Restor Dent Endod.

2013 Aug;38(3):134-140.

Flexural strength and microstructure of two lithium disilicate glass ceramics for CAD/CAM restoration in the dental clinic

- Affiliations

-

- 1Department of Conservative Dentistry, Seoul National University School of Dentistry and Dental Research Institute, Seoul, Korea. hhson@snu.ac.kr

- 2Clinic for Persons with Disabilities, Seoul National University Dental Hospital, Seoul, Korea.

Abstract

OBJECTIVES

There has been a growing interest in glass ceramic systems with good esthetics, high fracture resistance and bonding durability, and simplified fabrication techniques using CAD/CAM. The aim of this study is to compare flexural strength before and after heat treatment of two lithium disilicate CAD/CAM blocks, IPS e.max CAD (Ivoclar Vivadent) and Rosetta SM (Hass), and to observe their crystalline structures.

MATERIALS AND METHODS

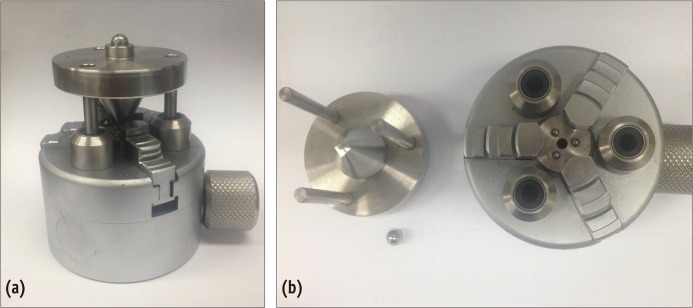

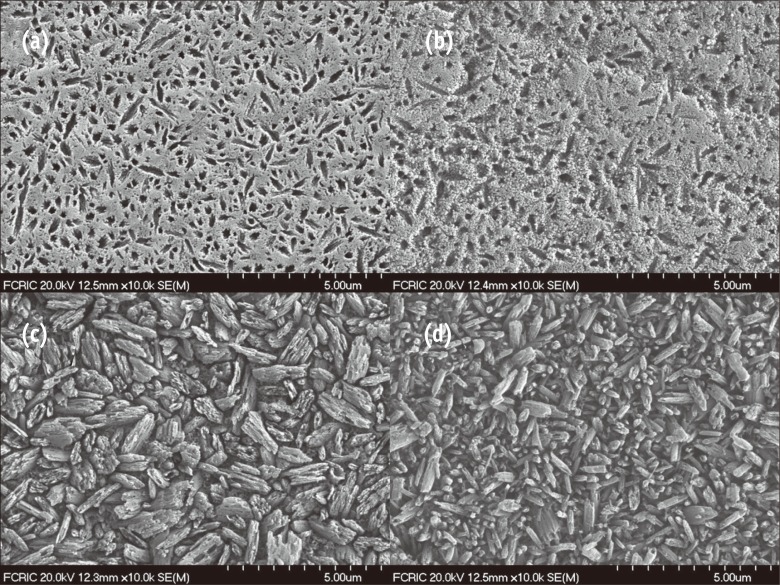

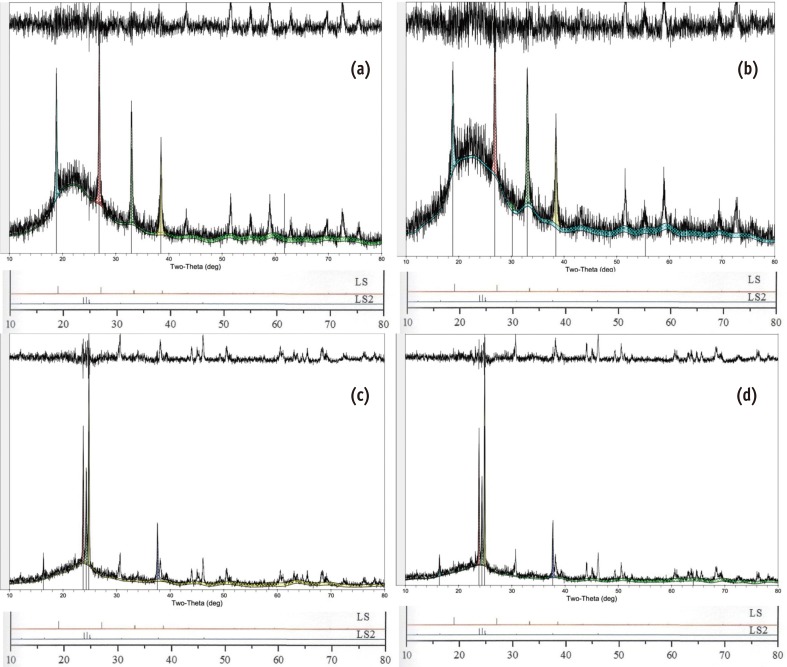

Biaxial flexural strength was tested according to ISO 6872 with 20 disc form specimens sliced from each block before and after heat treatment. Also, the crystalline structures were observed using field-emission scanning microscopy (FE-SEM, Hitachi) and x-ray diffraction (XRD, Rigaku) analysis. The mean values of the biaxial flexural strength were analyzed by the Mann-Whitney U test at a significance level of p = 0.05.

RESULTS

There were no statistically significant differences in flexural strength between IPS e.max CAD and Rosetta SM either before heat treatment or after heat treatment. For both ceramics, the initial flexural strength greatly increased after heat treatment, with significant differences (p < 0.05). The FE-SEM images presented similar patterns of crystalline structure in the two ceramics. In the XRD analysis, they also had similar patterns, presenting high peak positions corresponding to the standard lithium metasilicate and lithium disilicate at each stage of heat treatment.

CONCLUSIONS

IPS e.max CAD and Rosetta SM showed no significant differences in flexural strength. They had a similar crystalline pattern and molecular composition.

Keyword

MeSH Terms

Figure

Reference

-

1. Hooshmand T, Parvizi S, Keshvad A. Effect of surface acid etching on the biaxial flexural strength of two hot-pressed glass ceramics. J Prosthodont. 2008; 17:415–419. PMID: 18482364.

Article2. Miyazaki T, Hotta Y. CAD/CAM systems available for the fabrication of crown and bridge restorations. Aust Dent J. 2011; 56(Suppl 1):97–106. PMID: 21564120.

Article3. Lin WS, Ercoli C, Feng C, Morton D. The effect of core material, veneering porcelain, and fabrication technique on the biaxial flexural strength and weibull analysis of selected dental ceramics. J Prosthodont. 2012; 21:353–362. PMID: 22462639.

Article4. Gonzaga CC, Okada CY, Cesar PF, Miranda WG Jr, Yoshimura HN. Effect of processing induced particle alignment on the fracture toughness and fracture behavior of multiphase dental ceramics. Dent Mater. 2009; 25:1293–1301. PMID: 19570570.

Article5. Charlton DG, Roberts HW, Tiba A. Measurement of select physical and mechanical properties of 3 machinable ceramic materials. Quintessence Int. 2008; 39:573–579. PMID: 19107265.6. Siarampi E, Kontonasaki E, Papadopoulou L, Kantiranis N, Zorba T, Paraskevopoulos KM, Koidis P. Flexural strength and the probability of failure of cold isostatic pressed zirconia core ceramics. J Prosthet Dent. 2012; 108:84–95. PMID: 22867805.

Article7. Jin J, Takahashi H, Iwasaki N. Effect of test method on flexural strength of recent dental ceramics. Dent Mater J. 2004; 23:490–496. PMID: 15688709.

Article8. ISO-Standards ISO 6872 Dentistry-Ceramic materials. 3rd ed. Geneva: International Organization for Standardization;2008. p. 11–12.9. Albakry M, Guazzato M, Swain MV. Biaxial flexural strength, elastic moduli, and x-ray diffraction characterization of three pressable all-ceramic materials. J Prosthet Dent. 2003; 89:374–380. PMID: 12690350.

Article10. Seo DG, Roh BD. The comparison of relative reliability on biaxial and three point flexural strength testing methods of light curing composite resin. J Korean Acad Conserv Dent. 2006; 31:58–65.

Article11. Buso L, Oliveira-Júnior OB, Hiroshi Fujiy F, Leão Lombardo GH, Ramalho Sarmento H, Campos F, Assunção Souza RO. Biaxial flexural strength of CAD/CAM ceramics. Minerva Stomatol. 2011; 60:311–319. PMID: 21666567.12. Harrer W, Danzer R, Supancic P. Influence of the surface quality of ceramic specimens on the results of B3B-tests. In : 18th European Conference on Fracture; Dresden, Germany. 2010.13. Harrer W, Danzer R, Morrell R. Influence of surface defects on the biaxial strength of a silicon nitride ceramic-Increase of strength by crack healing. J Eur Ceram Soc. 2012; 32:27–35.14. Reich S, Schierz O. Chair-side generated posterior lithium disilicate crowns after 4 years. Clin Oral Investig. updated 2012 Nov 8. Available from: http://link.springer.com.15. Fasbinder DJ. Materials for chairside CAD/CAM restorations. Compend Contin Educ Dent. 2010; 31:702–704. 706708–709. PMID: 21197938.16. Fischer J, Stawarczyk B, Hämmerle CH. Flexural strength of veneering ceramics for zirconia. J Dent. 2008; 36:316–321. PMID: 18339469.

Article17. Schultheis S, Strub JR, Gerds TA, Guess PC. Monolithic and bi-layer CAD/CAM lithium-disilicate versus metal-ceramic fixed dental prostheses: Comparison of fracture loads and failure modes after fatigue. Clin Oral Investig. 2013; 17:1407–1413.

Article18. Kuzielová E, Palou M, Kozánková J. Crystallization mechanism and bioactivity of lithium disilicate glasses in relation to CaO, P2O5, CaF2 addition. Ceram Silik. 2007; 51:136–141.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Mechanical Properties Of Reused Lithium Disilicate Glass-Ceramic Of Ips Empress 2 System

- Mechanical Properties and Microstructure of the Leucite-Reinforced Glass-Ceramics for Dental CAD/CAM

- FLEXURE STRENGTH AND MICROSTRUCTURE OF IPS EMPRESS 2 GLASS-CERAMIC ON HEAT PRESSING AND HEAT TREATMENTS

- Evaluation of marginal fit of 2 CAD-CAM anatomic contour zirconia crown systems and lithium disilicate glass-ceramic crown

- Comparative analysis of transmittance for different types of commercially available zirconia and lithium disilicate materials