J Dent Rehabil Appl Sci.

2023 Sep;39(3):158-167. 10.14368/jdras.2023.39.3.158.

Fabrication of complete dentures made with monolithic discs through CAD/CAM using facial scan data and individual tray duplicating temporary denture: a case report

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Dankook University, Cheonan, Republic of Korea

- KMID: 2549282

- DOI: http://doi.org/10.14368/jdras.2023.39.3.158

Abstract

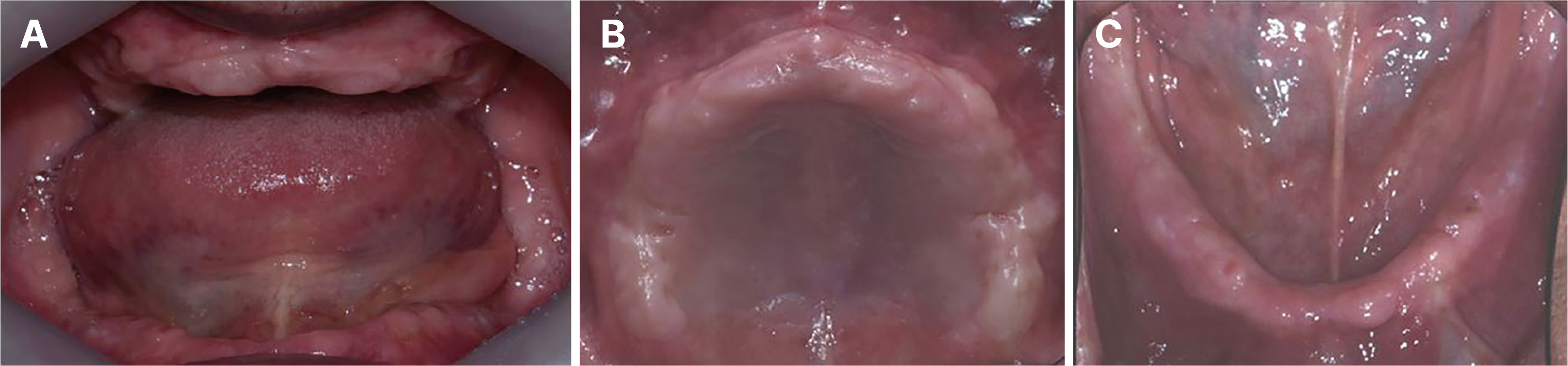

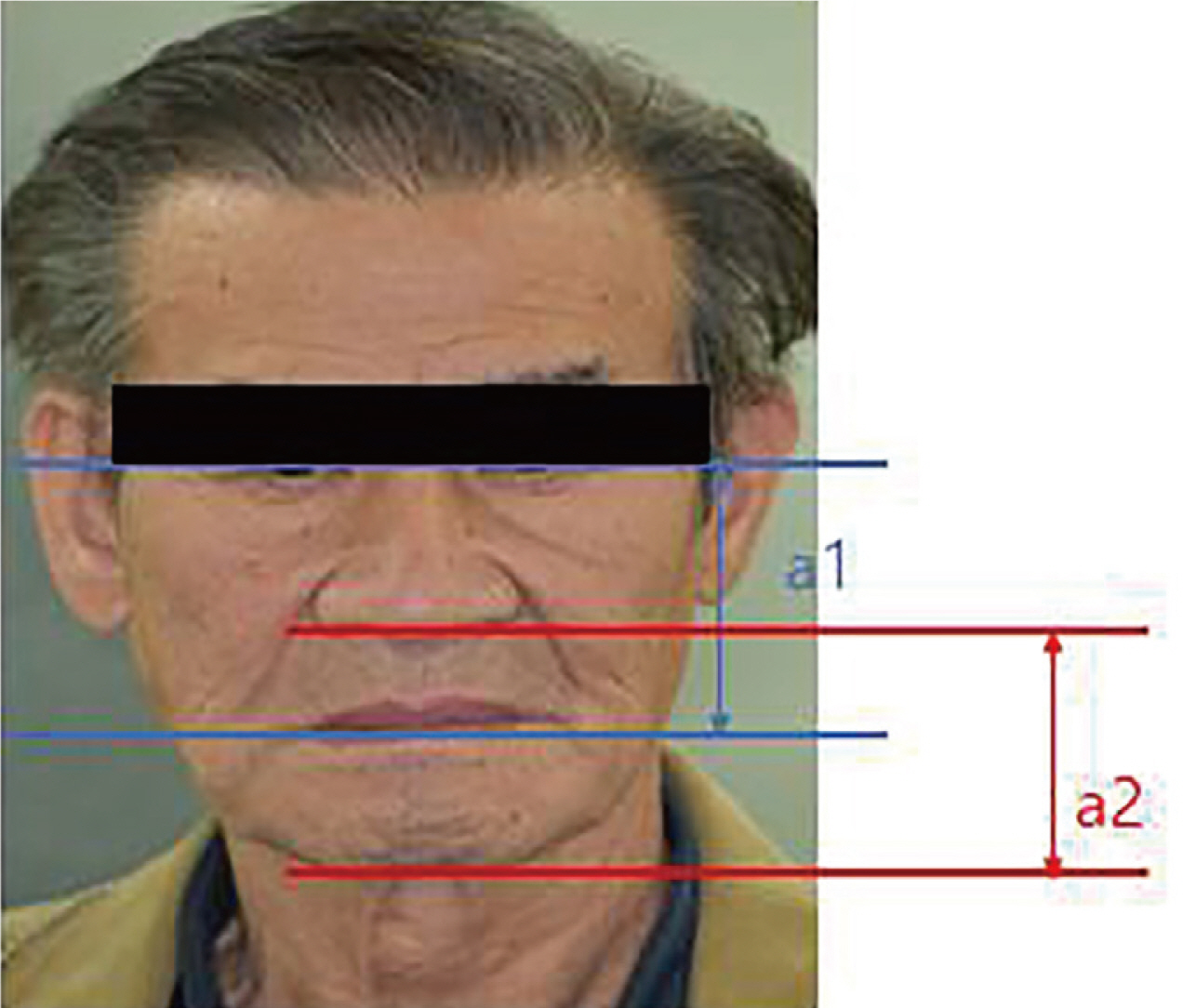

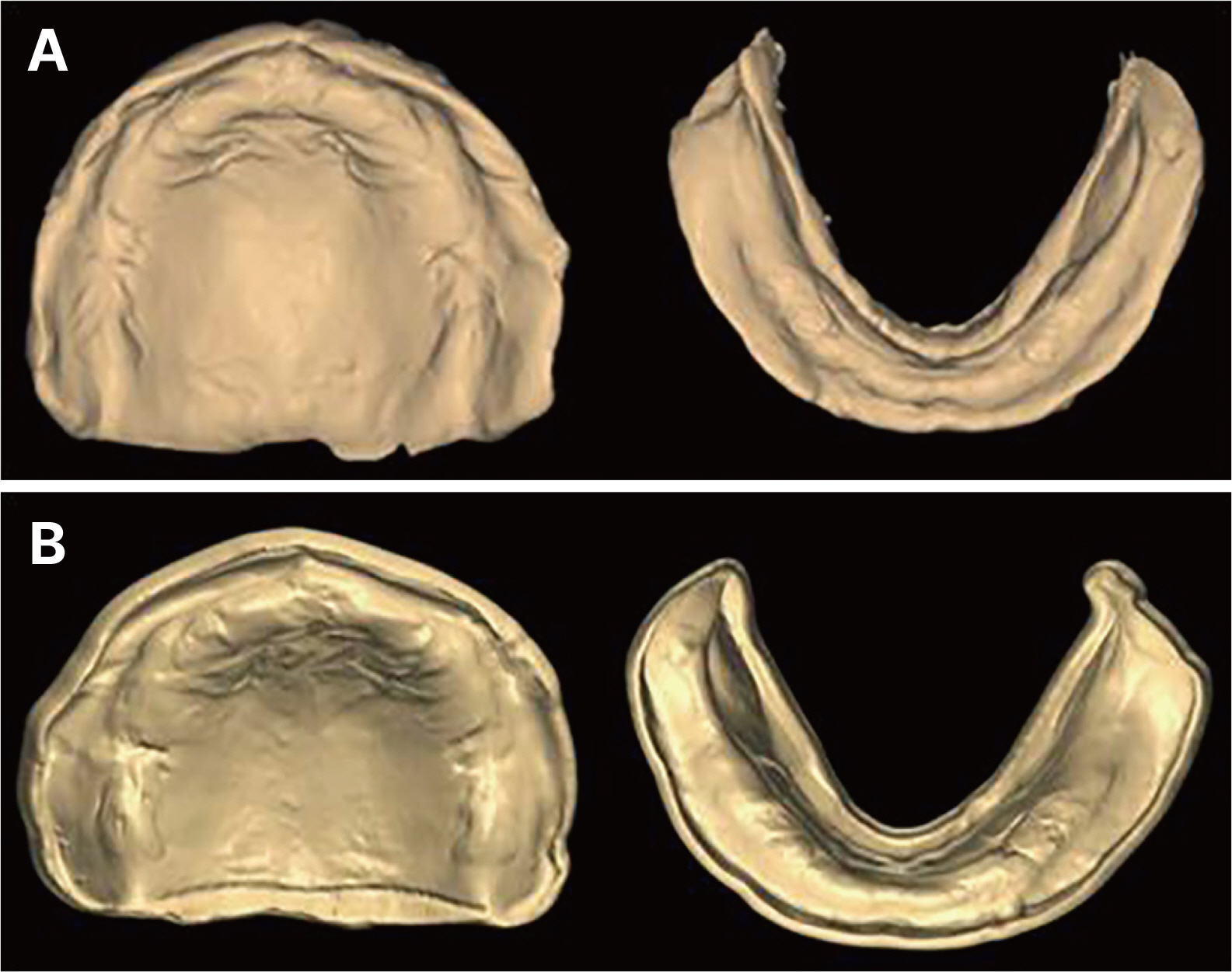

- As digital technology has advanced in the field of dentistry, the use of computer-aided design/computer-aided manufacturing (CAD/CAM) has brought changes to the stages of dental treatment. The use of CAD/CAM technology in dental restoration offers clinical efficiency and convenience by reducing production time and appointment intervals, while also simplifying the fabrication process to reduce errors. In this case, digital replication and printing of temporary teeth were used to aid a patient with complex medical histories and physical disabilities. The final impression obtained with silicone impression material included information on the vertical dimension, centric relation, and the angle and length of the anterior teeth, which shortened the production time and appointment intervals and increased patient satisfaction. The final restoration was fabricated using milling and monolithic disc techniques, demonstrating appropriate stability, retention, and support, resulting in functional and aesthetic satisfaction.

Keyword

Figure

Reference

-

References

1. Maeda Y, Minoura M, Tsutsumi S, Okada M, Nokubi T. 1994; A CAD/CAM system for removable denture. Part I: Fabrication of complete dentures. Int J Prosthodont. 7:17–21.2. Goodacre CJ, Garbacea A, Naylor WP, Daher T, Marchack CB, Lowry J. 2012; CAD/CAM fabricated complete dentures: concepts and clinical methods of obtaining required morphological data. J Prosthet Dent. 107:34–46. DOI: 10.1016/S0022-3913(12)60015-8. PMID: 22230914.3. Dusmukhamedov S, Lee CN, Jeong SM, Choi BH. 2021; Digital denture fabrication: a technical note. Appl Sci. 11:8093. DOI: 10.3390/app11178093.4. Miyazaki T, Hotta Y, Kunii J, Kuriyama S, Tamaki Y. 2009; A review of dental CAD/CAM: current status and future perspectives from 20 years of experience. Dent Mater J. 28:44–56. DOI: 10.4012/dmj.28.44. PMID: 19280967.5. Lee JJ, Song KY, Park JM. 2019; Application and considerationof digital technology for removable complete denture. J Korean Dent Assoc. 57:534–43.6. Goodacre BJ, Goodacre CJ, Baba NZ, Kattadiyil MT. 2018; Comparison of denture tooth movement between CAD-CAM and conventional fabrication techniques. J Prosthet Dent. 119:108–15. DOI: 10.1016/j.prosdent.2017.02.009. PMID: 28506652.7. Patzelt SB, Vonau S, Stampf S, Att W. 2013; Assessing the feasibility and accuracy of digitizing edentulous jaws. J Am Dent Assoc. 144:914–20. DOI: 10.14219/jada.archive.2013.0209. PMID: 23904578.8. Kattadiyil MT, Goodacre CJ, Baba NZ. 2013; CAD/CAM complete dentures: a review of two commercial fabrication systems. J Calif Dent Assoc. 41:407–16. DOI: 10.1080/19424396.2013.12222317. PMID: 23875432.9. Zeidan AAE, Sherif AF, Baraka Y, Abualsaud R, Abdelrahim RA, Gad MM, Helal MA. 2022; Evaluation of the effect of different construction techniques of CAD-CAM milled, 3D-printed, and polyamide denture base resins on flexural strength: an in vitro comparative study. J Prosthodont. 32:77–82. DOI: 10.1111/jopr.13514. PMID: 35343012.10. Aguirre BC, Chen JH, Kontogiorgos ED, Murchison DF, Nagy WW. 2020; Flexural strength of denture base acrylic resins processed by conventional and CAD-CAM methods. J Prosthet Dent. 123:641–6. DOI: 10.1016/j.prosdent.2019.03.010. PMID: 31353106.11. Ayman AD. 2017; The residual monomer content and mechanical properties of CAD/CAM resins used in the fabrication of complete dentures as compared to heat cured resins. Electron Physician. 9:4766–72. DOI: 10.19082/4766. PMID: 28894533. PMCID: PMC5586991.12. Steinmassl O, Dumfahrt H, Grunert I, Steinmassl PA. 2018; Influence of CAD/CAM fabrication on denture surface properties. J Oral Rehabil. 45:406–13. DOI: 10.1111/joor.12621. PMID: 29473188.13. Hamza TA, Ezzat HA, El-Hossary MM, Katamish HA, Shokry TE, Rosenstiel SF. 2013; Accuracy of ceramic restorations made with two CAD/CAM systems. J Prosthet Dent. 109:83–7. DOI: 10.1016/S0022-3913(13)60020-7. PMID: 23395333.14. Lo Russo L, Park JM, Troiano G, Salamini A, Lo Muzio E, Guida L. 2023; Assessment of tooth displacement during the cast-free digital processing of milled dentures. J Prosthet Dent. 129:199–204. DOI: 10.1016/j.prosdent.2021.04.028. PMID: 34116841.15. Al-Fouzan AF, Al-Mejrad LA, Albarrag AM. 2017; Adherence of Candida to complete denture surfaces in vitro: A comparison of conventional and CAD/CAM complete dentures. J Adv Prosthodont. 9:402–8. DOI: 10.4047/jap.2017.9.5.402. PMID: 29142649. PMCID: PMC5673618.16. Maragliano-Muniz P, Kukucka ED. 2021; Incorporting digital dentures into clinical practice: flexible work flows and improved clinical outcomes. J Prosthodont. 30:125–32. DOI: 10.1111/jopr.13277. PMID: 33128422.17. Silva NRFA, Kukucka ED. 2022; Innovative subtractive production of a digital removable complete denture from start to finish: a JPD Digital video presentation. J Prosthet Dent. 127:1–5. DOI: 10.1016/j.prosdent.2021.12.002. PMID: 35027149.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Fabrication of complete denture using conventional method and monolithic digital denture system: a case report

- Fabrication of CAD-CAM complete denture using existing provisional denture and digital facebow transfer

- Fabrication of complete denture using CAD-based vertical dimension increase and monolithic disc: a case report

- Fabrication of maxillary complete denture and mandibular implant retained overdenture using CAD-CAM system and Monolithic disc: a case report

- Rehabilitation of fully edentulous patient using Ceramill full denture system (FDS)