J Adv Prosthodont.

2011 Dec;3(4):177-185. 10.4047/jap.2011.3.4.177.

Accuracy of five implant impression technique: effect of splinting materials and methods

- Affiliations

-

- 1Lee Yeon Hab Dental Clinic, Daegu, Korea. leeddsms@hotmail.com

- 2Plant Dental Clinic, Changwon, Korea.

- KMID: 2054751

- DOI: http://doi.org/10.4047/jap.2011.3.4.177

Abstract

- PURPOSE

The aim of this study was to evaluate the effect of dimensional stability of splinting material on the accuracy of master casts.

MATERIALS AND METHODS

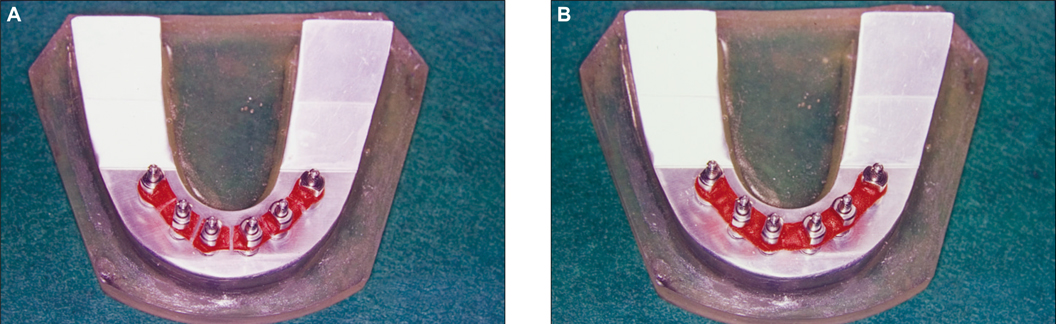

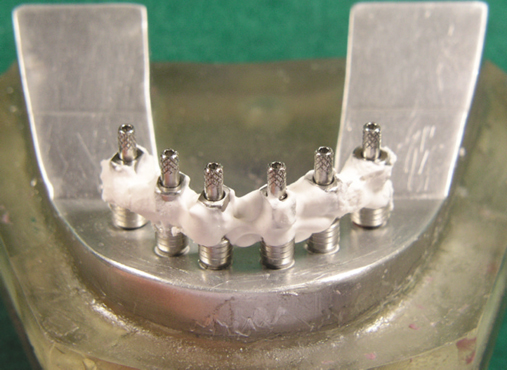

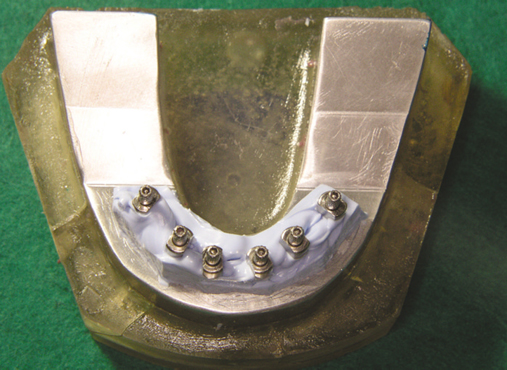

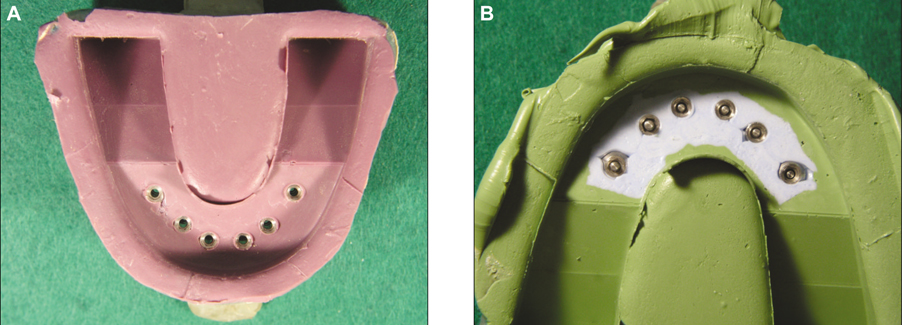

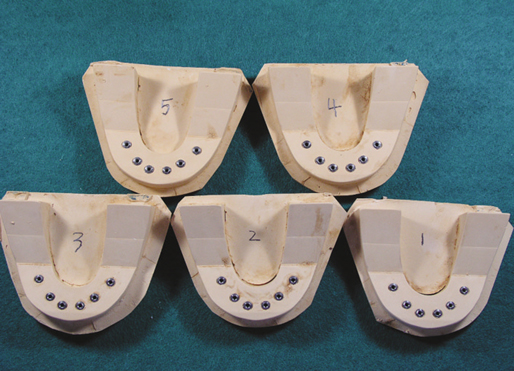

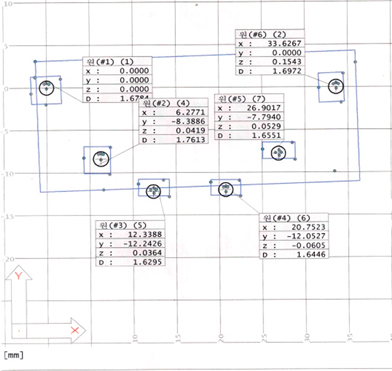

A stainless steel metal model with 6 implants embedded was used as a master model. Implant level impressions were made after square impression copings were splinted using 5 different techniques as follows. (1) Splinted with autopolymerizing resin and sectioned, reconnected to compensate polymerization shrinkage before the impression procedure. (2) Splinted with autopolymerizing resin just before impression procedure. (3) Primary impression made with impression plaster and secondary impression were made over with polyether impression material. (4) Splinted with impression plaster. (5) Splinted with VPS bite registration material. From master model, 5 impressions and 5 experimental casts, total 25 casts were made for each of 5 splinting methods. The distortion values of each splinting methods were measured using coordinate measuring machine, capable of recordings in the x-, y-, z-axes. A one-way analysis of variance (ANOVA) at a confidence level of 95% was used to evaluate the data and Tukey's studentized range test was used to determine significant differences between the groups.

RESULTS

Group 1 showed best accuracy followed by Group 3 & 4. Group 2 and 5 showed relatively larger distortion value than other groups. No significant difference was found between group 3, 4, 5 in x-axis, group 2, 3, 4 in y-axis and group 1, 3, 4, 5 in z-axis (P<.0001).

CONCLUSION

Both Splinting impression copings with autopolymerizing resin following compensation of polymerization shrinkage and splinting method with impression plaster can enhance the accuracy of master cast and impression plaster can be used simple and effective splinting material for implant impression procedure.

Keyword

MeSH Terms

Figure

Cited by 1 articles

-

Comparative accuracy of implant impression techniques with different splinting materials

J Dent Rehabil Appl Sci. 2023;39(1):9-20. doi: 10.14368/jdras.2023.39.1.9.

Reference

-

1. Adell R, Lekholm U, Rockler B, Brånemark PI. A 15-year study of osseointegrated implants in the treatment of the edentulous jaw. Int J Oral Surg. 1981. 10:387–416.2. Zarb GA, Schmitt A. The longitudinal clinical effectiveness of osseointegrated dental implants in anterior partially edentulous patients. Int J Prosthodont. 1993. 6:180–188.3. Goll GE. Production of accurately fitting full-arch implant frameworks: Part I-Clinical procedures. J Prosthet Dent. 1991. 66:377–384.4. Rangert B, Jemt T, Jörneus L. Forces and moments on Branemark implants. Int J Oral Maxillofac Implants. 1989. 4:241–247.5. Zarb GA, Schmitt A. The longitudinal clinical effectiveness of osseointegrated dental implants: the Toronto Study. Part II: The prosthetic results. J Prosthet Dent. 1990. 64:53–61.6. Jemt T. Failures and complications in 391 consecutively inserted fixed prostheses supported by Brånemark implants in edentulous jaws: a study of treatment from the time of prosthesis placement to the first annual checkup. Int J Oral Maxillofac Implants. 1991. 6:270–276.7. Jemt T. In vivo measurements of precision of fit involving implant-supported prostheses in the edentulous jaw. Int J Oral Maxillofac Implants. 1996. 11:151–158.8. Kallus T, Bessing C. Loose gold screws frequently occur in fullarch fixed prostheses supported by osseointegrated implants after 5 years. Int J Oral Maxillofac Implants. 1994. 9:169–178.9. Johansson G, Palmqvist S. Complications, supplementary treatment, and maintenance in edentulous arches with implant-supported fixed prostheses. Int J Prosthodont. 1990. 3:89–92.10. Tan KB, Rubenstein JE, Nicholls JI, Yuodelis RA. Three-dimensional analysis of the casting accuracy of one-piece, osseointegrated implant-retained prostheses. Int J Prosthodont. 1993. 6:346–363.11. Stumpel LJ 3rd, Quon SJ. Adhesive abutment cylinder luting. J Prosthet Dent. 1993. 69:398–400.12. Humphries RM, Yaman P, Bloem TJ. The accuracy of implant master casts constructed from transfer impressions. Int J Oral Maxillofac Implants. 1990. 5:331–336.13. Tautin FS. Impression making for osseointegrated dentures. J Prosthet Dent. 1985. 54:250–251.14. Henry PJ. An alternative method for the production of accurate casts and occlusal records in osseointegrated implant rehabilitation. J Prosthet Dent. 1987. 58:694–697.15. Carr AB, Stewart RB. Full-arch implant framework casting accuracy: preliminary in vitro observation for in vivo testing. J Prosthodont. 1993. 2:2–8.16. Assif D, Fenton A, Zarb G, Schmitt A. Comparative accuracy of implant impression procedures. Int J Periodontics Restorative Dent. 1992. 12:112–121.17. Barrett MG, de Rijk WG, Burgess JO. The accuracy of six impression techniques for osseointegrated implants. J Prosthodont. 1993. 2:75–82.18. Carr AB. Comparison of impression techniques for a five-implant mandibular model. Int J Oral Maxillofac Implants. 1991. 6:448–455.19. Gordon GE, Johnson GH, Drennon DG. The effect of tray selection on the accuracy of elastomeric impression materials. J Prosthet Dent. 1990. 63:12–15.20. Rueda LJ, Sy-Muñoz JT, Naylor WP, Goodacre CJ, Swartz ML. The effect of using custom or stock trays on the accuracy of gypsum casts. Int J Prosthodont. 1996. 9:367–373.21. Burns J, Palmer R, Howe L, Wilson R. Accuracy of open tray implant impressions: an in vitro comparison of stock versus custom trays. J Prosthet Dent. 2003. 89:250–255.22. Branemark PI, Zarb GA, Albrektsson T. Tissue-integrated prostheses. Osseointegration in clinical dentistry. 1985. Chicago: Quintessence;11–12. 253–257.23. Hsu CC, Millstein PL, Stein RS. A comparative analysis of the accuracy of implant transfer techniques. J Prosthet Dent. 1993. 69:588–593.24. Phillips KM, Nicholls JI, Ma T, Rubenstein J. The accuracy of three implant impression techniques: A three-dimensional analysis. Int J Oral Maxillofac Implants. 1994. 9:533–540.25. Herbst D, Nel JC, Driessen CH, Becker PJ. Evaluation of impression accuracy for osseointegrated implant supported superstructures. J Prosthet Dent. 2000. 83:555–561.26. Spector MR, Donovan TE, Nicholls JI. An evaluation of impression techniques for osseointegrated implants. J Prosthet Dent. 1990. 63:444–447.27. Inturregui JA, Aquilino SA, Ryther JS, Lund PS. Evaluation of three impression techniques for osseointegrated oral implants. J Prosthet Dent. 1993. 69:503–509.28. Burawi G, Houston F, Byrne D, Claffey N. A comparison of the dimensional accuracy of the splinted and unsplinted impression techniques for the Bone-Lock implant system. J Prosthet Dent. 1997. 77:68–75.29. Assif D, Marshak B, Schmidt A. Accuracy of implant impression techniques. Int J Oral Maxillofac Implants. 1996. 11:216–222.30. Naconecy MM, Teixeira ER, Shinkai RS, Frasca LC, Cervieri A. Evaluation of the accuracy of 3 transfer techniques for implant-supported prostheses with multiple abutments. Int J Oral Maxillofac Implants. 2004. 19:192–198.31. Vigolo P, Majzoub Z, Cordioli G. Evaluation of the accuracy of three techniques used for multiple implant abutment impressions. J Prosthet Dent. 2003. 89:186–192.32. Cabral LM, Guedes CG. Comparative analysis of 4 impression techniques for implants. Implant Dent. 2007. 16:187–194.33. Rhyu SM, Cho IH, Lim HS, Lim JH. A comparative study on the accuracy of master casts by implant impression techniques. J Korean Acad Prosthodont. 2002. 40:18–29.34. Brånemark PI. Osseointegration and its experimental background. J Prosthet Dent. 1983. 50:399–410.35. Millington ND, Leung T. Inaccurate fit of implant superstructures. Part 1: Stresses generated on the superstructure relative to the size of fit discrepancy. Int J Prosthodont. 1995. 8:511–516.36. Jemt T, Book K. Prosthesis misfit and marginal bone loss in edentulous implant patients. Int J Oral Maxillofac Implants. 1996. 11:620–625.37. Jemt T, Lie A. Accuracy of implant-supported prostheses in the edentulous jaw: analysis of precision of fit between cast gold-alloy frameworks and master casts by means of a three-dimensional photogrammetric technique. Clin Oral Implants Res. 1995. 6:172–180.38. Mojon P, Oberholzer JP, Meyer JM, Belser UC. Polymerization shrinkage of index and pattern acrylic resins. J Prosthet Dent. 1990. 64:684–688.39. ANSI-ADA Specification No.25 Dental gypsum products. 2000. Chicago: American dental association council on dental materials and equipment.40. Dumbrigue HB, Gurun DC, Javid NS. Prefabricated acrylic resin bars for splinting implant transfer copings. J Prosthet Dent. 2000. 84:108–110.41. Assif D, Nissan J, Varsano I, Singer A. Accuracy of implant impression splinted techniques: effect of splinting material. Int J Oral Maxillofac Implants. 1999. 14:885–888.42. Nissan J, Barnea E, Krauze E, Assif D. Impression technique for partially edentulous patients. J Prosthet Dent. 2002. 88:103–104.43. Eid N. An implant impression technique using a plaster splinting index combined with a silicone impression. J Prosthet Dent. 2004. 92:575–577.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Comparative accuracy of implant impression techniques with different splinting materials

- A Comparative Study on the Accuracy of Master Casts by Implant Impression Techniques

- Comparative accuracy of new implant impression technique using abutments as impression copings with an angulated implant model

- Reverse engineering technique on the evaluation of impression accuracy in angulated implants

- A STUDY OF IMPRESSION TECHNIQUE USING PUTTY MATERIAL OF PVS IMPRESSION MATERIAL