J Dent Rehabil Appl Sci.

2020 Sep;36(3):168-175. 10.14368/jdras.2020.36.3.168.

Evaluation of physical properties of polycarbonate temporary restoration materials

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Chosun University, Gwangju, Republic of Korea

- KMID: 2512111

- DOI: http://doi.org/10.14368/jdras.2020.36.3.168

Abstract

- Purpose

The purpose is to test and evaluate the physical properties of commonly used temporary restoration materials and newly emerged materials.

Materials and Methods

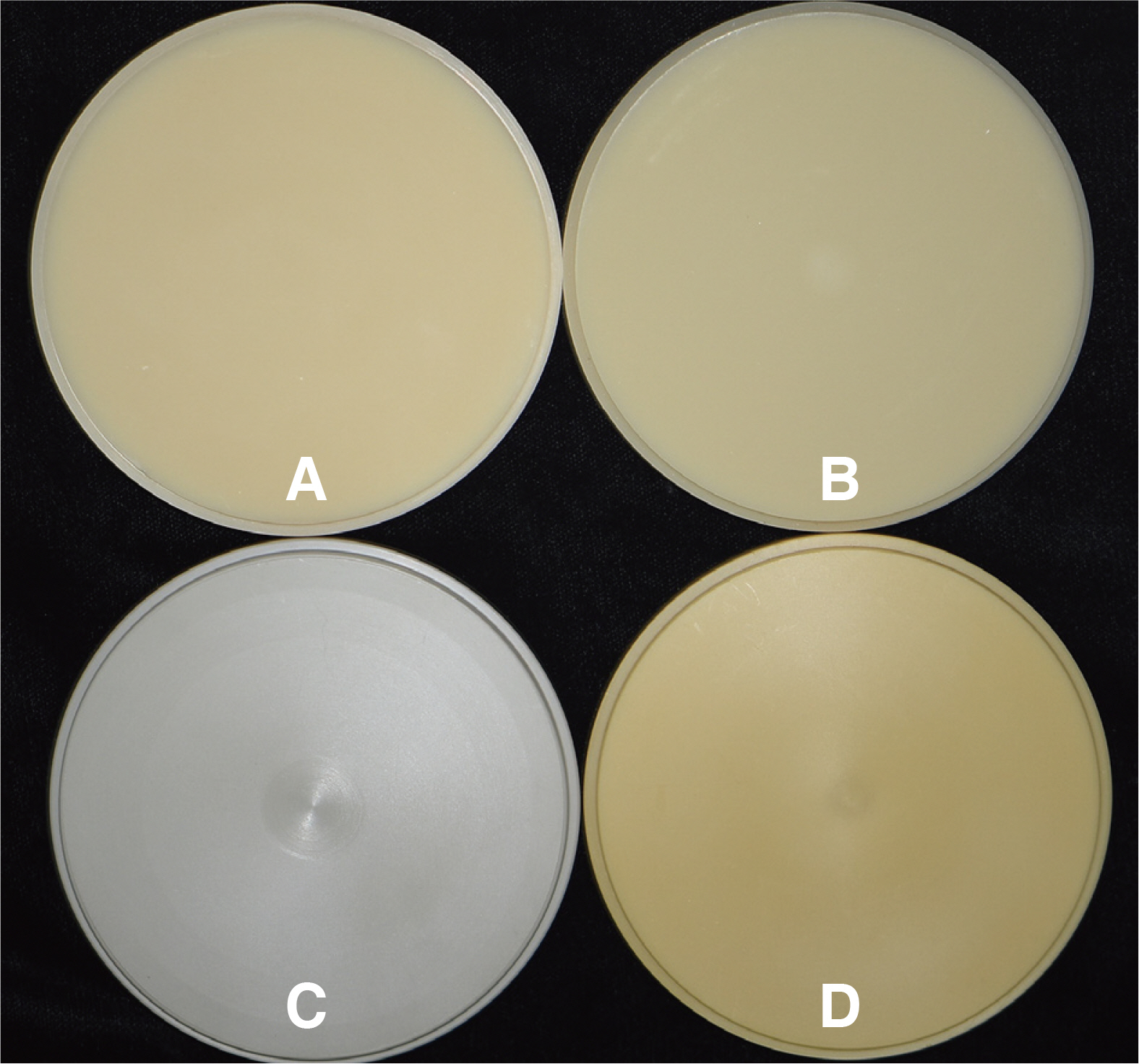

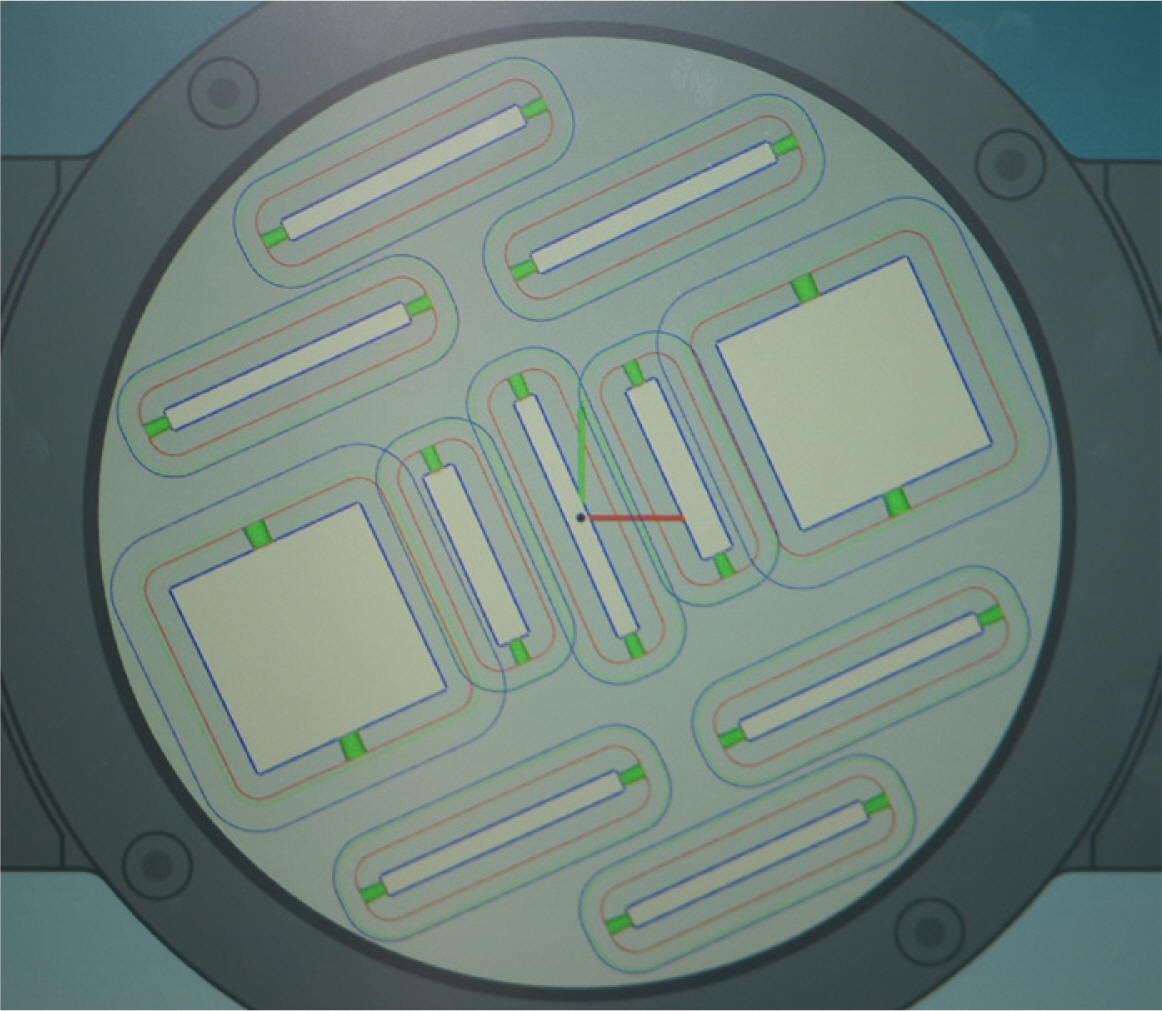

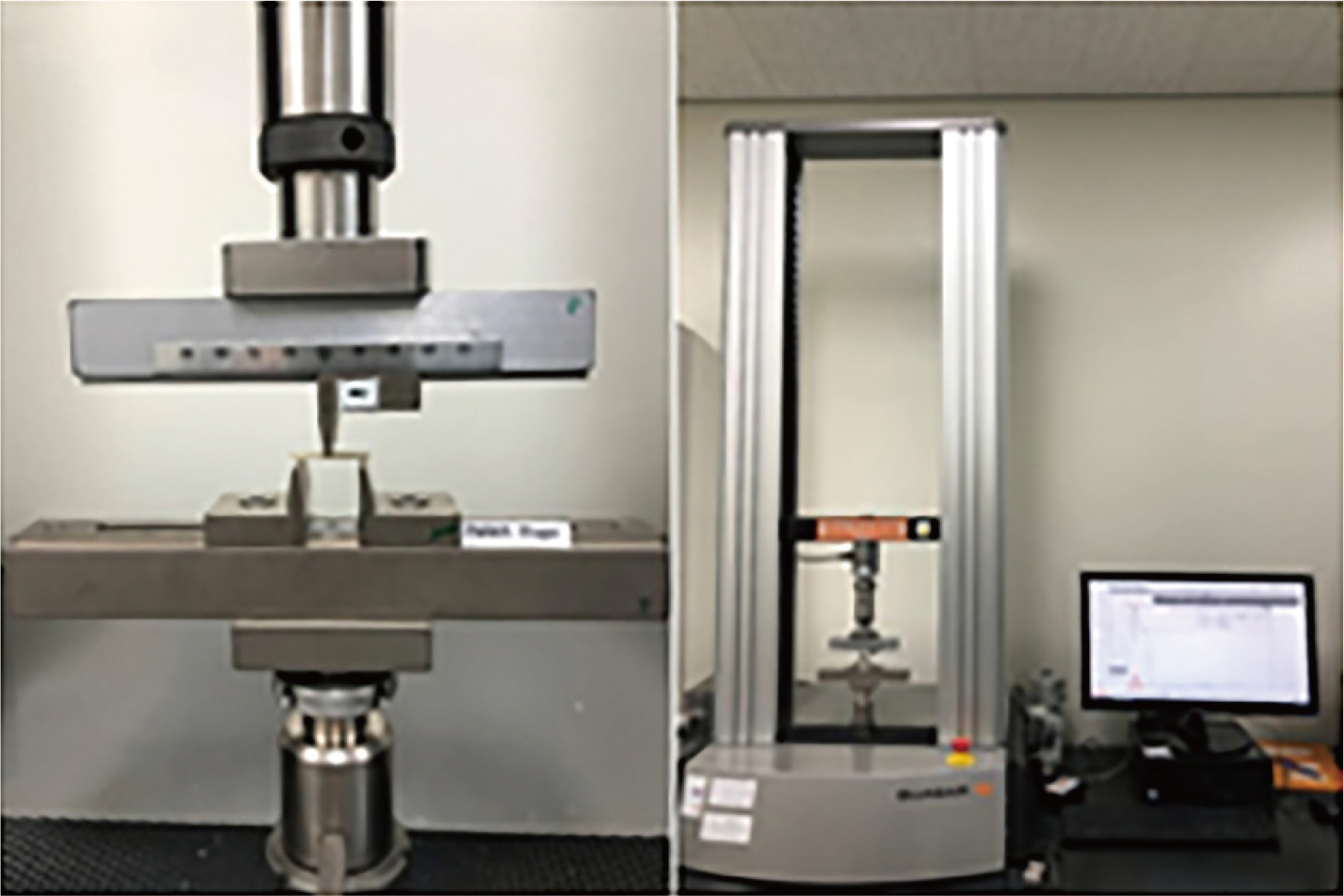

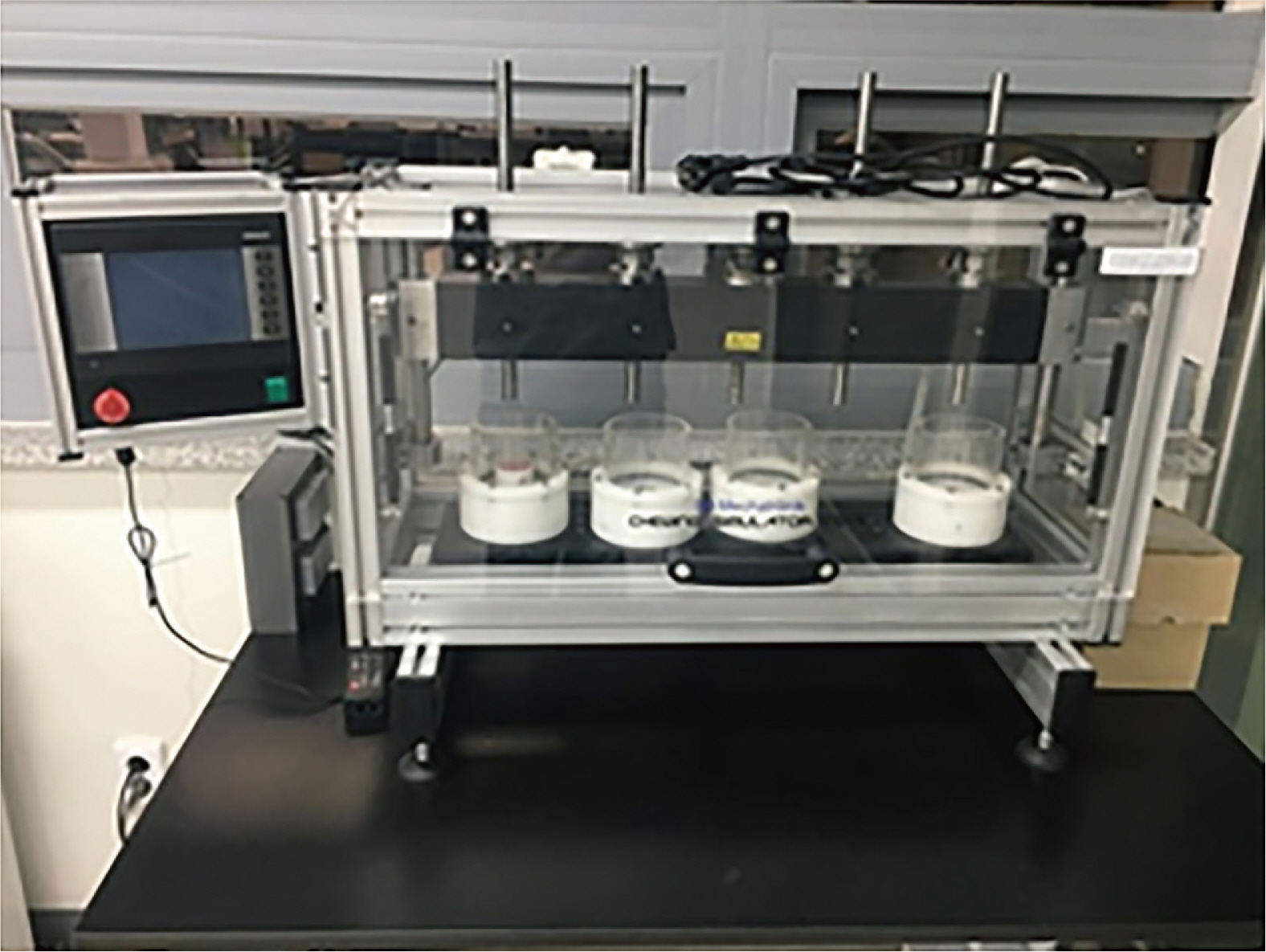

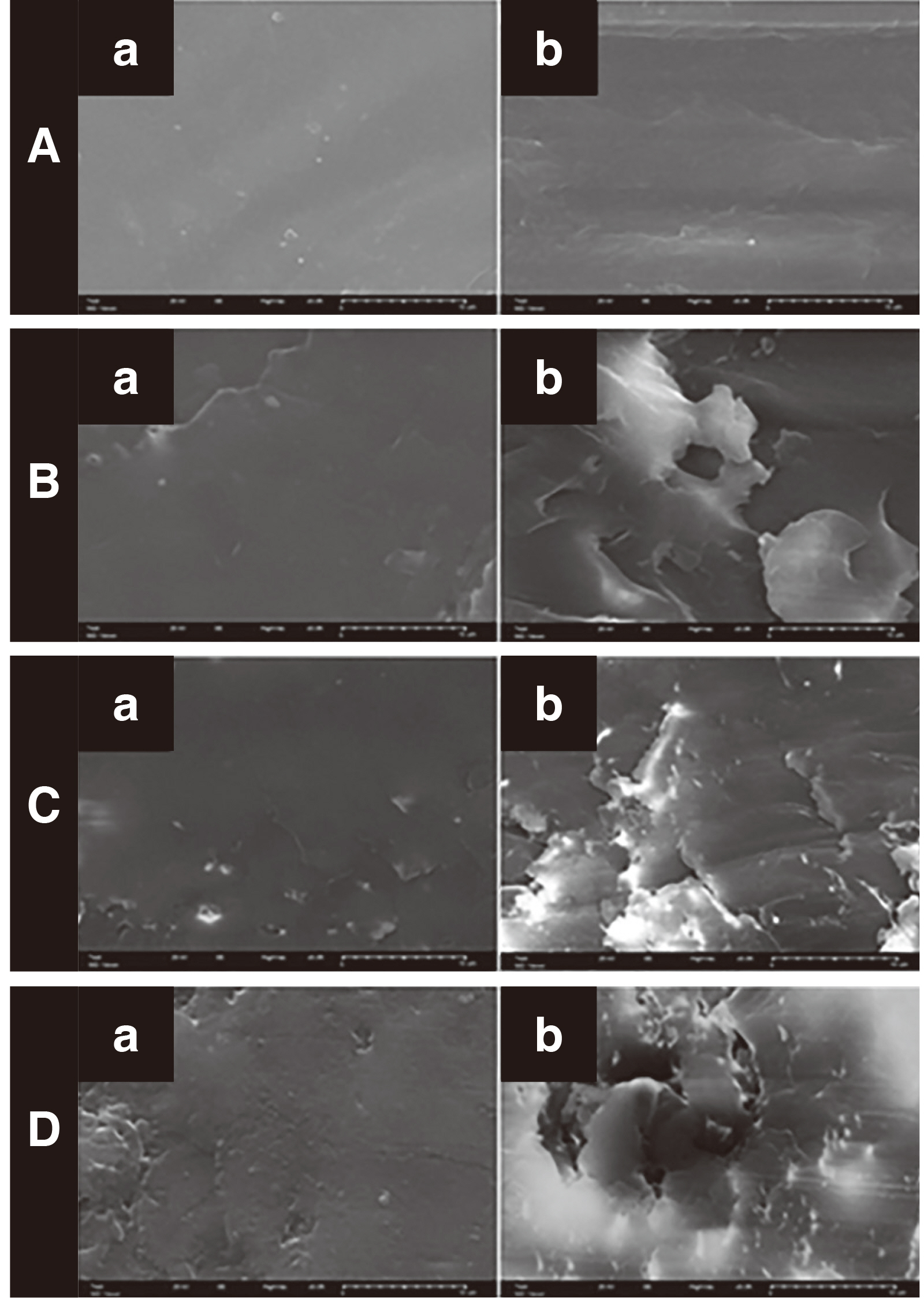

Four groups of polymer materials were evaluated: Polymethyl methacrylate (PMMA) 2 groups, Polyetheretherketone (PEEK), Polycarbonate. Four physical properties were tested: surface hardness, bending strength, abrasion resistance during wear, wear behavior. The 3-axis bending strength and Vickers hardness test were measured using a universal testing machines respectively. The microstructure was observed with a scanning electron microscope and weight comparison was evaluated after 100,000 chewing tests using a chewing simulator. Kruskal wallis test was performed to evaluate statistical significance.

Results

The four groups showed the highest flexural strength and Vickers hardness of PEEK, followed by PC, PMMA-H, PMMA-T. Microstructure observation also showed the least surface roughness in the PEEK group, followed by PC, PMMA-H, PMMA-T.

Conclusion

PC is considered to have sufficient mechanical properties that can be applied to the manufacture of temporary teeth. However, further studies, such as biocompatibility, are considered to be necessary for practical clinical applications.

Figure

Reference

-

References

1. Prasad DK, Shetty M, Alva H, Prasad DA. 2012; Provisional Restorations in Prosthodontic Rehabilitations - Concepts, Materials and Techniques. J Heal Allied Sci NU. 02:72–7.2. Burns DR, Beck DA, Nelson SK. 2003; A review of selected dental literature on contemporary provisional fixed prosthodontic treatment: Report of the Committee on Research in Fixed Prosthodontics of the Academy of Fixed Prosthodontics. J Prosthet Dent. 90:474–97. DOI: 10.1016/s0022-3913(03)00259-2. PMID: 14586312.3. Singh A, Garg S. 2016; Comparative evaluation of flexural strength of provisional crown and bridge materials-an invitro study. J Clin Diagn Res. 10:ZC72–7. DOI: 10.7860/JCDR/2016/19582.8291. PMID: 27656568. PMCID: PMC5028505.4. Abdullah AO, Tsitrou EA, Pollington S. 2016; Comparative in vitro evaluation of CAD/CAM vs conventional provisional crowns. J Appl Oral Sci. 24:258–63. DOI: 10.1590/1678-775720150451. PMID: 27383707. PMCID: PMC5022219.5. Tahayeri A, Morgan M, Fugolin AP, Bompolaki D, Athirasala A, Pfeifer CS, Ferracane JL, Bertassoni LE. 2018; 3D printed versus conventionally cured provisional crown and bridge dental materials. Dent Mater. 34:192–200. DOI: 10.1016/j.dental.2017.10.003. PMID: 29110921. PMCID: PMC5801146.6. Vallittu PK. 1998; The effect of glass fiber reinforcement on the fracture resistance of a provisional fixed partial denture. J Prosthet Dent. 79:125–30. DOI: 10.1016/s0022-3913(98)70204-5. PMID: 9513095.7. Tjong SC. 2006; Structural and mechanical properties of polymer nanocomposites. Mater Sci Eng R Rep. 53:73–197.8. Balkenhol M, Köhler H, Orbach K, Wöstmann B. 2009; Fracture toughness of cross-linked and non-cross-linked temporary crown and fixed partial denture materials. Dent Mater. 25:917–28. DOI: 10.1016/j.dental.2009.01.099. PMID: 19249090.9. Karaokutan I, Sayin G, Kara O. 2015; In vitro study of fracture strength of provisional crown materials. J Adv Prosthodont. 7:27–31. DOI: 10.4047/jap.2015.7.1.27. PMID: 25722834. PMCID: PMC4341183.10. Hong MG, Shin SY. 2020; Comparative study of surface modification on bond strength of polyetherketoneketone adhesively bonded to resins for temporary restoration. J Dent Rehabil Appl Sci. 36:1–11.11. Lee KS, Shin JH, Kim JE, Kim JH, Lee WC, Shin SW, Lee JY. 2017; Biomechanical Evaluation of a Tooth Restored with High Performance Polymer PEKK Post-Core System: A 3D Finite Element Analysis. Biomed Res Int. 2017:1373127. DOI: 10.1155/2017/1373127. PMID: 28386547. PMCID: PMC5366183.12. Han KH, Lee JY, Shin SW. 2016; Implant- and Tooth-Supported Fixed Prostheses Using a High-Performance Polymer (Pekkton) Framework. Int J Prosthodont. 29:451–4. DOI: 10.11607/ijp.4688. PMID: 27611747.13. Zoidis P, Papathanasiou I. 2016; Modified PEEK resinbonded fixed dental prosthesis as an interim restoration after implant placement. J Prosthet Dent. 116:637–41. DOI: 10.1016/j.prosdent.2016.04.024. PMID: 27475921.14. Hallmann L, Mehl A, Sereno N, Hämmerle CHF. 2012; The improvement of adhesive properties of PEEK through different pre-treatments. Appl Surf Sci. 258:7213–8.15. Haleem A, Javaid M. 2019; Polyether ether ketone (PEEK) and its manufacturing of customised 3D printed dentistry parts using additive manufacturing. Clin Epidemiol Glob Health. 7:654–60.16. Skirbutis G, Dzinguté A, Masiliūnaité V, Šulcaité G, Žilinskas J. 2018; PEEK polymer’s properties and its use in prosthodontics. A review. Stomatologija. 20:54–8.17. Lui JL, Setcos JC, Phillips RW. 1986; Temporary restorations: a review. Oper Dent. 11:103–10. PMID: 3532042.18. King CJ, Young FA, Cleveland JL. 1973; Polycarbonate resin and its use in the matrix technique for temporary coverage. J Prosthet Dent. 30:789–94. DOI: 10.1016/0022-3913(73)90232-1. PMID: 4520885.19. Mathur S, Shah A, Makwana R, Shah M, Shah A, Jathal N. 2013; Provisional restorative materials in fixed prosthodontics: A comprehensive review. B Bhavnagar Univ J Dent. 3:49–57.20. Skal’s’kyi VR, Makeev VF, Stankevych OM, Kyrmanov OS, Vynnyts’ka SI. 2015; Alternation of the types of fracture for dental polymers in different stages of crack propagation. Mater Dent. 50:836–43.21. Rayyan MM, Aboushelib M, Sayed NM, Ibrahim A, Jimbo R. 2015; Comparison of interim restorations fabricated by CAD/CAM with those fabricated manually. J Prosthet Dent. 114:414–9. DOI: 10.1016/j.prosdent.2015.03.007. PMID: 26001490.22. Digholkar S, Madhav VNV, Palaskar J. 2016; Evaluation of the flexural strength and microhardness of provisional crown and bridge materials fabricated by different methods. J Indian Prosthodont Soc. 16:328–34. DOI: 10.4103/0972-4052.191288. PMID: 27746595. PMCID: PMC5062140.23. Kassem YM, Alshimy AM, El-Shabrawy SM. 2019; Mechanical Evaluation of Polyetheretherketone Compared With Zirconia As a Dental Implant Material. Alexandria Dent J. 44:61–6.24. Schwitalla AD, Spintig T, Kallage I, Müller WD. 2015; Flexural behavior of PEEK materials for dental application. Dent Mater. 31:1377–84. DOI: 10.1016/j.dental.2015.08.151. PMID: 26361808.25. Wimmer T, Huffmann AMS, Eichberger M, Schmidlin PR, Stawarczyk B. 2016; Two-body wear rate of PEEK, CAD/CAM resin composite and PMMA: Effect of specimen geometries, antagonist materials and test set-up configuration. Dent Mater. 32:127–36. DOI: 10.1016/j.dental.2016.03.005. PMID: 27033460.26. Kwon SJ, Lawson NC, McLaren EE, Nejat AH, Burgess JO. 2018; Comparison of the mechanical properties of translucent zirconia and lithium disilicate. J Prosthet Dent. 120:132–7. DOI: 10.1016/j.prosdent.2017.08.004. PMID: 29310875.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Isoflurane cracks the polycarbonate connector of extra-corporeal circuit: A case report

- Use of temporary filling material for index fabrication in Class IV resin composite restoration

- Decoronation and implant restoration of ankylosed tooth resulted from anterior avulsion: A case report

- A comparative study on the accuracy of impression body according to the types of impression tray

- Coronal microleakage of four temporary restorative materials in Class II-type endodontic access preparations