J Korean Acad Prosthodont.

2012 Jan;50(1):29-35.

Study of heat transfer to the implant-bone interface induced by grinding of occlusal surface of implant gold prosthesis

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Pusan National University, Yangsan, Korea. jeonyc@paran.com

Abstract

- PURPOSE

The purpose of this study was to analyze temperature change along the implant-bone interface induced by grinding the occlusal surface of implant gold prosthesis and to compare the temperature generated by grinding of prosthesis with different cooling methods.

MATERIALS AND METHODS

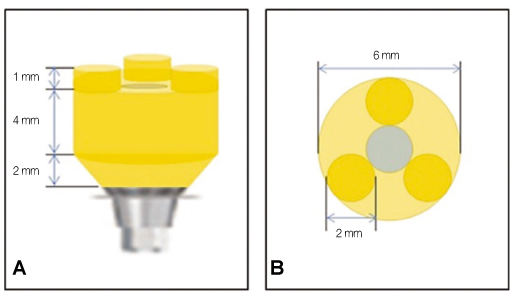

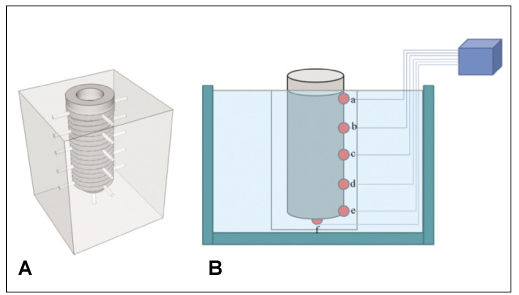

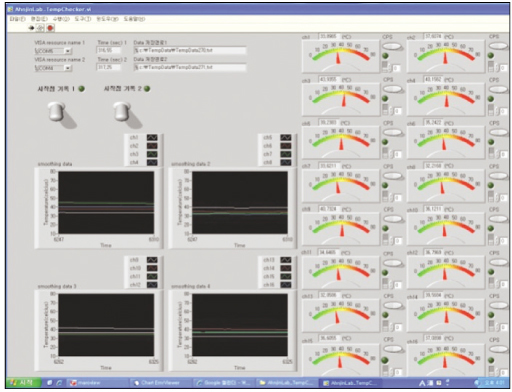

The experimental gold prostheses were fabricated with dental gold alloy and castable abutment. The prostheses had 3 cylindrical protrusions on the occlusal surface with 1mm in height. Temperature was measured using 16 thermocouple wires attached to the implant fixture surface and the fixture was embedded in an acrylic resin block inside the 37degrees C water bath. Cylinders were grinded for a period of 30 second with a low-speed handpiece with green stone point. One cylindrical protrusion was grinded without cooling, the second one was grinded with air blow, and the third one was grinded with water-spray.

RESULTS

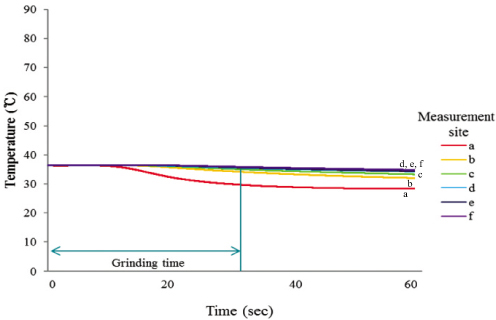

The mean maximum temperature was measured more than 47degrees C of the implant and the maximum temperature was measured at the cervical portion of the implant in the group without cooling. There was statistically significant difference between the group without cooling and the groups with cooling (P<.05). However, there was no significant difference at all portion of implant in the groups with cooling (P>.05).

CONCLUSION

The results of this study support that the grinding of implant gold prosthesis without cooling may damage the peri-implant tissue. The continuous use of air blow and water-spray adjacent to prosthesis during the grinding of implant gold prosthesis may prove to be beneficial for cooling of the implant.

Keyword

Figure

Reference

-

1. Brånemark PI, Hansson BO, Adell R, Breine U, Lindström J, Hallén O, Ohman A. Osseointegrated implants in the treatment of the edentulous jaw. Experience from a 10-year period. Scand J Plast Reconstr Surg Suppl. 1977. 16:1–132.2. Adell R, Lekholm U, Rockler B, Brånemark PI. A 15-year study of osseointegrated implants in the treatment of the edentulous jaw. Int J Oral Surg. 1981. 10:387–416.

Article3. Kreisler M, Al Haj H, d'Hoedt B. Temperature changes at the implant-bone interface during simulated surface decontamination with an Er:YAG laser. Int J Prosthodont. 2002. 15:582–587.4. Huh JB, Eckert SE, Ko SM, Choi YG. Heat transfer to the implant-bone interface during preparation of a zirconia/alumina abutment. Int J Oral Maxillofac Implants. 2009. 24:679–683.5. Eriksson AR, Albrektsson T. Temperature threshold levels for heat-induced bone tissue injury: a vital-microscopic study in the rabbit. J Prosthet Dent. 1983. 50:101–107.

Article6. Eriksson A, Albrektsson T, Grane B, McQueen D. Thermal injury to bone. A vital-microscopic description of heat effects. Int J Oral Surg. 1982. 11:115–121.7. Scarano A, Piattelli A, Assenza B, Carinci F, Di Donato L, Romani GL, Merla A. Infrared thermographic evaluation of temperature modifications induced during implant site preparation with cylindrical versus conical drills. Clin Implant Dent Relat Res. 2011. 13:319–323.

Article8. Sener BC, Dergin G, Gursoy B, Kelesoglu E, Slih I. Effects of irrigation temperature on heat control in vitro at different drilling depths. Clin Oral Implants Res. 2009. 20:294–298.

Article9. Scarano A, Carinci F, Quaranta A, Di Iorio D, Assenza B, Piattelli A. Effects of bur wear during implant site preparation: an in vitro study. Int J Immunopathol Pharmacol. 2007. 20:23–26.

Article10. Sharawy M, Misch CE, Weller N, Tehemar S. Heat generation during implant drilling: the significance of motor speed. J Oral Maxillofac Surg. 2002. 60:1160–1169.

Article11. Benington IC, Biagioni PA, Briggs J, Sheridan S, Lamey PJ. Thermal changes observed at implant sites during internal and external irrigation. Clin Oral Implants Res. 2002. 13:293–297.

Article12. Brisman DL. The effect of speed, pressure, and time on bone temperature during the drilling of implant sites. Int J Oral Maxillofac Implants. 1996. 11:35–37.13. Sumer M, Misir AF, Telcioglu NT, Guler AU, Yenisey M. Comparison of heat generation during implant drilling using stainless steel and ceramic drills. J Oral Maxillofac Surg. 2011. 69:1350–1354.

Article14. Misir AF, Sumer M, Yenisey M, Ergioglu E. Effect of surgical drill guide on heat generated from implant drilling. J Oral Maxillofac Surg. 2009. 67:2663–2668.

Article15. Patel Z, Geerts GA. Temperature changes along a dental implant. Int J Prosthodont. 2011. 24:58–63.16. Ormianer Z, Feuerstein O, Assad R, Samet N, Weiss EI. In vivo changes in dental implant temperatures during hot beverage intake: a pilot study. Implant Dent. 2009. 18:38–45.

Article17. Feuerstein O, Zeichner K, Imbari C, Ormianer Z, Samet N, Weiss EI. Temperature changes in dental implants following exposure to hot substances in an ex vivo model. Clin Oral Implants Res. 2008. 19:629–633.

Article18. Mouhyi J, Sennerby L, Nammour S, Guillaume P, Van Reck J. Temperature increases during surface decontamination of titanium implants using CO2 laser. Clin Oral Implants Res. 1999. 10:54–61.

Article19. Brägger U, Wermuth W, Török E. Heat generated during preparation of titanium implants of the ITI Dental Implant System: an in vitro study. Clin Oral Implants Res. 1995. 6:254–259.

Article20. Gross M, Laufer BZ, Ormianar Z. An investigation on heat transfer to the implant-bone interface due to abutment preparation with high-speed cutting instruments. Int J Oral Maxillofac Implants. 1995. 10:207–212.

Article21. Gabay E, Cohen O, Machtei EE. Heat production during prosthetic preparation of a one-piece dental implant. Int J Oral Maxillofac Implants. 2010. 25:1131–1136.22. Cohen O, Gabay E, Machtei EE. Cooling profile following prosthetic preparation of 1-piece dental implants. J Oral Implantol. 2010. 36:273–279.

Article23. Nissan J, Gross M, Ormianer Z, Barnea E, Assif D. Heat transfer of impression plasters to an implant-bone interface. Implant Dent. 2006. 15:83–88.

Article24. Ormianer Z, Laufer BZ, Nissan J, Gross M. An investigation of heat transfer to the implant-bone interface related to exothermic heat generation during setting of autopolymerizing acrylic resins applied directly to an implant abutment. Int J Oral Maxillofac Implants. 2000. 15:837–842.25. Friberg B, Jemt T, Lekholm U. Early failures in 4,641 consecutively placed Brånemark dental implants: a study from stage 1 surgery to the connection of completed prostheses. Int J Oral Maxillofac Implants. 1991. 6:142–146.26. Esposito M, Hirsch J, Lekholm U, Thomsen P. Differential diagnosis and treatment strategies for biologic complications and failing oral implants: a review of the literature. Int J Oral Maxillofac Implants. 1999. 14:473–490.27. Esposito M, Thomsen P, Ericson LE, Sennerby L, Lekholm U. Histopathologic observations on late oral implant failures. Clin Implant Dent Relat Res. 2000. 2:18–32.

Article28. Lundskog J. Heat and bone tissue. An experimental investigation of the thermal properties of bone and threshold levels for thermal injury. Scand J Plast Reconstr Surg. 1972. 9:1–80.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Implant complications in bruxism patients

- Clinical cases of implant-supported fixed dental prosthesis using modified lingual screw system (T-screw system)

- Stress analysis of supporting tissues and implants according to implant fixture shapes and implant-abutment connections

- Stress analysis with nonlinear modelling of the load transfer characteristics across the osseointegrated interfaces of dental implant

- Biomechanical stress and microgap analysis of bone-level and tissue-level implant abutment structure according to the five different directions of occlusal loads