J Dent Rehabil Appl Sci.

2022 Sep;38(3):127-137. 10.14368/jdras.2022.38.3.127.

Effect of milling and sintering process on integrity of zirconia prosthesis: a literature review

- Affiliations

-

- 1Department of Prosthodontics and Research Institute of Oral Science, College of Dentistry, Gangneung-Wonju National University, Gangneung, Republic of Korea

- KMID: 2535018

- DOI: http://doi.org/10.14368/jdras.2022.38.3.127

Abstract

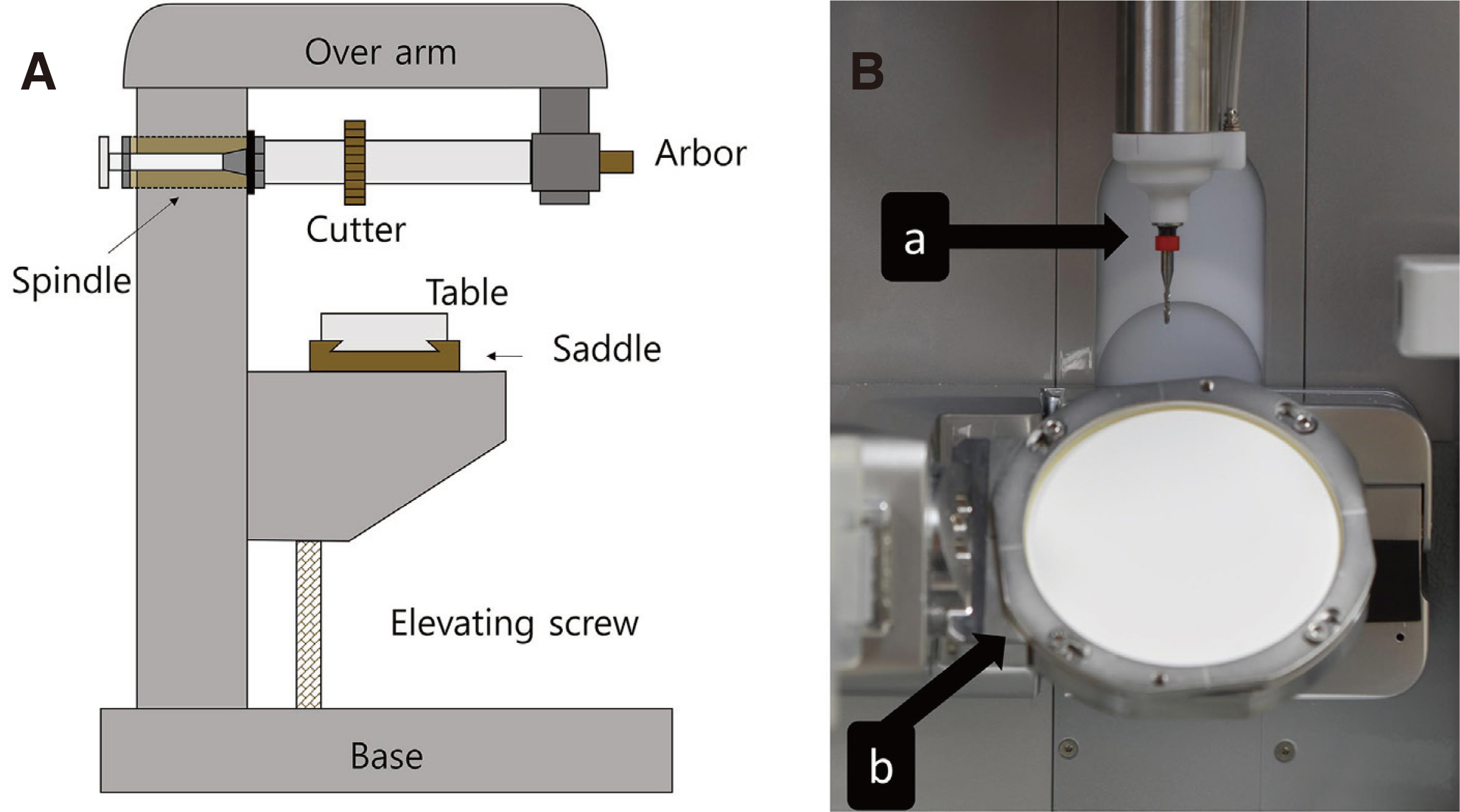

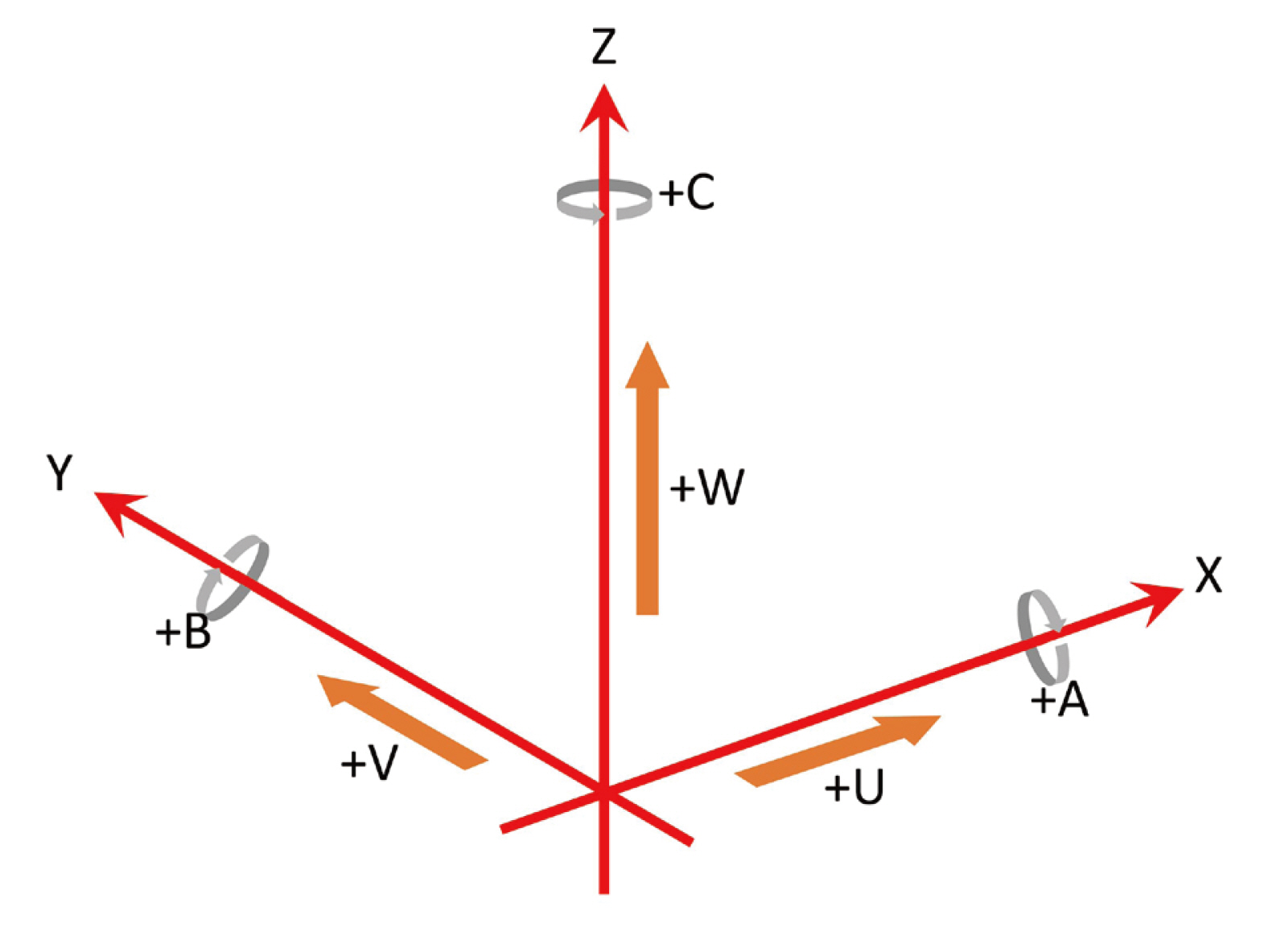

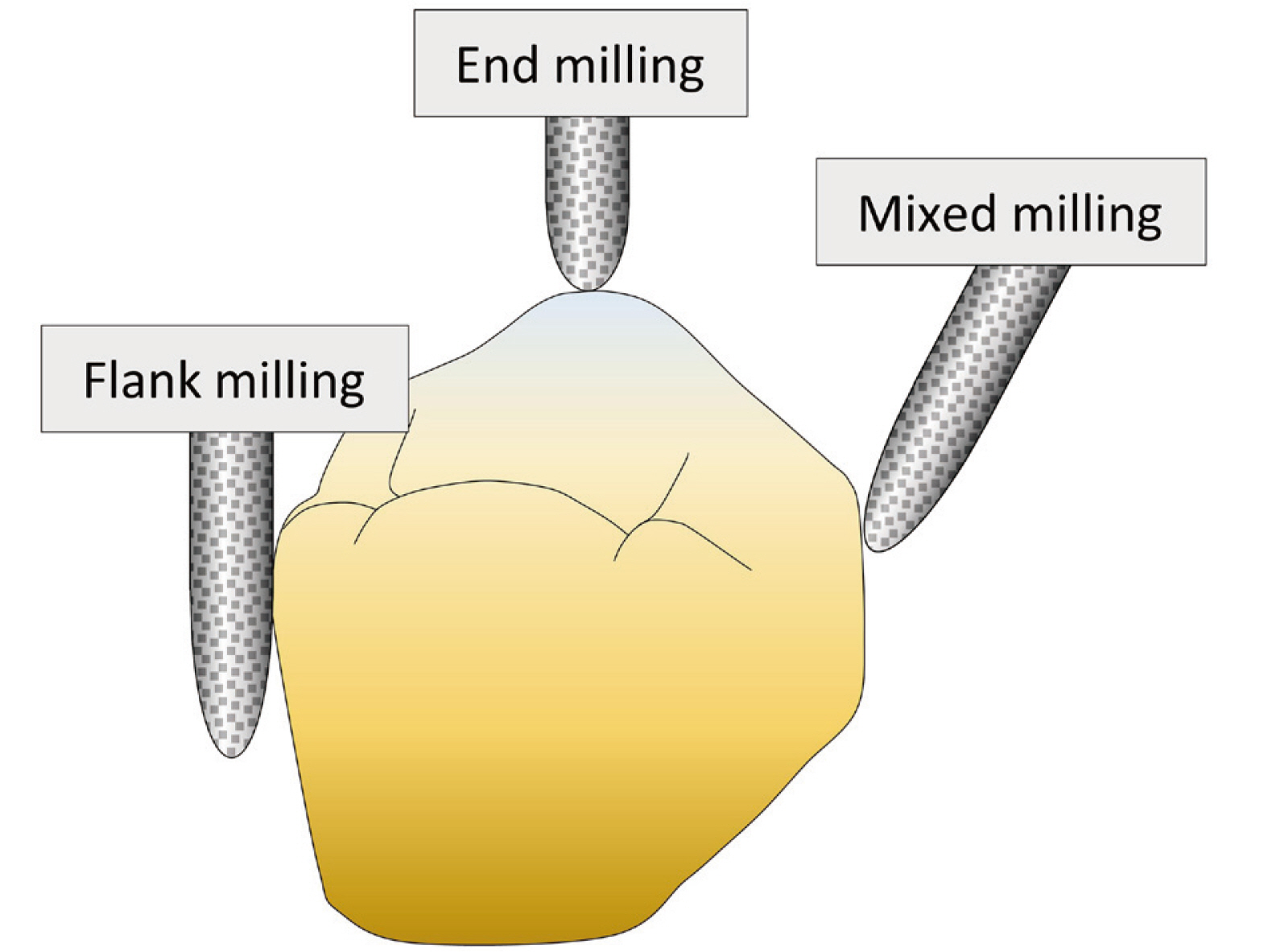

- Zirconia is fabricated through various processes. Each element in fabricating process can affect the physical properties of the definitive prosthesis. In particular, both the milling process and the sintering process can affect the final integrity of the zirconia prosthesis. Most of the milling machines adopt the ultra-precision 5-axis machining method, and the results vary depending on which milling method was used and how the milling equipment was managed. Milling blocks are selected according to cutting efficiency and aesthetic reproducibility. The sintering method can affect the grain growth and optical properties, and an accurate evaluation can be made only with additional research on the recent speed sintering procedure. Not only the sintering temperature but also the temperature holding time can affect the quality of definitive prosthesis.

Figure

Reference

-

References

1. Zhang Y, Lawn BR. 2018; Novel zirconia materials in dentistry. J Dent Res. 97:140–7. DOI: 10.1177/0022034517737483. PMID: 29035694. PMCID: PMC5784474.

Article2. Lebon N, Tapie L, Vennat E. 2020; Influence of milling tool and prosthetic materials on roughness of the dental CAD CAM prostheses in end milling mode. Appl Sci. 10:2238. DOI: 10.3390/app10072238. PMID: bbe22c95083a4945822b425acbec8cc6.

Article3. Ahmed WM, Troczynski T, McCullagh AP, Wyatt CCL, Carvalho RM. 2019; The influence of altering sintering protocols on the optical and mechanical properties of zirconia: A review. J Esthet Restor Dent. 31:423–30. DOI: 10.1111/jerd.12492. PMID: 31140674.

Article4. Schweiger J, Kieschnick A. 2017. CAD/CAM in digital dentistry. DaehanNarae;Seoul: p. 91–108. DOI: 10.1111/jerd.12492.5. Bosch G, Ender A, Mehl A. 2014; A 3-dimensional accuracy analysis of chairside CAD/CAM milling processes. J Prosthet Dent. 112:1425–31. DOI: 10.1016/j.prosdent.2014.05.012. PMID: 24993373.

Article6. Sadilek M, Poruba Z, Čepová L, Šajgalík M. 2020; Increasing the accuracy of free-form surface multiaxis milling. Materials (Basel). 14:25. DOI: 10.3390/ma14010025. PMID: 33374664. PMCID: PMC7793485. PMID: 72d1f353fa4a47649bf18608fab84eb8.

Article7. Lebon N, Tapie L, Vennat E, Mawussi B. 2019; A computer-aided tool to predict dental crown prosthesis surface integrity after milling. Comput Aided Des Appl. 16:894–903. DOI: 10.14733/cadaps.2019.894-903.

Article8. Benoit A, Issaoui H, Lebon N. 2020; Impact of machining process on the flexural strength of CAD/CAM blocks for dental restorations. Comput Methods Biomech Biomed Engin. 23:S31–2. DOI: 10.1080/10255842.2020.1811501.

Article9. Lebon N, Tapie L, Vennat E, Mawussi B. 2015; Influence of CAD/CAM tool and material on tool wear and roughness of dental prostheses after milling. J Prosthet Dent. 114:236–47. DOI: 10.1016/j.prosdent.2014.12.021. PMID: 25957240.

Article10. Burgess JO. 2018; Zirconia: The material, its evolution, and composition. Compend Contin Educ Dent. 39:4–8. PMID: 30299108.11. Saridag S, Tak O, Alniacik G. 2013; Basic properties and types of zirconia: An overview. World J Stomatol. 2:40–7. DOI: 10.5321/wjs.v2.i3.40.

Article12. Michailova M, Elsayed A, Fabel G, Edelhoff D, Zylla IM, Stawarczyk B. 2020; Comparison between novel strength-gradient and color-gradient multilayered zirconia using conventional and high-speed sintering. J Mech Behav Biomed Mater. 111:103977. DOI: 10.1016/j.jmbbm.2020.103977. PMID: 32799133.

Article13. Rosentritt M, Preis V, Schmid A, Strasser T. 2022; Multilayer zirconia: Influence of positioning within blank and sintering conditions on the in vitro performance of 3-unit fixed partial dentures. J Prosthet Dent. 127:141–5. DOI: 10.1016/j.prosdent.2020.11.009. PMID: 33386137.14. Suzuki S, Katsuta Y, Ueda K, Watanabe F. 2020; Marginal and internal fit of three-unit zirconia fixed dental prostheses: Effects of prosthesis design, cement space, and zirconia type. J Prosthodont Res. 64:460–7. DOI: 10.1016/j.jpor.2019.12.005. PMID: 32276830.

Article15. Ueda K, Watanabe F, Katsuta Y, Seto M, Ueno D, Hiroyasu K, Suzuki S, Erdelt K, Güth JF. 2021; Marginal and internal fit of three-unit fixed dental prostheses fabricated from translucent multicolored zirconia: Framework versus complete contour design. J Prosthet Dent. 125:340.e1–6. DOI: 10.1016/j.prosdent.2020.08.023. PMID: 33198991.

Article16. Oghbaei M, Mirzaee O. 2010; Microwave versus conventional sintering: A review of fundamentals, advantages and applications. J Alloys Compounds. 494:175–89. DOI: 10.1016/j.jallcom.2010.01.068.

Article17. Luz JN, Kaizer MDR, Ramos NC, Anami LC, Thompson VP, Saavedra G, Zhang Y. 2021; Novel speed sintered zirconia by microwave technology. Dent Mater. 37:875–81. DOI: 10.1016/j.dental.2021.02.026. PMID: 33715863.

Article18. Lawson NC, Maharishi A. 2020; Strength and translucency of zirconia after high-speed sintering. J Esthet Restor Dent. 32:219–25. DOI: 10.1111/jerd.12524. PMID: 31515932.

Article19. Stawarczyk B, Ozcan M, Hallmann L, Ender A, Mehl A, Hammerlet CH. 2013; The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Investig. 17:269–74. DOI: 10.1007/s00784-012-0692-6. PMID: 22358379.

Article20. Grambow J, Wille S, Kern M. 2021; Impact of changes in sintering temperatures on characteristics of 4YSZ and 5YSZ. J Mech Behav Biomed Mater. 120:104586. DOI: 10.1016/j.jmbbm.2021.104586. PMID: 34044252.

Article21. Too TDC, Inokoshi M, Nozaki K, Shimizubata M, Nakai H, Liu H, Minakuchi S. 2021; Influence of sintering conditions on translucency, biaxial flexural strength, microstructure, and low-temperature degradation of highly translucent dental zirconia. Dent Mater J. 40:1320–8. DOI: 10.4012/dmj.2020-448. PMID: 34193728.

Article22. Kilinc H, Sanal FA. 2021; Effect of sintering and aging processes on the mechanical and optical properties of translucent zirconia. J Prosthet Dent. 126:129.e1–7. DOI: 10.1016/j.prosdent.2021.03.024. PMID: 33965239.

Article23. Ebeid K, Wille S, Hamdy A, Salah T, El-Etreby A, Kern M. 2014; Effect of changes in sintering parameters on monolithic translucent zirconia. Dent Mater. 30:e419–24. DOI: 10.1016/j.dental.2014.09.003. PMID: 25262211.

Article24. Durkan R, Şimşek H, Deste Gökay G, Yilmaz B. 2021; Effects of sintering time on translucency and color of translucent zirconia ceramics. J Esthet Restor Dent. 33:654–9. DOI: 10.1111/jerd.12723. PMID: 33638578.

Article25. Sato T, Ishitsuka M, Shimada M. 1988; Thermal shock resistance of ZrO2 based ceramics. Mater Des. 9:204–12. DOI: 10.1016/0261-3069(88)90032-5.

Article26. Kaizer MR, Gierthmuehlen PC, Dos Santos MB, Cava SS, Zhang Y. 2017; Speed sintering translucent zirconia for chairside one-visit dental restorations: Optical, mechanical, and wear characteristics. Ceram Int. 43:10999–1005. DOI: 10.1016/j.ceramint.2017.05.141. PMID: 29097830. PMCID: PMC5662116.

Article27. Yang CC, Ding SJ, Lin TH, Yan M. 2020; Mechanical and optical properties evaluation of rapid sintered dental zirconia. Ceram Int. 46:26668–74. DOI: 10.1016/j.ceramint.2020.07.137.

Article28. Asaad R, Aboushahba ME. 2020; Influence of different sintering protocols on translucency and fracture resistance of monolithic zirconia crowns. Egypt Dent J. 66:2649–60. DOI: 10.21608/edj.2020.42653.1257.

Article29. Kim KB, Kim JH, Lee KW. 2009; The influence of microwave sintering process on the adaptation of CAD/CAM zirconia core. J Dent Rehabil Appl Sci. 25:95–107.30. Monaco C, Prete F, Leonelli C, Esposito L, Tucci A. 2015; Microstructural study of microwave sintered zirconia for dental applications. Ceram Int. 41:1255–61. DOI: 10.1016/j.ceramint.2014.09.055.

Article31. Ramesh S, Zulkifli NI, Tan CY, Wong YH, Tarlochan F, Ramesh S, Teng W, Sopyan I, Bang LT, Sarhan AAD. 2018; Comparison between microwave and conventional sintering on the properties and microstructural evolution of tetragonal zirconia. Ceram Int. 44:8922–7. DOI: 10.1016/j.ceramint.2018.02.086.

Article32. Cokic SM, Vleugels J, Van Meerbeek B, Camargo B, Willems E, Li M, Zhang F. 2020; Mechanical properties, aging stability and translucency of speed-sintered zirconia for chairside restorations. Dent Mater. 36:959–72. DOI: 10.1016/j.dental.2020.04.026. PMID: 32493658.

Article33. Liu H, Inokoshi M, Nozaki K, Shimizubata M, Nakai H, Cho Too TD, Minakuchi S. 2022; Influence of high-speed sintering protocols on translucency, mechanical properties, microstructure, crystallography, and low-temperature degradation of highly translucent zirconia. Dent Mater. 38:451–68. DOI: 10.1016/j.dental.2021.12.028. PMID: 34961644.

Article34. Ahmed WM, Abdallah MN, McCullagh AP, Wyatt CCL, Troczynski T, Carvalho RM. 2019; Marginal discrepancies of monolithic zirconia crowns: The influence of preparation designs and sintering techniques. J Prosthodont. 28:288–98. DOI: 10.1111/jopr.13021. PMID: 30656786.

Article35. Nakamura T, Nakano Y, Usami H, Okamura S, Wakabayashi K, Yatani H. 2020; In vitro investigation of fracture load and aging resistance of high-speed sintered monolithic tooth-borne zirconia crowns. J Prosthodont Res. 64:182–7. DOI: 10.1016/j.jpor.2019.07.003. PMID: 31699614.

Article36. Elisa Kauling A, Güth JF, Erdelt K, Edelhoff D, Keul C. 2020; Influence of speed sintering on the fit and fracture strength of 3-unit monolithic zirconia fixed partial dentures. J Prosthet Dent. 124:380–6. DOI: 10.1016/j.prosdent.2019.09.003. PMID: 31780110.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Review on factors affecting the optical properties of dental zirconia

- Comparative clinical study of the marginal discrepancy of fixed dental prosthesis fabricated by the milling-sintering method using a presintered alloy

- The dimension analysis of prepared natural teeth for developing customized zirconia block

- Effect of sintering condition and aging on hardness and optical properties of monolithic zirconia

- Effect of sintering programs and surface treatments on monolithic zirconia