J Adv Prosthodont.

2012 Nov;4(4):218-226. 10.4047/jap.2012.4.4.218.

Finite element modeling technique for predicting mechanical behaviors on mandible bone during mastication

- Affiliations

-

- 1Architectural Engineering Department, Ewha Womans University, Seoul, Korea. hskim3@ewha.ac.kr

- 2Graduate School of Clinical Dentistry, Ewha Womans University, Seoul, Korea.

- KMID: 2176421

- DOI: http://doi.org/10.4047/jap.2012.4.4.218

Abstract

- PURPOSE

The purpose of this study was to propose finite element (FE) modeling methods for predicting stress distributions on teeth and mandible under chewing action.

MATERIALS AND METHODS

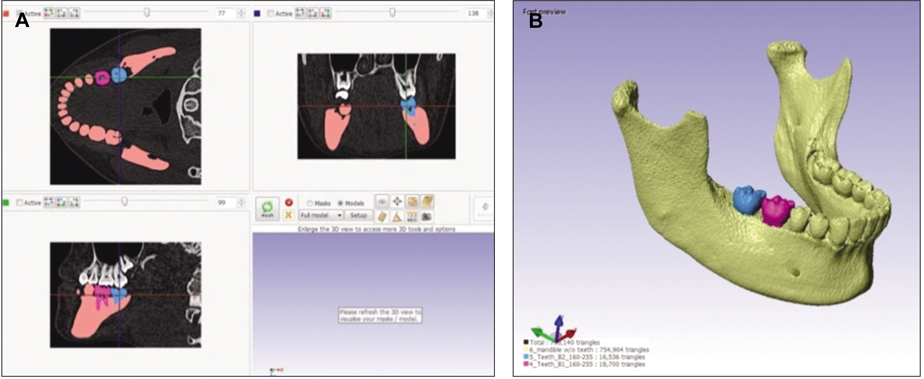

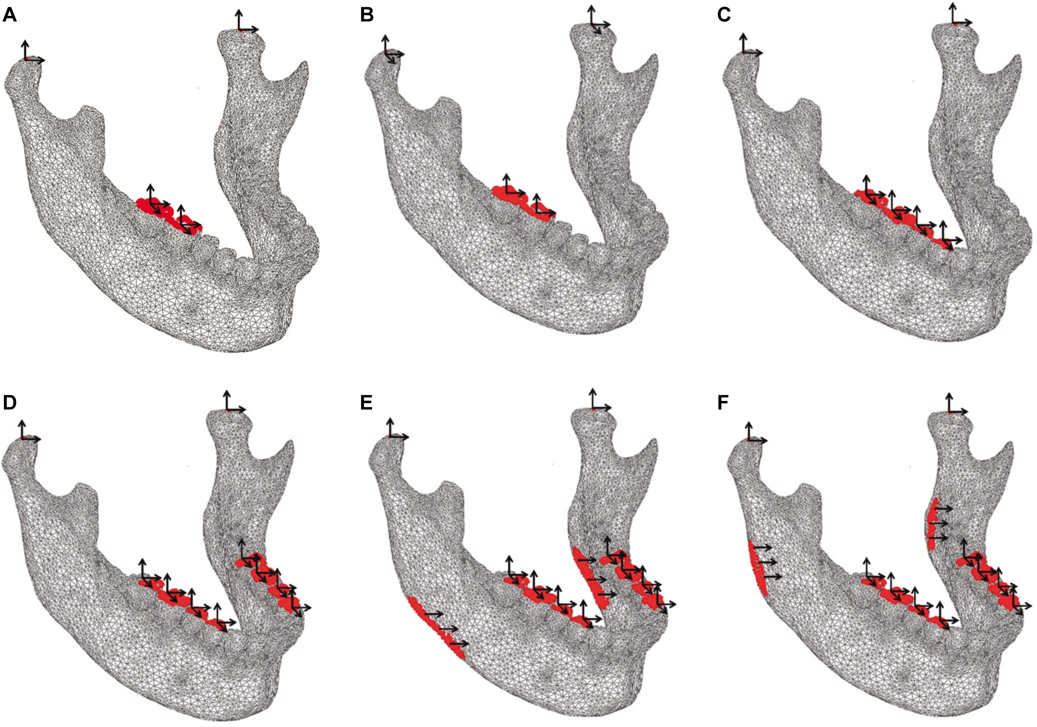

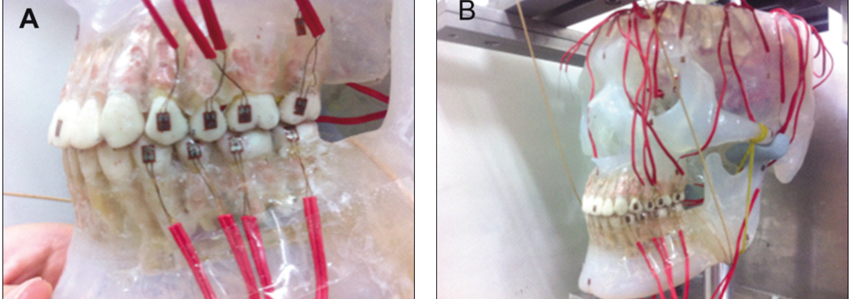

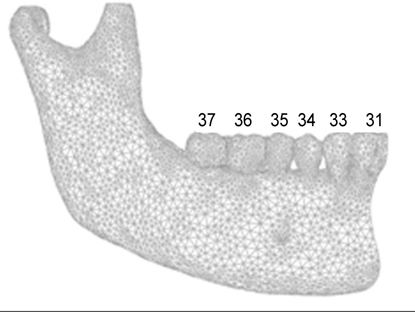

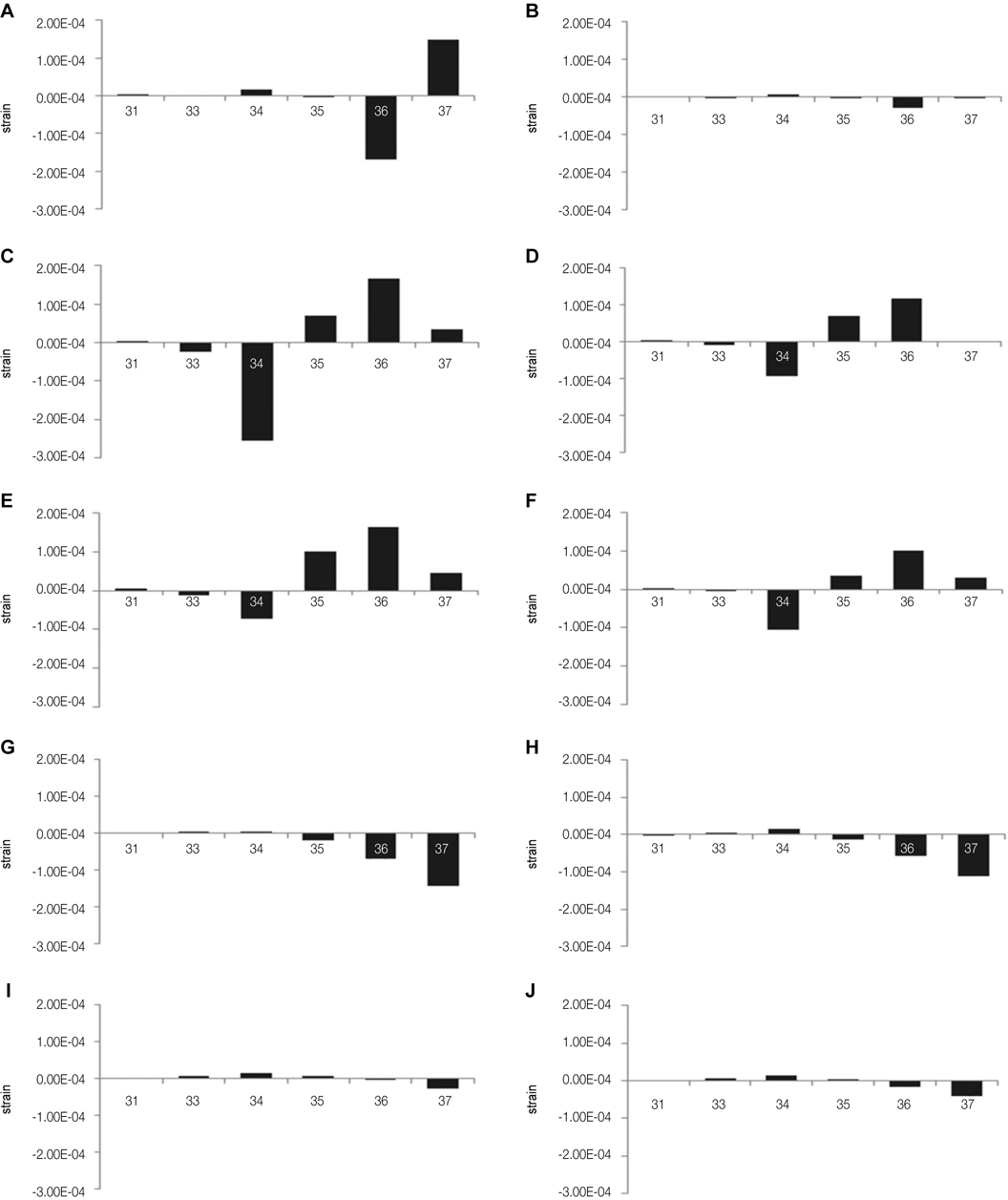

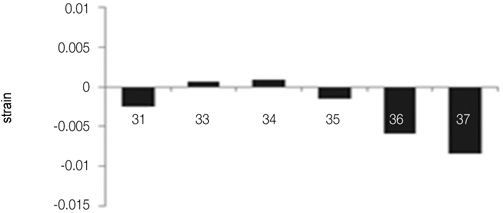

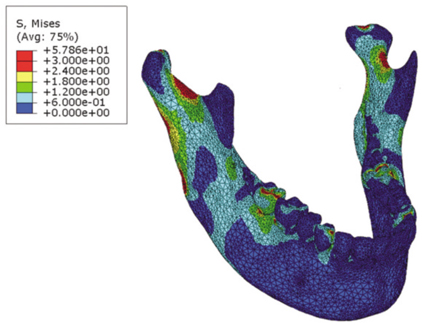

For FE model generation, CT images of skull were translated into 3D FE models, and static analysis was performed considering linear material behaviors and nonlinear geometrical effect. To find out proper boundary and loading conditions, parametric studies were performed with various areas and directions of restraints and loading. The loading directions are prescribed to be same as direction of masseter muscle, which was referred from anatomy chart and CT image. From the analysis, strain and stress distributions of teeth and mandible were obtained and compared with experimental data for model validation.

RESULTS

As a result of FE analysis, the optimized boundary condition was chosen such that 8 teeth were fixed in all directions and condyloid process was fixed in all directions except for forward and backward directions. Also, fixing a part of mandible in a lateral direction, where medial pterygoid muscle was attached, gave the more proper analytical results. Loading was prescribed in a same direction as masseter muscle. The tendency of strain distributions between the teeth predicted from the proposed model were compared with experimental results and showed good agreements.

CONCLUSION

This study proposes cost efficient FE modeling method for predicting stress distributions on teeth and mandible under chewing action. The proposed modeling method is validated with experimental data and can further be used to evaluate structural safety of dental prosthesis.

MeSH Terms

Figure

Reference

-

1. Eser A, Akça K, Eckert S, Cehreli MC. Nonlinear finite element analysis versus ex vivo strain gauge measurements on immediately loaded implants. Int J Oral Maxillofac Implants. 2009. 24:439–446.2. Iplikçioğlu H, Akça K, Cehreli MC, Sahin S. Comparison of non-linear finite element stress analysis with in vitro strain gauge measurements on a Morse taper implant. Int J Oral Maxillofac Implants. 2003. 18:258–265.3. Wierszycki M, Kakol W, Lodygowski T. Fatigue algorithm for dental implant. Found Civ Environ Eng. 2006. 7:363–380.4. Lin D, Li Q, Li W, Ichim I, Swain M. Damage evaluation of bone tissues with dental implants. Key Eng Mater. 2007. 905–908.5. Lang LA, Kang B, Wang RF, Lang BR. Finite element analysis to determine implant preload. J Prosthet Dent. 2003. 90:539–546.6. Ihde S, Goldmann T, Himmlova L, Aleksic Z. The use of finite element analysis to model bone-implant contact with basal implants. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2008. 106:39–48.7. Cruz M, Wassall T, Toledo EM, da Silva Barra LP, Cruz S. Finite element stress analysis of dental prostheses supported by straight and angled implants. Int J Oral Maxillofac Implants. 2009. 24:391–403.8. Ban JH, Shin SW, Kim SJ, Lee JY. Three-dimensional finite element analysis on stress distribution of the mandibular implant-supported cantilever prostheses depending on the designs. J Korean Acad Prosthodont. 2009. 47:70–81.9. Paek JH, Lee CG, Kim TH, Kim MJ, Kim HS, Kwon KR, Woo YH. A FEM study on stress distribution of tooth-supported over dentures retained by telescopic crowns. J Korean Acad Prosthodont. 2012. 50:10–20.10. Himmlová L, Dostálová T, Kácovská A, Konvicková S. Influence of implant length and diameter on stress distribution: a finite element analysis. J Prosthet Dent. 2004. 91:20–25.11. Satis R, Ambrosio L, Nicolais L. Barbucci R, editor. Mechanical Properties oftooth structures. Integrated biomaterials science. 2002. New York: Kluwer Academic;589–599.12. Karl M, Graef F, Heckmann S, Taylor T. A methodology to study the effects of prosthesis misfit over time: an in vivo model. Int J Oral Maxillofac Implants. 2009. 24:689–694.13. Watanabe F, Uno I, Hata Y, Neuendorff G, Kirsch A. Analysis of stress distribution in a screw-retained implant prosthesis. Int J Oral Maxillofac Implants. 2000. 15:209–218.14. Karl M, Wichmann MG, Heckmann SM, Krafft T. Strain development in 3-unit implant-supported CAD/CAM restorations. Int J Oral Maxillofac Implants. 2008. 23:648–652.15. Cook Rd, Malkus DS, Plesha ME, Witt RJ. Concepts and Applications of Finite Element Analysis. 1989. 4th ed. New York: John Wiley & Sons;259–268.16. Wierszycki M, Kakol W, Lodygowski T. The screw loosening and fatigue analyses of three dimensional dental implant model. Proceedings of the 2006 Abaqus Users Conference. Rhode Island. USA: Abaqus INC;389–403.17. Netter FH. The CIBA Collection of Medical Illustrations. 1997. Vol. 1:Nervous System.18. Sohn BS, Heo SJ, Koak JY, Kim SK, Lee SY. Strain of implants depending on occlusion types in mandibular implant-supported fixed prostheses. J Adv Prosthodont. 2011. 3:1–9.19. Qadeer S, Kerstein R, Kim RJ, Huh JB, Shin SW. Relationship between articulation paper mark size and percentage of force measured with computerized occlusal analysis. J Adv Prosthodont. 2012. 4:7–12.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Three-dimensional finite element analysis of unilateral mastication in malocclusion cases using cone-beam computed tomography and a motion capture system

- Three-dimensional finite element analysis of implant-supported crown in fibula bone model

- Finite Element Analysis of Reconstruction of Mandibular Symphysis Defects Using Reconstruction Plates

- A Review of Finite Element Modeling for Anterior Cervical Discectomy and Fusion

- Finite element analysis of peri-implant bone stresses induced by root contact of orthodontic microimplant