J Adv Prosthodont.

2014 Oct;6(5):372-378. 10.4047/jap.2014.6.5.372.

A comparative study on the bond strength of porcelain to the millingable Pd-Ag alloy

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Dankook University, Cheonan, Republic of Korea. syshin@dankook.ac.kr

- KMID: 2284737

- DOI: http://doi.org/10.4047/jap.2014.6.5.372

Abstract

- PURPOSE

The porcelain fused to gold has been widely used as a restoration both with the natural esthetics of the porcelain and durability and marginal fit of metal casting. However, recently, due to the continuous rise in the price of gold, an interest towards materials to replace gold alloy is getting higher. This study compared the bond strength of porcelain to millingable palladium-silver (Pd-Ag) alloy, with that of 3 conventionally used metal-ceramic alloys.

MATERIALS AND METHODS

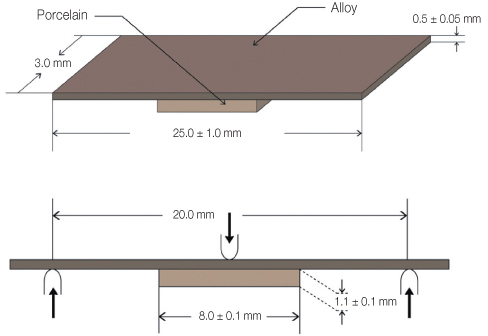

Four types of metal-ceramic alloys, castable nonprecious nickel-chrome alloy, castable precious metal alloys containing 83% and 32% of gold, and millingable Pd-Ag alloy were used to make metal specimens (n=40). And porcelain was applied on the center area of metal specimen. Three-point bending test was performed with universal testing machine. The bond strength data were analyzed with a one-way ANOVA and post hoc Scheffe's tests (alpha=.05).

RESULTS

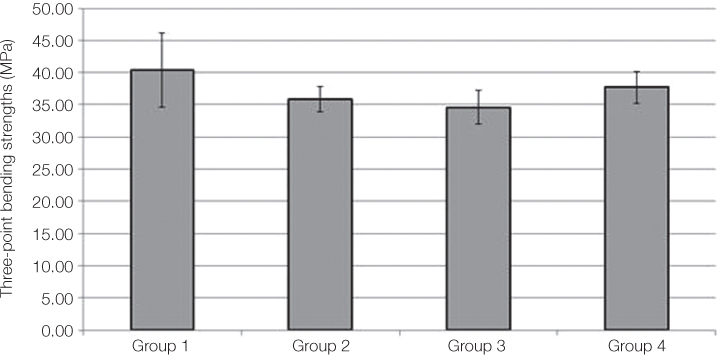

The 3-point bending test showed the strongest (40.42 +/- 5.72 MPa) metal-ceramic bond in the nonprecious Ni-Cr alloy, followed by millingable Pd-Ag alloy (37.71 +/- 2.46 MPa), precious metal alloy containing 83% of gold (35.89 +/- 1.93 MPa), and precious metal alloy containing 32% of gold (34.59 +/- 2.63 MPa). Nonprecious Ni-Cr alloy and precious metal alloy containing 32% of gold showed significant difference (P<.05).

CONCLUSION

The type of metal-ceramic alloys affects the bond strength of porcelain. Every metal-ceramic alloy used in this study showed clinically applicable bond strength with porcelain (25 MPa).

MeSH Terms

Figure

Cited by 1 articles

-

Comparative clinical study of the marginal discrepancy of fixed dental prosthesis fabricated by the milling-sintering method using a presintered alloy

Mijoo Kim, Jaewon Kim, Hang-Nga Mai, Tae-Yub Kwon, Yong-Do Choi, Cheong-Hee Lee, Du-Hyeong Lee

J Adv Prosthodont. 2019;11(5):280-285. doi: 10.4047/jap.2019.11.5.280.

Reference

-

1. Brecker SC. Porcelain baked to gold-A new medium in prosthodontics. J Prosthet Dent. 1956; 6:801–810.2. Bagby M, Marshall SJ, Marshall GW Jr. Metal ceramic compatibility: a review of the literature. J Prosthet Dent. 1990; 63:21–25.3. Kim CM, Lee JH, Cho IH. A study on the bond strength of non-precious alloys used for the porcelain fused to metal crown. J Korean Acad Stomatognathic Funct Occlusion. 2006; 22:203–210.4. Kim I, Yang HS. A study on the bond strength between reused dental alloys and porcelain. J Korean Acad Prosthodont. 1993; 31:181–190.5. do Prado RA, Panzeri H, Fernandes Neto AJ, das Neves FD, da Silva MR, Mendonça G. Shear bond strength of dental porcelains to nickel-chromium alloys. Braz Dent J. 2005; 16:202–206.6. Moffa JP, Lugassy AA, Guckes AD, Gettleman L. An evaluation of nonprecious alloys for use with porcelain veneers. Part I. Physical properties. J Prosthet Dent. 1973; 30:424–431.7. Kelly JR, Rose TC. Nonprecious alloys for use in fixed prosthodontics: a literature review. J Prosthet Dent. 1983; 49:363–370.8. Morris HF. Veterans Administration Cooperative Studies Project No. 147. Part IV: Biocompatibility of base metal alloys. J Prosthet Dent. 1987; 58:1–5.9. Spear F, Holloway J. Which all-ceramic system is optimal for anterior esthetics? J Am Dent Assoc. 2008; 139:19S–24S.10. Magne P, Magne M, Belser U. The esthetic width in fixed prosthodontics. J Prosthodont. 1999; 8:106–118.11. O'Boyle KH, Norling BK, Cagna DR, Phoenix RD. An investigation of new metal framework design for metal ceramic restorations. J Prosthet Dent. 1997; 78:295–301.12. Stappert CF, Dai M, Chitmongkolsuk S, Gerds T, Strub JR. Marginal adaptation of three-unit fixed partial dentures constructed from pressed ceramic systems. Br Dent J. 2004; 196:766–770.13. Campbell SD, Sozio RB. Evaluation of the fit and strength of an all-ceramic fixed partial denture. J Prosthet Dent. 1988; 59:301–306.14. Kelly JR, Tesk JA, Sorensen JA. Failure of all-ceramic fixed partial dentures in vitro and in vivo: analysis and modeling. J Dent Res. 1995; 74:1253–1258.15. Zervas PJ, Papazoglou E, Beck FM, Carr AB. Distortion of three-unit implant frameworks during casting, soldering, and simulated porcelain firings. J Prosthodont. 1999; 8:171–179.16. Katsoulis J, Mericske-Stern R, Rotkina L, Zbären C, Enkling N, Blatz MB. Precision of fit of implant-supported screw-retained 10-unit computer-aided-designed and computer-aidedmanufactured frameworks made from zirconium dioxide and titanium: an in vitro study. Clin Oral Implants Res. 2014; 25:165–174.17. Gilbert JL, Covey DA, Lautenschlager EP. Bond characteristics of porcelain fused to milled titanium. Dent Mater. 1994; 10:134–140.18. Reich S, Wichmann M, Nkenke E, Proeschel P. Clinical fit of all-ceramic three-unit fixed partial dentures, generated with three different CAD/CAM systems. Eur J Oral Sci. 2005; 113:174–179.19. Bachhav VC, Aras MA. Zirconia-based fixed partial dentures: a clinical review. Quintessence Int. 2011; 42:173–182.20. Huget EF, Civjan S. Status report on palladium-silver-based crown and bridge alloys. J Am Dent Assoc. 1974; 89:383–385.21. Goodacre CJ. Palladium-silver alloys: a review of the literature. J Prosthet Dent. 1989; 62:34–37.22. Kansu G, Aydin AK. Evaluation of the biocompatibility of various dental alloys: Part I-Toxic potentials. Eur J Prosthodont Restor Dent. 1996; 4:129–136.23. International Organization for Standardization. ISO 9693: metal-ceramic dental restorative systems. 2012.24. Knap FJ, Ryge G. Study of bond strength of dental porcelain fused to metal. J Dent Res. 1966; 45:1047–1051.25. Silver M, Klein G, Howard MC. An evaluation and comparison of porcelain-fused-to-cast metals. J Prosthet Dent. 1960; 10:1055–1064.26. Ozcan M. Fracture reasons in ceramic-fused-to-metal restorations. J Oral Rehabil. 2003; 30:265–269.27. Fairhurst CW, Anusavice KJ, Ringle RD, Twiggs SW. Porcelain-metal thermal compatibility. J Dent Res. 1981; 60:815–819.28. Shell JS, Nielsen JP. Study of the bond between gold alloys and porcelain. J Dent Res. 1962; 41:1424–1437.29. de Melo RM, Travassos AC, Neisser MP. Shear bond strengths of a ceramic system to alternative metal alloys. J Prosthet Dent. 2005; 93:64–69.30. Mackert JR Jr, Ringle RD, Parry EE, Evans AL, Fairhurst CW. The relationship between oxide adherence and porcelain-metal bonding. J Dent Res. 1988; 67:474–478.31. McLean JW. The metal-ceramic restoration. Dent Clin North Am. 1983; 27:747–761.32. Barghi N, McKeehan-Whitmer M, Aranda R. Comparison of fracture strength of porcelain-veneered-to-high noble and base metal alloys. J Prosthet Dent. 1987; 57:23–26.33. Lee EH, Jeon YC, Jeong CM, Lim JS. Effect of degassing condition on ceramic bond strength of Ni-Cr alloys. J Korean Acad Prosthodont. 2000; 38:461–471.34. Jochen DG, Caputo AA, Matyas J. Effect of metal surface treatment on ceramic bond strength. J Prosthet Dent. 1986; 55:186–188.35. Külünk T, Kurt M, Ural Ç, Külünk Ş, Baba S. Effect of different air-abrasion particles on metal-ceramic bond strength. J Dent Sci. 2011; 6:140–146.36. Anusavice KJ, Dehoff PH, Fairhurst CW. Comparative evaluation of ceramic-metal bond tests using finite element stress analysis. J Dent Res. 1980; 59:608–613.37. Lenz J, Schwarz S, Schwickerath H, Sperner F, Schäfer A. Bond strength of metal-ceramic systems in three-point flexure bond test. J Appl Biomater. 1995; 6:55–64.38. Papazoglou E, Brantley WA. Porcelain adherence vs force to failure for palladium-gallium alloys: a critique of metal-ceramic bond testing. Dent Mater. 1998; 14:112–119.39. Hammad IA, Talic YF. Designs of bond strength tests for metal-ceramic complexes: review of the literature. J Prosthet Dent. 1996; 75:602–608.40. Barghi N, Lorenzana RE. Optimum thickness of opaque and body porcelain. J Prosthet Dent. 1982; 48:429–431.41. Warpeha WS Jr, Goodkind RJ. Design and technique variables affecting fracture resistance of metal-ceramic restorations. J Prosthet Dent. 1976; 35:291–298.42. Lahori M, Nagrath R, Sisodia S, Dagar P. The effect of surface treatments on the bond strength of a nonprecious alloy-ceramic interface: an invitro study. J Indian Prosthodont Soc. 2014; 14:151–155.43. Li BH, Ye JT, Liao JK, Zhuang PL, Zhang YP, Li JY. Effect of pretreatments on the metal-ceramic bonding strength of a Pd-Ag alloy. J Dent. 2014; 42:319–328.44. Gilbert JL, Covey DA, Lautenschlager EP. Bond characteristics of porcelain fused to milled titanium. Dent Mater. 1994; 10:134–140.45. Anusavice KJ, Dehoff PH, Gray A, Lee RB. Delayed crack development in porcelain due to incompatibility stress. J Dent Res. 1988; 67:1086–1091.46. Rosenstiel SF, Land MF, Fujimoto J. Contemporary fixed prosthodontics. 4th ed. St. Louis, Mo: Mosby Elsevier;2006. p. 743–750.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of metal primers and tarnish treatment on bonding between dental alloys and veneer resin

- THE EFFECT OF Ti ON THE SHEARBONDING STRENGTH BEWEEN DENTAL PORCELAIN AND Ni-Cr NONPRECIOUS ALLOY

- Bond-strength of several metal-meramic alloys and meneered-porcelain

- EFFECT OF METAL PRIMER TREAMENT OF THE Au-Ag-Pd ALLOY SURFACE ON THE METAL-RESIN BONDING

- EFFECT OF GOLD ELECTRODEPOSIT ON THE BOND STRENGTH BETWEEN ALLOYS AND VENEERED RESIN