J Dent Rehabil Appl Sci.

2018 Sep;34(3):157-166. 10.14368/jdras.2018.34.3.157.

Comparative study of two CAD software programs on consistency between custom abutment design and the output

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Kyungpook National University, Daegu, Republic of Korea. kblee@knu.ac.kr

- 2Advanced Dental Device Development Institute, Kyungpook National University, Daegu, Republic of Korea.

- 3Department of Dental Science, Graduate School, Kyungpook National University, Daegu, Republic of Korea.

- KMID: 2422634

- DOI: http://doi.org/10.14368/jdras.2018.34.3.157

Abstract

- PURPOSE

This study was aimed to compare the consistency between the custom abutment design and the output in two CAD software programs.

MATERIALS AND METHODS

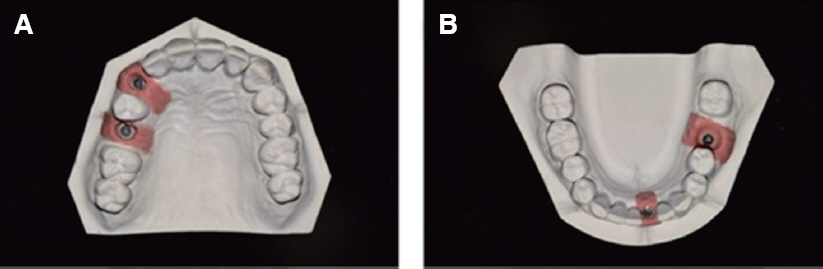

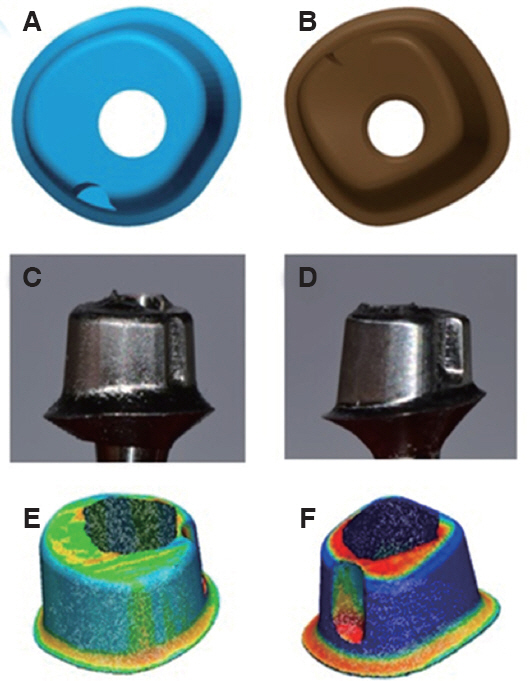

Customized abutments were designed by using 3Shape Dental System CAD software and Delta9 CAD software on a plaster model with implants (CRM STL file). After milling of the designed abutments, the abutments were scanned with a contact method scanner (Test STL file). We overlaid the Test STL file with each CRM STL file by using inspection software, and then compared the milling reproducibility by measuring the output error of the specimens from each CAD software program.

RESULTS

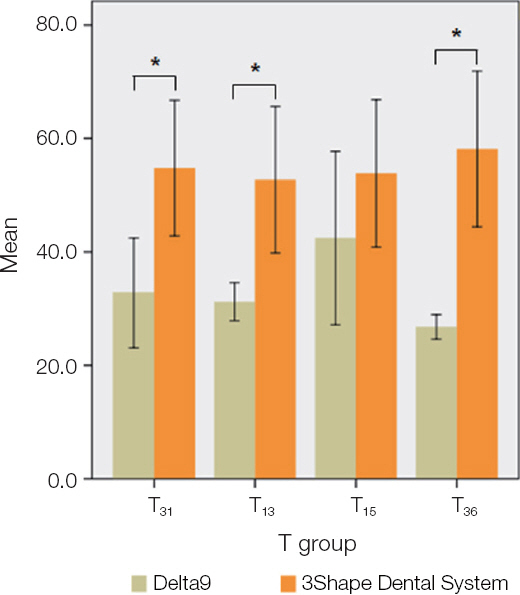

The Delta9 showed better milling reproducibility than 3Shape when comparing the milling errors obtained with a full scan of all specimens (P < .05) and also when comparing the axial wall region specifically according to the axial angle. With 0.9 mm marginal radius, the Delta9 showed better consistency between the design and the output than 3Shape (P < .05). While, anti-rotation form had no significant difference in error between the two systems. When cumulative errors were compared, the Delta9 showed better milling reproducibility in almost cases (P < .05).

CONCLUSION

Delta9 showed a significantly smaller error for most of the abutment design options. This means that it is possible to facilitate generation of printouts with reliable reproducibility and high precision with respect to the planned design.

Figure

Reference

-

References

1. Kim JW, Heo YR, Kim HJ, Chung CH. A comparative study on the fit and screw joint stability of ready-made abutment and CAD-CAM custommade abutment. J Korean Acad Prosthodont. 2013; 51:276–83. DOI: 10.4047/jkap.2013.51.4.276.2. Priest G. Virtual-designed and computer-milled implant abutments. J Oral Maxillofac Surg. 2005; 63:22–32. DOI: 10.1016/j.joms.2005.05.158. PMID: 16125013.3. Alshhrani WM, Al Amri MD. Customized CADCAM healing abutment for delayed loaded implants. J Prosthet Dent. 2016; 116:176–9. DOI: 10.1016/j.prosdent.2016.01.024. PMID: 27038526.4. Thulasidas S, Givan DA, Lemons JE, O'Neal SJ, Ramp LC, Liu PR. Influence of implant angulation on the fracture resistance of zirconia abutments. J Prosthodont. 2015; 24:127–35. DOI: 10.1111/jopr.12182. PMID: 24975560.5. Vinnakota DN. Effect of preparation convergence on retention of multiple unit restorations-An in vitro study. Contemp Clin Dent. 2015; 6:409–13. DOI: 10.4103/0976-237X.161904. PMID: 26321845. PMCID: PMC4549997.6. Corazza PH, Feitosa SA, Borges AL, Della Bona A. Influence of convergence angle of tooth preparation on the fracture resistance of Y-TZP-based allceramic restorations. Dent Mater. 2013; 29:339–47. DOI: 10.1016/j.dental.2012.12.007. PMID: 23333235.7. Tiu J, Al-Amleh B, Waddell JN, Duncan WJ. Reporting numeric values of complete crowns. Part 2:Retention and resistance theories. J Prosthet Dent. 2015; 114:75–80. DOI: 10.1016/j.prosdent.2015.01.007. PMID: 25858217.8. Shillingburg HT, Sather DA, Wilson EL, Cain JR, Mitchell DL, Blanco LJ, Kessler JC. Fundamentals of fixed prosthodontics. 4th ed. Hanover Park: Quintessence;2012. p. 132–3.9. Alghazzawi TF. Advancements in CAD/CAM technology:options for practical implementation. J Prosthodont Res. 2016; 60:72–84. DOI: 10.1016/j.jpor.2016.01.003. PMID: 26935333.10. Yamanishi Y, Yamaguchi S, Imazato S, Nakano T, Yatani H. Effects of the implant design on periimplant bone stress and abutment micromovement:three-dimensional finite element analysis of original computer-aided design models. J Periodontol. 2014; 85:e333–8. DOI: 10.1902/jop.2014.140107. PMID: 24835549.11. Komine F, Iwai T, Kobayashi K, Matsumura H. Marginal and internal adaptation of zirconium dioxide ceramic copings and crowns with different finish line designs. Dent Mater J. 2007; 26:659–64. DOI: 10.4012/dmj.26.659. PMID: 18203465.12. Beuer F, Aggstaller H, Edelhoff D, Gernet W. Effect of preparation design on the fracture resistance of zirconia crown copings. Dent Mater J. 2008; 27:362–7. DOI: 10.4012/dmj.27.362. PMID: 18717163.13. May KB, Russell MM, Razzoog ME, Lang BR. Precision of fit:the Procera AllCeram crown. J Prosthet Dent. 1998; 80:394–404. DOI: 10.1016/S0022-3913(98)70002-2. PMID: 9791784.14. Kim CM, Jeon JH, Lee JJ, Kim JH, Kim WC. Precision evaluation of crown prosthesis manufactured by two bur and three bur. J Korean Acad Dent Tech. 2016; 38:57–62. DOI: 10.14347/kadt.2016.38.2.57.15. Schaefer O, Watts DC, Sigusch BW, Kuepper H, Guentsch A. Marginal and internal fit of pressed lithium disilicate partial crowns in vitro:a three-dimensional analysis of accuracy and reproducibility. Dent Mater. 2012; 28:320–6. DOI: 10.1016/j.dental.2011.12.008. PMID: 22265824.16. International Organization for Standardization. ISO-12836:2015. Dentistry - digitizing devices for CAD/CAM systems for indirect dental restorations- Test methods for assessing accuracy. updated 2018 Sep 12. Available from: https://www.iso.org/standard/68414.html.17. Lee GT, Kim JH, Kim WC, Kim JH. Three-dimensional evaluation on the repeatability and reproducibility of dental scanner-based digital models. J Korean Acad Dent Tech. 2012; 34:213–20. DOI: 10.14347/kadt.2012.34.3.213.18. Persson A, Andersson M, Oden A, Sandborgh-Englund G. A three-dimensional evaluation of a laser scanner and a touch-probe scanner. J Prosthet Dent. 2006; 95:194–200. DOI: 10.1016/j.prosdent.2006.01.003. PMID: 16543016.19. Sahu N, Lakshmi N, Azhagarasan NS, Agnihotri Y, Rajan M, Hariharan R. Comparison of the effect of implant abutment surface modifications on retention of implant-supported restoration with a polymer based cement. J Clin Diagn Res. 2014; 8:239–42. PMID: 24596785. PMCID: PMC3939563.20. Enkling N, Ueda T, Gholami H, Bayer S, Katsoulis J, Mericske-Stern R. Precision of fit and retention force of cast non-precious-crowns on standard titanium implant-abutment with different design and height. Clin Oral Implants Res. 2014; 25:451–7. DOI: 10.1111/clr.12167. PMID: 23551713.21. Huh JB, Shim JS. The factors caused errors in the production process of CAD/CAM prosthesis based on experience. J Korean Dent Assoc. 2014; 52:332–45.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- A comparative study on the fit and screw joint stability of ready-made abutment and CAD-CAM custom-made abutment

- Effect of repeated learning for two dental CAD software programs

- Evaluating usability of and satisfaction with two types of dental CAD software

- Considerations for Fabrication of CAD-CAM Abutments: Part I. Selection of Titanium Block and Fabrication Process

- Influence of the implant abutment types and the dynamic loading on initial screw loosening