J Adv Prosthodont.

2010 Sep;2(3):81-87. 10.4047/jap.2010.2.3.81.

Sintering behavior and mechanical properties of zirconia compacts fabricated by uniaxial press forming

- Affiliations

-

- 1BK21 project, School of Dentistry, Chonnam National University, Gwangju, Korea. psw320@chonnam.ac.kr

- 2Dental Science Research Institute, Department of Prosthodontics, School of Dentistry, Chonnam National University, Gwangju, Korea.

- 3Division of Materials Science and Engineering, Research Institute for Functional Surface Engineering, Chonnam National University, Gwangju, Korea.

- KMID: 2118111

- DOI: http://doi.org/10.4047/jap.2010.2.3.81

Abstract

- PURPOSE

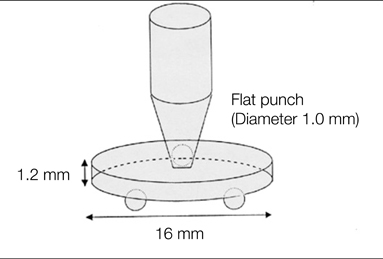

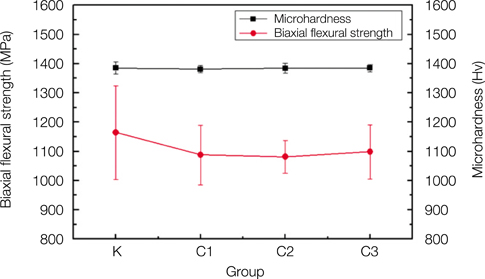

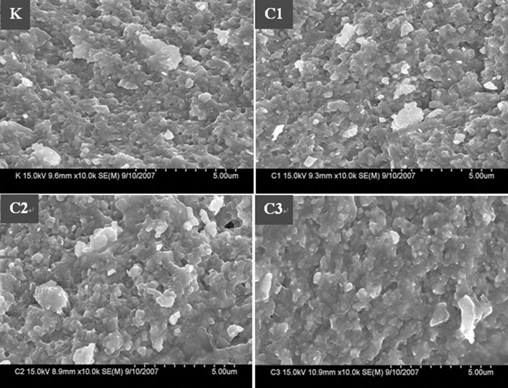

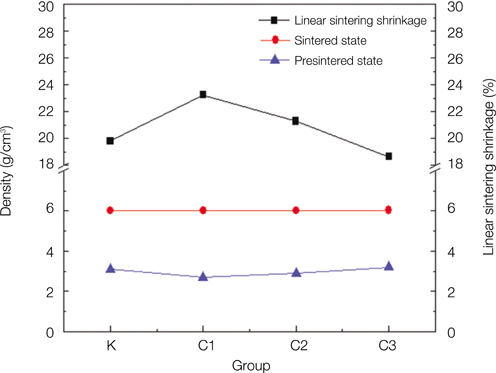

The purpose of this study was to compare the linear sintering behavior of presintered zirconia blocks of various densities. The mechanical properties of the resulting sintered zirconia blocks were then analyzed. MATERIAL AND METHODS: Three experimental groups of dental zirconia blocks, with a different presintering density each, were designed in the present study. Kavo Everest(R) ZS blanks (Kavo, Biberach, Germany) were used as a control group. The experimental group blocks were fabricated from commercial yttria-stabilized tetragonal zirconia powder (KZ-3YF (SD) Type A, KCM. Corporation, Nagoya, Japan). The biaxial flexural strengths, microhardnesses, and microstructures of the sintered blocks were then investigated. The linear sintering shrinkages of blocks were calculated and compared.

RESULTS

Despite their different presintered densities, the sintered blocks of the control and experimental groups showed similar mechanical properties. However, the sintered block had different linear sintering shrinkage rate depending on the density of the presintered block. As the density of the presintered block increased, the linear sintering shrinkage decreased. In the experimental blocks, the three sectioned pieces of each block showed the different linear shrinkage depending on the area. The tops of the experimental blocks showed the lowest linear sintering shrinkage, whereas the bottoms of the experimental blocks showed the highest linear sintering shrinkage.

CONCLUSION

Within the limitations of this study, the density difference of the presintered zirconia block did not affect the mechanical properties of the sintered zirconia block, but affected the linear sintering shrinkage of the zirconia block.

Figure

Reference

-

1. Lehner CR, Schärer P. All-ceramic crowns. Curr Opin Dent. 1992. 2:45–52.2. Bindl A, Mörmann WH. An up to 5-year clinical evaluation of posterior in-ceram CAD/CAM core crowns. Int J Prosthodont. 2002. 15:451–456.3. Mörmann WH, Bindl A. All-ceramic, chair-side computer-aided design/computer-aided machining restorations. Dent Clin North Am. 2002. 46:405–426.4. Pera P, Gilodi S, Bassi F, Carossa S. In vitro marginal adaptation of alumina porcelain ceramic crowns. J Prosthet Dent. 1994. 72:585–590.5. Rinke S, Hüls A, Jahn L. Marginal accuracy and fracture strength of conventional and copy-milled all-ceramic crowns. Int J Prosthodont. 1995. 8:303–310.6. Sulaiman F, Chai J, Jameson LM, Wozniak WT. A comparison of the marginal fit of In-Ceram, IPS Empress, and Procera crowns. Int J Prosthodont. 1997. 10:478–484.7. Marquardt P, Strub JR. Survival rates of IPS empress 2 all-ceramic crowns and fixed partial dentures: results of a 5-year prospective clinical study. Quintessence Int. 2006. 37:253–259.8. Sorensen JA, Kang SK, Torres TJ, Knode H. In-Ceram fixed partial dentures: three-year clinical trial results. J Calif Dent Assoc. 1998. 26:207–214.9. Sorensen JA, Cruz M, Mito WT, Raffeiner O, Meredith HR, Foser HP. A clinical investigation on three-unit fixed partial dentures fabricated with a lithium disilicate glass-ceramic. Pract Periodontics Aesthet Dent. 1999. 11:95–106.10. Tinschert J, Natt G, Mautsch W, Augthun M, Spiekermann H. Fracture resistance of lithium disilicate-, alumina-, and zirconia-based three-unit fixed partial dentures: a laboratory study. Int J Prosthodont. 2001. 14:231–238.11. Guazzato M, Albakry M, Ringer SP, Swain MV. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dent Mater. 2004. 20:449–456.12. Tinschert J, Zwez D, Marx R, Anusavice KJ. Structural reliability of alumina-, feldspar-, leucite-, mica- and zirconia-based ceramics. J Dent. 2000. 28:529–535.13. Porter DL, Heuer AH. Mechanisms of toughening partially stabilized zirconia (PSZ). J Am Ceram Soc. 1977. 60:183–184.14. Cales B. Colored zirconia ceramics for dental applications. Bioceramics. 1998. 11:591–594.15. Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999. 15:426–433.16. Garvie RC, Hannink RH, Pascoe RT. Ceramic steel? Nature. 1975. 258:703–704.17. Kitazaki H, Takahashi H, Hasegawa S, Nishimura F. Effect of amount of grinding on flexural strength of dental ceramics. J Med Dent Sci. 2001. 48:7–13.18. Chevalier J, Cales B, Drouin JM. Low-temperature aging of Y-TZP ceramics. J Am Ceram Soc. 1999. 82:2150–2154.19. Piconi C, Maccauro G. Zirconia as a ceramic biomaterial. Biomaterials. 1999. 20:1–25.20. Duke ES. The status of CAD/CAM in restorative dentistry. Compend Contin Educ Dent. 2001. 22:968–972.21. Suttor D, Bunke K, Hoescheler S, Hauptmann H, Hertlein G. LAVA-the system for all-ceramic ZrO2 crown and bridge frameworks. Int J Comput Dent. 2001. 4:195–206.22. Heydecke G, Butz F, Binder JR, Strub JR. Material characteristics of a novel shrinkage-free ZrSiO4 ceramic for the fabrication of posterior crowns. Dent Mater. 2007. 23:785–791.23. ISO 6872. International standard for dental ceramic. 1995. 2nd ed.24. Callister WD, Failure . Callister WD, editor. Fundamental of materials science and engineering. An integrated approach. 2005. 2nd ed. USA: John Wiley & Sons Inc;282–356.25. Fréchette V. Failure analysis of brittle materials. Advances in ceramics. 1990. vol. 28. Westerville, OH: American Ceramic Society.26. Ban S, Anusavice KJ. Influence of test method on failure stress of brittle dental materials. J Dent Res. 1990. 69:1791–1799.27. Giordano R. Materials for chairside CAD/CAM-produced restorations. J Am Dent Assoc. 2006. 137:14S–21S.28. Zirconia-Physical and mechanical property comparison of the different types of zirconias. 2003. http://www.azom.com.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of milling and sintering process on integrity of zirconia prosthesis: a literature review

- Effect of sintering condition and aging on hardness and optical properties of monolithic zirconia

- Effect of speed sintering on flexural strength, density, and linear shrinkage of monolithic zirconia

- Review on factors affecting the optical properties of dental zirconia

- Color stability of fully- and pre-crystalized chair-side CAD-CAM lithium disilicate restorations after required and additional sintering processes