J Adv Prosthodont.

2018 Apr;10(2):128-131. 10.4047/jap.2018.10.2.128.

Precision of the milled full-arch framework fabricated using pre-sintered soft alloy: A pilot study

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Kyungpook National University, Daegu, Republic of Korea. deweylee@knu.ac.kr

- 2Department of Prosthodontics, School of Dentistry, A3DI, Kyungpook National University, Daegu, Republic of Korea.

- KMID: 2409632

- DOI: http://doi.org/10.4047/jap.2018.10.2.128

Abstract

- PURPOSE

This study aimed to evaluate the marginal discrepancy of full-arch frameworks in implant-supported prostheses fabricated using pre-sintered soft alloy (PSA).

MATERIALS AND METHODS

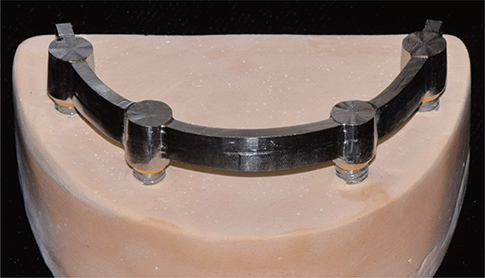

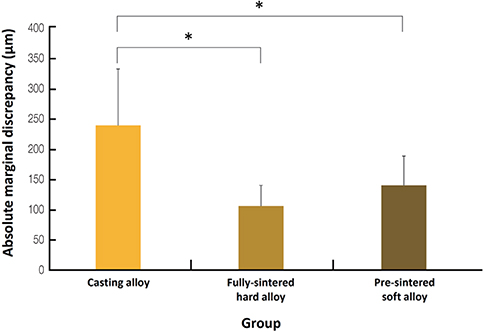

Full-arch metal frameworks were fabricated on the edentulous implant model using casting alloy (CA), fully-sintered hard alloy (FHA), and PSA (n = 4 in each group). To evaluate the misfit of the framework to the abutments, the absolute marginal discrepancy (AMD) values of the frameworks were measured in cross-sectional images that had been drawn as part of the triple-scan protocol. The AMD values were compared among the tested alloy groups using the Kruskal-Wallis test, with a post hoc Mann-Whitney U test (α=.05).

RESULTS

The FHA and PSA groups showed lower marginal discrepancies than the CA group (P < .001). However, the FHA group did not differ significantly from the PSA group.

CONCLUSION

Soft alloy milling is comparable to hard alloy milling, and it is more precise than casting in terms of the marginal fit of implant-supported, full-arch prostheses.

Keyword

Figure

Cited by 1 articles

-

Comparative clinical study of the marginal discrepancy of fixed dental prosthesis fabricated by the milling-sintering method using a presintered alloy

Mijoo Kim, Jaewon Kim, Hang-Nga Mai, Tae-Yub Kwon, Yong-Do Choi, Cheong-Hee Lee, Du-Hyeong Lee

J Adv Prosthodont. 2019;11(5):280-285. doi: 10.4047/jap.2019.11.5.280.

Reference

-

1. Holmes JR, Bayne SC, Holland GA, Sulik WD. Considerations in measurement of marginal fit. J Prosthet Dent. 1989; 62:405–408.

Article2. Henry PJ. An alternative method for the production of accurate casts and occlusal records in osseointegrated implant rehabilitation. J Prosthet Dent. 1987; 58:694–697.

Article3. Aparicio C. A new method for achieving passive fit of an interim restoration supported by Brånemark implants: a technical note. Int J Oral Maxillofac Implants. 1995; 10:614–618.4. Contrepois M, Soenen A, Bartala M, Laviole O. Marginal adaptation of ceramic crowns: a systematic review. J Prosthet Dent. 2013; 110:447–454.

Article5. Pimenta MA, Frasca LC, Lopes R, Rivaldo E. Evaluation of marginal and internal fit of ceramic and metallic crown copings using x-ray microtomography (micro-CT) technology. J Prosthet Dent. 2015; 114:223–228.

Article6. Ziebert GJ, Hurtado A, Glapa C, Schiffleger BE. Accuracy of one-piece castings, preceramic and postceramic soldering. J Prosthet Dent. 1986; 55:312–317.

Article7. Sarfati E, Harter JC. Comparative accuracy of fixed partial dentures made as one-piece castings or joined by solder. Int J Prosthodont. 1992; 5:377–383.8. Rinke S, Rasing H, Gersdorff N, Buergers R, Roediger M. Implant-supported overdentures with different bar designs: A retrospective evaluation after 5–19 years of clinical function. J Adv Prosthodont. 2015; 7:338–343.

Article9. Eisenmann E, Mokabberi A, Walter MH, Freesmeyer WB. Improving the fit of implant-supported superstructures using the spark erosion technique. Int J Oral Maxillofac Implants. 2004; 19:810–818.10. Ortorp A, Jemt T, Bäck T, Jälevik T. Comparisons of precision of fit between cast and CNC-milled titanium implant frameworks for the edentulous mandible. Int J Prosthodont. 2003; 16:194–200.11. Paniz G, Stellini E, Meneghello R, Cerardi A, Gobbato EA, Bressan E. The precision of fit of cast and milled full-arch implant-supported restorations. Int J Oral Maxillofac Implants. 2013; 28:687–693.

Article12. Agustín-Panadero R, Peñarrocha-Oltra D, Gomar-Vercher S, Ferreiroa A, Peñarrocha-Diago M. Implant-supported overdenture manufactured using CAD/CAM techniques to achieve horizontal path insertion between the primary and secondary structure: A clinical case report. J Adv Prosthodont. 2015; 7:264–270.

Article13. Lee DH, Lee BJ, Kim SH, Lee KB. Shear bond strength of porcelain to a new millable alloy and a conventional castable alloy. J Prosthet Dent. 2015; 113:329–335.

Article14. Park JK, Kim HY, Kim WC, Kim JH. Evaluation of the fit of metal ceramic restorations fabricated with a pre-sintered soft alloy. J Prosthet Dent. 2016; 116:909–915.

Article15. Kim EH, Lee DH, Kwon SM, Kwon TY. A microcomputed tomography evaluation of the marginal fit of cobalt-chromium alloy copings fabricated by new manufacturing techniques and alloy systems. J Prosthet Dent. 2017; 117:393–399.

Article16. Kelvin Khng KY, Ettinger RL, Armstrong SR, Lindquist T, Gratton DG, Qian F. In vitro evaluation of the marginal integrity of CAD/CAM interim crowns. J Prosthet Dent. 2016; 115:617–623.17. Shamseddine L, Mortada R, Rifai K, Chidiac JJ. Fit of pressed crowns fabricated from two CAD-CAM wax pattern process plans: A comparative in vitro study. J Prosthet Dent. 2017; 118:49–54.18. Alfaro DP, Ruse ND, Carvalho RM, Wyatt CC. Assessment of the internal fit of lithium disilicate crowns using micro-CT. J Prosthodont. 2015; 24:381–386.

Article19. Nakamura T, Dei N, Kojima T, Wakabayashi K. Marginal and internal fit of Cerec 3 CAD/CAM all-ceramic crowns. Int J Prosthodont. 2003; 16:244–248.20. Lee KB, Park CW, Kim KH, Kwon TY. Marginal and internal fit of all-ceramic crowns fabricated with two different CAD/CAM systems. Dent Mater J. 2008; 27:422–426.

Article21. De Santis R, Gloria A, Russo T, D'Amora U, Varriale A, Veltri M, Balleri P, Mollica F, Riccitiello F, Ambrosio L. Reverse engineering of mandible and prosthetic framework: Effect of titanium implants in conjunction with titanium milled full arch bridge prostheses on the biomechanics of the mandible. J Biomech. 2014; 47:3825–3829.

Article22. Bae SY, Park JY, Jeong ID, Kim HY, Kim JH, Kim WC. Three-dimensional analysis of marginal and internal fit of copings fabricated with polyetherketoneketone (PEKK) and zirconia. J Prosthodont Res. 2017; 61:106–112.

Article23. Lee DH. Digital approach to assessing the 3-dimensional misfit of fixed dental prostheses. J Prosthet Dent. 2016; 116:836–839.

Article24. Holst S, Karl M, Wichmann M, Matta RE. A new triple-scan protocol for 3D fit assessment of dental restorations. Quintessence Int. 2011; 42:651–657.25. Real-Voltas F, Romano-Cardozo E, Figueras-Alvarez O, Brufau-de Barbera M, Cabratosa-Termes J. Comparison of the marginal fit of cobalt-chromium metal-ceramic crowns fabricated by CAD/CAM techniques and conventional methods at three production stages. Int J Prosthodont. 2017; 30:304–305.

Article26. Zhou Y, Li Y, Ma X, Huang Y, Wang J. Role of span length in the adaptation of implant-supported cobalt chromium frameworks fabricated by three techniques. J Adv Prosthodont. 2017; 9:124–129.

Article27. Park JM, Hämmerle CHF, Benic GI. Digital technique for in vivo assessment of internal and marginal fit of fixed dental prostheses. J Prosthet Dent. 2017; 118:452–454.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Comparison of the mechanical properties and microstructures of fractured surface for Co-Cr alloy fabricated by conventional cast, 3-D printing laser-sintered and CAD/CAM milled techniques

- Considerations for the Survival of Complete Arch Implant-Supported Zirconia Restorations; Status of Antagonistic Arches and Stress Distribution on Frameworks: A Case Report

- FRACTURE STRENGTH AND MARGINAL FIT OF IN-CERAM, COPY-MILLED IN-CERAM, AND IPS EMPRESS 2 ALL-CERAMIC BRIDGES

- CAD-CAM fabricated Milled-bar and Implant Overdenture after Reconstruction with a Fibular Free Flap: A Clinical Report

- Influence of finish line design on the marginal fit of nonprecious metal alloy coping fabricated by 3D printing, milling and casting using CAD-CAM