Restor Dent Endod.

2012 May;37(2):74-78.

Effect of internal stress on cyclic fatigue failure in K3

- Affiliations

-

- 1Department of Conservative Dentistry, Gangneung-Wonju National University School of Dentistry, Gangneung, Korea. drendo@gwnu.ac.kr

Abstract

OBJECTIVES

This study aimed to evaluate the relationship between the cyclic fatigue of a K3 file and internal stress intentionally induced until the activation of the auto-stop function of the torque-controlled motor.

MATERIALS AND METHODS

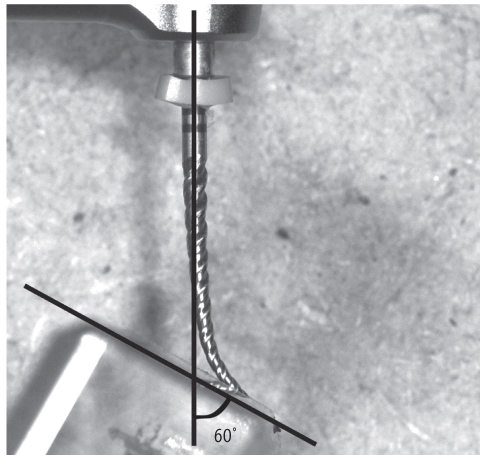

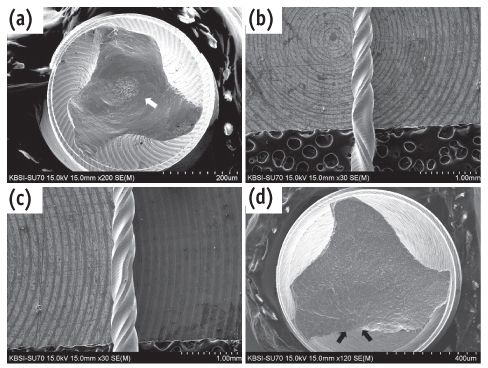

K3 (Sybron Endo) .04 and .06 taper, size 25, 30, 35, 40 and 45 were used in this study. To give the internal stress, the K3 files were put into the .02 taper Endo-Training-Bloc (Dentsply Maillefer) until the activation of the auto-stop function of the torque-controlled motor. The rotation speed was 300 rpm and torque value was 1.0 N.cm. K3 were grouped by the number of induced internal stress and randomly distributed to 4 experimental groups (n = 10, Stress 0 [control], Stress 1, Stress 2 and Stress 3). For measuring the cyclic fatigue failure, the K3 files were worked against a sloped glass block and time for file separation was recorded. Data was statistically analyzed Statistical analyses were performed using two-way ANOVA and Duncan post-hoc test at p < 0.05 level.

RESULTS

Except .04 taper size 30 in Stress 1 group, there were statistically significant differences in time for file separation between control and all experimental groups. K3 with .04 taper showed higher cyclic fatigue resistance than those of .06 taper.

CONCLUSION

In the limitation of this study, the cyclic fatigue of the K3 file was influenced by the accumulated internal stress from use until the auto-stop function was activated by the torque-controlled motor. Therefore, clinicians should avoid the reuse of the K3 file that has undergone auto-stops.

Figure

Reference

-

1. Walia HM, Brantley WA, Gerstein H. An initial investigation of the bending and torsional properties of Nitinol root canal files. J Endod. 1988. 14:346–351.

Article2. Gambill JM, Alder M, del Rio CE. Comparison of nickel-titanium and stainless steel hand-file instrumentation using computed tomography. J Endod. 1996. 22:369–375.

Article3. Glossen CR, Haller RH, Dove SB, del Rio CE. A comparison of root canal preparations using Ni-Ti hand, Ni-Ti engine-driven, and K-Flex endodontic instruments. J Endod. 1995. 21:146–151.

Article4. Elliott LM, Curtis RV, Pitt Ford TR. Cutting pattern of nickel-titanium files using two preparation techniques. Endod Dent Traumatol. 1998. 14:10–15.

Article5. Cheung GSP. Instrument fracture: mechanisms, removal of fragments, and clinical outcomes. Endodontic Topics. 2009. 16:1–26.

Article6. Kramkowski TR, Bahcall J. An in vitro comparison of torsional stress and cyclic fatigue resistance of ProFile GT and ProFile GT Series X rotary nickel-titanium files. J Endod. 2009. 35:404–407.

Article7. Pruett JP, Clement DJ, Carnes DL Jr. Cyclic fatigue testing of nickel-titanium endodontic instruments. J Endod. 1997. 23:77–85.

Article8. Sattapan B, Nervo GJ, Palamara JE, Messer HH. Defects in rotary nickel-titanium files after clinical use. J Endod. 2000. 26:161–165.

Article9. Kuhn G, Tavernier B, Jordan L. Influence of structure on nickel-titanium endodontic instruments failure. J Endod. 2001. 27:516–520.

Article10. Gambarini G. Advantages and disadvantages of new torque-controlled endodontic motors and low-torque NiTi rotary instrumentation. Aust Endod J. 2001. 27:99–104.

Article11. Berutti E, Negro AR, Lendini M, Pasqualini D. Influence of manual preflaring and torque on the failure rate of ProTaper rotary instruments. J Endod. 2004. 30:228–230.

Article12. Barbosa FO, Gomes JA, de Araújo MC. Fractographic analysis of K3 nickel-titanium rotary instruments submitted to different modes of mechanical loading. J Endod. 2008. 34:994–998.

Article13. Li UM, Lee BS, Shih CT, Lan WH, Lin CP. Cyclic fatigue of endodontic nickel titanium rotary instruments: static and dynamic tests. J Endod. 2002. 28:448–451.

Article14. Park SH, Seo HW, Hong CU. An evaluation of rotational stability in endodontic electronic motors. J Korean Acad Conserv Dent. 2010. 35:246–256.

Article15. Melo MC, Pereira ES, Viana AC, Fonseca AM, Buono VT, Bahia MG. Dimensional characterization and mechanical behaviour of K3 rotary instruments. Int Endod J. 2008. 41:329–338.

Article16. Plotino G, Grande NM, Cordaro M, Testarelli L, Gambarini G. A review of cyclic fatigue testing of nickel-titanium rotary instruments. J Endod. 2009. 35:1469–1476.

Article17. Bahia MG, Buono VT. Decrease in the fatigue resistance of nickel-titanium rotary instruments after clinical use in curved root canals. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2005. 100:249–255.

Article18. Haikel Y, Gasser P, Allemann C. Dynamic fracture of hybrid endodontic hand instruments compared with traditional files. J Endod. 1991. 17:217–220.

Article19. Haïkel Y, Serfaty R, Bateman G, Senger B, Allemann C. Dynamic and cyclic fatigue of engine-driven rotary nickel-titanium endodontic instruments. J Endod. 1999. 25:434–440.

Article20. Cheung GS, Darvell BW. Fatigue testing of a NiTi rotary instrument. Part 1: strain-life relationship. Int Endod J. 2007. 40:612–618.

Article21. Schäfer E, Dzepina A, Danesh G. Bending properties of rotary nickel-titanium instruments. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2003. 96:757–763.

Article22. Ullmann CJ, Peters OA. Effect of cyclic fatigue on static fracture loads in ProTaper nickel-titanium rotary instruments. J Endod. 2005. 31:183–186.

Article23. Shin YM, Kim ES, Kim KM, Kum KY. Effect of surface defects and cross-sectional configuration on the fatigue fracture of NiTi rotary files under cyclic loading. J Korean Acad Conserv Dent. 2004. 29:267–272.

Article24. Lee JK, Kim ES, Kang MW, Kum KY. The effect of surface defects on the cyclic fatigue fracture of HEROShaper Ni-Ti rotary files in a dynamic model: a fractographic analysis. J Korean Acad Conserv Dent. 2007. 32:130–137.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Cyclic fatigue of the sodium hypochlorite treated and/or steam autoclaved nickel-titanium endodontic files

- Effect of internal stress on cyclic fatigue failure in .06 taper ProFile

- Effect of surface defects and cross-sectional configuration on the fatigue fracture of NiTi rotary files under cyclic loading

- Cyclic fatigue resistance tests of Nickel-Titanium rotary files using simulated canal and weight loading conditions

- A study of the cause of metal failure in treatment of femur shaft fracture: Fractographical and clinical analysis of metal failure