J Dent Rehabil Appl Sci.

2021 Sep;37(3):101-110. 10.14368/jdras.2021.37.3.101.

A study on the shear bond strength between 3D printed resin and provisional resin after thermal cycling

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Dankook University, Cheonan, Republic of Korea

- KMID: 2525984

- DOI: http://doi.org/10.14368/jdras.2021.37.3.101

Abstract

- Purpose

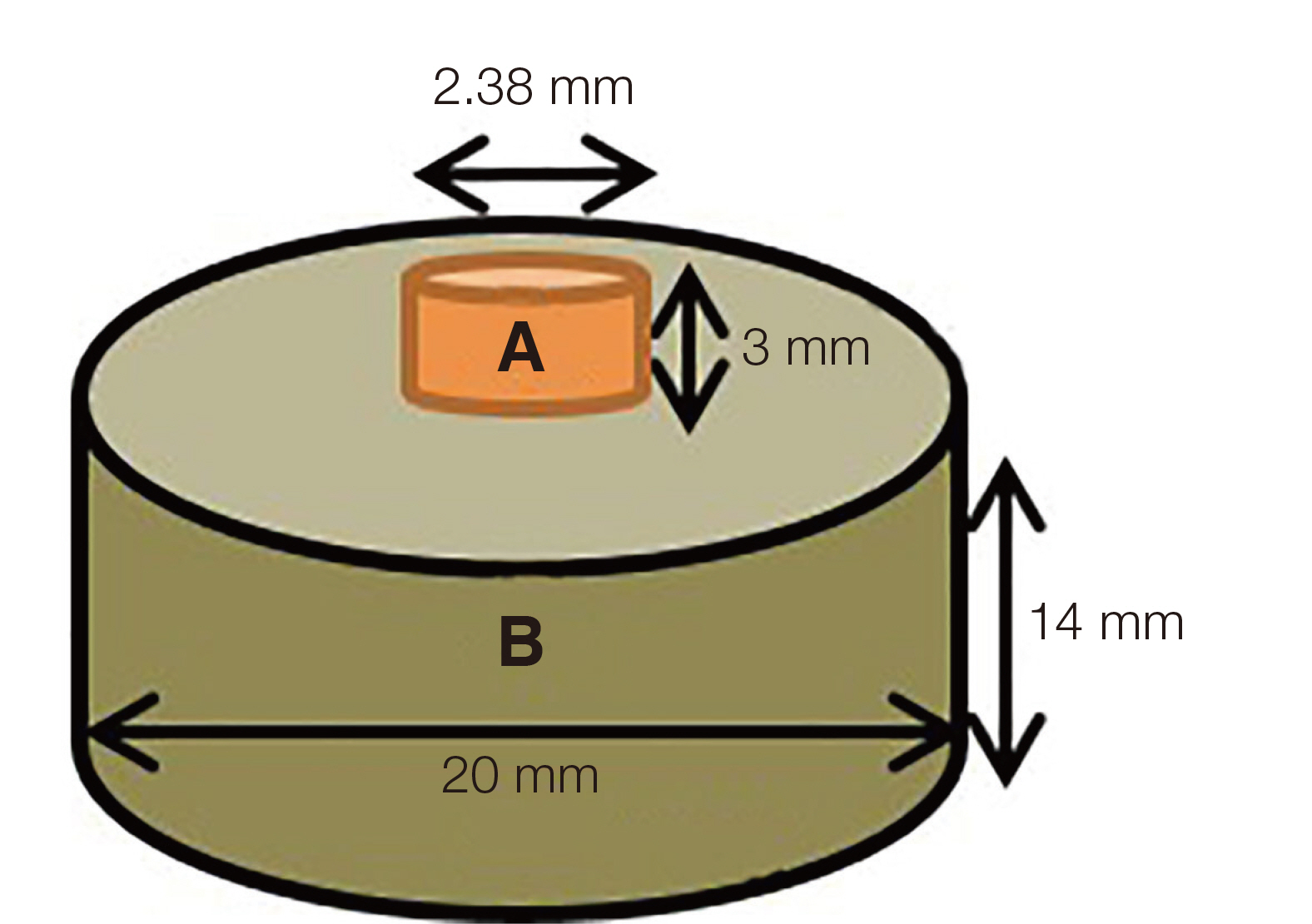

In this study, we intended to study the change in bond strength according to the thermal cycling of provisional resin and 3D printed resin for making provisional restoration. Materials and Methods: Through DLP method, 3D printed resin powder was used to produce 3D printed resin samples. The samples were grouped into eight groups, according to types of provisional resin (PMMA, bis-acryl resin) which is to be bonded on the samples and numbers of thermal cycling (control, 2,000, 3,000, 5,000 cycles). Shear bond strength of the bonded samples was measured on the universal testing machine.

Results

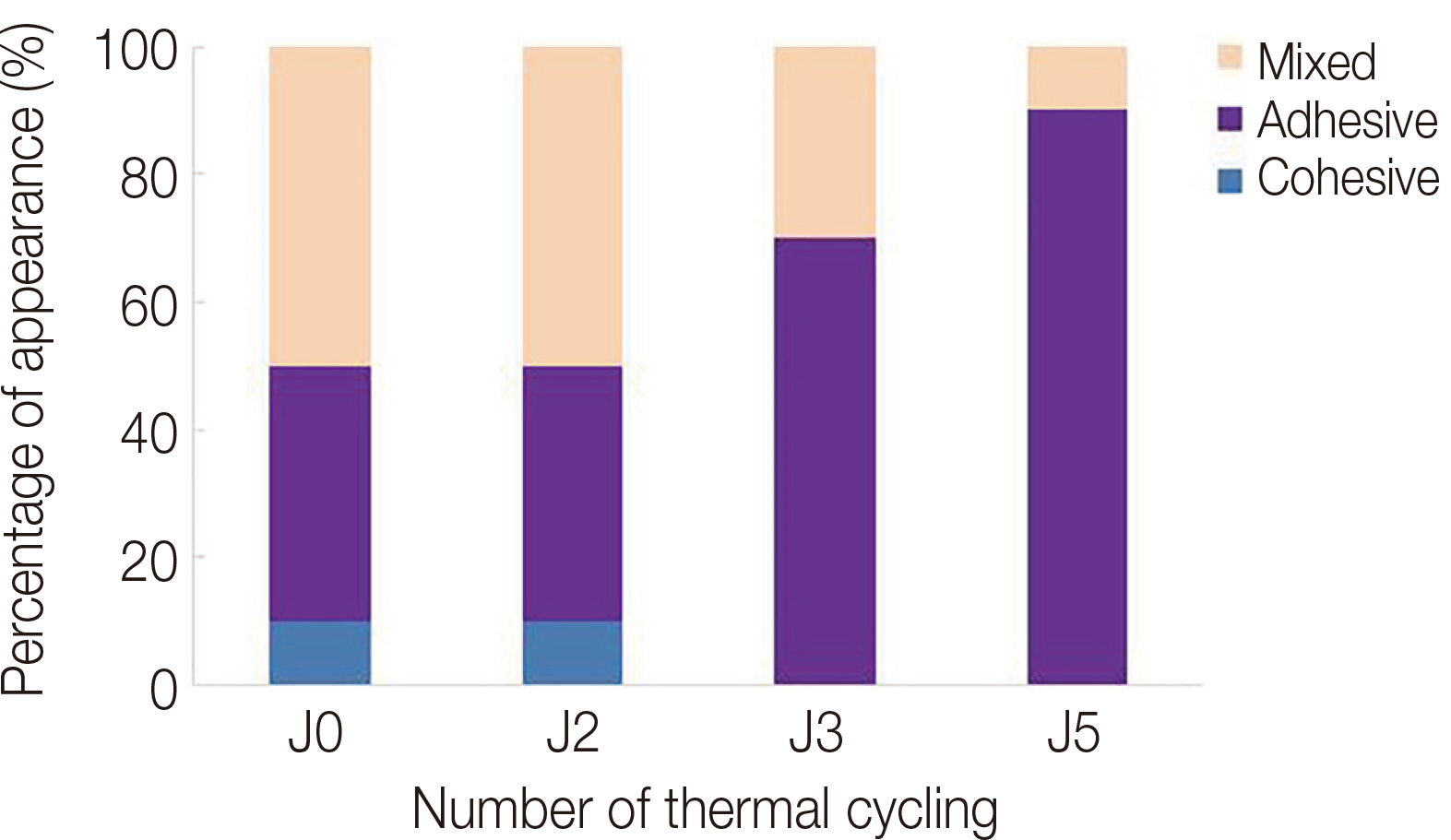

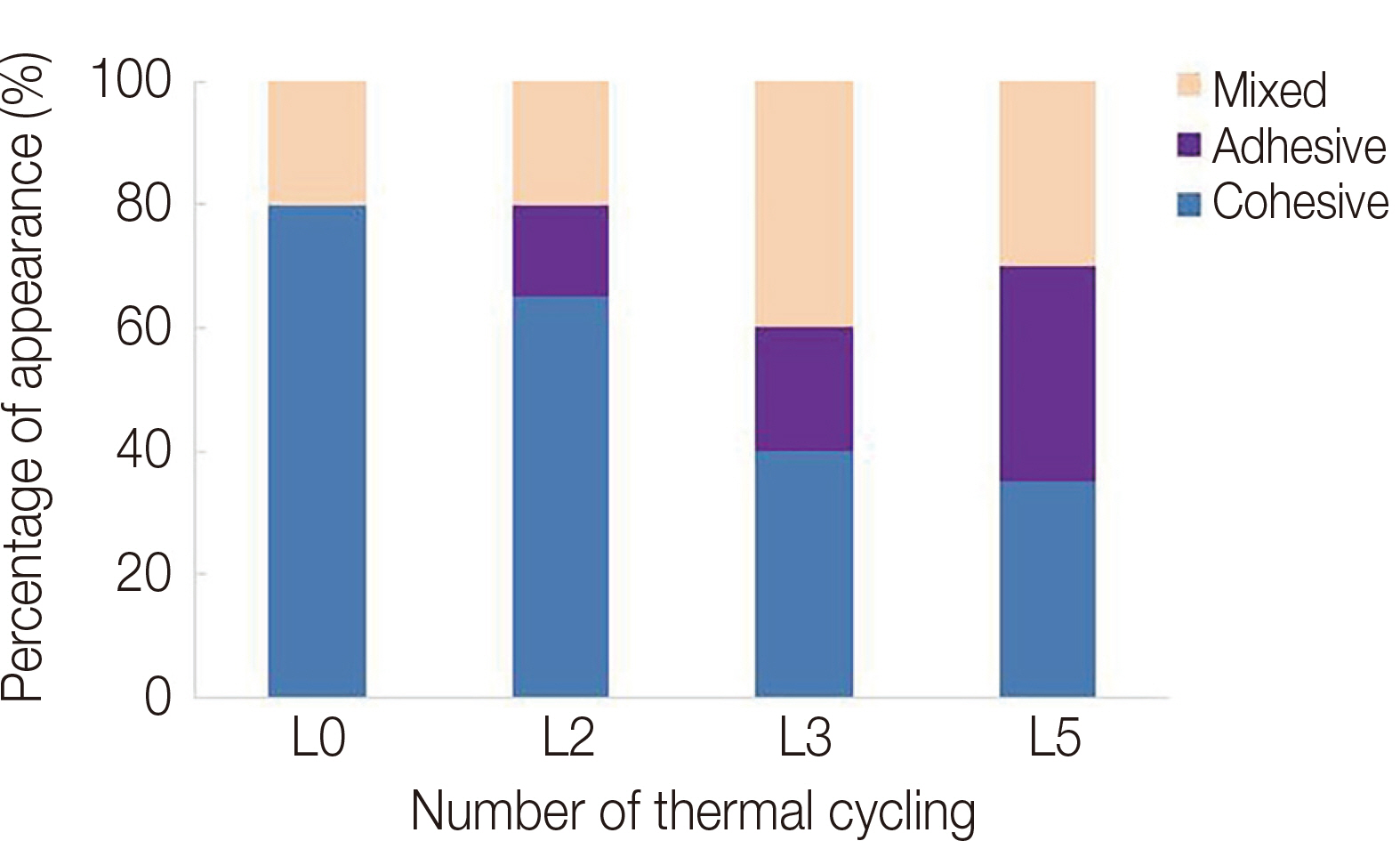

As the number of thermal cycling increased, the shear bond strength of PMMA and bis-acryl resin for 3D printed resins decreased except between 3,000 cycles and 5,000 cycles in PMMA groups. In the PMMA group, there were significant differences in shear bond strength between less number than 3,000 cycles (P < 0.05) and no significant differences between more number than 3,000 cycles (P > 0.05). In the bis-acryl resin group, there were significant differences in shear bond strength between control and 2,000 cycles, control and 3,000 cycles, and control and 5,000 cycles (P < 0.05), no significant difference between 2,000 and 3,000 cycles, between 3,000 and 5,000 cycles (P > 0.05).

Conclusion

The shear bond strength between 3D printed resin and provisional resin tended to decrease after thermal cycling.

Figure

Reference

-

References

1. Shillingburg HT, Hobo S, Whitsett LD. 1998. Provisional restorations. Fundamentals of Fixed Prosthodontics. 4th ed. Quintessence Int;Chicago: p. 225–56.2. Waerhaug J. 1980; Temporary restorations: advantages and disadvantages. Dent Clin North Am. 24:305–16.3. Federick DR. 1975; The provisional fixed partial denture. J Prosthet Dent. 34:520–6. DOI: 10.1016/0022-3913(75)90039-6. PMID: 1102669.4. Tom TN, Uthappa MA, Sunny K, Begum F, Nautiyal M, Tamore S. 2016; Provisional restorations: an overview of materials used. J Adv Clin Res Insights. 3:212–4. DOI: 10.15713/ins.jcri.141.5. Christensen GJ. 1996; Provisional restorations for fixed prosthodontics. J Am Dent Assoc. 127:249–52. DOI: 10.14219/jada.archive.1996.0177. PMID: 8682995.6. Burns DR, Beck DA, Nelson SK. Committee on Research in Fixed Prosthodontics of the Academy of Fixed Prosthodontics. 2003; A review of selected dental literature on contemporary provisional fixed prosthodontic treatment: report of the Committee on Research in Fixed Prosthodontics of the Academy of Fixed Prosthodontics. J Prosthet Dent. 90:474–97. DOI: 10.1016/S0022-3913(03)00259-2. PMID: 14586312.7. Astudillo-Rubio D, Delgado-Gaete A, Bellot-Arcís C, Montiel-Company JM, Pascual-Moscardó A, Almerich-Silla JM. 2018; Mechanical properties of provisional dental materials: a systematic review and meta-analysis. PLoS One. 13:e0193162. DOI: 10.1371/journal.pone.0193162. PMID: 29489883. PMCID: PMC5830998.8. Crispin BJ, Caputo AA. 1979; Color stability of temporary restorative materials. J Prosthet Dent. 42:27–33. DOI: 10.1016/0022-3913(79)90326-3. PMID: 6928032.9. Doray PG, Li D, Powers JM. 2001; Color stability of provisional restorative materials after accelerated aging. J Prosthodont. 10:212–6. DOI: 10.1111/j.1532-849X.2001.00212.x. PMID: 11781969.10. Nivedita S, Prithviraj DR. 2006; A comparative study to evaluate the marginal accuracy of provisional restorations fabricated by light polymerized resin and autopolymerized resin: a scanning electron microscope study. J Indian Prosthodont Soc. 6:122–7. DOI: 10.4103/0972-4052.29362.11. Crivello JV, Reichmanis E. 2014; Photopolymer materials and processes for advanced technologies. Chem Mater. 26:533–48. DOI: 10.1021/cm402262g.12. Kim YH, Jung BY, Han SS, Woo CW. 2020; Accuracy evaluation of 3D printed interim prosthesis fabrication using a CBCT scanning based digital model. PLoS One. 15:e0240508. DOI: 10.1371/journal.pone.0240508. PMID: 33064731. PMCID: PMC7567388.13. Son YT, Son K, Lee KB. 2020; Marginal and internal fit of interim crowns fabricated with 3D printing and milling method. J Dent Rehabil Appl Sci. 36:254–61. DOI: 10.14368/jdras.2020.36.4.254.14. Kim SB, Kim NH, Kim JH, Moon HS. 2018; Evaluation of the fit of metal copings fabricated using stereolithography. J Prosthet Dent. 120:693–8. DOI: 10.1016/j.prosdent.2018.01.012. PMID: 29807735.15. Papacchini F, Toledano M, Monticelli F, Osorio R, Radovic I, Polimeni A, García-Godoy F, Ferrari M. 2007; Hydrolytic stability of composite repair bond. Eur J Oral Sci. 115:417–24. DOI: 10.1111/j.1600-0722.2007.00475.x. PMID: 17850431.16. Galindo D, Soltys JL, Graser GN. 1998; Long-term reinforced fixed provisional restorations. J Prosthet Dent. 79:698–701. DOI: 10.1016/S0022-3913(98)70078-2. PMID: 9627900.17. Lim NK, Shin SY. 2020; Bonding of conventional provisional resin to 3D printed resin: the role of surface treatments and type of repair resins. J Adv Prosthodont. 12:322–8. DOI: 10.4047/jap.2020.12.5.322. PMID: 33149854. PMCID: PMC7604236.18. Liu Y, Ye H, Wang Y, Zhao Y, Sun Y, Zhou Y. 2018; Three dimensional analysis of internal adaptations of crowns cast from resin patterns fabricated using computer-aided design/computer-assisted manufacturing technologies. Int J Prosthodont. 31:386–93. DOI: 10.11607/ijp.5678. PMID: 29772034.19. Rayyan MM, Aboushelib M, Sayed NM, Ibrahim A, Jimbo R. 2015; Comparison of interim restorations fabricated by CAD/CAM with those fabricated manually. J Prosthet Dent. 114:414–9. DOI: 10.1016/j.prosdent.2015.03.007. PMID: 26001490.20. Galante R, Figueiredo-Pina CG, Serro AP. 2019; Additive manufacturing of ceramics for dental applications: a review. Dent Mater. 35:825–46. DOI: 10.1016/j.dental.2019.02.026. PMID: 30948230.21. Stansbury JW, Idacavage MJ. 2016; 3D printing with polymers: challenges among expanding options and opportunities. Dent Mater. 32:54–64. DOI: 10.1016/j.dental.2015.09.018. PMID: 26494268.22. Alharbi N, Osman RB, Wismeijer D. 2016; Factors influencing the dimensional accuracy of 3D-printed full-coverage dental restorations using stereolithography technology. Int J Prosthodont. 29:503–10. DOI: 10.11607/ijp.4835. PMID: 27611757.23. Park GS, Kim SK, Heo SJ, Koak JY, Seo DG. 2019; Effects of printing parameters on the fit of implantsupported 3D printing resin prosthetics. Materials (Basel). 12:2533. DOI: 10.3390/ma12162533. PMID: 31395801. PMCID: PMC6720497.24. Elsaka SE. 2014; Bond strength of novel CAD/CAM restorative materials to self adhesive resin cement: the effect of surface treatments. J Adhes Dent. 16:531–40. DOI: 10.3290/j.jad.a33198. PMID: 25516881.25. Gilbert S, Keul C, Roos M, Edelhoff D, Stawarczyk B. 2016; Bonding between CAD/CAM resin and resin composite cements dependent on bonding agents: three different in vitro test methods. Clin Oral Investig. 20:227–36. DOI: 10.1007/s00784-015-1494-4. PMID: 26001334.26. Bähr N, Keul C, Edelhoff D, Eichberger M, Roos M, Gernet W, Stawarczyk B. 2013; Effect of different adhesives combined with two resin composite cements on shear bond strength to polymeric CAD/CAM materials. Dent Mater J. 32:492–501. DOI: 10.4012/dmj.2012-329. PMID: 23719013.27. Keul C, Martin A, Wimmer T, Roos M, Gernet W, Stawarczyk B. 2013; Tensile bond strength of PMMAand composite-based CAD/CAM materials to luting cements after different conditioning methods. Int J Adhes Adhesiv. 46:122–7. DOI: 10.1016/j.ijadhadh.2013.06.003.28. Ha SR, Kim SH, Lee JB, Han JS, Yeo IS. 2016; Improving shear bond strength of temporary crown and fixed dental prosthesis resins by surface treatments. J Mater Sci. 51:1463–75. DOI: 10.1007/s10853-015-9466-2.29. da Costa TR, Serrano AM, Atman AP, Loguercio AD, Reis A. 2012; Durability of composite repair using different surface treatments. J Dent. 40:513–21. DOI: 10.1016/j.jdent.2012.03.001. PMID: 22410401.30. Yoshida K, Kamada K, Atsuta M. 2001; Effects of two silane coupling agents, a bonding agent, and thermal cycling on the bond strength of a CAD/CAM composite material cemented with two resin luting agents. J Prosthet Dent. 85:184–9. DOI: 10.1067/mpr.2001.113628. PMID: 11208209.31. Jeong KW, Kim SH. 2019; Influence of surface treatments and repair materials on the shear bond strength of CAD/CAM provisional restorations. J Adv Prosthodont. 11:95–104. DOI: 10.4047/jap.2019.11.2.95. PMID: 31080570. PMCID: PMC6491361.32. Ellakwa AE, Shortall AC, Burke FJ, Marquis PM. 2003; Effects of grit blasting and silanization on bond strengths of a resin luting cement to Belleglass HP indirect composite. Am J Dent. 16:53–7. PMID: 12744414.33. Lise DP, Van Ende A, De Munck J, Vieira L, Baratieri LN, Van Meerbeek B. 2017; Microtensile bond strength of composite cement to novel CAD/CAM materials as a function of surface treatment and aging. Oper Dent. 42:73–81. DOI: 10.2341/15-263-L. PMID: 27689770.34. Lung CYK, Matinlinna JP. 2012; Aspects of silane coupling agents and surface conditioning in dentistry: an overview. Dent Mater. 28:467–77. DOI: 10.1016/j.dental.2012.02.009. PMID: 22425571.35. Lee J, Lee S. 2015; Evaluation of add-on methods for bis-acryl composite resin interim restorations. J Prosthet Dent. 114:594–601. DOI: 10.1016/j.prosdent.2015.02.020. PMID: 25979444.36. Albahri R, Yoon HI, Lee JD, Yoon S, Lee SJ. 2021; Shear bond strength of provisional repair materials bonded to 3D printed resin. J Dent Sci. 16:261–7. DOI: 10.1016/j.jds.2020.05.003. PMID: 33384807. PMCID: PMC7770250.37. Zhi L, Bortolotto T, Krejci I. 2016; Comparative in vitro wear resistance of CAD-CAM composite resin and ceramic materials. J Prosthet Dent. 115:199–202. DOI: 10.1016/j.prosdent.2015.07.011. PMID: 26460171.38. Flury S, Diebold E, Peutzfeldt A, Lussi A. 2017; Effect of artificial toothbrushing and water storage on the surface roughness and micromechanical properties of tooth-colored CAD-CAM materials. J Prosthet Dent. 117:767–74. DOI: 10.1016/j.prosdent.2016.08.034. PMID: 27836147.39. Marro FG, Mestra A, Jiménez-Piqué E, Chintapalli R, Anglada M. 2012; Surface mechanical properties of advanced zirconia after hydrothermal exposure. IOP Conference Series Materials Science and Engineering. 31:012015. DOI: 10.1088/1757-899X/31/1/012015.40. Morresi AL, D'Amario M, Capogreco M, Gatto R, Marzo G, D'Arcangelo C, Monaco A. 2014; Thermal cycling for restorative materials: does a standardized protocol exist in laboratory testing? A literature review. J Mech Behav Biomed Mater. 29:295–308. DOI: 10.1016/j.jmbbm.2013.09.013. PMID: 24135128.41. Gu HJ, Jun SK, Kim DA, Kim HW, Lee HH. 2008; Effect of the thermocycling on the mechanical properties of resin composite. Korean J Dent Mater. 35:155–64.42. Minami H, Hori S, Kurashige H, Murahara S, Muraguchi K, Minesaki Y, Tanaka T. 2007; Effects of thermal cycling on surface texture of restorative composite materials. Dent Mater J. 26:316–22. DOI: 10.4012/dmj.26.316. PMID: 17694738.43. Gale MS, Darvell BW. 1999; Thermal cycling procedures for laboratory testing of dental restorations. J Dent. 27:89–99. DOI: 10.1016/S0300-5712(98)00037-2. PMID: 10071465.44. Palla ES, Kontonasaki E, Kantiranis N, Papadopoulou L, Zorba T, Paraskevopoulos KM, Koidis P. 2018; Color stability of lithium disilicate ceramics after aging and immersion in common beverages. J Prosthet Dent. 119:632–42. DOI: 10.1016/j.prosdent.2017.04.031. PMID: 28923549.45. Torstenson B, Brännström M. 1988; Contraction gap under composite resin restorations: effect of hygroscopic expansion and thermal stress. Oper Dent. 13:24–31. PMID: 3270035.46. Stawarczyk B, Basler T, Ender A, Roos M, Özcan M, Hämmerle C. 2012; Effect of surface conditioning with airborne-particle abrasion on the tensile strength of polymeric CAD/CAM crowns luted with selfadhesive and conventional resin cements. J Prosthet Dent. 107:94–101. DOI: 10.1016/S0022-3913(12)60031-6. PMID: 22304743.47. Piwowarczyk A, Lauer HC, Sorensen JA. 2004; In vitro shear bond strength of cementing agents to fixed prosthodontic restorative materials. J Prosthet Dent. 92:265–73. DOI: 10.1016/j.prosdent.2004.06.027. PMID: 15343162.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- THE EFFECTS OF THERMAL CYCLING ON THE BOND STRENGTH OF SELF-CURING RESIN

- Bonding of conventional provisional resin to 3D printed resin: the role of surface treatments and type of repair resins

- In Vitro Study on the Bond Strength Between 3D-Printed Resin and Resin Cement for Pediatric Crown Restoration

- Comparison of shear bond strength between hard relining material and 3D-printing denture base resin containing silica micro-gel

- A comparison study on shear bond strength of 3D printed resin and conventional heat-cured denture base resin to denture relining materials