J Adv Prosthodont.

2019 Feb;11(1):1-6. 10.4047/jap.2019.11.1.1.

The effects of surface grinding and polishing on the phase transformation and flexural strength of zirconia

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Chosun University, Gwangju, Republic of Korea. son0513@chosun.ac.kr

- 2Good Face Dental Clinic, Seoul, Republic of Korea.

- 3Department of Prosthodontics, Faculty of Dentistry, University Airlangga, Kota SBY, Jawa Timur, Indonesia.

- KMID: 2438925

- DOI: http://doi.org/10.4047/jap.2019.11.1.1

Abstract

- PURPOSE

The purpose of this in vitro study was to evaluate the effect of surface grinding and polishing procedures using high speed zirconia diamond burs with different grit sizes on the phase transformation and flexural strength of zirconia.

MATERIALS AND METHODS

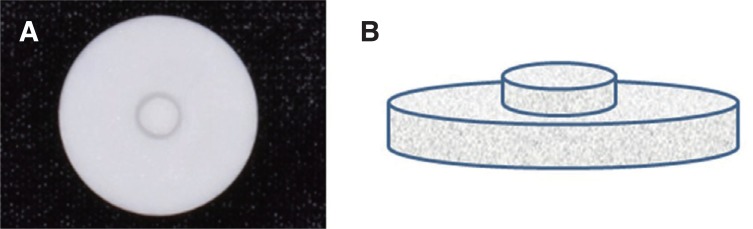

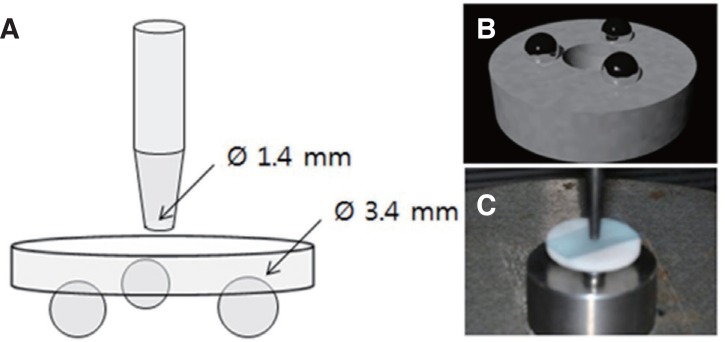

Forty disc shape specimens (15 × 1.25 mm) with a cylindrical projection in the center of each disc (1 × 3 mm) were fabricated with 3Y-TZP (Prettau, Zirkonzahn, Italy). The specimens were divided into 4 groups (n=10) according to the grinding and polishing procedures: Control group - grinding (coarse-grit diamond bur), Group 1 - grinding (coarse-grit diamond bur) + polishing, Group 2 - grinding (fine-grit diamond bur) + polishing, and Group 3 - grinding (fine grit diamond bur). Each specimen was analyzed by 3D-OM, XRD analysis, and biaxial flexural strength test.

RESULTS

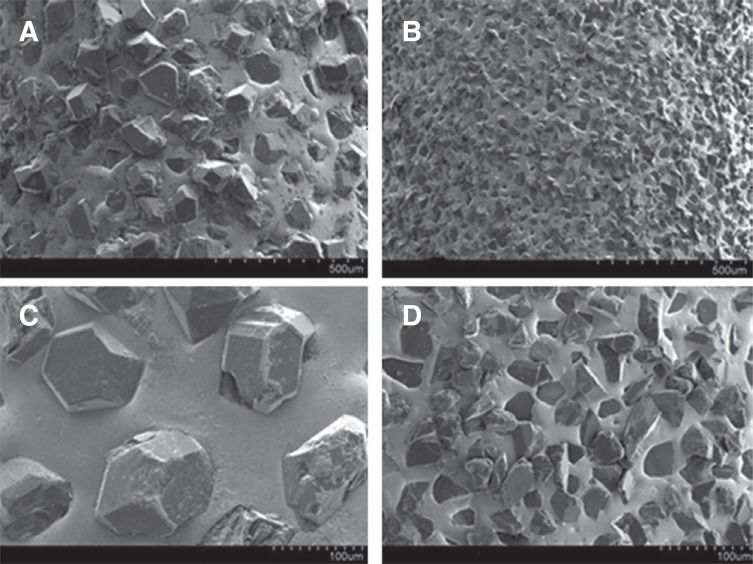

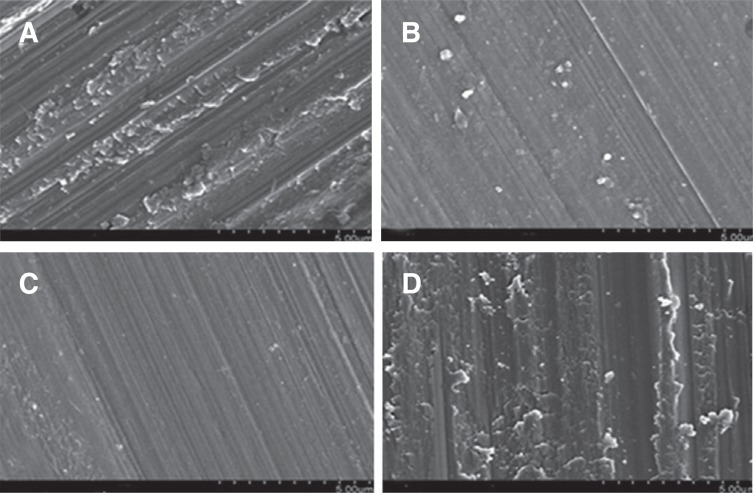

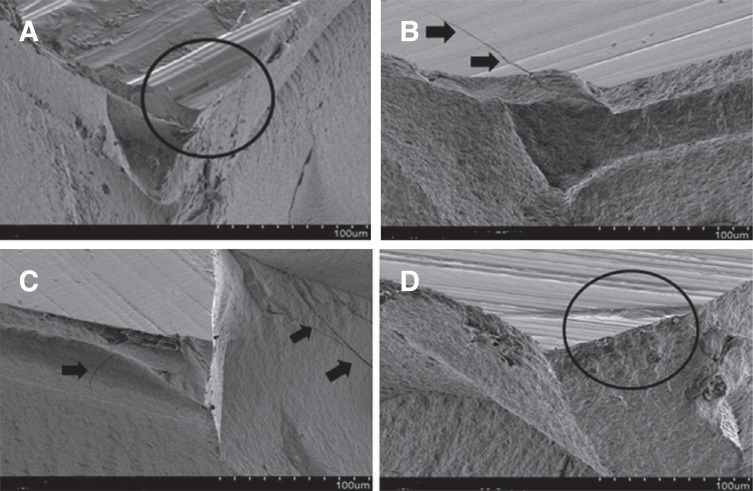

Based on the surface morphology by 3D-OM images, polished specimens showed smoother surface and lower roughness value (Ra). In the result of XRD analysis, partial phase transformation from tetragonal to monoclinic zirconia occurred in all groups. Control group, ground with a coarse grit diamond bur, showed more t→m phase transformation and lower flexural strength than Groups 1 and 2 significantly.

CONCLUSION

The flexural strength in all specimens after grinding and polishing showed over 500 MPa, and those were clinically acceptable. However, grinding with a coarse grit diamond bur without polishing induced the phase transformation and low strength. Therefore, surface polishing is required for the occlusal adjustment using a high speed zirconia diamond bur to reduce the phase transformation and to prevent the decrease of flexural strength of zirconia.

Keyword

Figure

Reference

-

1. Kim DJ. Transformation of tetragonal zirconia. Ceramics. 1993; 8:157–165.2. Işeri U, Ozkurt Z, Yalnız A, Kazazoılu E. Comparison of different grinding procedures on the flexural strength of zirconia. J Prosthet Dent. 2012; 107:309–315. PMID: 22546308.3. Garvie RC, Hannink RH, Pascoe RT. Ceramic steel? Nature. 1975; 258:703–704.

Article4. Sakuma T, Yoshizawa YI, Suto H. The rhombohedral phase produced in partially-stabilized zirconia. J Mater Sci Lett. 1985; 4:29–30.

Article5. Karakoca S, Yilmaz H. Influence of surface treatments on surface roughness, phase transformation, and biaxial flexural strength of Y-TZP ceramics. J Biomed Mater Res B Appl Biomater. 2009; 91:930–937. PMID: 19637376.

Article6. Hannik RHJ, Kelly PM, Muddle BC. Transformation toughening in zirconia-containing ceramics. J Am Ceram Soc. 2000; 83:461–487.7. Kao HC, Ho FY, Yang CC, Wei WJ. Surface machining of fine-grain Y-TZP. J Eur Ceram Soc. 2000; 20:2447–2455.

Article8. Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. Strength and reliability of surface treated Y-TZP dental ceramics. J Biomed Mater Res. 2000; 53:304–313. PMID: 10898871.9. Mitov G, Heintze SD, Walz S, Woll K, Muecklich F, Pospiech P. Wear behavior of dental Y-TZP ceramic against natural enamel after different finishing procedures. Dent Mater. 2012; 28:909–918. PMID: 22608163.

Article10. Nakanishi T, Kobayashi T, Miyazaki T. Mechanical properties and cyclic fatigue of the newly developed ceramic material for artificial joints. J Ceram Soc Jpn. 2007; 115:466–470.

Article11. Garvie RC, Nicholson PS. Phase analysis in zirconia systems. J Am Ceram Soc. 1972; 55:303–305.

Article12. ISO 6872. Dental ceramic. Geneva; Switzerland: International Standards Organization (ISO);1995.13. Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999; 15:426–433. PMID: 10863444.14. Ha SB, Chae W, Lee JC. A study on the surface roughness and bending strength for zirconia ceramic grinding. J Korean Soc Precis Eng. 2000; 17:131–136.15. Kosmać T, Wagner R, Claussen N. X-Ray determination of transformation depths in ceramics containing tetragonal ZrO2. J Am Ceram Soc. 1981; 64:72–73.16. Kim DJ, Lee HL, Jung HJ. Effect of surface grinding on low temperature degradation of 3Y-TZP. J Korean Ceram Soc. 1993; 30:164–168.17. Hasegawa H. Rhombohedral phase produced in abraded surfaces of partially stabilized zirconia (PSZ). J Mater Sci Lett. 1983; 2:91–93.

Article18. Lee JS, Shim JS, Jung HH. Phase transition of zirconia by surface treatments. J Korean Acad Dent Technol. 2010; 32:57–63.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- The effect of various polishing systems on surface roughness and phase transformation of monolithic zirconia

- Comparison of surface topography and roughness in different yttrium oxide compositions of dental zirconia after grinding and polishing

- Effect of different grinding burs on the physical properties of zirconia

- Comparative study of flexural strength of temporary restorative resin according to surface polishing and fabrication methods

- Effect of sintering programs and surface treatments on monolithic zirconia