J Dent Rehabil Appl Sci.

2020 Jun;36(2):128-137. 10.14368/jdras.2020.36.2.128.

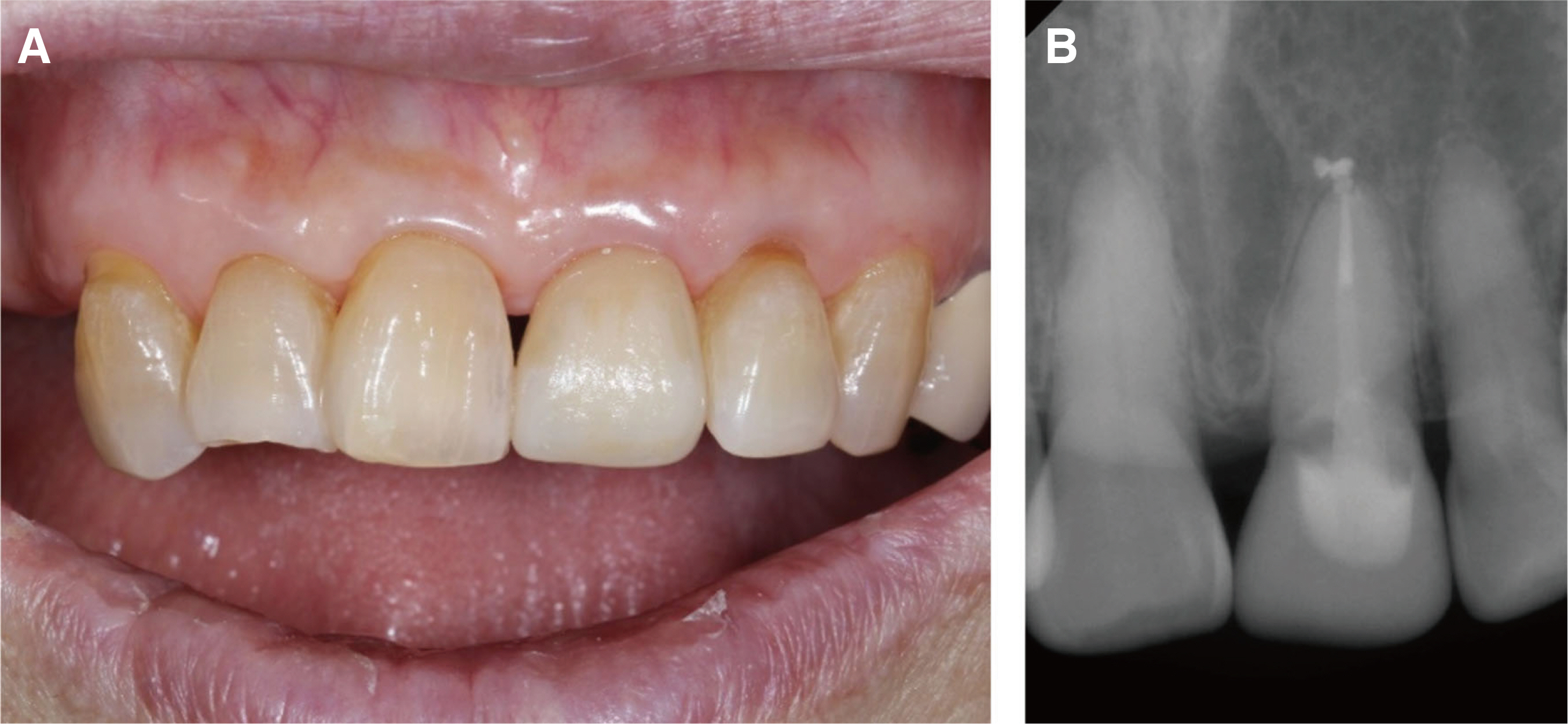

Chairside computer-aided design/computer-aided manufacturing (CAD/ CAM)-based restoration of anterior teeth with customized shade and surface characterization: a report of 2 cases

- Affiliations

-

- 1Department of Conservative Dentistry, Kyung Hee University Dental Hospital, Seoul, Republic of Korea

- 2Department of Conservative Dentistry, School of Dentistry, Kyung Hee University, Seoul, Republic of Korea

- 3GoodWill Dental Hospital, Busan, Republic of Korea

- KMID: 2503809

- DOI: http://doi.org/10.14368/jdras.2020.36.2.128

Abstract

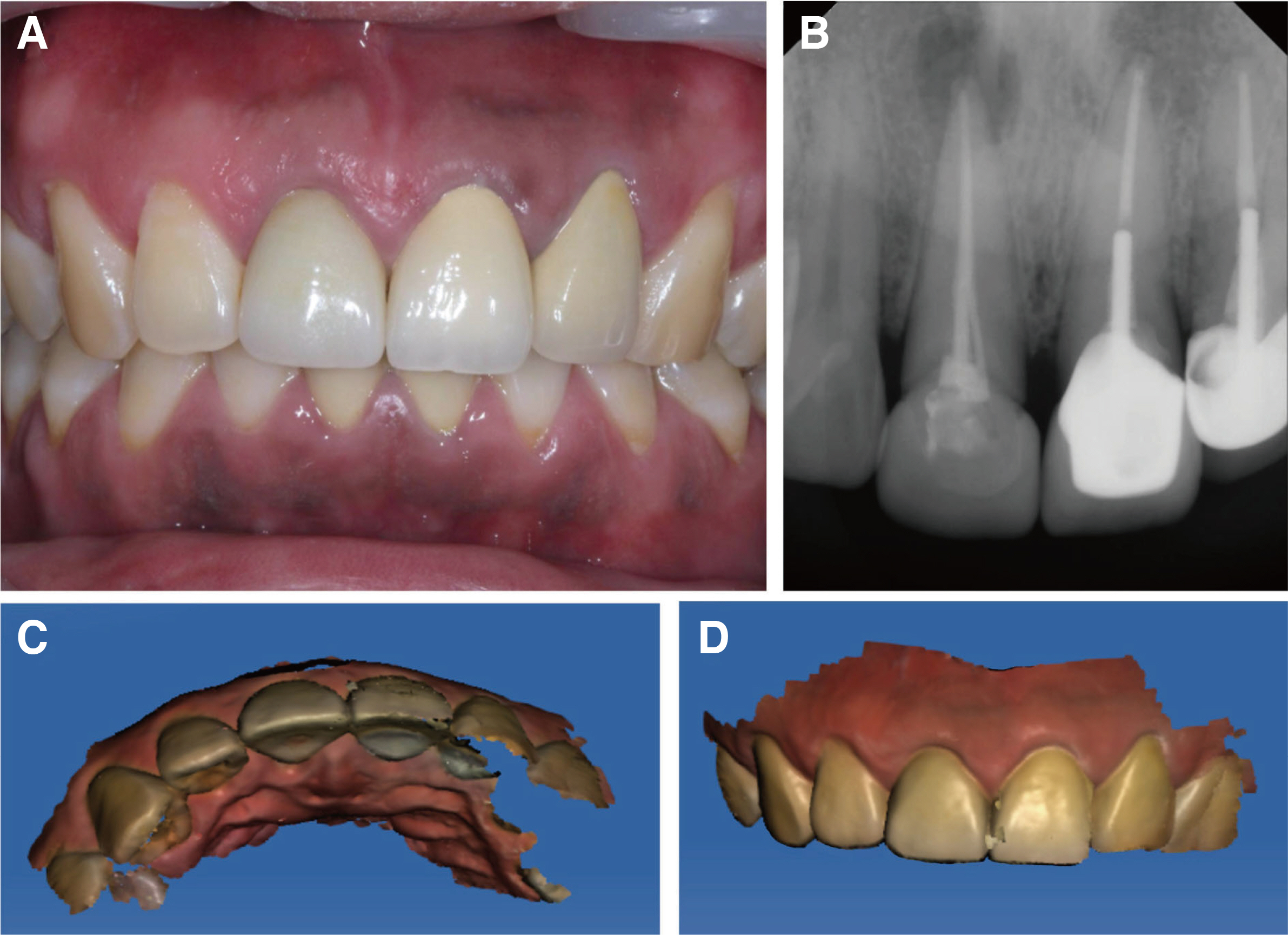

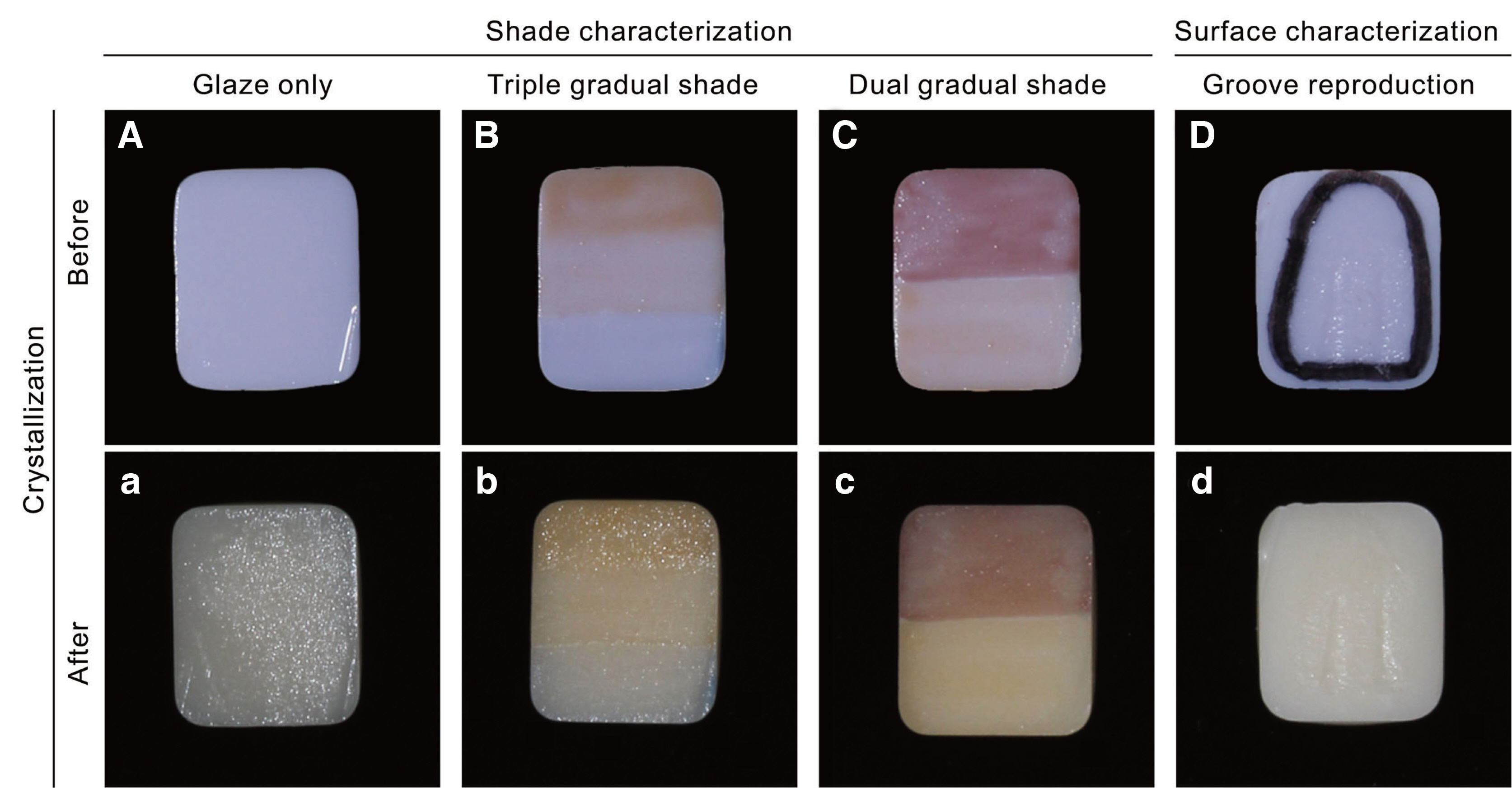

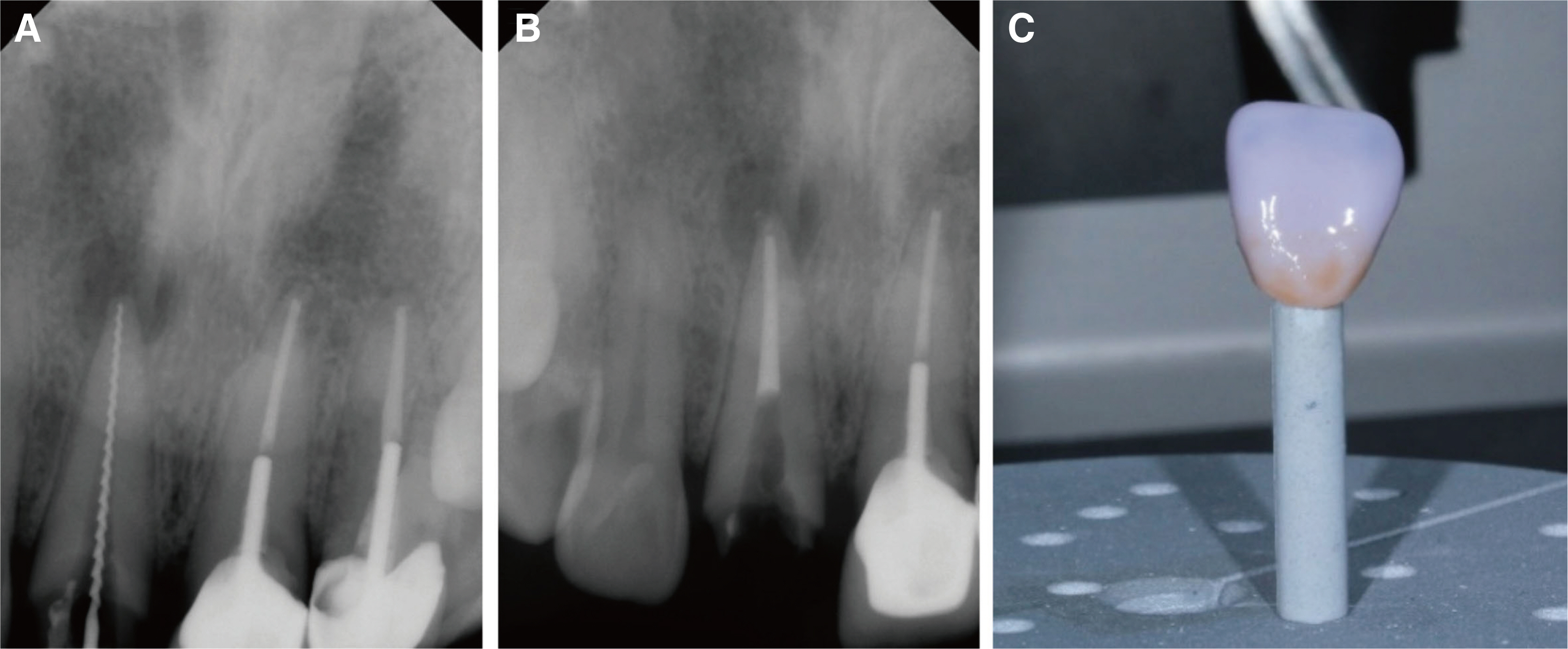

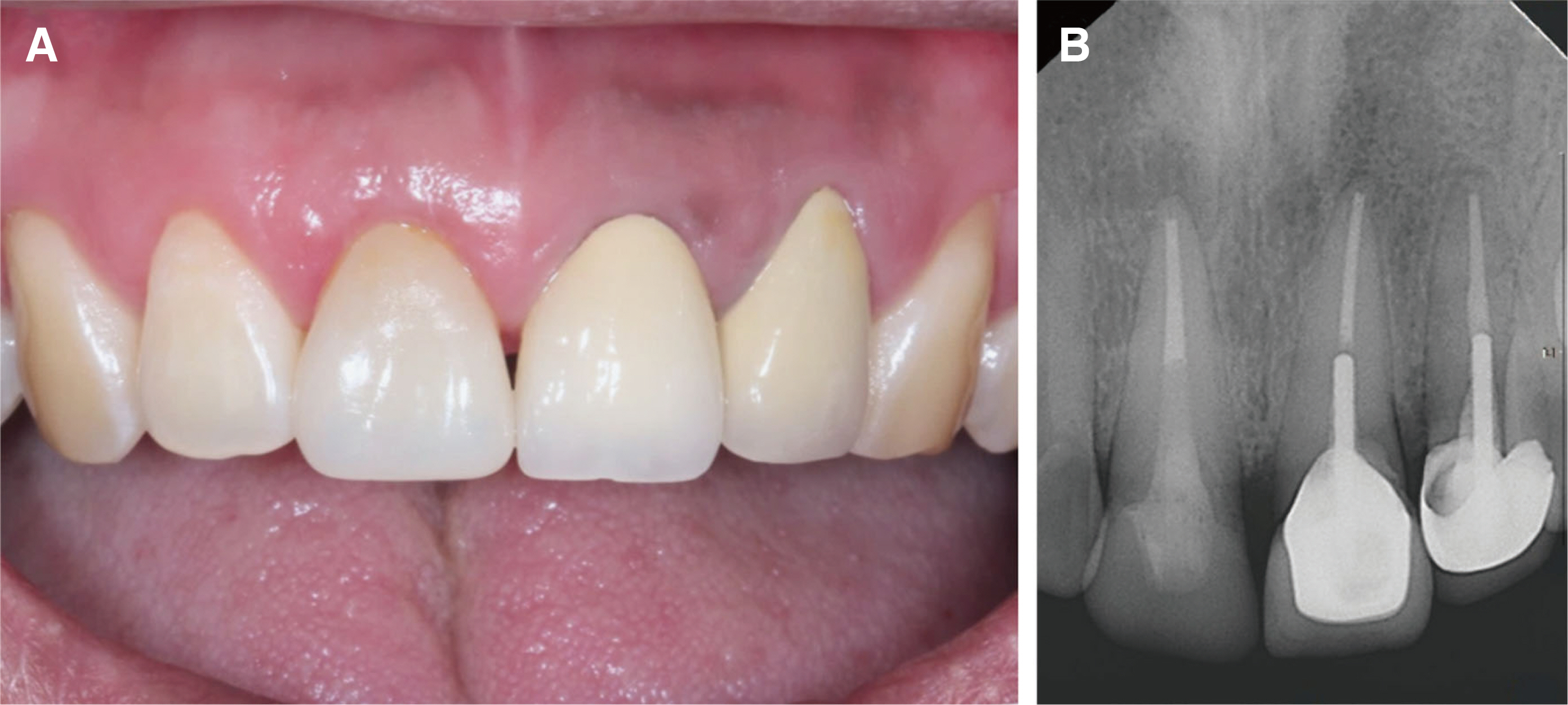

- Over the last 30 years, the use of chairside computer-aided design (CAD) and computer-aided manufacturing (CAM) systems has evolved and has become increasingly popular in dentistry. Although CAD/CAM restorations have been used in the anterior dentition, satisfying the esthetic requirements of clinicians and patients, where the restorations are limited to the chairside, remains a challenge. To reproduce multi-shades of CAD/CAM restorations in the clinic, a preliminary experiment to express several shades on A2 lithium disilicate (LS2) blocks using a staining kit was performed. After measurement of the CIE L*a*b* value of specimens, it was compared with that of the commercial shade guide. This report presents two cases with individual customization of shade and surface characterization of the CAD/CAM restorations using predictable methods based on the preliminary experimental data. The anatomical shape of restoration was obtained from ‘copy and paste technique’ and ‘mirror image acquisition technique’. All treatment procedures and fabrication of restorations performed in this report were executed in the clinic itself.

Keyword

Figure

Reference

-

References

1. Mörmann WH. 2006; The evolution of the CEREC system. J Am Dent Assoc. 137 Suppl:7S–13S. DOI: 10.14219/jada.archive.2006.0398. PMID: 16950932.2. Siervo S, Pampalone A, Siervo P, Siervo R. 1994; Where is the gap? Machinable ceramic systems and conventional laboratory restorations at a glance. Quintessence Int. 25:773–9.3. Kim JH, Jeong JH, Lee JH, Cho HW. 2016; Fit of lithium disilicate crowns fabricated from conventional and digital impressions assessed with micro-CT. J Prosthet Dent. 116:551–7. DOI: 10.1016/j.prosdent.2016.03.028. PMID: 27422237.4. Tidehag P, Ottosson K, Sjögren G. 2014; Accuracy of ceramic restorations made using an in-office optical scanning technique: an in vitro study. Oper Dent. 39:308–16. DOI: 10.2341/12-309-L. PMID: 24111810.5. Abdel-Azim T, Rogers K, Elathamna E, Zandinejad A, Metz M, Morton D. 2015; Comparison of the marginal fit of lithium disilicate crowns fabricated with CAD/CAM technology by using conventional impressions and two intraoral digital scanners. J Prosthet Dent. 114:554–9. DOI: 10.1016/j.prosdent.2015.04.001. PMID: 26100929.6. Otto T, Schneider D. 2008; Long-term clinical results of chairside Cerec CAD/CAM inlays and onlays: a case series. Int J Prosthodont. 21:53–9. PMID: 18350948.7. Lu T, Peng L, Xiong F, Lin XY, Zhang P, Lin ZT, Wu BL. 2018; A 3-year clinical evaluation of endodontically treated posterior teeth restored with two different materials using the CEREC AC chair-side system. J Prosthet Dent. 119:363–8. DOI: 10.1016/j.prosdent.2017.04.022. PMID: 28689915.8. Fasbinder DJ. 2010; Materials for chairside CAD/CAM restorations. Compend Contin Educ Dent. 31:702–4. PMID: 21197938.9. Poticny DJ, Klim J. 2010; CAD/CAM in-office technology: innovations after 25 years for predictable, esthetic outcomes. J Am Dent Assoc. 141 Suppl 2:5S–9S. DOI: 10.14219/jada.archive.2010.0356. PMID: 20516108.10. Paravina RD, Ghinea R, Herrera LJ, Bona AD, Igiel C, Linninger M, Sakai M, Takahashi H, Tashkandi E, del Mar Perez M. 2015; Color difference thresholds in dentistry. J Esthet Restor Dent. 27 Suppl 1:S1–S9. DOI: 10.1111/jerd.12149. PMID: 25886208.11. Pieger S, Salman A, Bidra AS. 2014; Clinical outcomes of lithium disilicate single crowns and partial fixed dental prostheses: a systematic review. J Prosthet Dent. 112:22–30. DOI: 10.1016/j.prosdent.2014.01.005. PMID: 24674802.12. Johnston WM, Kao EC. 1989; Assessment of appearance match by visual observation and clinical colorimetry. J Dent Res. 68:819–22. DOI: 10.1177/00220345890680051301. PMID: 2715476.13. Goldstein RE. 2014. Esthetics in Dentistry. 2nd ed. Decker;Hamilton:14. Durán Ojeda G, Henríquez Gutiérrez I, Guzmán Marusic Á, Báez Rosales A, Tisi Lanchares JP. 2017; A step-by-step conservative approach for CAD-CAM laminate veneers. Case Rep Dent. 2017:3801419. DOI: 10.1155/2017/3801419. PMID: 28884029. PMCID: PMC5572585.15. Griffin JD Jr. 2006; Anterior CEREC CAD/CAM porcelain treatment of GERD eroded teeth. Contemp Esthet. 10:32–9.16. Miranda JS, de Pinho Barcellos AS, Campos TMB, Cesar PF, Amaral M, Kimpara ET. 2020; Effect of repeated firings and staining on the mechanical behavior and composition of lithium disilicate. Dent Mater. 36:e149–57. DOI: 10.1016/j.dental.2020.02.003. PMID: 32061444.17. Sarac D, Sarac YS, Kulunk S, Ural C, Kulunk T. 2006; The effect of polishing techniques on the surface roughness and color change of composite resins. J Prosthet Dent. 96:33–40. DOI: 10.1016/j.prosdent.2006.04.012. PMID: 16872928.18. Brodbelt RH, O'brien WJ, Fan PL. 1980; Translucency of dental porcelains. J Dent Res. 59:70–5. DOI: 10.1177/00220345800590011101. PMID: 6927988.19. Fondriest J. 2006; Shade matching in restorative dentistry: the science and strategies. Int J Periodontics Restorative Dent. 23:467–79.20. Awad D, Stawarczyk B, Liebermann A, Ilie N. 2015; Translucency of esthetic dental restorative CAD/CAM materials and composite resins with respect to thickness and surface roughness. J Prosthet Dent. 113:534–40. DOI: 10.1016/j.prosdent.2014.12.003. PMID: 25749093.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Functional and esthetic improvement through reconstruction of anterior guidance using the modified Dahl principle and copy-milled technique of CAD/CAM system: A case report

- Fabricating a Ceramic-Pressed-to-Metal Restoration with Computer-Aided Design, Computer-Aided Manufacturing and Selective Laser Sintering: A Case Report

- Fabrication of computer-aided design/computer-aided manufacturing complete denture and conventional complete denture: case report

- CAD/CAM fabricated complete denture using 3D face scan: A case report

- Full-mouth rehabilitation in an amelogenesis imperfecta patient with anterior open bite using CAD/CAM system