J Korean Assoc Oral Maxillofac Surg.

2023 Jun;49(3):114-124. 10.5125/jkaoms.2023.49.3.114.

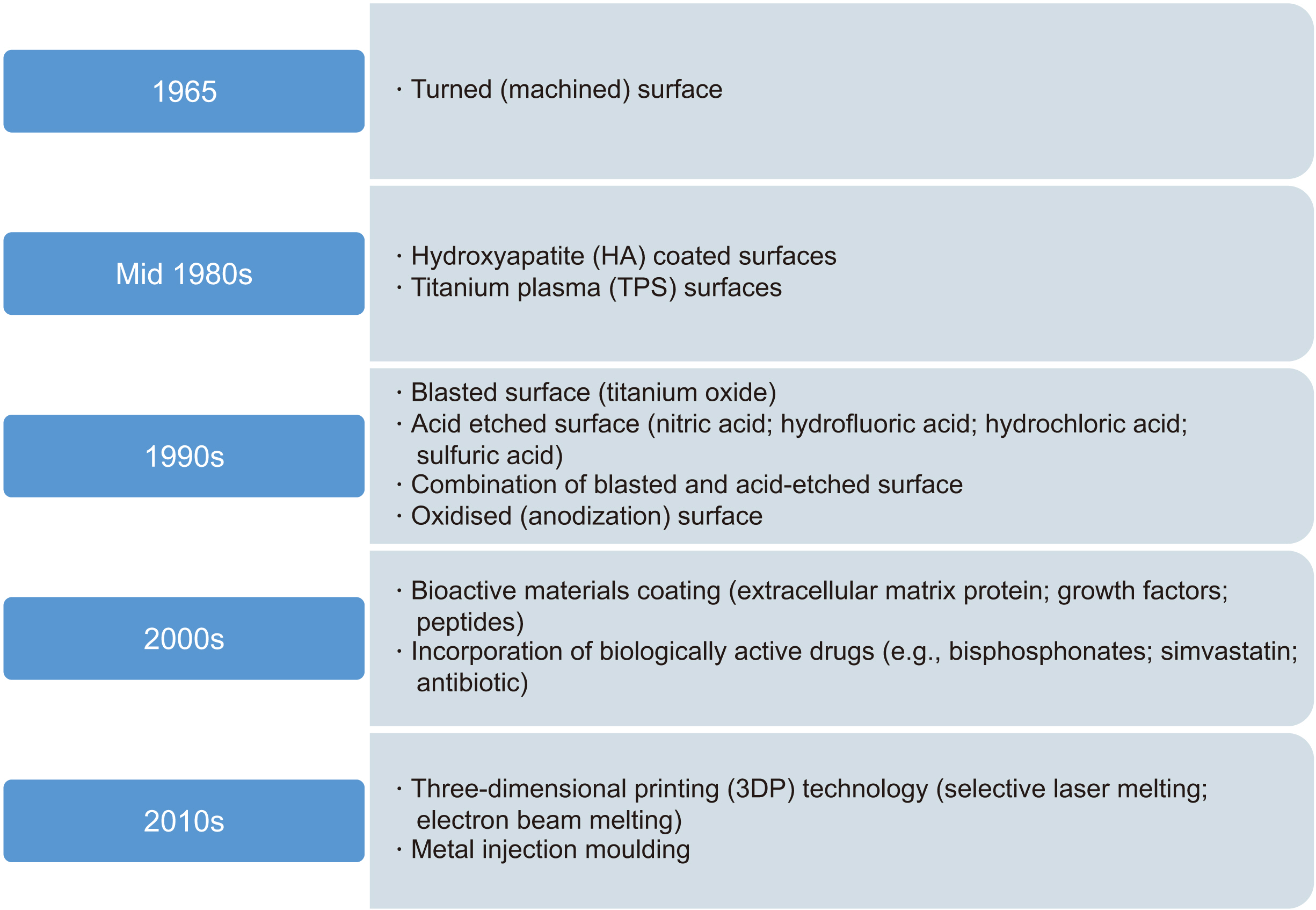

Surface structure characteristics of dental implants and their potential changes following installation: a literature review

- Affiliations

-

- 1Department of Conservative Dentistry and Prosthodontics, Faculty of Dentistry, Srinakharinwirot University, Bangkok, Thailand

- 2Department of Oral and Maxillofacial Surgery, Faculty of Dentistry, Chulalongkorn University, Bangkok, Thailand

- 3The Engineering Institute of Thailand under H.M. The King’s Patronage, Bangkok, Thailand

- 4Department of General Dentistry, Faculty of Dentistry, Srinakharinwirot University, Bangkok, Thailand

- 5Department of Oral and Maxillofacial Surgery, Faculty of Dentistry, Bangkokthonburi University, Bangkok, Thailand

- KMID: 2544313

- DOI: http://doi.org/10.5125/jkaoms.2023.49.3.114

Abstract

- Dental implants have been utilized for many years to treat individuals with missing teeth. To optimize the long-term success rate of such implants, new designs, surfaces, and materials have been analyzed. It is important for the clinician to have a background in the field of implant surface design, to be familiar with the strengths and limitations of the available options, and to be aware of the alterations in surface structure that may occur following installation. This article provides a detailed review of the structure and the surface characteristics of dental implants, the modifications of implant surface, as well as the methods of evaluating implant surface structure. Moreover, it provides information concerning the structural changes that may take place at the time of dental implant placement. It is important for clinicians to be aware of such changes to plan and execute implant procedures with the highest possible success and implant survival rates.

Figure

Reference

-

References

1. De Bruyn H, Christiaens V, Doornewaard R, Jacobsson M, Cosyn J, Jacquet W, et al. 2017; Implant surface roughness and patient factors on long-term peri-implant bone loss. Periodontol 2000. 73:218–27. https://doi.org/10.1111/prd.12177. DOI: 10.1111/prd.12177. PMID: 28000269.

Article2. Adell R, Lekholm U, Rockler B, Brånemark PI. 1981; A 15-year study of osseointegrated implants in the treatment of the edentulous jaw. Int J Oral Surg. 10:387–416. https://doi.org/10.1016/s0300-9785(81)80077-4. DOI: 10.1016/S0300-9785(81)80077-4. PMID: 6809663.

Article3. Berbel LO, Banczek EDP, Karoussis IK, Kotsakis GA, Costa I. 2019; Determinants of corrosion resistance of Ti-6Al-4V alloy dental implants in an in vitro model of peri-implant inflammation. PLoS One. 14:e0210530. https://doi.org/10.1371/journal.pone.0210530. DOI: 10.1371/journal.pone.0210530. PMID: 30703125. PMCID: PMC6354969.

Article4. Wennerberg A, Albrektsson T, Ulrich H, Krol JJ. 1992; An optical three-dimensional technique for topographical descriptions of surgical implants. J Biomed Eng. 14:412–8. https://doi.org/10.1016/0141-5425(92)90087-2. DOI: 10.1016/0141-5425(92)90087-2. PMID: 1405559.

Article5. Guan H, van Staden RC, Johnson NW, Loo YC. 2011; Dynamic modelling and simulation of dental implant insertion process-a finite element study. Finite Elem Anal Des. 47:886–97. https://doi.org/10.1016/j.finel.2011.03.005. DOI: 10.1016/j.finel.2011.03.005.

Article6. Albrektsson T, Brånemark PI, Hansson HA, Lindström J. 1981; Osseointegrated titanium implants. Requirements for ensuring a long-lasting, direct bone-to-implant anchorage in man. Acta Orthop Scand. 52:155–70. https://doi.org/10.3109/17453678108991776. DOI: 10.3109/17453678108991776. PMID: 7246093.

Article7. Albrektsson T, Buser D, Chen ST, Cochran D, DeBruyn H, Jemt T, et al. 2012; Statements from the Estepona consensus meeting on peri-implantitis, February 2-4, 2012. Clin Implant Dent Relat Res. 14:781–2. https://doi.org/10.1111/cid.12017. DOI: 10.1111/cid.12017. PMID: 23205721.

Article8. Adler L, Liedholm E, Silvegren M, Modin C, Buhlin K, Jansson L. 2016; Patient satisfaction 8-14 years after dental implant therapy - a questionnaire study. Acta Odontol Scand. 74:423–9. https://doi.org/10.1080/00016357.2016.1177661. DOI: 10.1080/00016357.2016.1177661. PMID: 27136739.

Article9. Testori T, Clauser C, Deflorian M, Capelli M, Zuffetti F, Fabbro MD. 2016; A retrospective analysis of the effectiveness of the longevity protocol for assessing the risk of implant failure. Clin Implant Dent Relat Res. 18:1113–8. https://doi.org/10.1111/cid.12428. DOI: 10.1111/cid.12428. PMID: 27271293.

Article10. Albrektsson T, Jacobsson M. 1987; Bone-metal interface in osseointegration. J Prosthet Dent. 57:597–607. https://doi.org/10.1016/0022-3913(87)90344-1. DOI: 10.1016/0022-3913(87)90344-1. PMID: 3298630.

Article11. Junker R, Dimakis A, Thoneick M, Jansen JA. 2009; Effects of implant surface coatings and composition on bone integration: a systematic review. Clin Oral Implants Res. 20 Suppl 4:185–206. https://doi.org/10.1111/j.1600-0501.2009.01777.x. DOI: 10.1111/j.1600-0501.2009.01777.x. PMID: 19663965.

Article12. Terheyden H, Lang NP, Bierbaum S, Stadlinger B. 2012; Osseointegration--communication of cells. Clin Oral Implants Res. 23:1127–35. https://doi.org/10.1111/j.1600-0501.2011.02327.x. DOI: 10.1111/j.1600-0501.2011.02327.x. PMID: 22092345.

Article13. Davies JE. 2003; Understanding peri-implant endosseous healing. J Dent Educ. 67:932–49. DOI: 10.1002/j.0022-0337.2003.67.8.tb03681.x. PMID: 12959168.

Article14. Glauser R, Schüpbach P, Gottlow J, Hämmerle CH. 2005; Periimplant soft tissue barrier at experimental one-piece mini-implants with different surface topography in humans: a light-microscopic overview and histometric analysis. Clin Implant Dent Relat Res. 7 Suppl 1:S44–51. https://doi.org/10.1111/j.1708-8208.2005.tb00074.x. DOI: 10.1111/j.1708-8208.2005.tb00074.x. PMID: 16137087.

Article15. Cochran D, Oates T, Morton D, Jones A, Buser D, Peters F. 2007; Clinical field trial examining an implant with a sand-blasted, acid-etched surface. J Periodontol. 78:974–82. https://doi.org/10.1902/jop.2007.060294. DOI: 10.1902/jop.2007.060294. PMID: 17539708.

Article16. Schwartz Z, Nasazky E, Boyan BD. 2005; Surface microtopography regulates osteointegration: the role of implant surface microtopography in osteointegration. Alpha Omegan. 98:9–19. PMID: 16122142.17. Jorge JR, Barão VA, Delben JA, Faverani LP, Queiroz TP, Assunção WG. 2013; Titanium in dentistry: historical development, state of the art and future perspectives. J Indian Prosthodont Soc. 13:71–7. https://doi.org/10.1007/s13191-012-0190-1. DOI: 10.1007/s13191-012-0190-1. PMID: 24431713. PMCID: PMC3634937.

Article18. Peñarrocha-Oltra D, Peñarrocha-Diago M, Canullo L, Covani U, Peñarrocha M. 2014; Patient-reported outcomes of immediate versus conventional loading with fixed full-arch prostheses in the maxilla: a nonrandomized controlled prospective study. Int J Oral Maxillofac Implants. 29:690–8. https://doi.org/10.11607/jomi.3516. DOI: 10.11607/jomi.3516. PMID: 24818209.

Article19. Dharmayanti AWS, Dubey R, Dubey NK, Deng WP. Pal K, Banerjee I, Sarkar P, Kim D, Deng WP, Dubey NK, editors. 2020. Implant surface modification strategies through antibacterial and bioactive components. Biopolymer-based formulations: biomedical and food applications. Elsevier;p. 647–73. DOI: 10.1016/B978-0-12-816897-4.00026-6.

Article20. Bencharit S, Byrd WC, Hosseini B. 2015; Immediate placement of a porous-tantalum, trabecular metal-enhanced titanium dental implant with demineralized bone matrix into a socket with deficient buccal bone: a clinical report. J Prosthet Dent. 113:262–9. https://doi.org/10.1016/j.prosdent.2014.09.022. DOI: 10.1016/j.prosdent.2014.09.022. PMID: 25702965. PMCID: PMC4380789.

Article21. Andani MT, Shayesteh Moghaddam N, Haberland C, Dean D, Miller MJ, Elahinia M. 2014; Metals for bone implants. Part 1. Powder metallurgy and implant rendering. Acta Biomater. 10:4058–70. https://doi.org/10.1016/j.actbio.2014.06.025. DOI: 10.1016/j.actbio.2014.06.025. PMID: 24956564.

Article22. Albrektsson T, Wennerberg A. 2004; Oral implant surfaces: part 2--review focusing on clinical knowledge of different surfaces. Int J Prosthodont. 17:544–64. PMID: 15543911.23. Albrektsson T, Wennerberg A. 2004; Oral implant surfaces: part 1--review focusing on topographic and chemical properties of different surfaces and in vivo responses to them. Int J Prosthodont. 17:536–43. PMID: 15543910.24. Dohan Ehrenfest DM, Coelho PG, Kang BS, Sul YT, Albrektsson T. 2010; Classification of osseointegrated implant surfaces: materials, chemistry and topography. Trends Biotechnol. 28:198–206. https://doi.org/10.1016/j.tibtech.2009.12.003. DOI: 10.1016/j.tibtech.2009.12.003. PMID: 20116873.

Article25. Wennerberg A, Galli S, Albrektsson T. 2011; Current knowledge about the hydrophilic and nanostructured SLActive surface. Clin Cosmet Investig Dent. 3:59–67. https://doi.org/10.2147/cciden.s15949. DOI: 10.2147/CCIDEN.S15949. PMID: 23674916. PMCID: PMC3652359.

Article26. Dohan Ehrenfest DM, Vazquez L, Park YJ, Sammartino G, Bernard JP. 2011; Identification card and codification of the chemical and morphological characteristics of 14 dental implant surfaces. J Oral Implantol. 37:525–42. https://doi.org/10.1563/aaid-joi-d-11-00080. DOI: 10.1563/AAID-JOI-D-11-00080. PMID: 21728785.

Article27. Wennerberg A, Albrektsson T. 2000; Suggested guidelines for the topographic evaluation of implant surfaces. Int J Oral Maxillofac Implants. 15:331–44. PMID: 10874798.28. Rupp F, Scheideler L, Rehbein D, Axmann D, Geis-Gerstorfer J. 2004; Roughness induced dynamic changes of wettability of acid etched titanium implant modifications. Biomaterials. 25:1429–38. https://doi.org/10.1016/j.biomaterials.2003.08.015. DOI: 10.1016/j.biomaterials.2003.08.015. PMID: 14643618.

Article29. Wennerberg A, Albrektsson T, Andersson B, Krol JJ. 1995; A histomorphometric and removal torque study of screw-shaped titanium implants with three different surface topographies. Clin Oral Implants Res. 6:24–30. https://doi.org/10.1034/j.1600-0501.1995.060103.x. DOI: 10.1034/j.1600-0501.1995.060103.x. PMID: 7669864.

Article30. Barfeie A, Wilson J, Rees J. 2015; Implant surface characteristics and their effect on osseointegration. Br Dent J. 218:E9. https://doi.org/10.1038/sj.bdj.2015.171. DOI: 10.1038/sj.bdj.2015.171. PMID: 25766196.

Article31. Coelho PG, Jimbo R, Tovar N, Bonfante EA. 2015; Osseointegration: hierarchical designing encompassing the macrometer, micrometer, and nanometer length scales. Dent Mater. 31:37–52. https://doi.org/10.1016/j.dental.2014.10.007. DOI: 10.1016/j.dental.2014.10.007. PMID: 25467952.

Article32. Kligman S, Ren Z, Chung CH, Perillo MA, Chang YC, Koo H, et al. 2021; The impact of dental implant surface modifications on osseointegration and biofilm formation. J Clin Med. 10:1641. https://doi.org/10.3390/jcm10081641. DOI: 10.3390/jcm10081641. PMID: 33921531. PMCID: PMC8070594.

Article33. Franchi M, Bacchelli B, Martini D, Pasquale VD, Orsini E, Ottani V, et al. 2004; Early detachment of titanium particles from various different surfaces of endosseous dental implants. Biomaterials. 25:2239–46. https://doi.org/10.1016/j.biomaterials.2003.09.017. DOI: 10.1016/j.biomaterials.2003.09.017. PMID: 14741589.

Article34. Arciola CR, Selan L, Battaglia R, Imbriani M, Rizzo S, et al. Rodriguez y Baena R. 2012; Evaluation of bacterial adhesion on machined titanium, Osseotite® and Nanotite® discs. Int J Artif Organs. 35:754–61. https://doi.org/10.5301/ijao.5000143. DOI: 10.5301/ijao.5000143. PMID: 23065893.

Article35. Nevins M, Kim DM, Jun SH, Guze K, Schupbach P, Nevins ML. 2010; Histologic evidence of a connective tissue attachment to laser microgrooved abutments: a canine study. Int J Periodontics Restorative Dent. 30:245–55. PMID: 20386781.36. Zechner W, Tangl S, Fürst G, Tepper G, Thams U, Mailath G, et al. 2003; Osseous healing characteristics of three different implant types. Clin Oral Implants Res. 14:150–7. https://doi.org/10.1034/j.1600-0501.2003.140203.x. DOI: 10.1034/j.1600-0501.2003.140203.x. PMID: 12656873.

Article37. Smeets R, Stadlinger B, Schwarz F, Beck-Broichsitter B, Jung O, Precht C, et al. 2016; Impact of dental implant surface modifications on osseointegration. Biomed Res Int. 2016:6285620. https://doi.org/10.1155/2016/6285620. DOI: 10.1155/2016/6285620. PMID: 27478833. PMCID: PMC4958483.

Article38. Coelho PG, Granjeiro JM, Romanos GE, Suzuki M, Silva NR, Cardaropoli G, et al. 2009; Basic research methods and current trends of dental implant surfaces. J Biomed Mater Res B Appl Biomater. 88:579–96. https://doi.org/10.1002/jbm.b.31264. DOI: 10.1002/jbm.b.31264. PMID: 18973274.

Article39. Kim HG, Yun PY, Kim YK, Kim IH. 2021; Comparison of sandblasted and acid-etched surface implants and new hydrophilic surface implants in the posterior maxilla using a 3-month early-loading protocol: a randomized controlled trial. J Korean Assoc Oral Maxillofac Surg. 47:175–82. https://doi.org/10.5125/jkaoms.2021.47.3.175. DOI: 10.5125/jkaoms.2021.47.3.175. PMID: 34187957. PMCID: PMC8249194.

Article40. Wennerberg A, Albrektsson T, Andersson B. 1995; An animal study of c.p. titanium screws with different surface topographies. J Mater Sci Mater Med. 6:302–9. https://doi.org/10.1007/BF00120275. DOI: 10.1007/BF00120275.

Article41. Wennerberg A, Ohlsson R, Rosén BG, Andersson B. 1996; Characterizing three-dimensional topography of engineering and biomaterial surfaces by confocal laser scanning and stylus techniques. Med Eng Phys. 18:548–56. https://doi.org/10.1016/1350-4533(95)00005-4. DOI: 10.1016/1350-4533(95)00005-4. PMID: 8892239.

Article42. Baró AM, García N, Miranda R, Vázquez L, Aparicio C, Olivé J, et al. 1986; Characterization of surface roughness in titanium dental implants measured with scanning tunnelling microscopy at atmospheric pressure. Biomaterials. 7:463–6. https://doi.org/10.1016/0142-9612(86)90036-0. DOI: 10.1016/0142-9612(86)90036-0. PMID: 3790677.

Article43. Wieland M, Textor M, Spencer ND, Brunette DM. 2001; Wavelength-dependent roughness: a quantitative approach to characterizing the topography of rough titanium surfaces. Int J Oral Maxillofac Implants. 16:163–81. PMID: 11324205.44. Gittens RA, McLachlan T, Olivares-Navarrete R, Cai Y, Berner S, Tannenbaum R, et al. 2011; The effects of combined micron-/submicron-scale surface roughness and nanoscale features on cell proliferation and differentiation. Biomaterials. 32:3395–403. https://doi.org/10.1016/j.biomaterials.2011.01.029. DOI: 10.1016/j.biomaterials.2011.01.029. PMID: 21310480. PMCID: PMC3350795.

Article45. Shalabi MM, Gortemaker A, Van't Hof MA, Jansen JA, Creugers NH. 2006; Implant surface roughness and bone healing: a systematic review. J Dent Res. 85:496–500. https://doi.org/10.1177/154405910608500603. DOI: 10.1177/154405910608500603. PMID: 16723643.

Article46. Linkow L, Cherchève R. 1970. Theories and techniques of oral implantology. Mosby;St. Louis (MO): p. 1. DOI: 10.1177/154405910608500603.47. Adell R. 1985; Tissue integrated prostheses in clinical dentistry. Int Dent J. 35:259–65. PMID: 3912327.48. Misch CE. 1988; Bone character: second vital implant criterion. Dent Today. 7:39–40.49. Choi YJ, Jun SH, Song YD, Chang MW, Kwon JJ. Subburaj K, editor. 2011. CT scanning and dental implant. CT scanning - techniques and applications. IntechOpen;DOI: 10.5772/19250.

Article50. Seriwatanachai D, Kiattavorncharoen S, Suriyan N, Boonsiriseth K, Wongsirichat N. 2015; Reference and techniques used in alveolar bone classification. J Interdiscipl Med Dent Sci. 3:172. DOI: 10.4172/2376-032X.1000172.

Article51. Turkyilmaz I, McGlumphy EA. 2008; Influence of bone density on implant stability parameters and implant success: a retrospective clinical study. BMC Oral Health. 8:32. https://doi.org/10.1186/1472-6831-8-32. DOI: 10.1186/1472-6831-8-32. PMID: 19025637. PMCID: PMC2614413.

Article52. Checa S, Prendergast PJ. 2010; Effect of cell seeding and mechanical loading on vascularization and tissue formation inside a scaffold: a mechano-biological model using a lattice approach to simulate cell activity. J Biomech. 43:961–8. https://doi.org/10.1016/j.jbiomech.2009.10.044. DOI: 10.1016/j.jbiomech.2009.10.044. PMID: 19954779.

Article53. Alam K, Qamar SZ, Iqbal M, Piya S, Al-Kindi M, Qureshi A, et al. 2023; Effect of drill quality on biological damage in bone drilling. Sci Rep. 13:6234. https://doi.org/10.1038/s41598-023-33381-y. DOI: 10.1038/s41598-023-33381-y. PMID: 37069203. PMCID: PMC10110507.

Article54. Freitas AC Jr, Bonfante EA, Giro G, Janal MN, Coelho PG. 2012; The effect of implant design on insertion torque and immediate micromotion. Clin Oral Implants Res. 23:113–8. https://doi.org/10.1111/j.1600-0501.2010.02142.x. DOI: 10.1111/j.1600-0501.2010.02142.x. PMID: 21426405.

Article55. Neugebauer J, Traini T, Thams U, Piattelli A, Zöller JE. 2006; Peri-implant bone organization under immediate loading state. Circularly polarized light analyses: a minipig study. J Periodontol. 77:152–60. https://doi.org/10.1902/jop.2006.040360. DOI: 10.1902/jop.2006.040360. PMID: 16460238.

Article56. Duyck J, Corpas L, Vermeiren S, Ogawa T, Quirynen M, Vandamme K, et al. 2010; Histological, histomorphometrical, and radiological evaluation of an experimental implant design with a high insertion torque. Clin Oral Implants Res. 21:877–84. https://doi.org/10.1111/j.1600-0501.2010.01895.x. DOI: 10.1111/j.1600-0501.2010.01895.x. PMID: 20528892.

Article57. Rosa MB, Albrektsson T, Francischone CE, Filho HO, Wennerberg A. 2013; Micrometric characterization of the implant surfaces from the five largest companies in Brazil, the second largest worldwide implant market. Int J Oral Maxillofac Implants. 28:358–65. https://doi.org/10.11607/jomi.2791. DOI: 10.11607/jomi.2791. PMID: 23527375.

Article58. Rodrigo D, Aracil L, Martin C, Sanz M. 2010; Diagnosis of implant stability and its impact on implant survival: a prospective case series study. Clin Oral Implants Res. 21:255–61. https://doi.org/10.1111/j.1600-0501.2009.01820.x. DOI: 10.1111/j.1600-0501.2009.01820.x. PMID: 19958375.

Article59. Tabassum A, Meijer GJ, Wolke JG, Jansen JA. 2010; Influence of surgical technique and surface roughness on the primary stability of an implant in artificial bone with different cortical thickness: a laboratory study. Clin Oral Implants Res. 21:213–20. https://doi.org/10.1111/j.1600-0501.2009.01823.x. DOI: 10.1111/j.1600-0501.2009.01823.x. PMID: 20070754.

Article60. Mints D, Elias C, Funkenbusch P, Meirelles L. 2014; Integrity of implant surface modifications after insertion. Int J Oral Maxillofac Implants. 29:97–104. https://doi.org/10.11607/jomi.3259. DOI: 10.11607/jomi.3259. PMID: 24451859.

Article61. Senna P, Antoninha Del Bel Cury A, Kates S, Meirelles L. 2015; Surface damage on dental implants with release of loose particles after insertion into bone. Clin Implant Dent Relat Res. 17:681–92. https://doi.org/10.1111/cid.12167. DOI: 10.1111/cid.12167. PMID: 24283455. PMCID: PMC4420732.

Article62. Robert-Perron E, Blais C, Thomas Y, Pelletier S, Dionne M. 2005; An integrated approach to the characterization of powder metallurgy components performance during green machining. Mater Sci Eng A. 402:325–34. https://doi.org/10.1016/j.msea.2005.05.019. DOI: 10.1016/j.msea.2005.05.019.

Article63. Meyer U, Bühner M, Büchter A, Kruse-Lösler B, Stamm T, Wiesmann HP. 2006; Fast element mapping of titanium wear around implants of different surface structures. Clin Oral Implants Res. 17:206–11. https://doi.org/10.1111/j.1600-0501.2005.01184.x. DOI: 10.1111/j.1600-0501.2005.01184.x. PMID: 16584417.

Article64. Flatebø RS, Johannessen AC, Grønningsaeter AG, Bøe OE, Gjerdet NR, Grung B, et al. 2006; Host response to titanium dental implant placement evaluated in a human oral model. J Periodontol. 77:1201–10. https://doi.org/10.1902/jop.2006.050406. DOI: 10.1902/jop.2006.050406. PMID: 16805683.

Article65. Salerno M, Itri A, Frezzato M, Rebaudi A. 2015; Surface microstructure of dental implants before and after insertion: an in vitro study by means of scanning probe microscopy. Implant Dent. 24:248–55. https://doi.org/10.1097/id.0000000000000244. DOI: 10.1097/ID.0000000000000244. PMID: 25853585.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Factors Affecting Survival of Maxillary Sinus Augmented Implants

- Techniques for dental implant nanosurface modifications

- Comparison of Clinical Initial Stability of Hydroxy-apatite Coated Implant and Sandblasted, Large-grit and Acid-etched Implant

- Short dental implants in the posterior maxilla: a review of the literature

- Clinical outcome of immediately and early loaded implants with laser treated surface: a 3-year retrospective study