J Adv Prosthodont.

2015 Jun;7(3):257-263. 10.4047/jap.2015.7.3.257.

Evaluation and comparison of the marginal adaptation of two different substructure materials

- Affiliations

-

- 1Department of Prosthodontics, Faculty of Dentistry, Firat University, Elazig, Turkey.

- 2Department of Prosthodontics, Faculty of Dentistry, Dicle University, Diyarbakir, Turkey. dentistsedat49@hotmail.com

- 3Diyarbakir Oral and Dental Health Center, Diyarbakir, Turkey.

- KMID: 2284712

- DOI: http://doi.org/10.4047/jap.2015.7.3.257

Abstract

- PURPOSE

In this study, we aimed to evaluate the amount of marginal gap with two different substructure materials using identical margin preparations.

MATERIALS AND METHODS

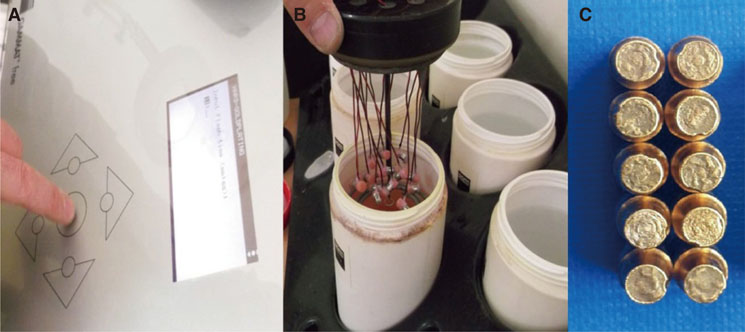

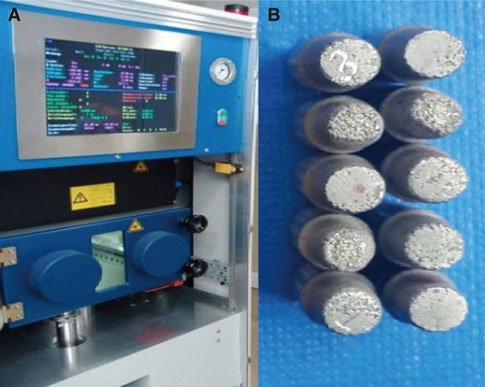

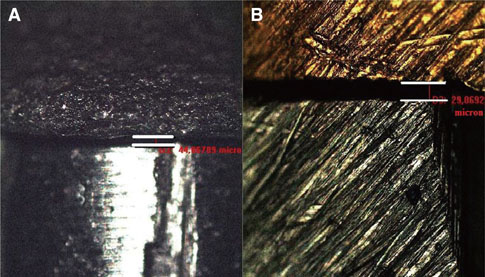

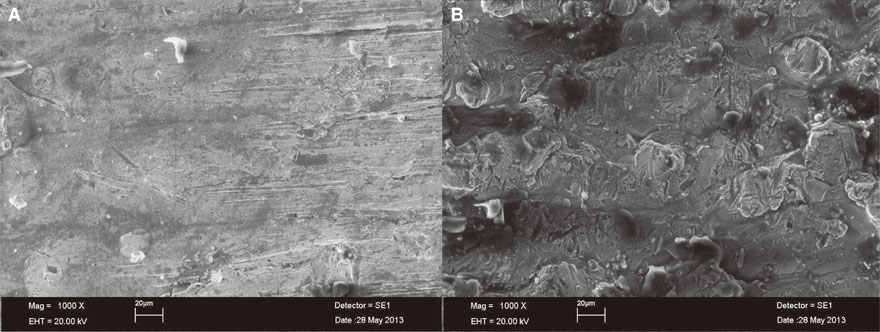

Twenty stainless steel models with a chamfer were prepared with a CNC device. Marginal gap measurements of the galvano copings on these stainless steel models and Co-Cr copings obtained by a laser-sintering method were made with a stereomicroscope device before and after the cementation process and surface properties were evaluated by scanning electron microscopy (SEM). A dependent t-test was used to compare the mean of the two groups for normally distributed data, and two-way variance analysis was used for more than two data sets. Pearson's correlation analysis was also performed to assess relationships between variables.

RESULTS

According to the results obtained, the marginal gap in the galvano copings before cementation was measured as, on average, 24.47 +/- 5.82 microm before and 35.11 +/- 6.52 microm after cementation; in the laser-sintered Co-Cr structure, it was, on average, 60.45 +/- 8.87 microm before and 69.33 +/- 9.03 microm after cementation. A highly significant difference (P<.001) was found in marginal gap measurements of galvano copings and a significant difference (P<.05) was found in marginal gap measurements of the laser-sintered Co-Cr copings. According to the SEM examination, surface properties of laser sintered Co-Cr copings showed rougher structure than galvano copings. The galvano copings showed a very smooth surface.

CONCLUSION

Marginal gaps values of both groups before and after cementation were within the clinically acceptable level. The smallest marginal gaps occurred with the use of galvano copings.

Keyword

MeSH Terms

Figure

Reference

-

1. Shillingburg HT, Hobo S, Whitsett LD, Brackett SE. Fundamentals of fixed prosthodontics. 3rd ed. Chicago: Quintessence Pub. Co.;1997. p. 290.2. Jacobs MS, Windeler AS. An investigation of dental luting cement solubility as a function of the marginal gap. J Prosthet Dent. 1991; 65:436–442.3. Yang JH, Song TJ, Han JS, Lee JB, Lee SH. Marginal fit of the aurogalvano crown system made using the electroforming technique. J Korean Acad Prosthodont. 2004; 42:679–684.4. Rudolf R, Anzel I, Dragoslav S. Dental materials - Challenge and usage of the latest inventions. Metalurgija. 2008; 14:135–142.5. Comlekoglu ME, Dundar M, Gungor MA, Aladag A, Artunc C. Dişhekimliğinde Alerji: Döküm Alaşımları, Polimerler ve Seramikler, [Allergy in Dentistry: Casting Alloys, Polymers and Ceramics]. EÜ Dişhek Fak Derg. 2008; 29:81–92.6. Zhang XH, Sun F. Clinical follow-up of ceramic bridges with auro-galvanoforming primary coping and Ni-Cr pontic for restoration of dentition defects. Chin Med J (Engl). 2009; 122:3007–3010.7. Setcos JC, Babaei-Mahani A, Silvio LD, Mjör IA, Wilson NH. The safety of nickel containing dental alloys. Dent Mater. 2006; 22:1163–1168.8. Wataha JC, Lockwood PE, Messer RL, Lewis JB, Mettenburg DJ. Brushing-induced surface roughness of nickel-, palladium-, and gold-based dental casting alloys. J Prosthet Dent. 2008; 99:455–460.9. Wataha JC. Biocompatibility of dental casting alloys: a review. J Prosthet Dent. 2000; 83:223–234.10. Rubo JH, Pegoraro LF, Marolato F, Rubo MH. The effect of tin-electroplating on the bond of four dental alloys to resin cement: an in vitro study. J Prosthet Dent. 1998; 80:27–31.11. Covington JS, McBride MA, Slagle WF, Disney AL. Quantization of nickel and beryllium leakage from base metal casting alloys. J Prosthet Dent. 1985; 54:127–136.12. O'brien WJ. Dental materials and their selection. 3rd ed. Quintessence Pub. Co. Inc.;2002. p. 309.13. Naumann M, Ernst J, Reich S, Weißhaupt P, Beuer F. Galvano vs. metal-ceramic crowns: up to 5-year results of a randomised split-mouth study. Clin Oral Investig. 2011; 15:657–660.14. Eroglu Z, Gurbulak AG. Investigation of fracture strength of galvano ceramic, metal ceramic three unit bridges. J Health Sci. 2011; 20:92–98.15. Vence BS. Electroforming technology for galvanoceramic restorations. J Prosthet Dent. 1997; 77:444–449.16. Weishaupt P, Bernimoulin JP, Lange KP, Rothe S, Naumann M, Hägewald S. Clinical and inflammatory effects of galvano-ceramic and metal-ceramic crowns on periodontal tissues. J Oral Rehabil. 2007; 34:941–947.17. Buso L, Hilgert E, Neisser MP, Bottino MA. Marginal fit of electroformed copings before and after the coction of the porcelain. Braz J Oral Sci. 2004; 3:409–413.18. Stewart RM. Electroforming as an alternative to full ceramic restorations and cast substructures. Trends Tech Contemp Dent Lab. 1994; 11:42–47.19. Vrijhoef MM, Spanauf HJ, Renggli HH, Wismann H, Somers GA. Electroforming as an alternative to casting: a preliminary report. Restorative Dent. 1985; 1:143145–146.20. Rogers OW. The electroformed gold matrix inlay technique. Aust Dent J. 1970; 15:316–323.21. Rogers OW. The dental application of electroformed pure gold. III. An investigation into an alternative ceramic bonding system for base metal alloys. Aust Dent J. 1980; 25:205–208.22. Hauk V. Structural and residual stress analysis by nondestructive methods: Evaluation-Application-Assessment. Elsevier;1997. p. 53–72.23. Moneret-Vautrin DA, Burnel D, Sainte-Laudy J, Beaudouin E, Croizier A. Allergy to nickel in dental alloys. Eur Ann Allergy Clin Immunol. 2004; 36:311–312.24. Senkutvan RS, Jacob S, Charles A, Vadgaonkar V, Jatol-Tekade S, Gangurde P. Evaluation of nickel ion release from various orthodontic arch wires: An in vitro study. J Int Soc Prev Community Dent. 2014; 4:12–16.25. Wataha JC, Messer RL. Casting alloys. Dent Clin North Am. 2004; 48:499–512.26. Kokubo Y, Tsumita M, Ohkubo C, Sakurai S, Fukushima S. Clinical evaluation of porcelain fused to electroformed gold copings: Preliminary results after 30-43 months. Prosthodont Res Pract. 2007; 6:50–56.27. Sönmez A. Galvano Kronlarda Marjinal Adaptasyonun ve Porselen Bağlantısının İn-vitro İncelenmesi ve Ni-Cr Alaşımlarla Karşılaştırılması, [In-vitro evaluation of marginal adaptation and porcelain bonding of galvano crowns and comparison with Ni-Cr alloys]. Başkent Üniversitesi Sağlık Bilimleri Enstitüsü PhD Thesis;2008. 15–22.28. Oyagüe RC, Sánchez-Turrión A, López-Lozano JF, Suárez-García MJ. Vertical discrepancy and microleakage of lasersintered and vacuum-cast implant-supported structures luted with different cement types. J Dent. 2012; 40:123–130.29. Örtorp A, Jönsson D, Mouhsen A, Vult von Steyern P. The fit of cobalt-chromium three-unit fixed dental prostheses fabricated with four different techniques: a comparative in vitro study. Dent Mater. 2011; 27:356–363.30. Andersson M, Carlsson L, Persson M, Bergman B. Accuracy of machine milling and spark erosion with a CAD/CAM system. J Prosthet Dent. 1996; 76:187–193.31. Bindl A, Mörmann WH. Fit of all-ceramic posterior fixed partial denture frameworks in vitro. Int J Periodontics Restorative Dent. 2007; 27:567–575.32. Att W, Komine F, Gerds T, Strub JR. Marginal adaptation of three different zirconium dioxide three-unit fixed dental prostheses. J Prosthet Dent. 2009; 101:239–247.33. Albert FE. Marginal Adaptation and Microleakace of Procem Allceram Copings- an in vitro study. University of Toronto PhD Thesis;2001. 20–22.34. Wu JC, Lai LC, Sheets CG, Earthman J, Newcomb R. A comparison of the marginal adaptation of cathode-arc vapor-deposited titanium and cast base metal copings. J Prosthet Dent. 2011; 105:403–409.35. Buso L, Neisser MP, Bottino MA. Evaluation of the marginal fit of electroformed copings in function of the cervical preparation. Cienc Odontol Bras. 2004; 7:14–20.36. Polansky R, Heschl A, Arnetzl G, Haas M, Wegscheider W. Comparision of the marginal fit of different all-ceramic and metal-ceramic crown system: an in vitro study. J Stomat Occl Med. 2010; 3:106–110.37. Yeo IS, Yang JH, Lee JB. In vitro marginal fit of three all-ceramic crown systems. J Prosthet Dent. 2003; 90:459–464.38. Gonzalo E, Suárez MJ, Serrano B, Lozano JF. A comparison of the marginal vertical discrepancies of zirconium and metal ceramic posterior fixed dental prostheses before and after cementation. J Prosthet Dent. 2009; 102:378–384.39. Cho L, Choi J, Yi YJ, Park CJ. Effect of finish line variants on marginal accuracy and fracture strength of ceramic optimized polymer/fiber-reinforced composite crowns. J Prosthet Dent. 2004; 91:554–560.40. Quintas AF, Oliveira F, Bottino MA. Vertical marginal discrepancy of ceramic copings with different ceramic materials, finish lines, and luting agents: an in vitro evaluation. J Prosthet Dent. 2004; 92:250–257.41. Ehrenberg D, Weiner GI, Weiner S. Long-term effects of storage and thermal cycling on the marginal adaptation of provisional resin crowns: a pilot study. J Prosthet Dent. 2006; 95:230–236.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Gap comparison between single crown and three-unit bridge zirconia substructures

- Estimation of relation between techniques of dye penetration for microleakage and SEM evaluation for marginal adaptation of the restoration

- Comparative analysis of the clinical techniques used in evaluation of marginal accuracy of cast restoration using stereomicroscopy as gold standard

- Effect of repetitive firing on passive fit of metal substructure produced by the laser sintering in implant-supported fixed prosthesis

- Marginal Adaptation Of The Conical Inner Crown Fabricated With Cad/cam