J Dent Rehabil Appl Sci.

2023 Jun;39(2):96-103. 10.14368/jdras.2023.39.2.96.

Fabrication of maxillary complete denture and mandibular implant retained overdenture using CAD-CAM system and Monolithic disc: a case report

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Chonnam National University, Gwangju, Republic of Korea

- KMID: 2549277

- DOI: http://doi.org/10.14368/jdras.2023.39.2.96

Abstract

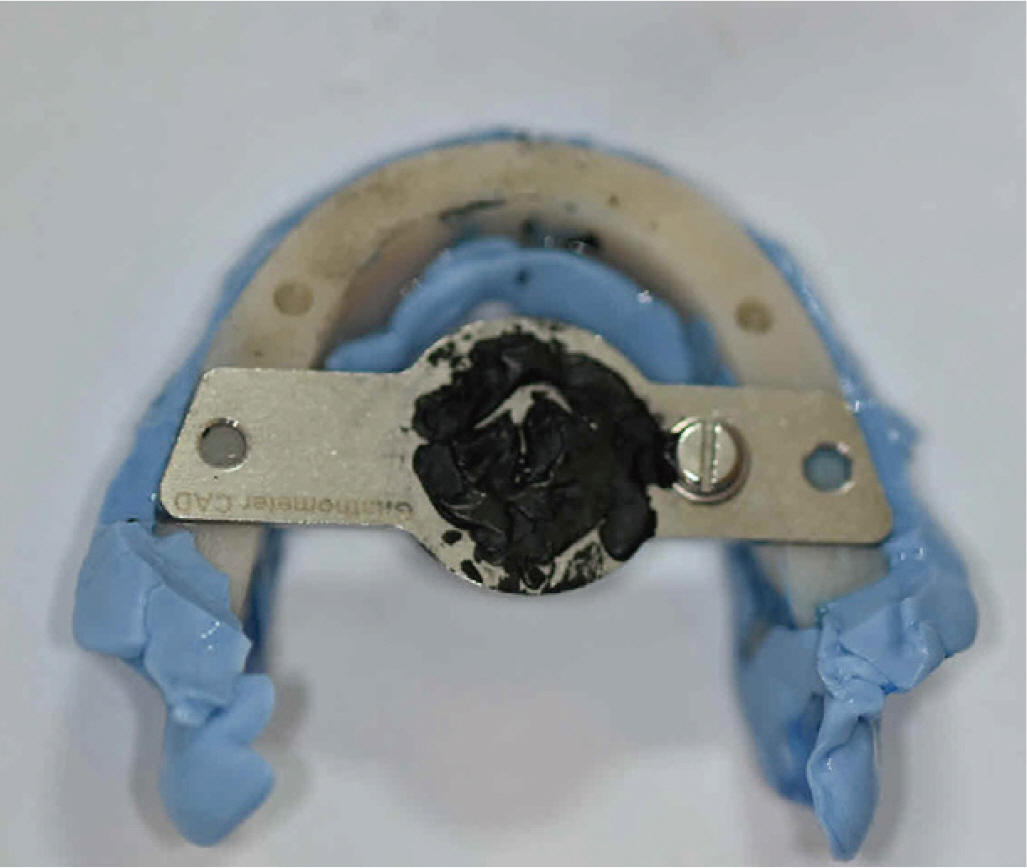

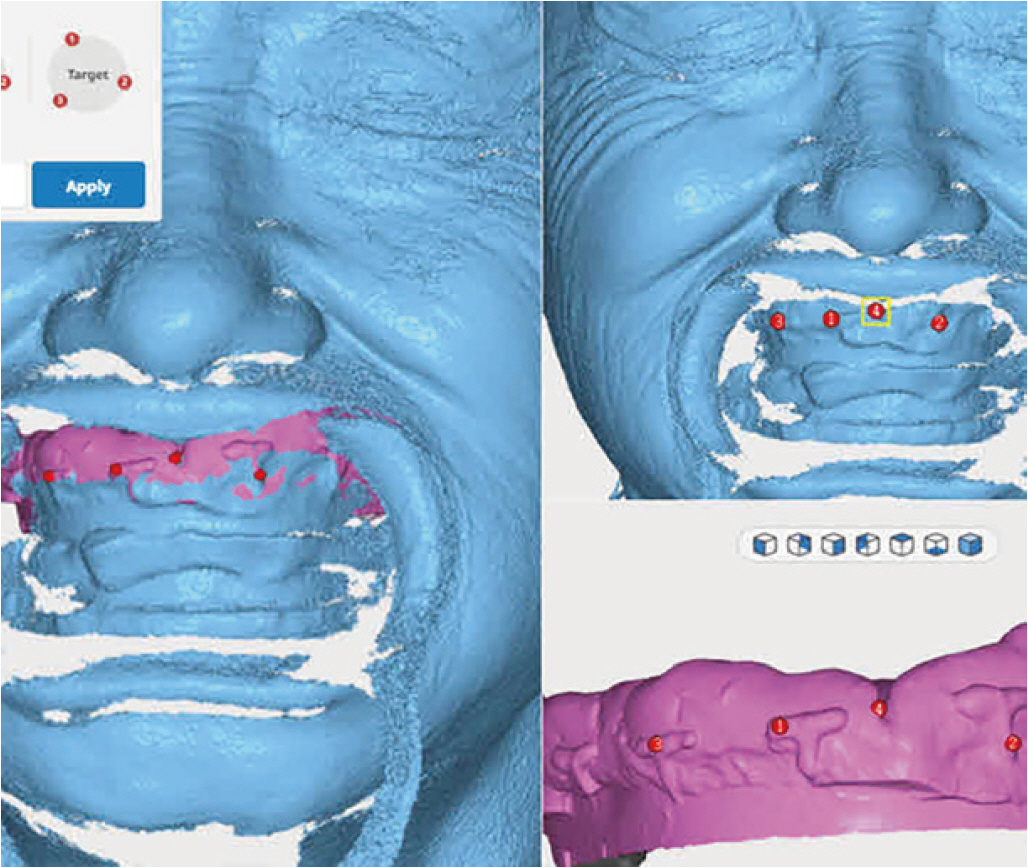

- Fabrication of dentures using CAD/CAM system has the advantage of reducing the number of patient visits and reducing errors during laboratory work. After the extraction of maxillary residual teeth, this patient changed to a completely edentulous state and the stability and retention of the existing mandibular complete denture were insufficient due to the absorption of the mandibular residual ridge, so the restoration of the mandibular implant retained overdenture and maxillary complete denture were planned. By digitizing the concept of BPS (Biofunctional prosthetic system) that uses the patient’s functional movement in closed mouth technique, the vertical dimension was taken by Gnathometer CAD and digital facebow transfer was performed using UTS CAD. In this case, fabrication of maxillary complete denture and mandibular implant-retained overdenture using monolithic disc and CAD/ CAM system demonstrated favorable denture retention, stability, and support and the patient is satisfied with improved functions and esthetic of dentures.

Figure

Reference

-

References

1. Kattadiyil MT, AlHelal A. 2017; An update on computer-engineered complete dentures: A systematic review on clinical outcomes. J Prosthet Dent. 117:478–85. DOI: 10.1016/j.prosdent.2016.08.017. PMID: 27881317.2. Abe J. 2010; Difference of preliminary impression takings between conventional mandibular complete denture and the mandibular complete denture intended with effective suction. Pract Prosthodont. 43:510–24.3. Pacquet W, Benoit A, Hatège-Kimana C, Wulfman C. 2019; Mechanical Properties of CAD/CAM Denture Base Resins. Int J Prosthodont. 32:104–6. DOI: 10.11607/ijp.6025. PMID: 30677121.

Article4. Maeda Y, Minoura M, Tsutsumi S, Okada M, Nokubi T. 1994; A CAD CAM system for removable denture. Part 1: Fabrication of Complete denture. Int J Prosthdont. 7:17–21.5. Steinmassel PA, Klaunzer F, Steinmassel O, Dumfahrt H, Grunert I. 2017; Evaluation of currently available CAD/CAM Denture system. Int J Prosthodont. 30:116–22. DOI: 10.11607/ijp.5031. PMID: 28267817.6. Abualsaud R, Gad MM. 2022; Flexural Strength of CAD/CAM Denture Base Materials: Systematic Review and Meta-analysis of In-vitro Studies. J Int Soc Prev Community Dent. 12:160–70. DOI: 10.4103/jispcd.JISPCD_310_21. PMID: 35462750. PMCID: PMC9022382.

Article7. Goodacre BJ, Goodacre CJ, Baba NZ, Kattadiyil MT. 2016; Comparison of denture base adaptation between CAD/CAM and conventional fabrication techniques. J Prosthet Dent. 116:249–56. DOI: 10.1016/j.prosdent.2016.02.017. PMID: 27112416.

Article8. Sayed ME, Swaid SM, Porwal A. 2017; Effect of Cast Modification on Linear Dimensional Change of Acrylic Tooth Position Following Maxillary Complete Denture Processing. J Prosthodont. 26:659–63. DOI: 10.1111/jopr.12445. PMID: 26883552.

Article9. Yamamoto S, Kanazawa M, Hirayama D, Nakamura T, Arakida T, Minakuchi S. 2016; In vitro evaluation of basal shapes and offset values of artificial teeth for CAD/CAM complete dentures. Comput Biol Med. 68:84–9. DOI: 10.1016/j.compbiomed.2015.11.004. PMID: 26623945.

Article10. Yamamoto S, Kanazawa M, Iwaki M, Jokanovic A, Minakuchi S. 2014; Effects of offset values for artificial teeth positions in CAD/CAM complete denture. Comput Biol Med. 52:1–7. DOI: 10.1016/j.compbiomed.2014.05.011. PMID: 24981734.

Article11. Ciocca L, Maltauro M, Cimini V, Breschi L, Montanari A, Anderlucci L, Meneghello R. 2023; Analysis of the trueness and precision of complete denture bases manufactured using digital and analog technologies. J Adv Prosthodont. 15:22–32. DOI: 10.4047/jap.2023.15.1.22. PMID: 36908755. PMCID: PMC9992699.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- A case of digital maxillary complete denture and mandibular implant overdenture fabricated by CAD-CAM technique

- Fabrication of CAD-CAM complete denture using existing provisional denture and digital facebow transfer

- Fabrication of complete denture using CAD-based vertical dimension increase and monolithic disc: a case report

- The Implant Retained Overdenture by Locator Attachments on the Edentulous Mandible: A Case Report

- Fabrication of complete denture using conventional method and monolithic digital denture system: a case report