J Adv Prosthodont.

2017 Aug;9(4):239-243. 10.4047/jap.2017.9.4.239.

Evaluation of marginal and internal gaps in single and three-unit metal frameworks made by micro-stereolithography

- Affiliations

-

- 1Department of Dental Laboratory Science and Engineering, College of Health Science, Korea University, Seoul, Republic of Korea. kuc2842@korea.ac.kr

- 2Department of Public Health Sciences, Graduate School & BK21+ Program in Public Health Sciences, Korea University, Seoul, Republic of Korea.

- KMID: 2398069

- DOI: http://doi.org/10.4047/jap.2017.9.4.239

Abstract

- PURPOSE

The purpose of this study is to compare single and three-unit metal frameworks that are produced by micro-stereolithography.

MATERIALS AND METHODS

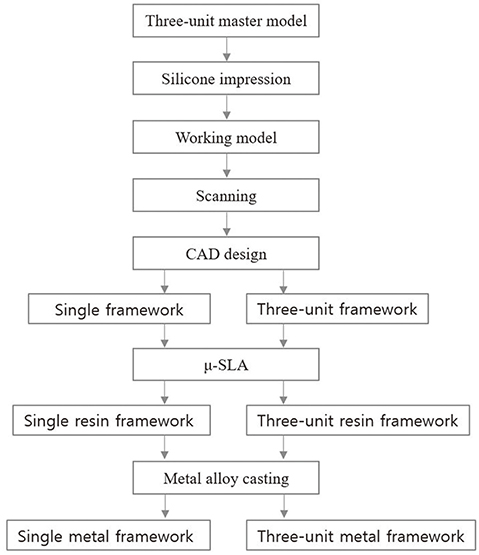

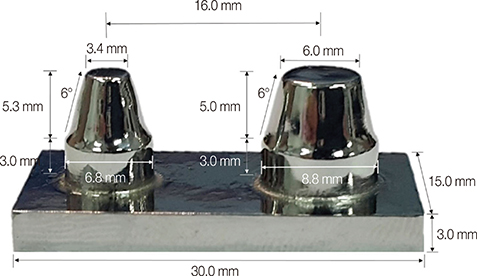

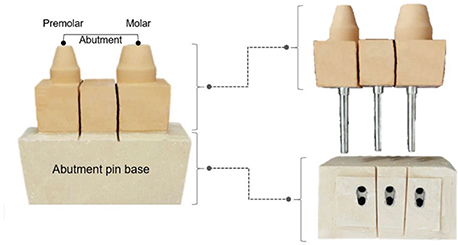

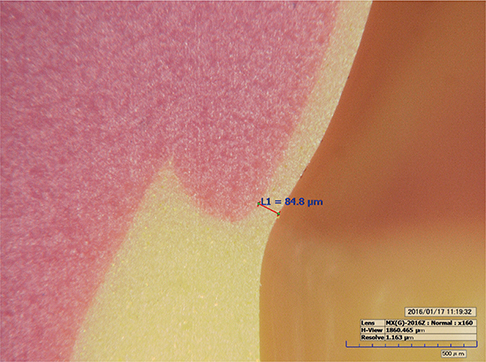

Silicone impressions of a selected molar and a premolar were used to make master abutments that were scanned into a stereolithography file. The file was processed with computer aided design software to create single and three-unit designs from which resin frameworks were created using micro-stereolithography. These resin frameworks were subjected to investment, burnout, and casting to fabricate single and three-unit metal ones that were measured under a digital microscope by using the silicone replica technique. The measurements were verified by means of the Mann-Whitney U test (α=.05).

RESULTS

The marginal gap was 101.9 ± 53.4 µm for SM group and 104.3 ± 62.9 µm for TUM group. The measurement of non-pontics in a single metal framework was 93.6 ± 43.9 µm, and that of non-pontics in a three-unit metal framework was 64.9 ± 46.5 µm. The dimension of pontics in a single metal framework was 110.2 ± 61.4 µm, and that of pontics in a three-unit metal framework was 143.7 ± 51.8 µm.

CONCLUSION

The marginal gap was smaller for the single metal framework than for the three-unit one, which requires further improvement before it can be used for clinical purposes.

MeSH Terms

Figure

Cited by 2 articles

-

Trueness and precision of scanning abutment impressions and stone models according to dental CAD/CAM evaluation standards

Jin-Hun Jeon, Seong-Sig Hwang, Ji-Hwan Kim, Woong-Chul Kim

J Adv Prosthodont. 2018;10(5):335-339. doi: 10.4047/jap.2018.10.5.335.Accuracy of provisional crowns made using stereolithography apparatus and subtractive technique

Seen-Young Kang, Jung-Hyun Park, Ji-Hwan Kim, Woong-Chul Kim

J Adv Prosthodont. 2018;10(5):354-360. doi: 10.4047/jap.2018.10.5.354.

Reference

-

1. Al Jabbari YS, Koutsoukis T, Barmpagadaki X, Zinelis S. Metallurgical and interfacial characterization of PFM Co-Cr dental alloys fabricated via casting, milling or selective laser melting. Dent Mater. 2014; 30:e79–e88.2. Kim KB, Kim WC, Kim HY, Kim JH. An evaluation of marginal fit of three-unit fixed dental prostheses fabricated by direct metal laser sintering system. Dent Mater. 2013; 29:e91–e96.3. Quante K, Ludwig K, Kern M. Marginal and internal fit of metal-ceramic crowns fabricated with a new laser melting technology. Dent Mater. 2008; 24:1311–1315.4. Galindo DF, Ercoli C, Graser GN, Tallents RH, Moss ME. Effect of soldering on metal-porcelain bond strength in repaired porcelain-fused-to-metal castings. J Prosthet Dent. 2001; 85:88–94.5. Zhao H, Hu X, Bush MB, Lawn BR. Cracking of porcelain coatings bonded to metal substrates of different modulus and hardness. J Mater Res. 2001; 16:1471–1478.6. Kokubo Y, Ohkubo C, Tsumita M, Miyashita A, Vult von Steyern P, Fukushima S. Clinical marginal and internal gaps of Procera AllCeram crowns. J Oral Rehabil. 2005; 32:526–530.7. McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971; 131:107–111.8. Ng J, Ruse D, Wyatt C. A comparison of the marginal fit of crowns fabricated with digital and conventional methods. J Prosthet Dent. 2014; 112:555–560.9. Örtorp A, Jönsson D, Mouhsen A, Vult von Steyern P. The fit of cobalt-chromium three-unit fixed dental prostheses fabricated with four different techniques: a comparative in vitro study. Dent Mater. 2011; 27:356–363.10. Park JY, Kim HY, Kim JH, Kim JH, Kim WC. Comparison of prosthetic models produced by traditional and additive manufacturing methods. J Adv Prosthodont. 2015; 7:294–302.11. Ucar Y, Akova T, Akyil MS, Brantley WA. Internal fit evaluation of crowns prepared using a new dental crown fabrication technique: laser-sintered Co-Cr crowns. J Prosthet Dent. 2009; 102:253–259.12. van Noort R. The future of dental devices is digital. Dent Mater. 2012; 28:3–12.13. Kocaağaoğlu H, Kılınç Hİ, Albayrak H, Kara M. In vitro evaluation of marginal, axial, and occlusal discrepancies in metal ceramic restorations produced with new technologies. J Prosthet Dent. 2016; 116:368–374.14. Kim CM, Kim SR, Kim JH, Kim HY, Kim WC. Trueness of milled prostheses according to number of ball-end mill burs. J Prosthet Dent. 2016; 115:624–629.15. Grant GT. Direct digital manufacturing. Clinical applications of digital dental technology hoboken. NJ: Wiley-Blackwell;2015. p. 41–57.16. Berger U. Aspects of accuracy and precision in the additive manufacturing of plastic gears. Virtual Phys Prototyp. 2015; 10:49–57.17. Leigh SJ, Purssell C, Bowen J, Hutchins DA, Covington JA, Billson DR. A miniature flow sensor fabricated by micro-stereolithography employing a magnetite/acrylic nanocomposite resin. Sens Actuators A: Physical. 2011; 168:66–71.18. Schuster M, Turecek C, Stampfl J, Varga F, Liska R. Biofunctional photopolymers for Micro-Stereolithography. In : Proceedings of the 8th International Symposium on Laser Precision Microfabrication; 2007. p. 1–5.19. Sayed NM. Shear bond strength and failure mode between veneering ceramic and metal cores after multiple firing cycles. Egyptian Dent J. 2015; 61:659–666.20. Soliman MSM, Mohsen CA, El-Mahallawi O, Abu-Eittah MRH. Effect of different cement spaces on the vertical marginal gap of full anatomical zirconia bridges. J Am Sci. 2015; 11:145–152.21. Dental Materials Research. In : 50th Anniversary symposium, National bureau of standards special publication No. 354; Oct., 6 to 8, 1969; Gaithersburg;1972. p. 61–66.22. Kul E, Aladag LI, Duymus ZY. Comparison of the metal-ceramic bond after recasting and after laser sintering. J Prosthet Dent. 2015; 114:109–113.23. Molin M, Karlsson S. The fit of gold inlays and three ceramic inlay systems. A clinical and in vitro study. Acta Odontol Scand. 1993; 51:201–206.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Evaluation of marginal and internal gap of three-unit metal framework according to subtractive manufacturing and additive manufacturing of CAD/CAM systems

- A study of precise fit of the CAM zirconia all-ceramic framework

- Role of span length in the adaptation of implant-supported cobalt chromium frameworks fabricated by three techniques

- Comparison of prosthetic models produced by traditional and additive manufacturing methods

- Comparison of internal adaptation of removable partial denture metal frameworks made by lost wax technique and printing technique of pattern using CAD