J Dent Rehabil Appl Sci.

2020 Dec;36(4):254-261. 10.14368/jdras.2020.36.4.254.

Marginal and internal fit of interim crowns fabricated with 3D printing and milling method

- Affiliations

-

- 1Department of Dental Science, Graduate School, Kyungpook National University, Daegu, Republic of Korea

- 2Advanced Dental Device Development Institute, Kyungpook National University, Daegu, Republic of Korea

- 3Department of Prosthodontics, School of Dentistry, Kyungpook National University, Daegu, Republic of Korea

- KMID: 2512120

- DOI: http://doi.org/10.14368/jdras.2020.36.4.254

Abstract

- Purpose

The purpose of this study was to assess the marginal and internal fit of interim crowns fabricated by two different manu-facturing method (subtractive manufacturing technology and additive manufacturing technology).

Materials and Methods

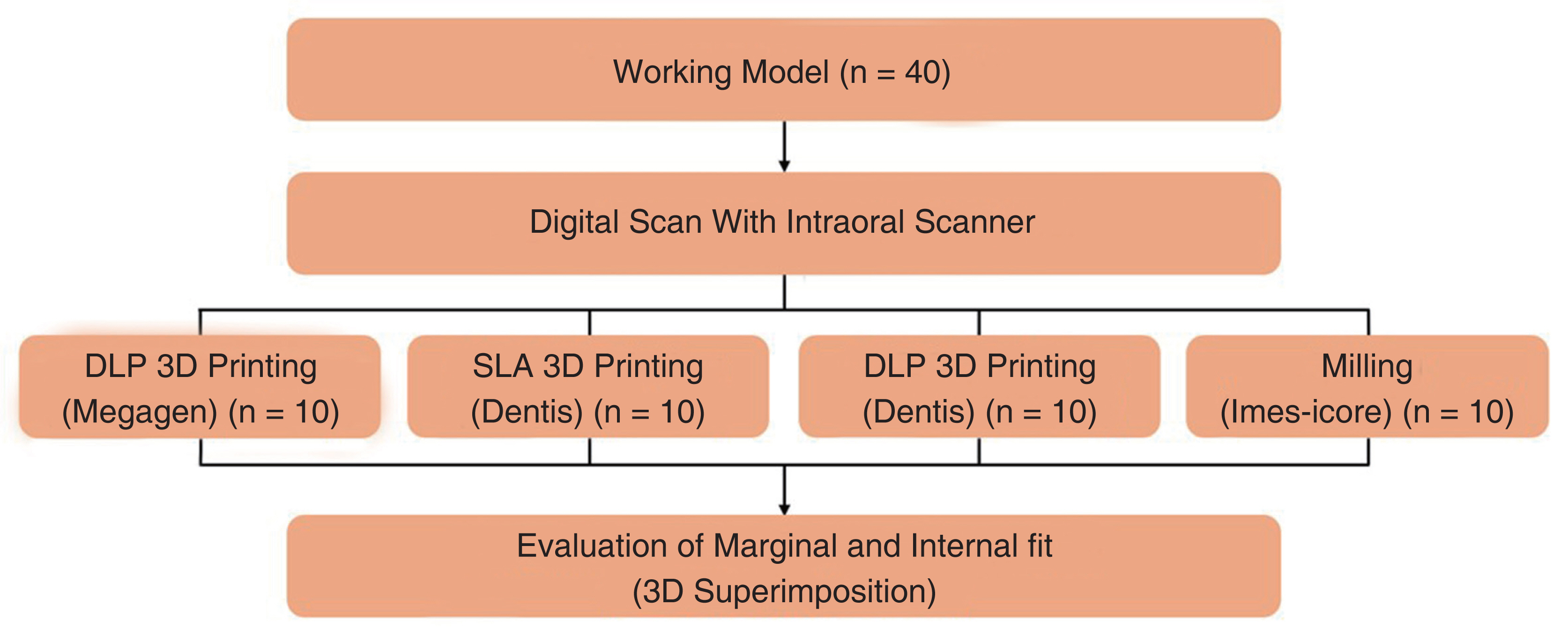

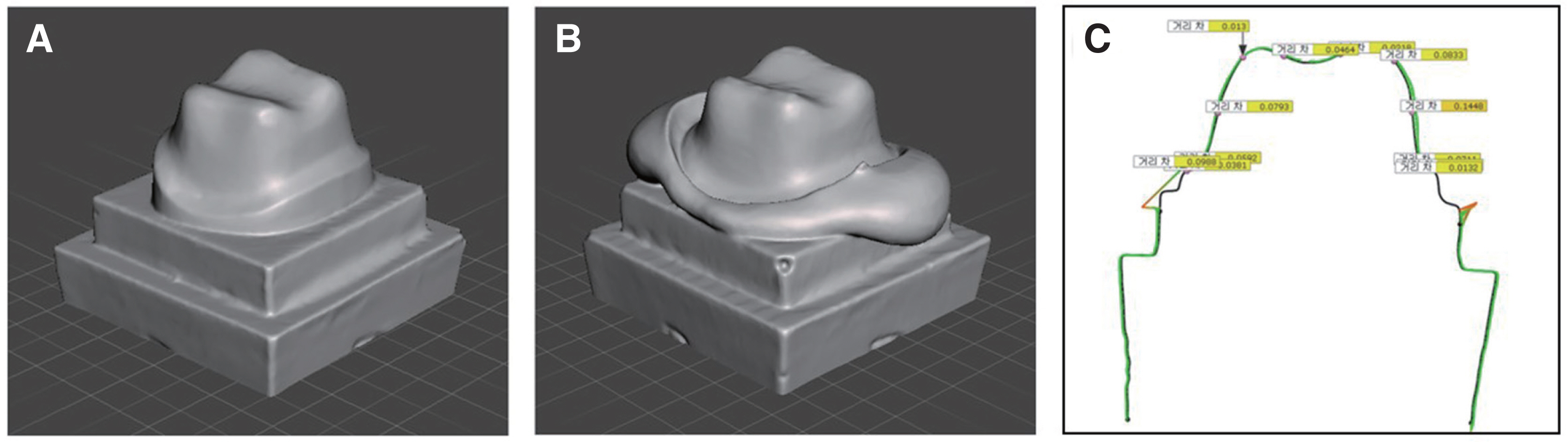

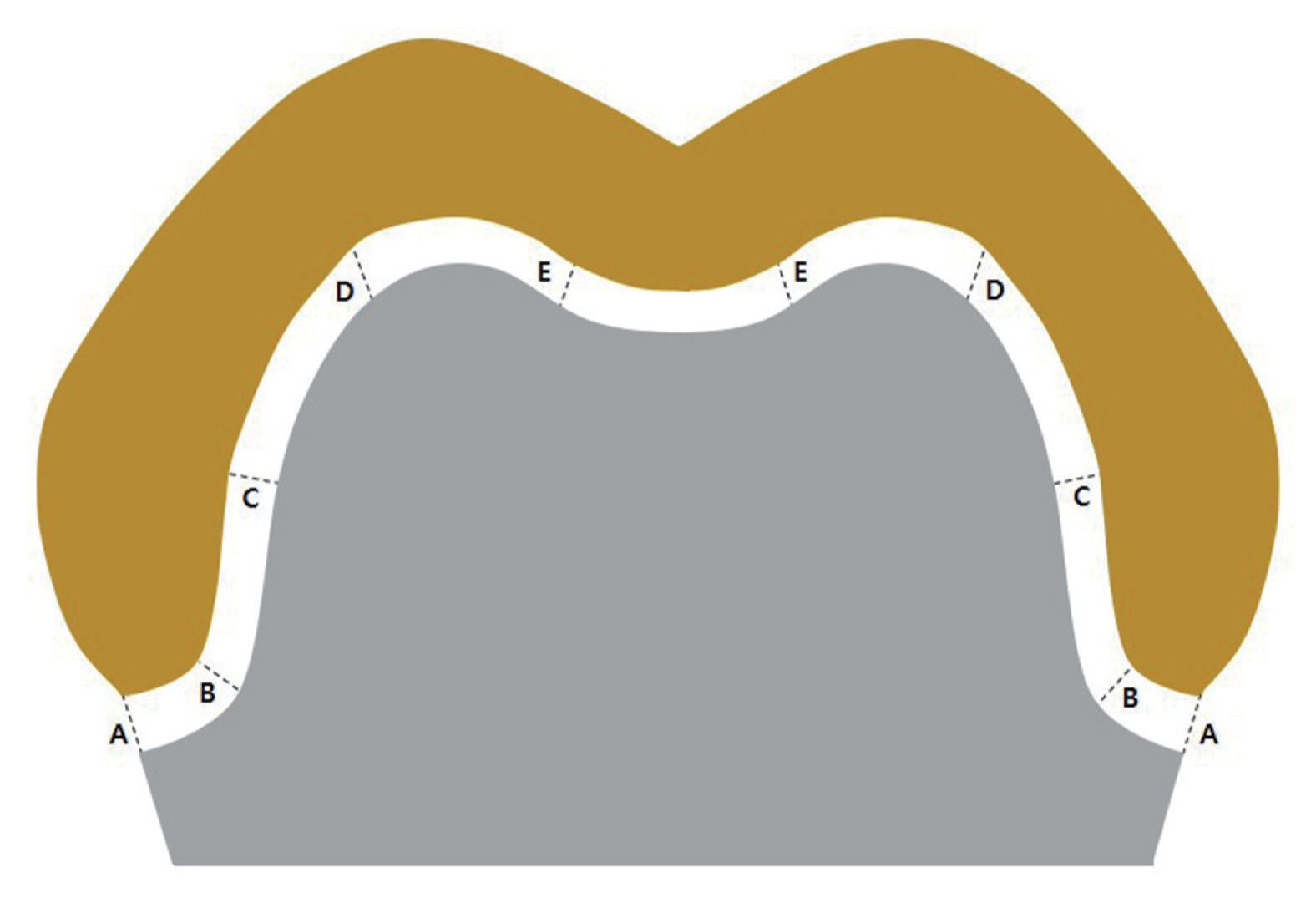

Forty study models were fabricated with plasters by making an impression of a master model of the maxillary right first molar for ceramic crown. On each study model, interim crowns (n = 40) were fabricated using three types of 3D printers (Meg-printer 2; Megagen, Zenith U; Dentis, and Zenith D; Dentis) and one type milling machine (imes-icore 450i; imes-icore GmbH). The internal of the interim crowns were filled with silicon and fitted to the study model. Internal scan data was obtained using an intraoral scanner. The fit of in-terim crowns were evaluated in the margin, absolute margin, axial, cusp, and occlusal area by using the superimposition of 3D scan data (Geomagic control X; 3D Systems). The Kruskal-wallis test, Mann-Whitney U test and Bonferroni correction method were used to compare the results among groups (α = 0.05).

Results

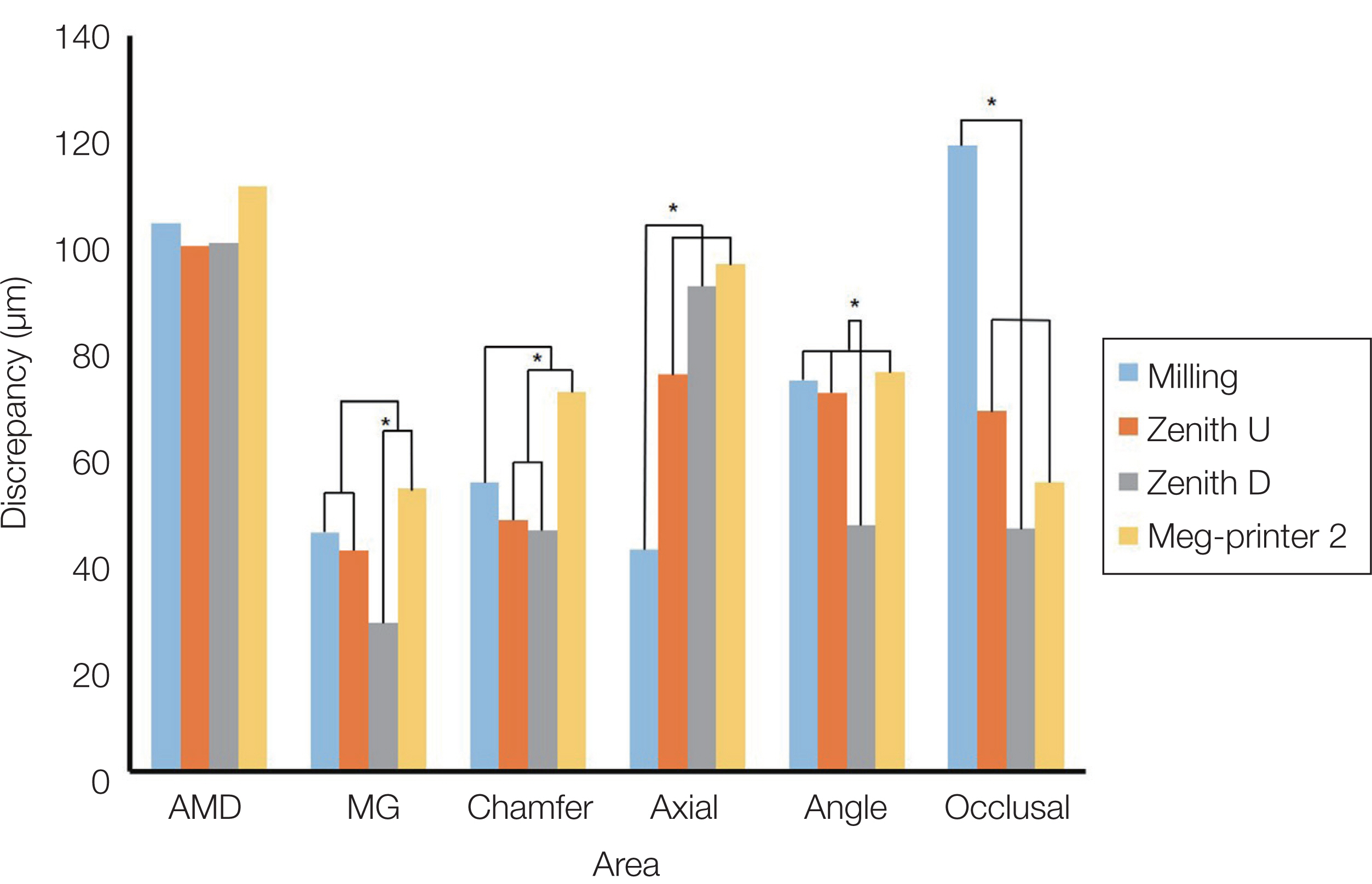

There was no significant difference in the absolute marginal discrepancy of the temporary crown manufactured by three 3D printers and one milling machine (P = 0.812). There was a significant difference between the milling machine and the 3D printer in the axial and occlusal area (P < 0.001). The temporary crown with the milling machine showed smaller axial gap and higher occlusal gap than 3D printer.

Conclusion

Since the marginal fit of the temporary crown produced by three types of 3D printers were all with in clinically acceptable range (< 120 µm), it can be sufficiently used for the fab-rication of the temporary crown.

Keyword

Figure

Reference

-

References

1. Burns DR, Beck DA, Nelson SK. 2003; A review of selected dental literature on contemporary provisional fixed prosthodontic treatment: report of the committee on research in fixed prosthodontics of the academy of fixed prosthodontics. J Prosthet Dent. 90:474–97. DOI: 10.1016/S0022-3913(03)00259-2. PMID: 14586312.2. Lee SH. 1982; Esthetic considerations for porcelain fused to metal restorations. J Korean Dent Assoc. 20:127–30.3. Lee WS, Lee DH, Lee KB. 2017; Evaluation of internal fit of interim crown fabricated with CAD/CAM milling and 3D printing system. J Adv Prosthodont. 9:265–70. DOI: 10.4047/jap.2017.9.4.265. PMID: 28874993. PMCID: PMC5582092.4. McLean JW, von Fraunhofer JA. 1971; The estimation of cement film thickness by an in vivo technique. Br Dent J. 131:107–11. DOI: 10.1038/sj.bdj.4802708. PMID: 5283545.5. Syed M, Chopra R, Sachdev V. 2015; Allergic reactions to dental materials-a systematic review. J Clin Diagn Res. 9:ZE04–9. DOI: 10.7860/JCDR/2015/15640.6589. PMID: 26557634. PMCID: PMC4625353.6. Arora A, Yadav A, Upadhyaya V, Jain P, Verma M. 2018; Comparison of marginal and internal adaptation of copings fabricated from three different fabrication techniques: An in vitro study. J Indian Prosthodont Soc. 18:102–7. DOI: 10.4103/jips.jips_327_17. PMID: 29692562. PMCID: PMC5903172.7. Alharbi N, Osman R, Wismeijer D. 2016; Effects of build direction on the mechanical properties of 3Dprinted complete coverage interim dental restorations. J Prosthet Dent. 115:760–7. DOI: 10.1016/j.prosdent.2015.12.002. PMID: 26803175.8. Park ME, Shin SY. 2018; Three-dimensional comparative study on the accuracy and reproducibility of dental casts fabricated by 3D printers. J Prosthet Dent. 119:861.e1–861.e7. DOI: 10.1016/j.prosdent.2017.08.020. PMID: 29475753.9. Sun J, Zhang FQ. 2012; The application of rapid prototyping in prosthodontics. J Prosthodont. 21:641–4. DOI: 10.1111/j.1532-849X.2012.00888.x. PMID: 22823471.10. Torabi K, Farjood E, Hamedani S. 2015; Rapid prototyping technologies and their applications in prosthodontics, a review of literature. J Dent (Shiraz). 16:1–9. PMID: 25759851. PMCID: PMC4345107.11. Mai HN, Lee KB, Lee DH. 2017; Fit of interim crowns fabricated using photopolymer-jetting 3D printing. J Prosthet Dent. 118:208–15. DOI: 10.1016/j.prosdent.2016.10.030. PMID: 28089333.12. Stopp S, Wolff T, Irlinger F, Lueth T. 2008; A new method for printer calibration and contour accuracy manufacturing with 3D-print technology. Rapid Prototyping J. 14:167–72. DOI: 10.1108/13552540810878030.13. Ebert J, Ozkol E, Zeichner A, Uibel K, Weiss O, Koops U, Telle R, Fischer H. 2009; Direct inkjet printing of dental prostheses made of zirconia. J Dent Res. 88:673–6. DOI: 10.1177/0022034509339988. PMID: 19641157.14. Kim SB, Kim NH, Kim JH, Moon HS. 2018; Evaluation of the fit of metal copings fabricated using stereolithography. J Prosthet Dent. 120:693–8. DOI: 10.1016/j.prosdent.2018.01.012. PMID: 29807735.15. Liu Y, Ye H, Wang Y, Zhao Y, Sun Y, Zhou Y. 2018; Threedimensional analysis of internal adaptations of crowns cast from resin patterns fabricated using computer-aided design/computer-assisted manufacturing technologies. Int J Prosthodont. 31:386–93. DOI: 10.11607/ijp.5678. PMID: 29772034.16. Rayyan MM, Aboushelib M, Sayed NM, Ibrahim A, Jimbo R. 2015; Comparison of interim restorations fabricated by CAD/CAM with those fabricated manually. J Prosthet Dent. 114:414–9. DOI: 10.1016/j.prosdent.2015.03.007. PMID: 26001490.17. Alharbi N, Alharbi S, Cuijpers VMJI, Osman RB, Wismeijer D. 2018; Three-dimensional evaluation of marginal and internal fit of 3D-printed interim restorations fabricated on different finish line designs. J Prosthodont Res. 62:218–26. DOI: 10.1016/j.jpor.2017.09.002. PMID: 29032176.18. Yu BY, Son KBD, Lee KB. 2020; Aug. 14. Evaluation of intaglio surface trueness and margin quality of interim crowns in accordance with the build angle of stereolithography apparatus 3-dimensional printing. J Prosthet Dent. S0022-3913(20)30385-1. doi:10.1016/j.prosdent.2020.04.028.[Epub ahead of print]. DOI: 10.1016/j.prosdent.2020.04.028. PMID: 32807402.19. Grajower R, Zuberi Y, Lewinstein I. 1989; Improving the fit of crowns with die spacers. J Prosthet Dent. 61:555–63. DOI: 10.1016/0022-3913(89)90275-8. PMID: 2664142.20. Puebla K, Arcaute K, Quintana R, Wicker RB. 2012; Effects of environmental conditions, aging, and build orientations on the mechanical properties of ASTM type I specimens manufactured via stereolithography. Rapid Prototyping J. 18:374–88. DOI: 10.1108/13552541211250373.21. Zoellner A, Brägger U, Fellmann V, Gaengler P. 2000; Correlation between clinical scoring of secondary caries at crown margins and histologically assessed extent of the lesions. Int J Prosthodont. 13:453–9. PMID: 11203669.22. Anadioti E, Aquilino SA, Gratton DG, Holloway JA, Denry I, Thomas GW, Qian F. 2014; 3D and 2D marginal fit of pressed and CAD/CAM lithium disilicate crowns made from digital and conventional impressions. J Prosthodont. 23:610–7. DOI: 10.1111/jopr.12180. PMID: 24995593.23. Lee HH, Lee DH, Lee KB. 2017; In vitro evaluation methods on adaptation of fixed dental prosthesis. J Dent Rehabil Appl Sci. 33:63–70. DOI: 10.14368/jdras.2017.33.2.63.24. Son KBD, Lee SB, Kang SH, Park JS, Lee KB, Jeon MS, Yun BJ. 2019; A comparison study of marginal and internal fit assessment methods for fixed dental prostheses. J Clin Med. 8:785. DOI: 10.3390/jcm8060785. PMID: 31159460. PMCID: PMC6617221.25. Groten M, Axmann D, Pröbster L, Weber H. 2000; Determination of the minimum number of marginal gap measurements required for practical in-vitro testing. J Prosthet Dent. 83:40–9. DOI: 10.1016/S0022-3913(00)70087-4. PMID: 10633021.26. Kuhn K, Ostertag S, Ostertag M, Walter MH, Luthardt RG, Rudolph H. 2015; Comparison of an analog and digital quantitative and qualitative analysis for the fit of dental copings. Comput Biol Med. 57:32–41. DOI: 10.1016/j.compbiomed.2014.11.017. PMID: 25528695.27. Revilla-Léon M, Olea-Vielba M, Esteso-Saiz A, Matínez-KIemm I, Özcan M. 2018; Marginal and internal gap of handmade, milled and 3D printed additive manufactured patterns for pressed lithium disilicate onlay restorations. Eur J Prosthodont Restor Dent. 26:31–8. DOI: 10.1922/EJPRD_01733RevillaLeon08. PMID: 29461746.28. Jang Y, Sim JY, Park JK, Kim WC, Kim HY, Kim JH. 2020; Accuracy of 3-unit fixed dental prostheses fabricated on 3D-printed casts. J Prosthet Dent. 123:135–42. DOI: 10.1016/j.prosdent.2018.11.004. PMID: 31027960.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Evaluation of internal fit of interim crown fabricated with CAD/CAM milling and 3D printing system

- A Surface Treatment Technique for Interim Crown Fabricated by Three-Dimensional Printing with Digital Light-Processing Technology

- Full mouth rehabilitation of patient with severe dental caries with implant fixed prosthesis fabricated with milling and 3D printing method: A case report

- Marginal and internal fit of 3D printed provisional crowns according to build directions

- Evaluation of the marginal and internal fit of a single crown fabricated based on a three-dimensional printed model