J Adv Prosthodont.

2018 Oct;10(5):367-373. 10.4047/jap.2018.10.5.367.

Evaluation of the marginal and internal fit of a single crown fabricated based on a three-dimensional printed model

- Affiliations

-

- 1Department of Dental Laboratory Science and Engineering, College of Health Science, Korea University, Seoul, Republic of Korea. kjh2804@korea.ac.kr

- 2Research Institute of Health Science, College of Health Science, Korea University, Seoul, Republic of Korea.

- 3Department of Public Health Sciences, Graduate School, Korea University, Seoul, Republic of Korea.

- KMID: 2422873

- DOI: http://doi.org/10.4047/jap.2018.10.5.367

Abstract

- PURPOSE

To evaluate the fit of a crown produced based on a 3D printed model and to investigate its clinical applicability.

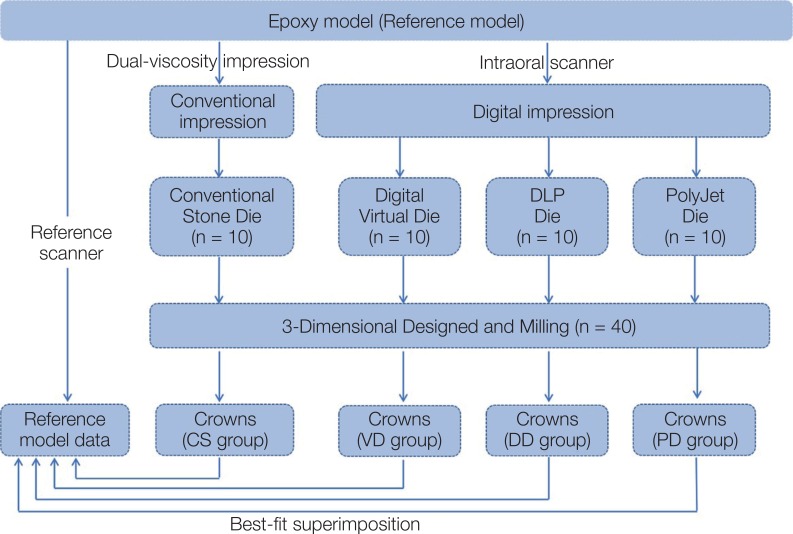

MATERIALS AND METHODS

A master die was fabricated with epoxy. Stone dies were fabricated from conventional impressions (Conventional stone die group: CS, n=10). Digital virtual dies were fabricated by making digital impressions (Digital Virtual die group: VD, n=10). 3D data obtained from the digital impression was used to fabricate 3D printed models (DLP die group: DD, n=10, PolyJet die group: PD, n=10). A total of 40 crowns were fabricated with a milling machine, based on CS, VD, DD and PD. The inner surface of all crowns was superimposed with the master die files by the "Best-fit alignment" method using the analysis software. One-way and 2-way ANOVA were performed to identify significant differences among the groups and areas and their interactive effects (α=.05). Tukey's HSD was used for post-hoc analysis.

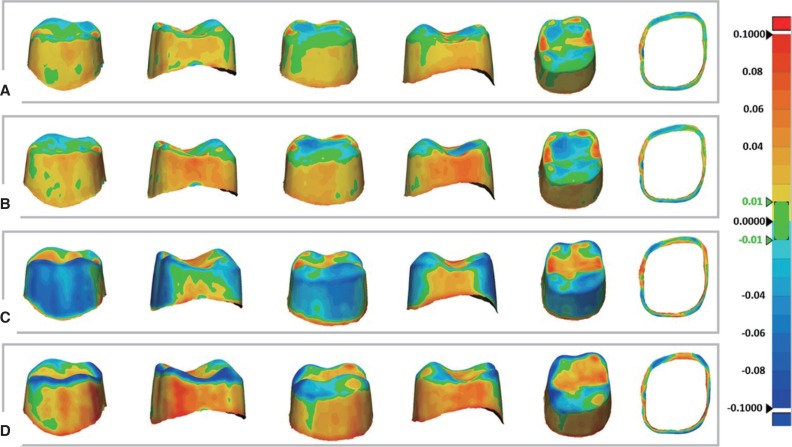

RESULTS

One-way ANOVA results revealed a significantly higher RMS value in the 3D printed models (DD and PD) than in the CS and DV. The RMS values of PD were the largest among the four groups. Statistically significant differences among groups (P < .001) and between areas (P < .001) were further revealed by 2-way ANOVA.

CONCLUSION

Although the fit of crowns fabricated based on the 3D printed models (DD and PD) was inferior to that of crowns prepared with CS and DV, the values of all four groups were within the clinically acceptable range ( < 120 µm).

Keyword

Figure

Reference

-

1. van Noort R. The future of dental devices is digital. Dent Mater. 2012; 28:3–12. PMID: 22119539.

Article2. Yau HT, Yang TJ, Lin YK. Comparison of 3-D printing and 5-axis milling for the production of dental e-models from intra-oral scanning. Comput Aided Des Appl. 2016; 13:32–38.

Article3. Holmes JR, Bayne SC, Holland GA, Sulik WD. Considerations in measurement of marginal fit. J Prosthet Dent. 1989; 62:405–408. PMID: 2685240.

Article4. Cho SH, Schaefer O, Thompson GA, Guentsch A. Comparison of accuracy and reproducibility of casts made by digital and conventional methods. J Prosthet Dent. 2015; 113:310–315. PMID: 25682531.

Article5. Ueda K, Beuer F, Stimmelmayr M, Erdelt K, Keul C, Güth JF. Fit of 4-unit FDPs from CoCr and zirconia after conventional and digital impressions. Clin Oral Investig. 2016; 20:283–289.

Article6. Fransson B, Oilo G, Gjeitanger R. The fit of metal-ceramic crowns, a clinical study. Dent Mater. 1985; 1:197–199. PMID: 3912241.

Article7. Karlsson S. The fit of Procera titanium crowns. An in vitro and clinical study. Acta Odontol Scand. 1993; 51:129–134. PMID: 8342403.

Article8. Hwang YC, Park YS, Kim HK, Hong YS, Ahn JS, Ryu JJ. The evaluation of working casts prepared from digital impressions. Oper Dent. 2013; 38:655–662. PMID: 23570301.

Article9. Pfeiffer J. Dental CAD/CAM technologies: the optical impression (I). Int J Comput Dent. 1998; 1:29–33. PMID: 11351456.10. Sun J, Zhang FQ. The application of rapid prototyping in prosthodontics. J Prosthodont. 2012; 21:641–644. PMID: 22823471.

Article11. Dawood A, Marti Marti B, Sauret-Jackson V, Darwood A. 3D printing in dentistry. Br Dent J. 2015; 219:521–529. PMID: 26657435.

Article12. Schaefer O, Kuepper H, Thompson GA, Cachovan G, Hefti AF, Guentsch A. Effect of CNC-milling on the marginal and internal fit of dental ceramics: a pilot study. Dent Mater. 2013; 29:851–858. PMID: 23743092.

Article13. Anadioti E, Aquilino SA, Gratton DG, Holloway JA, Denry I, Thomas GW, Qian F. 3D and 2D marginal fit of pressed and CAD/CAM lithium disilicate crowns made from digital and conventional impressions. J Prosthodont. 2014; 23:610–617. PMID: 24995593.

Article14. Anadioti E, Aquilino SA, Gratton DG, Holloway JA, Denry IL, Thomas GW, Qian F. Internal fit of pressed and computer-aided design/computer-aided manufacturing ceramic crowns made from digital and conventional impressions. J Prosthet Dent. 2015; 113:304–309. PMID: 25488521.

Article15. Keating AP, Knox J, Bibb R, Zhurov AI. A comparison of plaster, digital and reconstructed study model accuracy. J Orthod. 2008; 35:191–201. PMID: 18809782.

Article16. Schaefer O, Watts DC, Sigusch BW, Kuepper H, Guentsch A. Marginal and internal fit of pressed lithium disilicate partial crowns in vitro: a three-dimensional analysis of accuracy and reproducibility. Dent Mater. 2012; 28:320–326. PMID: 22265824.

Article17. Örtorp A, Jönsson D, Mouhsen A, Vult von Steyern P. The fit of cobalt-chromium three-unit fixed dental prostheses fabricated with four different techniques: a comparative in vitro study. Dent Mater. 2011; 27:356–363. PMID: 21163516.

Article18. Chochlidakis KM, Papaspyridakos P, Geminiani A, Chen CJ, Feng IJ, Ercoli C. Digital versus conventional impressions for fixed prosthodontics: A systematic review and meta-analysis. J Prosthet Dent. 2016; 116:184–190. PMID: 26946916.

Article19. McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971; 131:107–111. PMID: 5283545.

Article20. Ucar Y, Akova T, Akyil MS, Brantley WA. Internal fit evaluation of crowns prepared using a new dental crown fabrication technique: laser-sintered Co-Cr crowns. J Prosthet Dent. 2009; 102:253–259. PMID: 19782828.

Article21. Seelbach P, Brueckel C, Wöstmann B. Accuracy of digital and conventional impression techniques and workflow. Clin Oral Investig. 2013; 17:1759–1764.

Article22. Kim CM, Kim SR, Kim JH, Kim HY, Kim WC. Trueness of milled prostheses according to number of ball-end mill burs. J Prosthet Dent. 2016; 115:624–629. PMID: 26774318.

Article23. Mously HA, Finkelman M, Zandparsa R, Hirayama H. Marginal and internal adaptation of ceramic crown restorations fabricated with CAD/CAM technology and the heat-press technique. J Prosthet Dent. 2014; 112:249–256. PMID: 24795263.

Article24. Hoang LN, Thompson GA, Cho SH, Berzins DW, Ahn KW. Die spacer thickness reproduction for central incisor crown fabrication with combined computer-aided design and 3D printing technology: an in vitro study. J Prosthet Dent. 2015; 113:398–404. PMID: 25794915.25. Kale E, Seker E, Yilmaz B, Özcelik TB. Effect of cement space on the marginal fit of CAD-CAM-fabricated monolithic zirconia crowns. J Prosthet Dent. 2016; 116:890–895. PMID: 27460314.

Article26. Shim JS, Lee JS, Lee JY, Choi YJ, Shin SW, Ryu JJ. Effect of software version and parameter settings on the marginal and internal adaptation of crowns fabricated with the CAD/CAM system. J Appl Oral Sci. 2015; 23:515–522. PMID: 26537722.

Article27. Boitelle P, Tapie L, Mawussi B, Fromentin O. 3D fitting accuracy evaluation of CAD/CAM copings - comparison with spacer design settings. Int J Comput Dent. 2016; 19:27–43. PMID: 27027101.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of machining precision of single ceramic restorations on the marginal and internal fit

- A Surface Treatment Technique for Interim Crown Fabricated by Three-Dimensional Printing with Digital Light-Processing Technology

- Marginal and internal fit of 3D printed provisional crowns according to build directions

- Marginal fit of the auro galvano crown system made using the electroforming technique

- Marginal Adaptation Of The Conical Inner Crown Fabricated With Cad/cam