J Adv Prosthodont.

2013 Nov;5(4):471-478. 10.4047/jap.2013.5.4.471.

Annealing of Co-Cr dental alloy: effects on nanostructure and Rockwell hardness

- Affiliations

-

- 1Department of Prosthodontics, Dental Health Sciences Center, Gulhane Military Medical Academy, Ankara, Turkey. simelayyildiz@gmail.com

- 2Department of Physics, Karadeniz Technical University, Faculty of Science and Literature, Trabzon, Turkey.

- 3Department of Physics Engineering, Faculty of Engineering, Hacettepe University, Ankara, Turkey.

- 4Department of Public Health, Gulhane Military Medical Academy, Ankara, Turkey.

- 5Dental Health Service, Beytepe Military Hospital, Ankara, Turkey.

- KMID: 2176541

- DOI: http://doi.org/10.4047/jap.2013.5.4.471

Abstract

- PURPOSE

The aim of the study was to evaluate the effect of annealing on the nanostructure and hardness of Co-Cr metal ceramic samples that were fabricated with a direct metal laser sintering (DMLS) technique.

MATERIALS AND METHODS

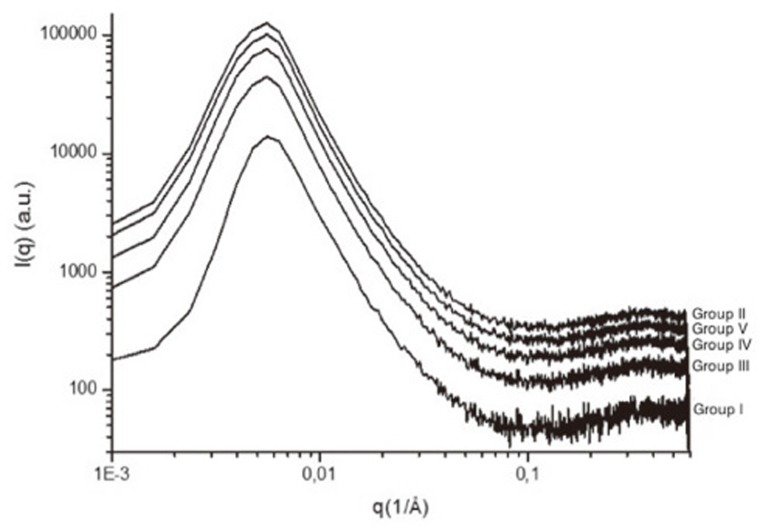

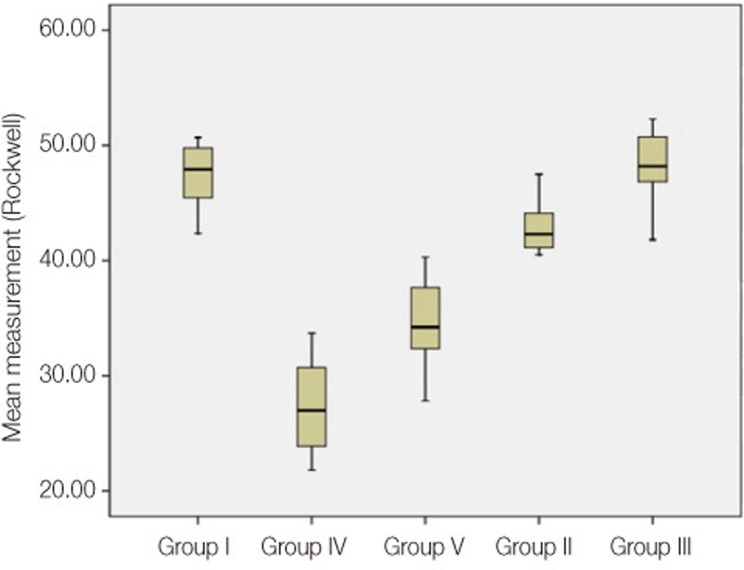

Five groups of Co-Cr dental alloy samples were manufactured in a rectangular form measuring 4 x 2 x 2 mm. Samples fabricated by a conventional casting technique (Group I) and prefabricated milling blanks (Group II) were examined as conventional technique groups. The DMLS samples were randomly divided into three groups as not annealed (Group III), annealed in argon atmosphere (Group IV), or annealed in oxygen atmosphere (Group V). The nanostructure was examined with the small-angle X-ray scattering method. The Rockwell hardness test was used to measure the hardness changes in each group, and the means and standard deviations were statistically analyzed by one-way ANOVA for comparison of continuous variables and Tukey's HSD test was used for post hoc analysis. P values of <.05 were accepted as statistically significant.

RESULTS

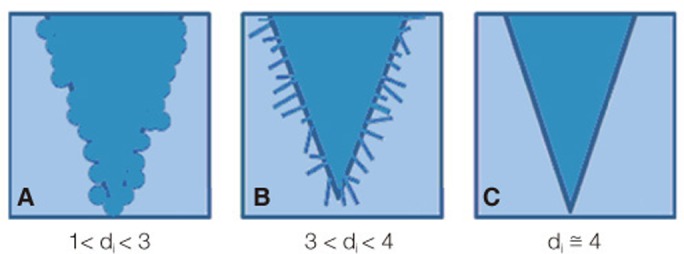

The general nanostructures of the samples were composed of small spherical entities stacked atop one another in dendritic form. All groups also displayed different hardness values depending on the manufacturing technique. The annealing procedure and environment directly affected both the nanostructure and hardness of the Co-Cr alloy. Group III exhibited a non-homogeneous structure and increased hardness (48.16 +/- 3.02 HRC) because the annealing process was incomplete and the inner stress was not relieved. Annealing in argon atmosphere of Group IV not only relieved the inner stresses but also decreased the hardness (27.40 +/- 3.98 HRC). The results of fitting function presented that Group IV was the most homogeneous product as the minimum bilayer thickness was measured (7.11 A).

CONCLUSION

After the manufacturing with DMLS technique, annealing in argon atmosphere is an essential process for Co-Cr metal ceramic substructures. The dentists should be familiar with the materials that are used in clinic for prosthodontics treatments.

MeSH Terms

Figure

Cited by 1 articles

-

What is the changing frequency of diamond burs?

Faruk Emir, Simel Ayyildiz, Cem Sahin

J Adv Prosthodont. 2018;10(2):93-100. doi: 10.4047/jap.2018.10.2.93.

Reference

-

1. Wataha JC. Biocompatibility of dental casting alloys: a review. J Prosthet Dent. 2000; 83:223–234. PMID: 10668036.

Article2. Pretti M, Hilgert E, Bottino MA, Avelar RP. Evaluation of the shear bond strength of the union between two CoCr-alloys and a dental ceramic. J Appl Oral Sci. 2004; 12:280–284. PMID: 20976397.

Article3. Grimaudo NJ. Biocompatibility of nickel and cobalt dental alloys. Gen Dent. 2001; 49:498–503. PMID: 12017794.4. Dobrzański LA, Reimann L. Influence of Cr and Co on hardness and corrosion resistance CoCrMo alloys used on dentures. J Achieve Mater Manuf Eng. 2011; 49:193–199.5. Karpuschewski B, Pieper HJ, Krause M, Döring J. In : Schuh G, Neugebauer R, Uhlmann E, editors. Future trends in production engineering. 1st ed. Proceedings of the first conference of the German Academic Society for production engineering; 8th-9th June 2011; Berlin, Germany. New York: Springer;2013.6. Fasbinder D. Using digital technology to enhance restorative dentistry. Compend Contin Educ Dent. 2012; 33:666–668. PMID: 23030729.7. Miyazaki T, Hotta Y, Kunii J, Kuriyama S, Tamaki Y. A review of dental CAD/CAM: current status and future perspectives from 20 years of experience. Dent Mater J. 2009; 28:44–56. PMID: 19280967.

Article8. Aboushelib MN, Elmahy WA, Ghazy MH. Internal adaptation, marginal accuracy and microleakage of a pressable versus a machinable ceramic laminate veneers. J Dent. 2012; 40:670–677. PMID: 22542500.

Article9. Figliuzzi M, Mangano F, Mangano C. A novel root analogue dental implant using CT scan and CAD/CAM: selective laser melting technology. Int J Oral Maxillofac Surg. 2012; 41:858–862. PMID: 22377004.

Article10. Jevremovic D, Puskar T, Kosec B, Vukelic D, Budak I, Aleksandrovic S, Egbeer D, Williams R. The analysis of the mechanical properties of F75 Co-Cr alloy for use in selective laser melting (SLM) manufacturing of removable partial dentures (RPD). Metal. 2012; 51:171–174.11. Hollander DA, von Walter M, Wirtz T, Sellei R, Schmidt-Rohlfing B, Paar O, Erli HJ. Structural, mechanical and in vitro characterization of individually structured Ti-6Al-4V produced by direct laser forming. Biomaterials. 2006; 27:955–963. PMID: 16115681.

Article12. Rodrigues WC, Broilo LR, Schaeffer L, Knörnschild G, Espinoza FRM. Powder metallurgical processing of Co-28%Cr-6%Mo for dental implants: Physical, mechanical and electrochemical properties. Powder Tech. 2011; 206:233–238.

Article13. Bauer JR, Grande RH, Rodrigues-Filho LE, Pinto MM, Loguercio AD. Does the casting mode influence microstructure, fracture and properties of different metal ceramic alloys? Braz Oral Res. 2012; 26:190–196. PMID: 22641437.

Article14. Gill P, Munroe N, Pulletikurthi C, Pandya S, Haider W. Effect of Manufacturing Process on the Biocompatibility and Mechanical Properties of Ti-30Ta Alloy. J Mater Eng Perform. 2011; 20:819–823. PMID: 21666859.

Article15. Manfredi D, Calignano F, Krishnan M, Canali R, Ambrosio EP, Atzeni E. From powders to dense metal parts: Characterization of a commercial AlSiMg alloy processed through direct metal laser sintering. Materials. 2013; 6:856–869.

Article16. Tandon R. Disegi JA, Kennedy RL, Pilliar R, editors. Cobalt Base Alloys for Biomedical Applications ASTM STP 1365. West Conshohocken, PA: American Society for Testing and Materials;1999.17. Bolzoni L, Esteban PG, Ruiz-Navas EM, Gordo E. Mechanical behaviour of pressed and sintered titanium alloys obtained from master alloy addition powders. J Mech Behav Biomed Mater. 2012; 15:33–45. PMID: 23026730.

Article18. Lohfeld S, McHugh PE. Laser sintering for the fabrication of tissue engineering scaffolds. Methods Mol Biol. 2012; 868:303–310. PMID: 22692618.

Article19. Castillo-de-Oyagüe R, Sánchez-Turrión A, López-Lozano JF, Albaladejo A, Torres-Lagares D, Montero J, Sáarez-García MJ. Vertical misfit of laser-sintered and vacuum-cast implant-supported crowncopings luted with definitive and temporary luting agents. Med Oral Patol Oral Cir Bucal. 2012; 17:e610–e617. PMID: 22322524.20. Traini T, Mangano C, Sammons RL, Mangano F, Macchi A, Piattelli A. Direct laser metal sintering as a new approach to fabrication of an isoelastic functionally graded material for manufacture of porous titanium dental implants. Dent Mater. 2008; 24:1525–1533. PMID: 18502498.

Article21. Girardin E, Renghini C, Dyson J, Calbucci V, Moroncini F, Albertini G. Characterization of porosity in a laser sintered MMCp using X-ray synchrotron phase contrast microtomography. Mater Sci Appl. 2011; 2:1322–1330.

Article22. Gaytan SM, Murr LE, Martinez E, Martinez JL, Machado BI, Ramirez DA, Medina F, Collins S, Wicker RB. Comparison of Microstructures and mechanical properties for solid and mesh cobalt-base alloy prototypes fabricated by electron beam melting. Metall Mater Trans A. 2010; 41:3216–3227.

Article23. Chen CL, Tatlock GJ, Jones AR. Effect of annealing temperatures on the secondary re-crystallization of extruded PM2000 steel bar. J Microsc. 2009; 233:474–481. PMID: 19250468.

Article24. Guo WH, Brantley WA, Li D, Clark WA, Monaghan P, Heshmati RH. Annealing study of palladium-silver dental alloys: Vickers hardness measurements and SEM microstructural observations. J Mater Sci Mater Med. 2007; 18:111–118. PMID: 17200820.

Article25. Porod G. Glatter O, Kratky O, editors. Small angel X-ray scattering. London, UK: Academic Press Inc;1982.26. Martin JE, Hurd AJ. Scattering from fractals. J Appl Crystallogr. 1987; 20:61–78.

Article27. EN ISO 18265: 2005. Metallic materials - Conversion of hardness values.28. Bezzon OL, Ribeiro RF, Rollo JM, Crosara S. Castability and resistance of ceramometal bonding in Ni-Cr and Ni-Cr-Be alloys. J Prosthet Dent. 2001; 85:299–304. PMID: 11264939.

Article29. Kern M, Thompson VP. Durability of resin bonds to a cobalt-chromium alloy. J Dent. 1995; 23:47–54. PMID: 7876416.

Article30. Wataha JC, Lockwood PE. Release of elements from dental casting alloys into cell-culture medium over 10 months. Dent Mater. 1998; 14:158–163. PMID: 10023206.

Article31. Wataha JC, Nelson SK, Lockwood PE. Elemental release from dental casting alloys into biological media with and without protein. Dent Mater. 2001; 17:409–414. PMID: 11445208.

Article32. Liu R, Xi SQ, Kapoor S, Wu XJ. Effects of chemical composition on solidification, microstructure and hardness of Co-Cr-W-Ni and Co-Cr-Mo-Ni alloy systems. Int J Res Rev Appl Sci. 2010; 5:110–122.33. Iseri U, Ozkurt Z, Kazazoglu E. Shear bond strengths of veneering porcelain to cast, machined and laser-sintered titanium. Dent Mater J. 2011; 30:274–280. PMID: 21597225.

Article34. Heat Treating. ASM Handbook. Vol. 4. Ohio: ASM International;1991.35. Tani T, Udoh K, Yasuda K, Van Tendeloo G, Van Landuyt J. Age-hardening mechanisms in a commercial dental gold alloy containing platinum and palladium. J Dent Res. 1991; 70:1350–1357. PMID: 1939828.

Article36. Kim HI, Lee DH, Sim JS, Kwon YH, Seol HJ. Age-hardening by miscibility limit of Au-Pt and Ag-Cu systems in an Au-Ag-Cu-Pt alloy. Mater Character. 2009; 60:357–362.

Article37. Nomura N, Abe M, Kawamura A, Fujinuma S, Chiba A, Masahashi N, Hanada S. Fabrication and mechanical properties of porous Co-Cr-Mo alloy compacts without Ni addition. Mater Trans. 2006; 47:283–286.38. Telu S, Patra A, Sankaranarayana M, Mitra R, Pabi SK. Microstructure and cyclic oxidation behavior of W-Cr alloys prepared by sintering of mechanically alloyed nanocrystalline powders. Int J Refract Met Hard Mater. 2013; 36:191–203.

Article39. Mackert JR Jr, Ringle RD, Fairhurst CW. High-temperature behavior of a Pd-Ag alloy for porcelain. J Dent Res. 1983; 62:1229–1235. PMID: 6581200.

Article40. McGinley EL, Coleman DC, Moran GP, Fleming GJ. Effects of surface finishing conditions on the biocompatibility of a nickel-chromium dental casting alloy. Dent Mater. 2011; 27:637–650. PMID: 21514653.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Correlation between microhardness and wear resistance of dental alloys against monolithic zirconia

- A comparative study on the physical properties of orthodontic pliers according to types of sterilization

- Comparison of the mechanical properties and microstructures of fractured surface for Co-Cr alloy fabricated by conventional cast, 3-D printing laser-sintered and CAD/CAM milled techniques

- Effect of metal primers and tarnish treatment on bonding between dental alloys and veneer resin

- Evaluation of Osseointegration around Tibial Implants in Rats by Ibandronate-Treated Nanotubular Ti-32Nb-5Zr Alloy