J Adv Prosthodont.

2014 Dec;6(6):491-497. 10.4047/jap.2014.6.6.491.

Influence of abutment materials on the implant-abutment joint stability in internal conical connection type implant systems

- Affiliations

-

- 1Department of Prosthodontics, School of Dentisty, Pusan National University, Yangsan, Republic of Korea. cmjeong@pusan.ac.kr

- 2Osstem Dental Implant Research Center (Osstem Implant), Busan, Republic of Korea.

- KMID: 2284723

- DOI: http://doi.org/10.4047/jap.2014.6.6.491

Abstract

- PURPOSE

This study evaluated the influence of abutment materials on the stability of the implant-abutment joint in internal conical connection type implant systems.

MATERIALS AND METHODS

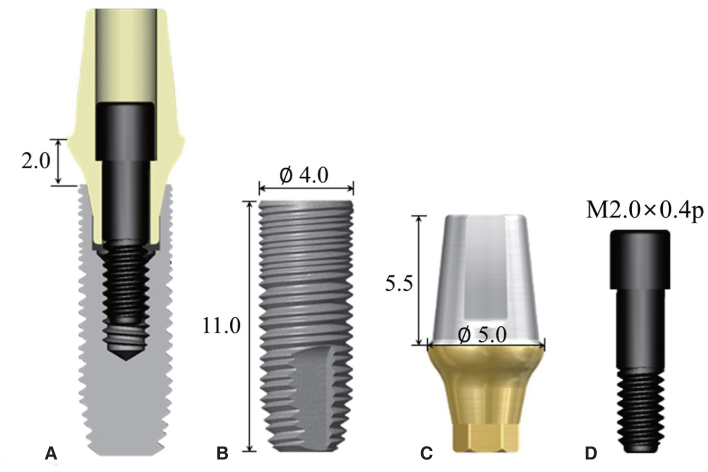

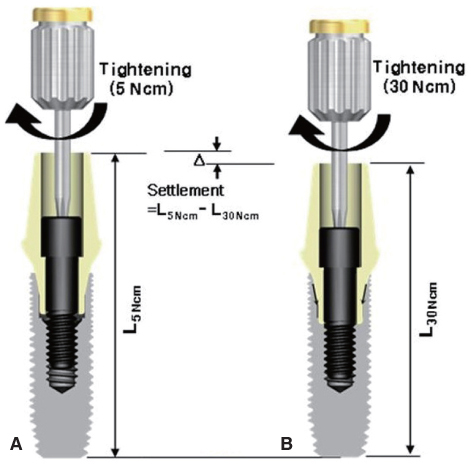

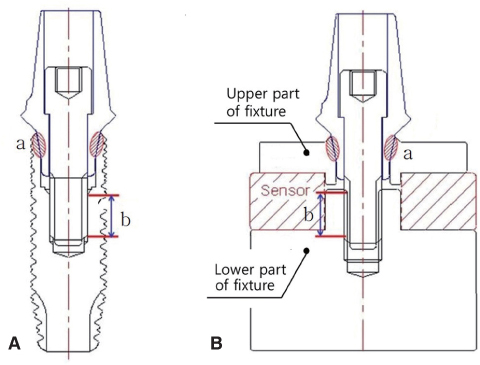

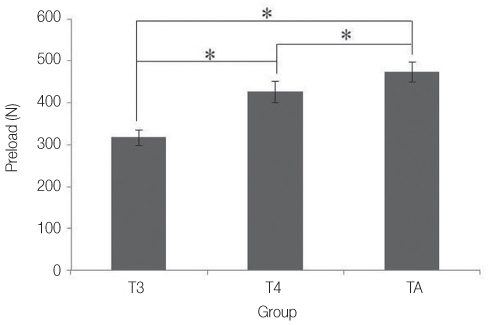

Internal conical connection type implants, cement-retained abutments, and tungsten carbide-coated abutment screws were used. The abutments were fabricated with commercially pure grade 3 titanium (group T3), commercially pure grade 4 titanium (group T4), or Ti-6Al-4V (group TA) (n=5, each). In order to assess the amount of settlement after abutment fixation, a 30-Ncm tightening torque was applied, then the change in length before and after tightening the abutment screw was measured, and the preload exerted was recorded. The compressive bending strength was measured under the ISO14801 conditions. In order to determine whether there were significant changes in settlement, preload, and compressive bending strength before and after abutment fixation depending on abutment materials, one-way ANOVA and Tukey's HSD post-hoc test was performed.

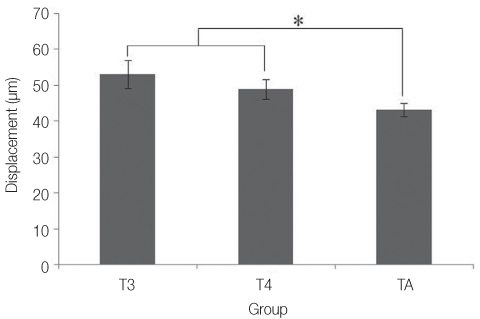

RESULTS

Group TA exhibited the smallest mean change in the combined length of the implant and abutment before and after fixation, and no difference was observed between groups T3 and T4 (P>.05). Group TA exhibited the highest preload and compressive bending strength values, followed by T4, then T3 (P<.001).

CONCLUSION

The abutment material can influence the stability of the interface in internal conical connection type implant systems. The strength of the abutment material was inversely correlated with settlement, and positively correlated with compressive bending strength. Preload was inversely proportional to the frictional coefficient of the abutment material.

Figure

Reference

-

1. Adell R, Lekholm U, Rockler B, Brånemark PI. A 15-year study of osseointegrated implants in the treatment of the edentulous jaw. Int J Oral Surg. 1981; 10:387–416.2. Adell R, Eriksson B, Lekholm U, Brånemark PI, Jemt T. Long-term follow-up study of osseointegrated implants in the treatment of totally edentulous jaws. Int J Oral Maxillofac Implants. 1990; 5:347–359.3. van Steenberghe D, Lekholm U, Bolender C, Folmer T, Henry P, Herrmann I, Higuchi K, Laney W, Linden U, Astrand P. Applicability of osseointegrated oral implants in the rehabilitation of partial edentulism: a prospective multicenter study on 558 fixtures. Int J Oral Maxillofac Implants. 1990; 5:272–281.4. Lindquist LW, Carlsson GE, Jemt T. A prospective 15-year follow-up study of mandibular fixed prostheses supported by osseointegrated implants. Clinical results and marginal bone loss. Clin Oral Implants Res. 1996; 7:329–336.5. Eckert SE, Wollan PC. Retrospective review of 1170 endosseous implants placed in partially edentulous jaws. J Prosthet Dent. 1998; 79:415–421.6. Zarb GA, Schmitt A. The longitudinal clinical effectiveness of osseointegrated dental implants: the Toronto study. Part I: Surgical results. J Prosthet Dent. 1990; 63:451–457.7. Zarb GA, Schmitt A. The longitudinal clinical effectiveness of osseointegrated dental implants: the Toronto study. Part III: Problems and complications encountered. J Prosthet Dent. 1990; 64:185–194.8. Steinebrunner L, Wolfart S, Ludwig K, Kern M. Implantabutment interface design affects fatigue and fracture strength of implants. Clin Oral Implants Res. 2008; 19:1276–1284.9. Rangert B, Jemt T, Jörneus L. Forces and moments on Branemark implants. Int J Oral Maxillofac Implants. 1989; 4:241–247.10. Burguete RL, Johns RB, King T, Patterson EA. Tightening characteristics for screwed joints in osseointegrated dental implants. J Prosthet Dent. 1994; 71:592–599.11. Haack JE, Sakaguchi RL, Sun T, Coffey JP. Elongation and preload stress in dental implant abutment screws. Int J Oral Maxillofac Implants. 1995; 10:529–536.12. Rangert B, Krogh PH, Langer B, Van Roekel N. Bending overload and implant fracture: a retrospective clinical analysis. Int J Oral Maxillofac Implants. 1995; 10:326–334.13. Taylor TD. Prosthodontic problems and limitations associated with osseointegration. J Prosthet Dent. 1998; 79:74–78.14. Khraisat A, Abu-Hammad O, Al-Kayed AM, Dar-Odeh N. Stability of the implant/abutment joint in a single-tooth external-hexagon implant system: clinical and mechanical review. Clin Implant Dent Relat Res. 2004; 6:222–229.15. Kitagawa T, Tanimoto Y, Odaki M, Nemoto K, Aida M. Influence of implant/abutment joint designs on abutment screw loosening in a dental implant system. J Biomed Mater Res B Appl Biomater. 2005; 75:457–463.16. Tsuge T, Hagiwara Y. Influence of lateral-oblique cyclic loading on abutment screw loosening of internal and external hexagon implants. Dent Mater J. 2009; 28:373–381.17. Khayat PG, Hallage PG, Toledo RA. An investigation of 131 consecutively placed wide screw-vent implants. Int J Oral Maxillofac Implants. 2001; 16:827–832.18. Balfour A, O'Brien GR. Comparative study of antirotational single tooth abutments. J Prosthet Dent. 1995; 73:36–43.19. Smedberg JI, Nilner K, Rangert B, Svensson SA, Glantz SA. On the influence of superstructure connection on implant preload: a methodological and clinical study. Clin Oral Implants Res. 1996; 7:55–63.20. Rangert BR, Sullivan RM, Jemt TM. Load factor control for implants in the posterior partially edentulous segment. Int J Oral Maxillofac Implants. 1997; 12:360–370.21. English CE. Biomechanical concerns with fixed partial dentures involving implants. Implant Dent. 1993; 2:221–242.22. Weinberg LA. Reduction of implant loading with therapeutic biomechanics. Implant Dent. 1998; 7:277–285.23. McGlumphy EA, Mendel DA, Holloway JA. Implant screw mechanics. Dent Clin North Am. 1998; 42:71–89.24. Martin WC, Woody RD, Miller BH, Miller AW. Implant abutment screw rotations and preloads for four different screw materials and surfaces. J Prosthet Dent. 2001; 86:24–32.25. Simon RL. Single implant-supported molar and premolar crowns: a ten-year retrospective clinical report. J Prosthet Dent. 2003; 90:517–521.26. Motosh N. Development of design charts for bolts preloaded up to the plastic range. J Manuf Sci Eng. 1976; 98:849–851.27. Jörnéus L, Jemt T, Carlsson L. Loads and designs of screw joints for single crowns supported by osseointegrated implants. Int J Oral Maxillofac Implants. 1992; 7:353–359.28. Park JK, Choi JU, Jeon YC, Choi KS, Jeong CM. Effects of abutment screw coating on implant preload. J Prosthodont. 2010; 19:458–464.29. Merz BR, Hunenbart S, Belser UC. Mechanics of the implant-abutment connection: an 8-degree taper compared to a butt joint connection. Int J Oral Maxillofac Implants. 2000; 15:519–526.30. Norton MR. An in vitro evaluation of the strength of an internal conical interface compared to a butt joint interface in implant design. Clin Oral Implants Res. 1997; 8:290–298.31. Hansson S. Implant-abutment interface: biomechanical study of flat top versus conical. Clin Implant Dent Relat Res. 2000; 2:33–41.32. Theoharidou A, Petridis HP, Tzannas K, Garefis P. Abutment screw loosening in single-implant restorations: a systematic review. Int J Oral Maxillofac Implants. 2008; 23:681–690.33. Winkler S, Ring K, Ring JD, Boberick KG. Implant screw mechanics and the settling effect: overview. J Oral Implantol. 2003; 29:242–245.34. Lee JS, Lee JS. Effect of various abutment systems on the removal torque and the abutment settling in the conical connection implant systems. J Korean Acad Prosthodont. 2012; 50:92–98.35. Bressan E, Paniz G, Lops D, Corazza B, Romeo E, Favero G. Influence of abutment material on the gingival color of implant-supported all-ceramic restorations: a prospective multicenter study. Clin Oral Implants Res. 2011; 22:631–637.36. Tamura Y, Yokoyama A, Watari F, Kawasaki T. Surface properties and biocompatibility of nitrided titanium for abrasion resistant implant materials. Dent Mater J. 2002; 21:355–372.37. Mengel R, Meer C, Flores-de-Jacoby L. The treatment of uncoated and titanium nitride-coated abutments with different instruments. Int J Oral Maxillofac Implants. 2004; 19:232–238.38. Niinomi M. Mechanical properties of biomedical titanium alloys. Mater Sci Eng A. 1998; 243:231–236.39. Bickford J. An Introduction to the design and behavior of bolted Joints. 3rd ed. New York: Marcel Dekker;1995.40. Corazza PH, de Moura Silva A, Cavalcanti Queiroz JR, Salazar Marocho SM, Bottino MA, Massi M, de Assunção e Souza RO. Carbon film coating of abutment surfaces: effect on the abutment screw removal torque. Implant Dent. 2014; 23:434–438.41. Budinski KG. Tribological properties of titanium alloys. Wear. 1991; 151:203–217.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of various abutment systems on the removal torque and the abutment settling in the conical connection implant systems

- Influence of implant-abutment interface design, implant diameter and prosthetic table width on strength of implant-abutment interface: three-dimensional finite element analysis

- Effect of a counter-torque device and the internal hexagon of abutment on the tightening torque transmitted to the implant

- Effect of casting procedure on screw loosening of UCLA abutment in two implant-abutment connection systems

- Fit of fixture/abutment/screw interfaces of internal connection implant system