J Adv Prosthodont.

2012 Aug;4(3):158-161. 10.4047/jap.2012.4.3.158.

Mechanical analysis of conventional and small diameter conical implant abutments

- Affiliations

-

- 1Dental School of Ribeirao Preto, University of Sao Paulo, Department of Dental Materials and Prosthodontics, Ribeirao Preto, SP, Brazil. renata@forp.usp.br

- KMID: 2176411

- DOI: http://doi.org/10.4047/jap.2012.4.3.158

Abstract

- PURPOSE

The aim of the present study was to evaluate if a smaller morse taper abutment has a negative effect on the fracture resistance of implant-abutment connections under oblique compressive loads compared to a conventional abutment.

MATERIALS AND METHODS

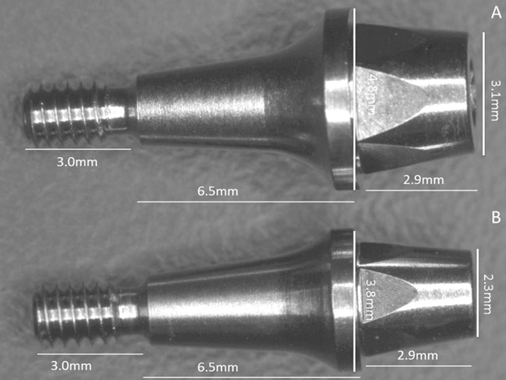

Twenty morse taper conventional abutments (4.8 mm diameter) and smaller abutments (3.8 mm diameter) were tightened (20 Ncm) to their respective implants (3.5 x 11 mm) and after a 10 minute interval, implant/abutment assemblies were subjected to static compressive test, performed in a universal test machine with 1 mm/min displacement, at 45degrees inclination. The maximum deformation force was determined. Data were statistically analyzed by student t test.

RESULTS

Maximum deformation force of 4.8 mm and 3.8 mm abutments was approximately 95.33 kgf and 95.25 kgf, respectively, but no fractures were noted after mechanical test. Statistical analysis demonstrated that the evaluated abutments were statistically similar (P=.230).

CONCLUSION

Abutment measuring 3.8 mm in diameter (reduced) presented mechanical properties similar to 4.8 mm (conventional) abutments, enabling its clinical use as indicated.

Keyword

MeSH Terms

Figure

Reference

-

1. Steinebrunner L, Wolfart S, Ludwig K, Kern M. Implant-abutment interface design affects fatigue and fracture strength of implants. Clin Oral Implants Res. 2008. 19:1276–1284.2. Bozkaya D, Müftü S. Mechanics of the taper integrated screwed-in (TIS) abutments used in dental implants. J Biomech. 2005. 38:87–97.3. Coppedê AR, Bersani E, de Mattos Mda G, Rodrigues RC, Sartori IA, Ribeiro RF. Fracture resistance of the implant-abutment connection in implants with internal hex and internal conical connections under oblique compressive loading: an in vitro study. Int J Prosthodont. 2009. 22:283–286.4. Norton MR. An in vitro evaluation of the strength of a 1-piece and 2-piece conical abutment joint in implant design. Clin Oral Implants Res. 2000. 11:458–464.5. Reddy MS, O'Neal SJ, Haigh S, Aponte-Wesson R, Geurs NC. Initial clinical efficacy of 3-mm implants immediately placed into function in conditions of limited spacing. Int J Oral Maxillofac Implants. 2008. 23:281–288.6. Khraisat A, Stegaroiu R, Nomura S, Miyakawa O. Fatigue resistance of two implant/abutment joint designs. J Prosthet Dent. 2002. 88:604–610.7. Weigl P. New prosthetic restorative features of Ankylos implant system. J Oral Implantol. 2004. 30:178–188.8. Perriard J, Wiskott WA, Mellal A, Scherrer SS, Botsis J, Belser UC. Fatigue resistance of ITI implant-abutment connectors - a comparison of the standard cone with a novel internally keyed design. Clin Oral Implants Res. 2002. 13:542–549.9. Okeson JP. Management of temporomandibular disorders and occlusion. 1998. 4th ed. St. Louis: Mosby;44.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Influence of implant-abutment interface design, implant diameter and prosthetic table width on strength of implant-abutment interface: three-dimensional finite element analysis

- Rotational tolerances of a titanium abutment in the as-received condition and after screw tightening in a conical implant connection

- Effect of a counter-torque device and the internal hexagon of abutment on the tightening torque transmitted to the implant

- The effect of the difference of the implant fixture and abutment diameter for stress distribution

- A comparative study of the 1-piece and 2-piece conical abutment joint: the strength and the fatigue resistance