Korean J Orthod.

2012 Jun;42(3):129-137. 10.4041/kjod.2012.42.3.129.

Variations in surface roughness of seven orthodontic archwires: an SEM-profilometry study

- Affiliations

-

- 1Department of Orthodontics and Dentofacial Orthopedics, Dental Branch, Islamic Azad University, Tehran, Iran. aminiorhod@yahoo.com

- 2Department of Dental Anatomy and Morphology, Dental Branch, Islamic Azad University, Tehran, Iran.

- KMID: 2272261

- DOI: http://doi.org/10.4041/kjod.2012.42.3.129

Abstract

OBJECTIVE

The purpose of this study was to evaluate the surface roughness (SR) of 2 types of orthodontic archwires made by 4 different manufacturers.

METHODS

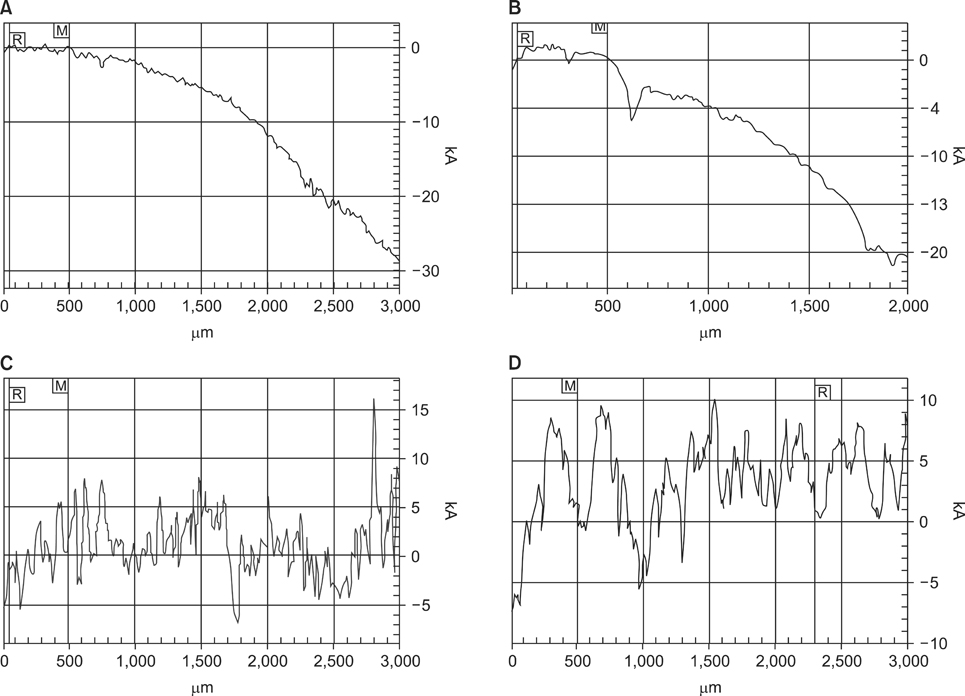

This in vitro experimental study was conducted on 35 specimens of 7 different orthodontic archwires, namely, 1 nickel-titanium (NiTi) archwire each from the manufacturers American Orthodontics, OrthoTechnology, All-Star Orthodontics, and Smart Technology, and 1 stainless steel (SS) archwire each from the manufacturers American Orthodontics, OrthoTechnology, and All-Star Orthodontics. After analyzing the composition of each wire by energy-dispersive X-ray analysis, the SR of each wire was determined by scanning electron microscopy (SEM) and surface profilometry. Data were analyzed using the Kruskal-Wallis and Mann-Whitney U tests (alpha < 0.05).

RESULTS

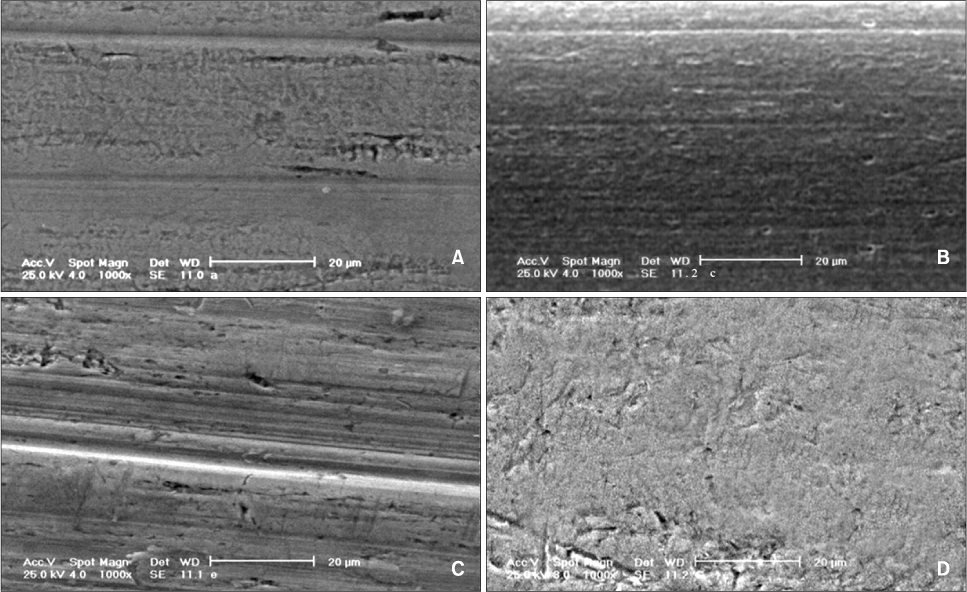

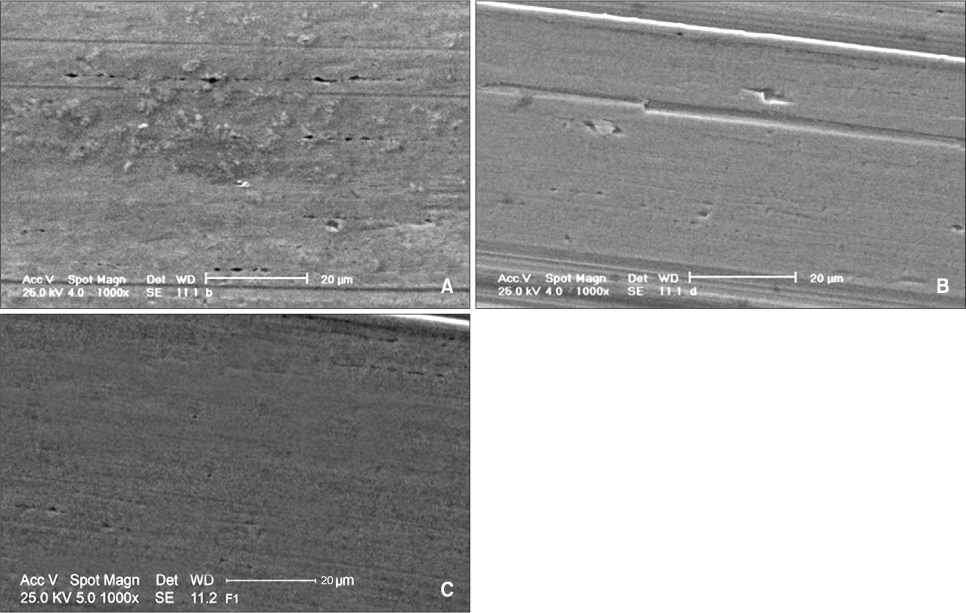

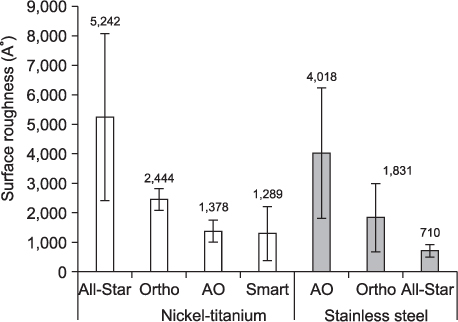

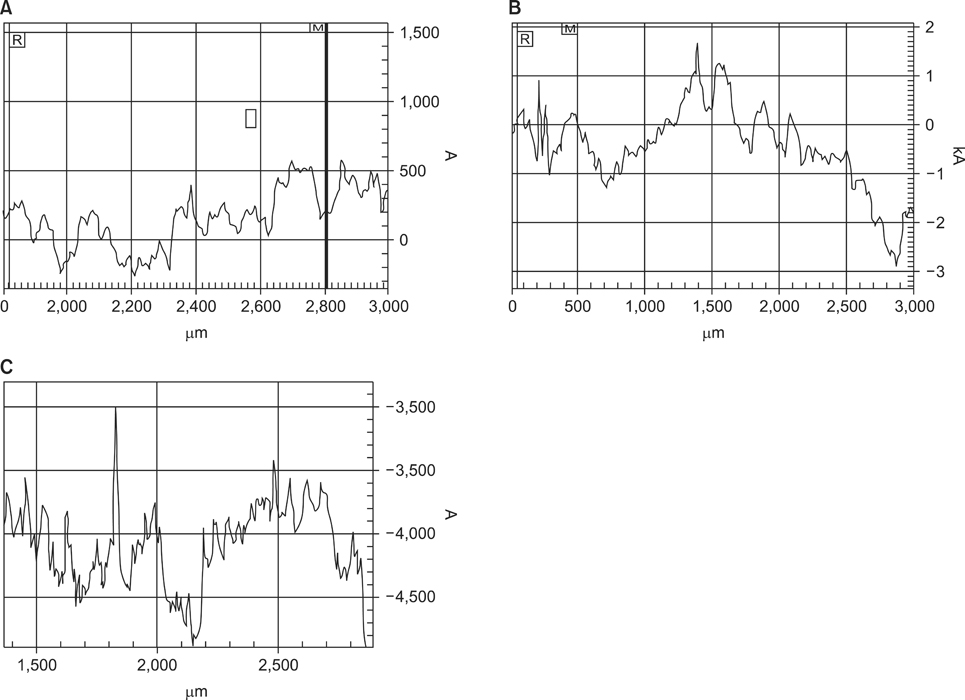

The average SR of NiTi wires manufactured by Smart Technology, American Orthodontics, OrthoTechnology, and All-Star Orthodontics were 1,289 +/- 915 Adegrees, 1,378 +/- 372 Adegrees, 2,444 +/- 369 Adegrees, and 5,242 +/- 2,832 Adegrees, respectively. The average SR of SS wires manufactured by All-Star Orthodontics, OrthoTechnology, and American Orthodontics were 710 +/- 210 Adegrees, 1,831 +/- 1,156 Adegrees, and 4,018 +/- 2,214 Adegrees, respectively. Similar to the results of profilometry, the SEM images showed more defects and cracks on the SS wire made by American Orthodontics and the NiTi wire made by All-Star Orthodontics than others.

CONCLUSIONS

The NiTi wire manufactured by All-Star Orthodontics and the SS wire made by American Orthodontics were the roughest wires.

Figure

Reference

-

1. Faccioni F, Franceschetti P, Cerpelloni M, Fracasso ME. In vivo study on metal release from fixed orthodontic appliances and DNA damage in oral mucosa cells. Am J Orthod Dentofacial Orthop. 2003. 124:687–693.

Article2. Bourauel C, Fries T, Drescher D, Plietsch R. Surface roughness of orthodontic wires via atomic force microscopy, laser specular reflectance, and profilometry. Eur J Orthod. 1998. 20:79–92.

Article3. Daems J, Celis JP, Willems G. Morphological characterization of as-received and in vivo orthodontic stainless steel archwires. Eur J Orthod. 2009. 31:260–265.

Article4. Kusy RP, Whitley JQ, Mayhew MJ, Buckthal JE. Surface roughness of orthodontic archwires via laser spectroscopy. Angle Orthod. 1988. 58:33–45.5. Huang HH. Variation in corrosion resistance of nickel-titanium wires from different manufacturers. Angle Orthod. 2005. 75:661–665.6. Huang HH. Variation in surface topography of different NiTi orthodontic archwires in various commercial fluoride-containing environments. Dent Mater. 2007. 23:24–33.

Article7. Elayyan F, Silikas N, Bearn D. Ex vivo surface and mechanical properties of coated orthodontic archwires. Eur J Orthod. 2008. 30:661–667.

Article8. Rapiejko C, Fouvry S, Grosgogeat B, Wendler B. A representative ex-situ fretting wear investigation of orthodontic arch-wire/bracket contacts. Wear. 2009. 266:850–858.

Article9. Baccetti T, Franchi L, Camporesi M, Defraia E, Barbato E. Forces produced by different nonconventional bracket or ligature systems during alignment of apically displaced teeth. Angle Orthod. 2009. 79:533–539.

Article10. Widu F, Drescher D, Junker R, Bourauel C. Corrosion and biocompatibility of orthodontic wires. J Mater Sci Mater Med. 1999. 10:275–281.11. Oshida Y, Sachdeva RC, Miyazaki S. Microanalytical characterization and surface modification of TiNi orthodontic archwires. Biomed Mater Eng. 1992. 2:51–69.

Article12. Amini F, Borzabadi Farahani A, Jafari A, Rabbani M. In vivo study of metal content of oral mucosa cells in patients with and without fixed orthodontic appliances. Orthod Craniofac Res. 2008. 11:51–56.

Article13. Amini F, Jafari A, Amini P, Sepasi S. Metal ion release from fixed orthodontic appliances--an in vivo study. Eur J Orthod. 2012. 34:126–130.

Article14. Bishara SE. Oral lesions caused by an orthodontic retainer: a case report. Am J Orthod Dentofacial Orthop. 1995. 108:115–117.

Article15. Staffolani N, Damiani F, Lilli C, Guerra M, Staffolani NJ, Belcastro S, et al. Ion release from orthodontic appliances. J Dent. 1999. 27:449–454.

Article16. Prososki RR, Bagby MD, Erickson LC. Static frictional force and surface roughness of nickel-titanium arch wires. Am J Orthod Dentofacial Orthop. 1991. 100:341–348.

Article17. Shin JS, Oh KT, Hwang CJ. In vitro surface corrosion of stainless steel and NiTi orthodontic appliances. Aust Orthod J. 2003. 19:13–18.18. Khosravanifard B, Nemati-Anaraki S, Nili S, Rakhshan V. Assessing the effects of three resin removal methods and bracket sandblasting on shear bond strength of metallic orthodontic brackets and enamel surface. Orthod Waves. 2011. 70:27–38.

Article19. Kusy RP, Whitley JQ. Effects of surface roughness on the coefficients of friction in model orthodontic systems. J Biomech. 1990. 23:913–925.

Article20. Verstrynge A, Van Humbeeck J, Willems G. In-vitro evaluation of the material characteristics of stainless steel and beta-titanium orthodontic wires. Am J Orthod Dentofacial Orthop. 2006. 130:460–470.

Article21. Mohlin B, Müller H, Odman J, Thilander B. Examination of Chinese NiTi wire by a combined clinical and laboratory approach. Eur J Orthod. 1991. 13:386–391.

Article22. Neumann P, Bourauel C, Jäger A. Corrosion and permanent fracture resistance of coated and conventional orthodontic wires. J Mater Sci Mater Med. 2002. 13:141–147.23. Pernier C, Grosgogeat B, Ponsonnet L, Benay G, Lissac M. Influence of autoclave sterilization on the surface parameters and mechanical properties of six orthodontic wires. Eur J Orthod. 2005. 27:72–81.

Article24. Brantley WA. Brantley WA, Eliades T, editors. Orthodontic wires. Orthodontic Materials: Scientific and Clinical Aspects. 2001. Stuttgart-New York: Thieme;77–105.25. Kapila S, Sachdeva R. Mechanical properties and clinical applications of orthodontic wires. Am J Orthod Dentofacial Orthop. 1989. 96:100–109.

Article26. Jackson CM, Wagner HJ, Wasilewski RJ. NASA No SP 5110. 55-nitinol-the alloy with a memory--its physical metallurgy, properties and applications. 1972. Washington D.C.:

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- A comparative study of roughness of enamel surface to various interdental enamel stripping methods in vitro

- Comparison of surface topography and roughness in different yttrium oxide compositions of dental zirconia after grinding and polishing

- Influence of surface treatment on the insertion pattern of self-drilling orthodontic mini-implants

- The effect of conditioning by Tetracycline-HCl on implant surface: The SEM study and surface roughness measurements: RBM surface

- Surface roughness and surface free energy components of various orthodontic adhesives