J Periodontal Implant Sci.

2012 Apr;42(2):59-63. 10.5051/jpis.2012.42.2.59.

Surface characteristics of a novel hydroxyapatite-coated dental implant

- Affiliations

-

- 1Department of Periodontology, Research Institute for Periodontal Regeneration, Yonsei University College of Dentistry, Seoul, Korea.

- 2Division in Anatomy and Developmental Biology, Department of Oral Biology, Human Identification Research Center, Yonsei University College of Dentistry, Seoul, Korea. hjk776@yuhs.ac

- 3Research Institute of Dentis Co., Daegu, Korea.

- KMID: 2027788

- DOI: http://doi.org/10.5051/jpis.2012.42.2.59

Abstract

- PURPOSE

This study evaluated the surface characteristics and bond strength produced using a novel technique for coating hydroxyapatite (HA) onto titanium implants.

METHODS

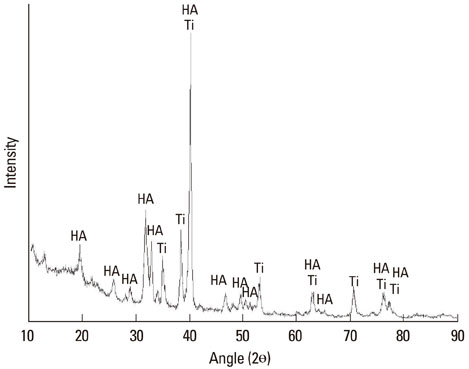

HA was coated on the titanium implant surface using a super-high-speed (SHS) blasting method with highly purified HA. The coating was performed at a low temperature, unlike conventional HA coating methods. Coating thickness was measured. The novel HA-coated disc was fabricated. X-ray diffraction analysis was performed directly on the disc to evaluate crystallinity. Four novel HA-coated discs and four resorbable blast medium (RBM) discs were prepared. Their surface roughnesses and areas were measured. Five puretitanium, RBM-treated, and novel HA-coated discs were prepared. Contact angle was measured. Two-way analysis of variance and the post-hoc Scheffe's test were used to analyze differences between the groups, with those with a probability of P<0.05 considered to be statistically significant. To evaluate exfoliation of the coating layer, 7 sites on the mandibles from 7 mongrel dogs were used. Other sites were used for another research project. In total, seven novel HA-coated implants were placed 2 months after extraction of premolars according to the manufacturer's instructions. The dogs were sacrificed 8 weeks after implant surgery. Implants were removed using a ratchet driver. The surface of the retrieved implants was evaluated microscopically.

RESULTS

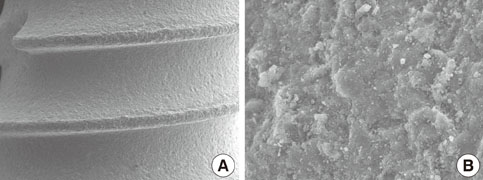

A uniform HA coating layer was formed on the titanium implants with no deformation of the RBM titanium surface microtexture when an SHS blasting method was used.

CONCLUSIONS

These HA-coated implants exhibited increased roughness, crystallinity, and wettability when compared with RBM implants.

MeSH Terms

Figure

Cited by 1 articles

-

Bone apposition on implants coated with calcium phosphate by ion beam assisted deposition in oversized drilled sockets: a histologic and histometric analysis in dogs

Min-Soo Kim, Ui-Won Jung, Sungtae Kim, Jung-Seok Lee, In-Seop Lee, Seong-Ho Choi

J Periodontal Implant Sci. 2013;43(1):18-23. doi: 10.5051/jpis.2013.43.1.18.

Reference

-

1. Chaffee NR, Cooper LF. Fixed partial dentures combining both resin-bonded and conventional retainers: a clinical report. J Prosthet Dent. 2000. 83:272–275.2. Shalabi MM, Gortemaker A, Van't Hof MA, Jansen JA, Creugers NH. Implant surface roughness and bone healing: a systematic review. J Dent Res. 2006. 85:496–500.

Article3. Wennerberg A, Albrektsson T. Effects of titanium surface topography on bone integration: a systematic review. Clin Oral Implants Res. 2009. 20:Suppl 4. 172–184.

Article4. Wennerberg A, Albrektsson T. On implant surfaces: a review of current knowledge and opinions. Int J Oral Maxillofac Implants. 2010. 25:63–74.

Article5. de Groot K, Geesink R, Klein CP, Serekian P. Plasma sprayed coatings of hydroxylapatite. J Biomed Mater Res. 1987. 21:1375–1381.

Article6. Thomas KA, Kay JF, Cook SD, Jarcho M. The effect of surface macrotexture and hydroxylapatite coating on the mechanical strengths and histologic profiles of titanium implant materials. J Biomed Mater Res. 1987. 21:1395–1414.

Article7. Wang CY, Zhao BH, Ai HJ, Wang YW. Comparison of biological characteristics of mesenchymal stem cells grown on two different titanium implant surfaces. Biomed Mater. 2008. 3:015004.

Article8. Park YS, Yi KY, Lee IS, Han CH, Jung YC. The effects of ion beam-assisted deposition of hydroxyapatite on the grit-blasted surface of endosseous implants in rabbit tibiae. Int J Oral Maxillofac Implants. 2005. 20:31–38.

Article9. Gottlander M, Albrektsson T. Histomorphometric studies of hydroxylapatite-coated and uncoated CP titanium threaded implants in bone. Int J Oral Maxillofac Implants. 1991. 6:399–404.

Article10. Ji H, Marquis PM. Effect of heat treatment on the microstructure of plasma-sprayed hydroxyapatite coating. Biomaterials. 1993. 14:64–68.

Article11. Zyman Z, Weng J, Liu X, Zhang X, Ma Z. Amorphous phase and morphological structure of hydroxyapatite plasma coatings. Biomaterials. 1993. 14:225–228.

Article12. Chen J, Wolke JG, de Groot K. Microstructure and crystallinity in hydroxyapatite coatings. Biomaterials. 1994. 15:396–399.13. Tsui YC, Doyle C, Clyne TW. Plasma sprayed hydroxyapatite coatings on titanium substrates. Part 2: optimisation of coating properties. Biomaterials. 1998. 19:2031–2043.14. Biesbrock AR, Edgerton M. Evaluation of the clinical predictability of hydroxyapatite-coated endosseous dental implants: a review of the literature. Int J Oral Maxillofac Implants. 1995. 10:712–720.

Article15. Liao H, Fartash B, Li J. Stability of hydroxyapatite-coatings on titanium oral implants (IMZ). 2 retrieved cases. Clin Oral Implants Res. 1997. 8:68–72.

Article16. Ong JL, Lucas LC, Lacefield WR, Rigney ED. Structure, solubility and bond strength of thin calcium phosphate coatings produced by ion beam sputter deposition. Biomaterials. 1992. 13:249–254.

Article17. Yoshinari M, Ohtsuka Y, Derand T. Thin hydroxyapatite coating produced by the ion beam dynamic mixing method. Biomaterials. 1994. 15:529–535.

Article18. van Dijk K, Schaeken HG, Wolke JG, Jansen JA. Influence of annealing temperature on RF magnetron sputtered calcium phosphate coatings. Biomaterials. 1996. 17:405–410.

Article19. Singh RK, Qian F, Nagabushnam V, Damodaran R, Moudgil BM. Excimer laser deposition of hydroxyapatite thin films. Biomaterials. 1994. 15:522–528.

Article20. Albrektsson T, Wennerberg A. Oral implant surfaces: Part 1--review focusing on topographic and chemical properties of different surfaces and in vivo responses to them. Int J Prosthodont. 2004. 17:536–543.

Article21. Yang Y, Bumgardner JD, Cavin R, Carnes DL, Ong JL. Osteoblast precursor cell attachment on heat-treated calcium phosphate coatings. J Dent Res. 2003. 82:449–453.

Article22. Katto M, Ishibashi K, Kurosawa K, Yokotani A, Kubodera S, Kameyama A, et al. Crystallized hydroxyapatite coatings deposited by PLD with targets of different densities. J Phys: Conf Ser. 2007. 59:75–78.

Article23. Cleries L, Fernandez-Pradas JM, Sardin G, Morenza JL. Dissolution behaviour of calcium phosphate coatings obtained by laser ablation. Biomaterials. 1998. 19:1483–1487.

Article24. Arias JL, Garcia-Sanz FJ, Mayor MB, Chiussi S, Pou J, Leon B, et al. Physicochemical properties of calcium phosphate coatings produced by pulsed laser deposition at different water vapour pressures. Biomaterials. 1998. 19:883–888.

Article25. Rupp F, Scheideler L, Olshanska N, de Wild M, Wieland M, Geis-Gerstorfer J. Enhancing surface free energy and hydrophilicity through chemical modification of microstructured titanium implant surfaces. J Biomed Mater Res A. 2006. 76:323–334.

Article26. Buser D, Broggini N, Wieland M, Schenk RK, Denzer AJ, Cochran DL, et al. Enhanced bone apposition to a chemically modified SLA titanium surface. J Dent Res. 2004. 83:529–533.

Article27. Ferguson SJ, Broggini N, Wieland M, de Wild M, Rupp F, Geis-Gerstorfer J, et al. Biomechanical evaluation of the interfacial strength of a chemically modified sandblasted and acid-etched titanium surface. J Biomed Mater Res A. 2006. 78:291–297.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- The effect of Er:YAG laser irradiation on the surface microstructure and roughness of hydroxyapatite-coated implant

- Teh Effect of Hydroxyapatite Coating on the Mechanical Strengths and Histologic Profiles of Porous Titanium Implants in Dogs

- CLINICAL STUDY OF ENDOSSEOUS HYDROXYAPATITE COATED IMPLANTS

- Effects of surface coating on the screw release of dental implant screw

- Early Postoperative Periprosthetic Radiological Findings in Cementless THRA : Comparison between Porous - coated Implant and Hydroxyapatite - coated Implant