Healthc Inform Res.

2015 Jul;21(3):201-205. 10.4258/hir.2015.21.3.201.

Clinical Application of Solid Model Based on Trabecular Tibia Bone CT Images Created by 3D Printer

- Affiliations

-

- 1Biomedical Engineering Branch, Division of Convergence Technology, National Cancer Center, Goyang, Korea. kimkg@ncc.re.kr

- KMID: 2125190

- DOI: http://doi.org/10.4258/hir.2015.21.3.201

Abstract

OBJECTIVES

The aim of this work is to use a 3D solid model to predict the mechanical loads of human bone fracture risk associated with bone disease conditions according to biomechanical engineering parameters.

METHODS

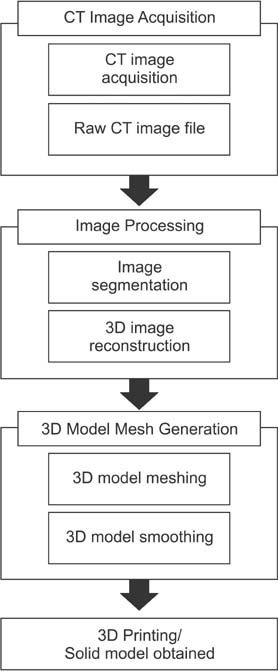

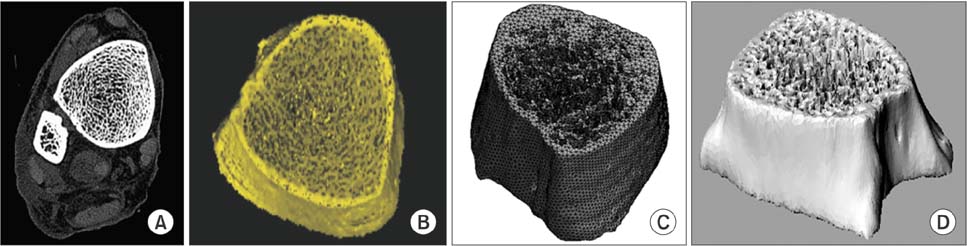

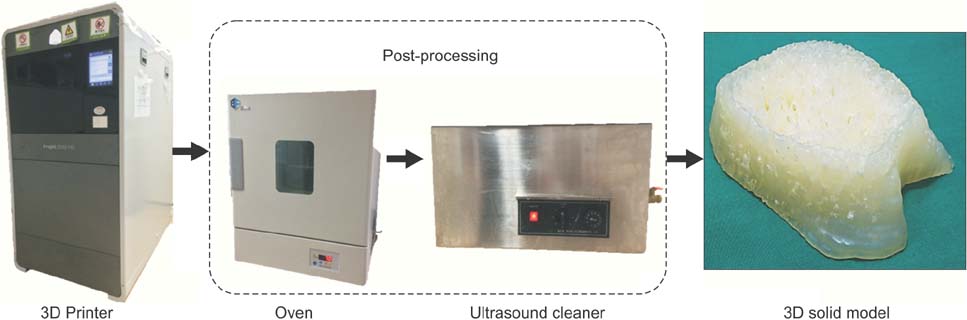

We used special image processing tools for image segmentation and three-dimensional (3D) reconstruction to generate meshes, which are necessary for the production of a solid model with a 3D printer from computed tomography (CT) images of the human tibia's trabecular and cortical bones. We examined the defects of the mechanism for the tibia's trabecular bones.

RESULTS

Image processing tools and segmentation techniques were used to analyze bone structures and produce a solid model with a 3D printer.

CONCLUSIONS

These days, bio-imaging (CT and magnetic resonance imaging) devices are able to display and reconstruct 3D anatomical details, and diagnostics are becoming increasingly vital to the quality of patient treatment planning and clinical treatment. Furthermore, radiographic images are being used to study biomechanical systems with several aims, namely, to describe and simulate the mechanical behavior of certain anatomical systems, to analyze pathological bone conditions, to study tissues structure and properties, and to create a solid model using a 3D printer to support surgical planning and reduce experimental costs. These days, research using image processing tools and segmentation techniques to analyze bone structures to produce a solid model with a 3D printer is rapidly becoming very important.

Keyword

Figure

Reference

-

1. Mao K, Wang Y, Xiao S, Liu Z, Zhang Y, Zhang X, et al. Clinical application of computer-designed polystyrene models in complex severe spinal deformities: a pilot study. Eur Spine J. 2010; 19(5):797–802.

Article2. Esses SJ, Berman P, Bloom AI, Sosna J. Clinical applications of physical 3D models derived from MDCT data and created by rapid prototyping. AJR Am J Roentgenol. 2011; 196(6):W683–W688.

Article3. Butscher A, Bohner M, Hofmann S, Gauckler L, Muller R. Structural and material approaches to bone tissue engineering in powder-based three-dimensional printing. Acta Biomater. 2011; 7(3):907–920.

Article4. Janssen I, Heymsfield SB, Ross R. Low relative skeletal muscle mass (sarcopenia) in older persons is associated with functional impairment and physical disability. J Am Geriatr Soc. 2002; 50(5):889–896.

Article5. Scifert CF, Brown TD, Lipman JD. Finite element analysis of a novel design approach to resisting total hip dislocation. Clin Biomech (Bristol, Avon). 1999; 14(10):697–703.

Article6. Ventola CL. Medical applications for 3D printing: current and projected uses. P T. 2014; 39(10):704–711.7. Niebur GL, Feldstein MJ, Yuen JC, Chen TJ, Keaveny TM. High-resolution finite element models with tissue strength asymmetry accurately predict failure of trabecular bone. J Biomech. 2000; 33(12):1575–1583.

Article8. Peltola SM, Melchels FP, Grijpma DW, Kellomaki M. A review of rapid prototyping techniques for tissue engineering purposes. Ann Med. 2008; 40(4):268–280.

Article9. Mertz L. Dream it, design it, print it in 3-D: what can 3-D printing do for you? IEEE Pulse. 2013; 4(6):15–21.

Article10. Rengier F, Mehndiratta A, von Tengg-Kobligk H, Zechmann CM, Unterhinninghofen R, Kauczor HU, Giesel FL. 3D printing based on imaging data: review of medical applications. Int J Comput Assist Radiol Surg. 2010; 5(4):335–341.

Article11. Lee MY, Chang CC, Ku YC. New layer-based imaging and rapid prototyping techniques for computer-aided design and manufacture of custom dental restoration. J Med Eng Technol. 2008; 32(1):83–90.

Article12. Harrysson OL, Hosni YA, Nayfeh JF. Custom-designed orthopedic implants evaluated using finite element analysis of patient-specific computed tomography data: femoral-component case study. BMC Musculoskelet Disord. 2007; 8:91.

Article13. Gross BC, Erkal JL, Lockwood SY, Chen C, Spence DM. Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences. Anal Chem. 2014; 86(7):3240–3253.

Article14. Patel P. Micro 3-D printer creates tiny structures in seconds [Internet]. Cambridge (MA): MIT Technology Review;c2013. cited at 2015 Jul 15. Available from: http://www.technologyreview.com/news/511856/micro-3-d-printer-creates-tiny-structures-in-seconds/.15. Moskvitch K. Artificial blood vessels created on a 3D printer [Internet]. London, UK: BBC News;2011. cited at 2015 Jul 15. Available from:http://www.bbc.com/news/technology-14946808.16. Ragaert K, De Baere I, Moerman M, Cardon L, Degrieck J. Design and thermoregulation of a new microextrusion dispense head for 3D-plotting of thermally sensitive thermoplastics. Polym Eng Sci. 2013; 53(2):273–282.

Article17. Lee SJ. 3D printer technology changes future of the health industry. KHIDI Brief. 2014; 111:1–16.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Optimal microcatheter shaping method customized for a patient-specific vessel using a three-dimensional printer

- Affordable and reliable three-dimensional printing: a prospective study of seven distal radius fractures

- Changes in the Microstructural and Mechanical Properties in the Medial Condyle of Human Distal Femur in Advanced Osteoarthritis

- Morphometric Analysis of Tibial Bone in Three Strains of Mice Using Micro-computed Tomography

- A method for mandibular dental arch superimposition using 3D cone beam CT and orthodontic 3D digital model