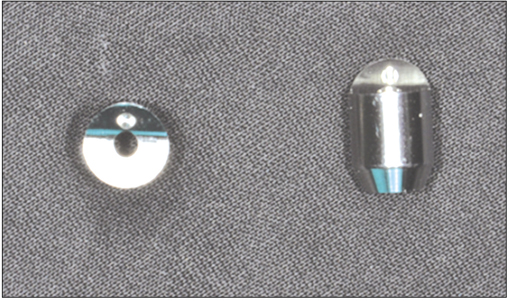

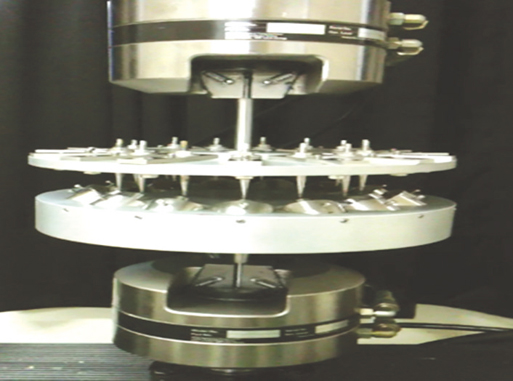

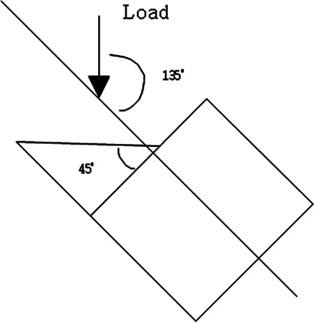

Twelve screw type implants (Implantium, Dentium Co., Seoul, Korea) were embedded in aluminum cylinder with acrylic resin. The implant specimens were equally divided into 3 groups, and connected to the prefabricated titanium abutments (Implantium, Dentium Co., Seoul, Korea), CADCAM custom-made titanium abutments (Myplant, Raphabio Co., Seoul, Korea) and CADCAM custom-made zirconia abutments (Zirconia Myplant, Raphabio Co., Seoul, Korea). The CAD-CAM milled titanium crown (Raphabio Co., Seoul, Korea) was cemented on each implant abutment by resin cement. Before cyclic loading, each abutment screw was tightened to 30 Ncm and the reverse torque value was measured about 30 minutes later. After the crown specimen was subjected to the sinusoidal cyclic loading (30 to 120 N, 500,000 cycles, 2 Hz), postloading reverse torque value was measured and the reverse torque loss ratio was calculated. Kruskal-Wallis test was used for statistical analysis of the reverse torque loss ratio.

RESULTS

The CADCAM custom-made titanium abutments presented higher values in reverse torque loss ratio without statistically significant differences than the prefabricated titanium abutments (P>.05). Reverse torque loss ratio of the custom-made zirconia abutments was significantly higher compared to that of the prefabricated titanium abutments (P=.014).

CONCLUSION

Within the limitation of the present in-vitro study, it was concluded that there was no significant difference in screw joint stability between the CADCAM custom-made titanium abutments and the prefabricated titanium abutments. On the other hand, the CADCAM custom-made zirconia abutments showed lower screw joint stability than prefabricated titanium abutments.

MeSH Terms

Figure

Cited by 2 articles

-

A comparative study on the fit and screw joint stability of ready-made abutment and CAD-CAM custom-made abutment

Jong-Wook Kim, Yu-Ri Heo, Hee-Jung Kim, Chae-Heon Chung

J Korean Acad Prosthodont. 2013;51(4):276-283. doi: 10.4047/jkap.2013.51.4.276.Fit analysis of CAD-CAM custom abutment using micro-CT

Gwang-Seok Min, Chae-Heon Chung, Hee-Jung Kim

J Korean Acad Prosthodont. 2016;54(4):370-378. doi: 10.4047/jkap.2016.54.4.370.

Reference

-

1. Brånemark PI. Osseointegration and its experimental background. J Prosthet Dent. 1983. 50:399–410.

Article2. Johns RB, Jemt T, Heath MR, Hutton JE, McKenna S, McNamara DC, van Steenberghe D, Taylor R, Watson RM, Herrmann I. A multicenter study of overdentures supported by Brånemark implants. Int J Oral Maxillofac Implants. 1992. 7:513–522.3. Jemt T, Laney WR, Harris D, Henry PJ, Krogh PH Jr, Polizzi G, Zarb GA, Herrmann I. Osseointegrated implants for single tooth replacement: a 1-year report from a multicenter prospective study. Int J Oral Maxillofac Implants. 1991. 6:29–36.4. Andersson B, Odman P, Lindvall AM, Lithner B. Single-tooth restorations supported by osseointegrated implants: results and experiences from a prospective study after 2 to 3 years. Int J Oral Maxillofac Implants. 1995. 10:702–711.5. Jörnéus L, Jemt T, Carlsson L. Loads and designs of screw joints for single crowns supported by osseointegrated implants. Int J Oral Maxillofac Implants. 1992. 7:353–359.6. Misch CE. Misch CE, editor. Principles for screw-retained prostheses. Contemporary implant dentistry. 1999. Missouri: CV Mosby.7. Bickford JH. An introduction to the design and behavior of bolted joints. 1995. New York: Marcel Dekker.8. Jemt T. Customized titanium single-implant abutments: 2-year follow-up pilot study. Int J Prosthodont. 1998. 11:312–316.9. Sundh A, Sjögren G. A study of the bending resistance of implant-supported reinforced alumina and machined zirconia abutments and copies. Dent Mater. 2008. 24:611–617.

Article10. Wu T, Liao W, Dai N, Tang C. Design of a custom angled abutment for dental implants using computer-aided design and nonlinear finite element analysis. J Biomech. 2010. 43:1941–1946.

Article11. Kim S, Kim HI, Brewer JD, Monaco EA Jr. Comparison of fracture resistance of pressable metal ceramic custom implant abutments with CAD/CAM commercially fabricated zirconia implant abutments. J Prosthet Dent. 2009. 101:226–230.

Article12. Henriksson K, Jemt T. Evaluation of custom-made procera ceramic abutments for single-implant tooth replacement: a prospective 1-year follow-up study. Int J Prosthodont. 2003. 16:626–630.13. Lang LA, Sierraalta M, Hoffensperger M, Wang RF. Evaluation of the precision of fit between the Procera custom abutment and various implant systems. Int J Oral Maxillofac Implants. 2003. 18:652–658.14. Magne P, Oderich E, Boff LL, Cardoso AC, Belser UC. Fatigue resistance and failure mode of CAD/CAM composite resin implant abutments restored with type III composite resin and porcelain veneers. Clin Oral Implants Res. 2011. 22:1275–1281.

Article15. Magne P, Paranhos MP, Burnett LH Jr, Magne M, Belser UC. Fatigue resistance and failure mode of novel-design anterior single-tooth implant restorations: influence of material selection for type III veneers bonded to zirconia abutments. Clin Oral Implants Res. 2011. 22:195–200.

Article16. Kreissl ME, Gerds T, Muche R, Heydecke G, Strub JR. Technical complications of implant-supported fixed partial dentures in partially edentulous cases after an average observation period of 5 years. Clin Oral Implants Res. 2007. 18:720–726.

Article17. Haack JE, Sakaguchi RL, Sun T, Coffey JP. Elongation and preload stress in dental implant abutment screws. Int J Oral Maxillofac Implants. 1995. 10:529–536.18. Martin WC, Woody RD, Miller BH, Miller AW. Implant abutment screw rotations and preloads for four different screw materials and surfaces. J Prosthet Dent. 2001. 86:24–32.

Article19. Cibirka RM, Nelson SK, Lang BR, Rueggeberg FA. Examination of the implant-abutment interface after fatigue testing. J Prosthet Dent. 2001. 85:268–275.

Article20. Breeding LC, Dixon DL, Nelson EW, Tietge JD. Torque required to loosen single-tooth implant abutment screws before and after simulated function. Int J Prosthodont. 1993. 6:435–439.21. Dixon DL, Breeding LC, Sadler JP, McKay ML. Comparison of screw loosening, rotation, and deflection among three implant designs. J Prosthet Dent. 1995. 74:270–278.

Article22. Carlsson GE, Haraldson T. Branemark PI, Zarb GA, Albrektsson T, editors. Functional response. Tissue integrated prostheses. Osseointegration in clinical dentistry. 1986. 4th ed. Chicago: Quintessence;74–78.23. Bates JF, Stafford GD, Harrison A. Masticatory function - a review of the literature. III. Masticatory performance and efficiency. J Oral Rehabil. 1976. 3:57–67.24. Richter EJ. In vivo vertical forces on implants. Int J Oral Maxillofac Implants. 1995. 10:99–108.25. Mericske-Stern R, Zarb GA. In vivo measurements of some functional aspects with mandibular fixed prostheses supported by implants. Clin Oral Implants Res. 1996. 7:153–161.

Article26. Patterson EA, Johns RB. Theoretical analysis of the fatigue life of fixture screws in osseointegrated dental implants. Int J Oral Maxillofac Implants. 1992. 7:26–33.27. Jaarda MJ, Razzoog ME, Gratton DG. Effect of preload torque on the ultimate tensile strength of implant prosthetic retaining screws. Implant Dent. 1994. 3:17–21.

Article28. Mitrani R, Nicholls JI, Phillips KM, Ma T. Accuracy of electronic implant torque controllers following time in clinical service. Int J Oral Maxillofac Implants. 2001. 16:394–399.29. Cantwell A, Hobkirk JA. Preload loss in gold prosthesis-retaining screws as a function of time. Int J Oral Maxillofac Implants. 2004. 19:124–132.30. Gutierrez J, Nicholls JI, Libman WJ, Butson TJ. Accuracy of the implant torque wrench following time in clinical service. Int J Prosthodont. 1997. 10:562–567.31. Kim DG, Park CJ, Cho LR. Comparison of accuracy of implant torque controllers. J Korean Acad Stomatog Func Occ. 2008. 24:157–168.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- A comparative study on the fit and screw joint stability of ready-made abutment and CAD-CAM custom-made abutment

- Fit analysis of CAD-CAM custom abutment using micro-CT

- Influence of the implant abutment types and the dynamic loading on initial screw loosening

- Considerations for Fabrication of CAD-CAM Abutments: Part I. Selection of Titanium Block and Fabrication Process

- Comparison of CAD/CAM abutment and prefabricated abutment in Morse taper internal type implant after cyclic loading: Axial displacement, removal torque, and tensile removal force