J Korean Assoc Oral Maxillofac Surg.

2013 Aug;39(4):197-199.

Use of the surface-based registration function of computer-aided design/computer-aided manufacturing software in medical simulation software for three-dimensional simulation of orthognathic surgery

- Affiliations

-

- 1Department of Oral and Maxillofacial Surgery, National Health Insurance Service Ilsan Hospital, Goyang, Korea. omfs1ksh@hanmail.net

Abstract

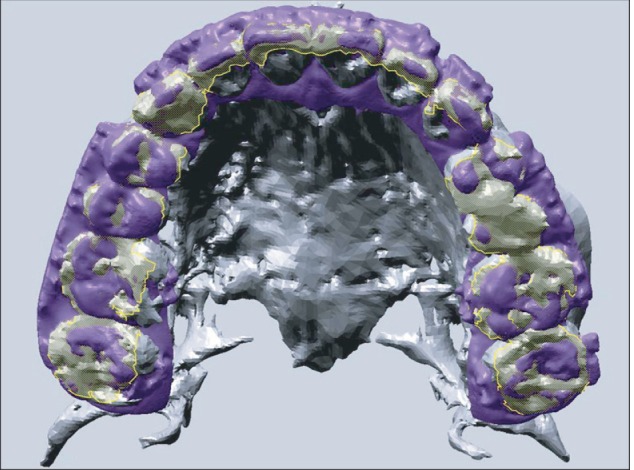

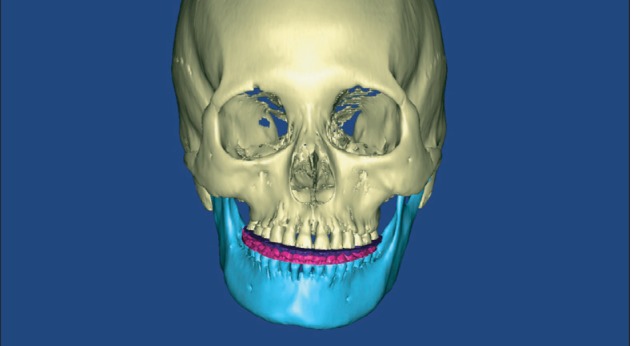

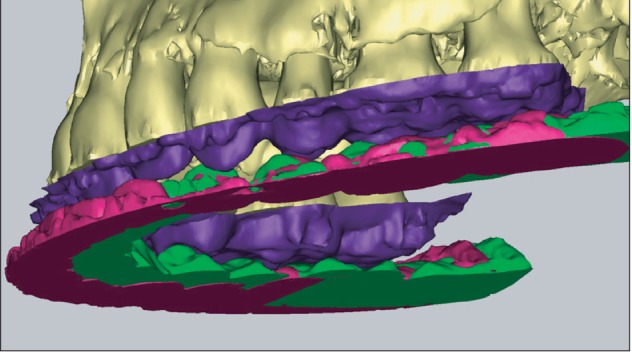

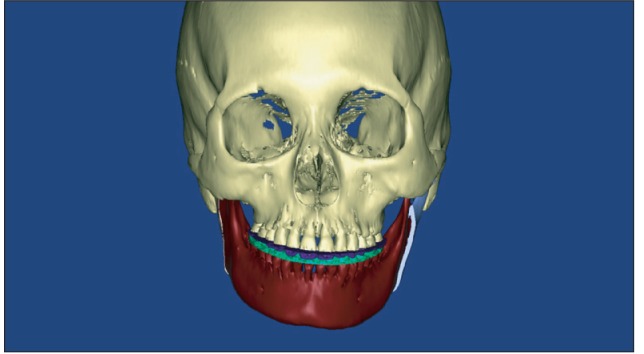

- Three-dimensional (3D) computed tomography image models are helpful in reproducing the maxillofacial area; however, they do not necessarily provide an accurate representation of dental occlusion and the state of the teeth. Recent efforts have focused on improvement of dental imaging by replacement of computed tomography with other detailed digital images. Unfortunately, despite the advantages of medical simulation software in dentofacial analysis, diagnosis, and surgical simulation, it lacks adequate registration tools. Following up on our previous report on orthognathic simulation surgery using computer-aided design/computer-aided manufacturing (CAD/CAM) software, we recently used the registration functions of a CAD/CAM platform in conjunction with surgical simulation software. Therefore, we would like to introduce a new technique, which involves use of the registration functions of CAD/CAM software followed by transfer of the images into medical simulation software. This technique may be applicable when using various registration function tools from different software platforms.

MeSH Terms

Figure

Reference

-

1. Kang SH, Kim MK, Park WS, Lee SH. Accurate computerised mandibular simulation in orthognathic surgery: a new method for integrating the planned postoperative occlusion model. Br J Oral Maxillofac Surg. 2010; 48:305–307. PMID: 19616350.

Article2. Kim BC, Lee CE, Park WS, Kang JW, Yi CK, Lee SH. Image fusion accuracy for the integration of digital dental model and 3D CT images by the point-based surface best fit algorithm. J Korean Assoc Oral Maxillofac Surg. 2008; 34:555–561.3. Kim BC, Lee CE, Park W, Kang SH, Zhengguo P, Yi CK, et al. Integration accuracy of digital dental models and 3-dimensional computerized tomography images by sequential point- and surface-based markerless registration. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2010; 110:370–378. PMID: 20591700.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Virtual Preoperative Simulation for Excision of Spinal Tumors: Surgeon Processing of Medical Computer-Assisted Design Software

- Clinical Application of Three-Dimensional Printing Technology in Craniofacial Plastic Surgery

- Genioplasty using a simple CAD/CAM (computer-aided design and computer-aided manufacturing) surgical guide

- CAD/CAM splint based on soft tissue 3D simulation for treatment of facial asymmetry

- Fabricating a Ceramic-Pressed-to-Metal Restoration with Computer-Aided Design, Computer-Aided Manufacturing and Selective Laser Sintering: A Case Report