J Adv Prosthodont.

2015 Jun;7(3):249-256. 10.4047/jap.2015.7.3.249.

Effect of atmospheric plasma versus conventional surface treatments on the adhesion capability between self-adhesive resin cement and titanium surface

- Affiliations

-

- 1Department of Prosthodontics, Faculty of Dentistry, Eskisehir Osmangazi University, Eskisehir, Turkey. emreseker@hotmail.com

- 2Department of Prosthodontics, Faculty of Dentistry, Ankara University, Ankara, Turkey.

- 3Department of Prosthodontics, Faculty of Dentistry, Biruni University, Istanbul, Turkey.

- KMID: 2284711

- DOI: http://doi.org/10.4047/jap.2015.7.3.249

Abstract

- PURPOSE

The aim of this study was to evaluate the effects of atmospheric plasma (APL) versus conventional surface treatments on the adhesion of self-adhesive resin cement to Ti-6Al-4V alloy.

MATERIALS AND METHODS

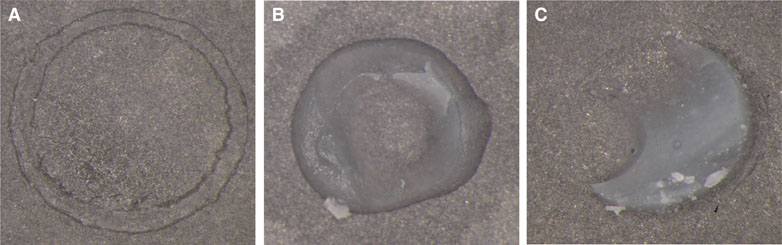

Sixty plates of machined titanium (Ti) discs were divided into five groups (n=12): 1) Untreated (CNT); 2) Sandblasted (SAB); 3) Tribochemically treated (ROC); 4) Tungsten CarbideBur (TCB); 5) APL treated (APL). SEM analysis and surface roughness (Ra) measurements were performed. Self-adhesive resin cement was bonded to the Ti surfaces and shear bond strength (SBS) tests, Ra and failure mode examinations were carried out. Data were analyzed by one-way analysis of variance and chi-squared test.

RESULTS

The lowest SBS value was obtained with CNT and was significantly different from all other groups except for APL. The ROC showed the highest SBS and Ra values of all the groups.

CONCLUSION

It was concluded that the effect of APL on SBS and Ra was not sufficient and it may not be a potential for promoting adhesion to titanium.

Keyword

MeSH Terms

Figure

Reference

-

1. McCracken M. Dental implant materials: commercially pure titanium and titanium alloys. J Prosthodont. 1999; 8:40–43.2. Berg E, Davik G, Hegdahl T, Gjerdet NR. Hardness, strength, and ductility of prefabricated titanium rods used in the manufacture of spark erosion crowns. J Prosthet Dent. 1996; 75:419–425.3. Ozcan M, Pfeiffer P, Nergiz I. A brief history and current status of metal-and ceramic surface-conditioning concepts for resin bonding in dentistry. Quintessence Int. 1998; 29:713–724.4. Tsuchimoto Y, Yoshida Y, Takeuchi M, Mine A, Yatani H, Tagawa Y, Van Meerbeek B, Suzuki K, Kuboki T. Effect of surface pre-treatment on durability of resin-based cements bonded to titanium. Dent Mater. 2006; 22:545–552.5. Asmussen E, Peutzfeldt A. Surface energy characteristics of adhesive monomers. Dent Mater. 1998; 14:21–28.6. Fonseca RG, Haneda IG, Almeida-Júnior AA, de Oliveira Abi-Rached F, Adabo GL. Efficacy of air-abrasion technique and additional surface treatment at titanium/resin cement interface. J Adhes Dent. 2012; 14:453–459.7. Inan O, Acar A, Halkaci S. Effects of sandblasting and electrical discharge machining on porcelain adherence to cast and machined commercially pure titanium. J Biomed Mater Res B Appl Biomater. 2006; 78:393–400.8. Fonseca RG, de Almeida JG, Haneda IG, Adabo GL. Effect of metal primers on bond strength of resin cements to base metals. J Prosthet Dent. 2009; 101:262–268.9. Akın H, Ozkurt Z, Kırmalı O, Kazazoglu E, Ozdemir AK. Shear bond strength of resin cement to zirconia ceramic after aluminum oxide sandblasting and various laser treatments. Photomed Laser Surg. 2011; 29:797–802.10. Bertolotti RL. Adhesion to porcelain and metal. Dent Clin North Am. 2007; 51:433–451.11. Taira Y, Matsumura H, Yoshida K, Tanaka T, Atsuta M. Adhesive bonding of titanium with a methacrylate-phosphate primer and self-curing adhesive resins. J Oral Rehabil. 1995; 22:409–412.12. Abi-Rached Fde O, Fonseca RG, Haneda IG, de Almeida-Júnior AA, Adabo GL. The effect of different surface treatments on the shear bond strength of luting cements to titanium. J Prosthet Dent. 2012; 108:370–376.13. Nishigawa G, Maruo Y, Oka M, Okamoto M, Minagi S, Irie M, Suzuki K. Effect of plasma treatment on adhesion of self-curing repair resin to acrylic denture base. Dent Mater J. 2004; 23:545–549.14. Duske K, Koban I, Kindel E, Schröder K, Nebe B, Holtfreter B, Jablonowski L, Weltmann KD, Kocher T. Atmospheric plasma enhances wettability and cell spreading on dental implant metals. J Clin Periodontol. 2012; 39:400–407.15. Koban I, Holtfreter B, Hübner NO, Matthes R, Sietmann R, Kindel E, Weltmann KD, Welk A, Kramer A, Kocher T. Antimicrobial efficacy of non-thermal plasma in comparison to chlorhexidine against dental biofilms on titanium discs in vitro - proof of principle experiment. J Clin Periodontol. 2011; 38:956–965.16. Idlibi AN, Al-Marrawi F, Hannig M, Lehmann A, Rueppell A, Schindler A, Jentsch H, Rupf S. Destruction of oral biofilms formed in situ on machined titanium (Ti) surfaces by cold atmospheric plasma. Biofouling. 2013; 29:369–379.17. Weltmann KD, Kindel E, Brandenburg R, Meyer C, Bussiahn R, Wilke C, von Woedtke T. Atmospheric pressure plasma jet for medical therapy: Plasma parameters and risk estimation. Contrib Plasma Phys. 2009; 49:631–640.18. Vogelsang A, Ohl A, Steffen H, Foest R, Schröder K, Weltmann KD. Locally resolved analysis of polymer surface functionalization by an atmospheric pressure argon microplasma jet with air entrainment. Plasma Process Polym. 2010; 7:16–24.19. Choi YH, Kim JH, Paek KH, Ju WT, Hwang YS. Characteristics of atmospheric pressure N2 cold plasma torch using 60-Hz AC power and its application to polymer surface modification. Surf Coat Technol. 2005; 193:319–324.20. Lee SB, Kim YK. Adhesion improvement of polyimide/metal interface by He/O2/NF3 atmospheric pressure plasma. Plasma Process Polym. 2009; 6:525–529.21. Han GJ, Chung SN, Chun BH, Kim CK, Oh KH, Cho BH. Effect of the applied power of atmospheric pressure plasma on the adhesion of composite resin to dental ceramic. J Adhes Dent. 2012; 14:461–469.22. Schneider R, de Goes MF, Henriques GE, Chan DC. Tensile bond strength of dual curing resin-based cements to commercially pure titanium. Dent Mater. 2007; 23:81–87.23. dos Santos JG, Fonseca RG, Adabo GL, dos Santos Cruz CA. Shear bond strength of metal-ceramic repair systems. J Prosthet Dent. 2006; 96:165–173.24. Valverde GB, Coelho PG, Janal MN, Lorenzoni FC, Carvalho RM, Thompson VP, Weltemann KD, Silva NR. Surface characterisation and bonding of Y-TZP following non-thermal plasma treatment. J Dent. 2013; 41:51–59.25. Marchesi G, Mazzoni A, Turco G, Cadenaro M, Ferrari M, Di Lenarda R, Breschi L. Aging affects the adhesive interface of posts luted with self-adhesive cements: a 1-year study. J Adhes Dent. 2013; 15:173–180.26. Papadopoulos T, Tsetsekou A, Eliades G. Effect of aluminium oxide sandblasting on cast commercially pure titanium surfaces. Eur J Prosthodont Restor Dent. 1999; 7:15–21.27. Watanabe I, Kurtz KS, Kabcenell JL, Okabe T. Effect of sandblasting and silicoating on bond strength of polymerglass composite to cast titanium. J Prosthet Dent. 1999; 82:462–467.28. Petridis H, Garefis P, Hirayama H, Kafantaris NM, Koidis PT. Bonding indirect resin composites to metal: part 2. Effect of alloy surface treatment on elemental composition of alloy and bond strength. Int J Prosthodont. 2004; 17:77–82.29. Sarafianou A, Seimenis I, Papadopoulos T. Effectiveness of different adhesive primers on the bond strength between an indirect composite resin and a base metal alloy. J Prosthet Dent. 2008; 99:377–387.30. Ozden N, Akaltan F, Suzer S, Akovali G. Time-related wettability characteristic of acrylic resin surfaces treated by glow discharge. J Prosthet Dent. 1999; 82:680–684.31. Silva NR, Coelho PG, Valverde GB, Becker K, Ihrke R, Quade A, Thompson VP. Surface characterization of Ti and Y-TZP following non-thermal plasma exposure. J Biomed Mater Res B Appl Biomater. 2011; 99:199–206.32. Nishigawa G, Maruo Y, Oka M, Oki K, Minagi S, Okamoto M. Plasma treatment increased shear bond strength between heat cured acrylic resin and self-curing acrylic resin. J Oral Rehabil. 2003; 30:1081–1084.33. Fang Z, Yang H, Qiu Y. Surface treatment of polyethylene terephthalate films using a microsecond pulse homogeneous dielectric barrier discharges in atmospheric air. IEEE Trans Plasma Sci. 2010; 38:1615–1623.34. Cho BH, Han GJ, Oh KH, Chung SN, Chun BH. The effect of plasma polymer coating using atmospheric-pressure glow discharge on the shear bond strength of composite resin to ceramic. J Mater Sci. 2011; 46:2755–2763.35. Elsaka SE, Swain MV. Effect of surface treatments on adhesion of low-fusing porcelain to titanium as determined by strain energy release rate. Dent Mater. 2011; 27:1213–1220.36. Miyakawa O, Watanabe K, Okawa S, Kanatani M, Nakano S, Kobayashi M. Surface contamination of titanium by abrading treatment. Dent Mater J. 1996; 15:11–21.37. Lim BS, Heo SM, Lee YK, Kim CW. Shear bond strength between titanium alloys and composite resin: sandblasting versus fluoride-gel treatment. J Biomed Mater Res B Appl Biomater. 2003; 64:38–43.38. Elsaka SE. Effect of surface pretreatments on the bonding strength and durability of self-adhesive resin cements to machined titanium. J Prosthet Dent. 2013; 109:113–120.39. Ozcan M, Valandro LF. Bond strength of two resin cements to titanium after different surface conditioning methods. Gen Dent. 2012; 60:e6–e12.40. ISO 10477. Dentistrypolymer-based crown and bridge materials. International Standards Organization (ISO). Geneva: Switzerland;2004.41. Matsumura H, Yanagida H, Tanoue N, Atsuta M, Shimoe S. Shear bond strength of resin composite veneering material to gold alloy with varying metal surface preparations. J Prosthet Dent. 2001; 86:315–319.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- The effects of non-thermal plasma and conventional treatments on the bond strength of fiber posts to resin cement

- Effect of different surface treatments on the shear bond strength of luting cements used with implant-supported prosthesis: An in vitro study

- Influence of different surface treatments on bond strength of novel CAD/CAM restorative materials to resin cement

- Effect of surface treatment of FRC-Post on bonding strength to resin cements

- Bond strength of self-adhesive resin cements to composite submitted to different surface pretreatments