Effect of surface defects and cross-sectional configuration on the fatigue fracture of NiTi rotary files under cyclic loading

- Affiliations

-

- 1Department of Conservative Dentistry, Yonsei University, Korea. kum6139@yumc.yonsei.ac.kr

- 2Department of Dental Materials, Yonsei University, Korea.

- KMID: 1987102

- DOI: http://doi.org/10.5395/JKACD.2004.29.3.267

Abstract

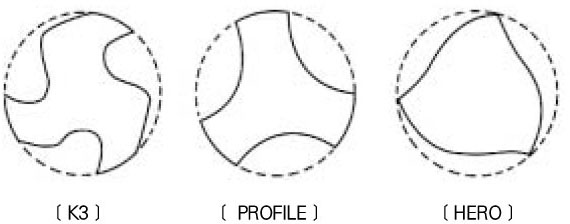

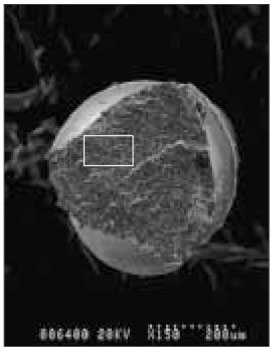

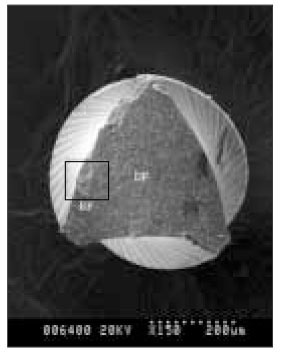

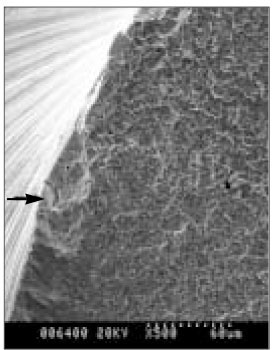

- The purpose of this in vitro study was to evaluate the effect of surface defects and cross-sectional configuration of NiTi rotary files on the fatigue life under cyclic loading. Three NiTi rotary files (K3(TM), ProFile(R), and HERO 642(R)) with #30/.04 taper were evaluated. Each rotary file was divided into 2 subgroups: control (no surface defects) and experimental group (artificial surface defects). A total of six groups of each 10 were tested. The NiTi rotary files were rotated at 300rpm using the apparatus which simulated curved canal (40 degree of curvature) until they fracture. The number of cycles to fracture was calculated and the fractured surfaces were observed with a scanning electron microscope. The data were analyzed statistically. The results showed that experimental groups with surface defects had lower number of cycles to fracture than control group but there was only a statistical significance between control and experimental group in the K3(TM) (p<0.05). There was no strong correlation between the cross-sectional configuration area and fracture resistance under experimental conditions. Several of fractured files demonstrated characteristic patterns of brittle fracture consistent with the propagation of pre-existing cracks. This data indicate that surface defects of NiTi rotary files may significantly decrease fatigue life and it may be one possible factor for early fracture of NiTi rotary files in clinical practice.

Keyword

MeSH Terms

Figure

Cited by 5 articles

-

Comparative study on morphology of cross-section and cyclic fatigue test with different rotary NiTi files and handling methods

Jae-Gwan Kim, Kee-Yeon Kum, Eui-Seong Kim

J Korean Acad Conserv Dent. 2006;31(2):96-102. doi: 10.5395/JKACD.2006.31.2.096.The Effect of Surface Defects on the Cyclic Fatigue Fracture of HEROShaper Ni-Ti rotary files in a Dynamic Model: A Fractographic Analysis

Jung-Kyu Lee, Eui-Sung Kim, Myoung-Whai Kang, Kee-Yeon Kum

J Korean Acad Conserv Dent. 2007;32(2):130-137. doi: 10.5395/JKACD.2007.32.2.130.Effect of cross-sectional area of 6 nickel-titanium rotary instruments on the fatigue fracture under cyclic flexural stress: A fractographic analysis

Soo-Youn Hwang, So-Ram Oh, Yoon Lee, Sang-Min Lim, Kee-Yeon Kum

J Korean Acad Conserv Dent. 2009;34(5):424-429. doi: 10.5395/JKACD.2009.34.5.424.An evaluation of rotational stability in endodontic electronic motors

Se-Hee Park, Hyun-Woo Seo, Chan-Ui Hong

J Korean Acad Conserv Dent. 2010;35(4):246-256. doi: 10.5395/JKACD.2010.35.4.246.Effect of internal stress on cyclic fatigue failure in K3

Jun-Young Kim, Jin-Woo Kim, Kyung-Mo Cho, Se-Hee Park

Restor Dent Endod. 2012;37(2):74-78. doi: 10.5395/rde.2012.37.2.74.

Reference

-

1. Mize SB, Pruett JP, Clement DJ, Carnes DL. Effect to sterilization on cyclic fatigue of rotary nickel-titanium endodontic instruments. J Endod. 1998. 24(12):843–847.

Article2. Pruett JP, Clement DJ, Carnes DL. Cyclic fatigue testing of nickel-titanium endodontic instruments. J Endod. 1997. 23(2):77–85.

Article3. Haikel Y, Serfaty R, Bateman G, Senger B, Allemann C. Dynamic and cyclic fatigue of engine-driven rotary nickel-titanium endodontic instruments. J Endod. 1999. 25(6):434–440.

Article4. Kuhn G, Tavernier B, Jordan L. Influence of structure on Nickel-Titanium endodontic instrument failure. J Endod. 2001. 27(8):516–520.5. Karn T. Fractographic analysis of experimentally separated NiTi rotary files. 2003. University of Connecticut;MS Thesis.6. Li UM, Lee BS, Shih CT, Lan WH, Lin CP. Cyclic fatigue of endodontic nickel-titanium rotary instruments: static and dynamic tests. J Endod. 2002. 28(6):448–451.

Article7. Turpin YL, Chagneau F, Vulcain JM. Impact of two theoretical cross-sections on torsional and bending stresses of nickel-titanium root canal instrument models. J Endod. 2000. 26(7):414–417.

Article8. Jeon IS, Spangberg LS, Yoon TC, Kazemi RB, Kum KY. Smear layer production of three NiTi rotary reamers in straight root canals. A SEM study. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2003. 96(5):601–607.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Comparative study on morphology of cross-section and cyclic fatigue test with different rotary NiTi files and handling methods

- Mechanical and geometric features of endodontic instruments and its clinical effect

- Effect of surface treatment on the mechanical properties of nickel-titanium files with a similar cross-section

- Comparison of the cyclic fatigue resistance of VDW.ROTATE, TruNatomy, 2Shape, and HyFlex CM nickel-titanium rotary files at body temperature

- Effect of glide path preparation with PathFile and ProGlider on the cyclic fatigue resistance of WaveOne nickel-titanium files