J Korean Acad Prosthodont.

2008 Oct;46(5):500-510. 10.4047/jkap.2008.46.5.500.

Detorque force and surface change of coated abutment screw after repeated closing and opening

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Chosun University, Korea. jhajung@mail.chosun.ac.kr

- KMID: 2000407

- DOI: http://doi.org/10.4047/jkap.2008.46.5.500

Abstract

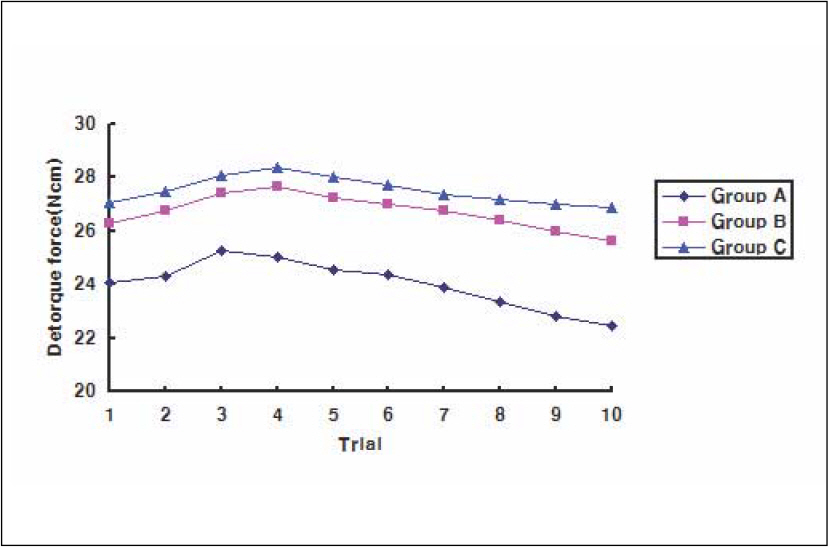

- STATEMENT OF PROBLEM: Recently researches about WC/C (Tungsten Carbide/Carbon) or TiN (Titanium Nitride) coating on abutment screws are going on. It decreases friction coefficient, resistance against corrosion and withdrawal of physical fragility when the coating is applied to the metal surfaces. It is reported that coated abutment screws improved abrasion, adaptability and detorque force. PURPOSE: This study is about the effects of coated abutment screws on loosening of screw and for the purpose of solving the loosening phenomenon of abutment screws which is clinical problem. MATERIAL AND METHODS: Detorque force and surface changes are compared when 10 times of repeated closing and opening are applied to both uncoated titanium abutment screws (Group A) and coated abutment screws with WC/C (Group B) and TiN (Group C). Each group was made up of 10 abutment screws. RESULTS: 1. Before repeated closing and opening, Somewhat rough surface with regular direction was observed in Group A. Coated granules were observed in group B and group C and overall coated layer appeared in regular and smooth form. 2. Before repeated closing and opening, The coated surface showed bigger and thicker size of coated granules in Group C than Group B. 3. After repeated closing and opening, abrasion and deformation of abutment screw surface was observed in Group A and Group B. Exfoliation phenomenon was observed in Group B. 4. Group A showed biggest range of decrease when the weight changes of abutment screws were measured before and after repeated closing and opening. Group C showed less weight changes than Group B but there was no statistical difference between two groups. 5. Group B and Group C showed higher average detorque force than Group A and there was statistical difference. 6. Group A showed more prominent decrease tendency of average detorque force than Group B and Group C. CONCLUSION: Coated abutment screws with WC/C or TiN did not show prominent surface changes than uncoated titanium abutment screws even though they were repeatedly used. And they showed excellent resistance against friction and high detorque force. Thus it is considered that adaptation of WC/C or TiN coating on abutment screws will improve the screw loosening problem.

Keyword

Figure

Cited by 3 articles

-

A study on accuracy and application of the implant torque controller used in dental clinic

Young-Hun Joo, Jin-Han Lee

J Korean Acad Prosthodont. 2011;49(3):197-205. doi: 10.4047/jkap.2011.49.3.197.A comparative study on the fit and screw joint stability of ready-made abutment and CAD-CAM custom-made abutment

Jong-Wook Kim, Yu-Ri Heo, Hee-Jung Kim, Chae-Heon Chung

J Korean Acad Prosthodont. 2013;51(4):276-283. doi: 10.4047/jkap.2013.51.4.276.Fit analysis of CAD-CAM custom abutment using micro-CT

Gwang-Seok Min, Chae-Heon Chung, Hee-Jung Kim

J Korean Acad Prosthodont. 2016;54(4):370-378. doi: 10.4047/jkap.2016.54.4.370.

Reference

-

1.Branemark PI. Osseointegration and its experimental background. J Prosthet Dent. 1983. 50:399–410.

Article2.Goodcare CJ., Kan JY., Rungcharassaeng K. Clinical complications of osseointgrated implants. J Prosthet Dent. 1999. 81:537–52.3.Tolman DE., Laney WR. Tissue-integrated prosthesis complications. Int J Oral Maxillofac Implants. 1992. 7:477–84.

Article4.Carlson B., Carlsson GE. Prosthodontic complications in osseointegrated dental implant treatment. Int J Oral Maxillofac Implants. 1994. 9:90–4.

Article5.Taylor TD. Prosthodontic problems and limitations associated with osseointegration. J Prosthet Dent. 1998. 79:74–8.

Article6.Goodcare CJ., Bernal G., Rungcharassaeng K., Kan JY. Clinical complications with implants and implant prostheses. J Prosthet Dent. 2003. 90:121–32.7.Jemt T. Failures and complications in 391 consecutively inserted fixed prostheses supported by Branemark implants in edentulous jaws: a study of treatment from the time of prosthesis placement the first annual check up. Int J Oral Maxillofac Implants. 1991. 6:270–6.8.Jemt T., Pettersson P. A 3-year follow-up study on single implant treatment. J Dent. 1993. 21:203–8.

Article9.Binon PP., Sutter F., Beaty K., Brunski J., Gulbransen H., Weiner R. The role of screws in implant systems. Int J Oral Maxillofac Implants. 1994. 9:8–63.10.Martin WC., Woody RD., Miller BH., Miller AW. Implant abutment screw rotations and preloads for four different screw materials and surfaces. J Prosthet Dent. 2001. 86:24–32.

Article11.Lang LA., May KB., Wang RF. The effect of the use of a counter-torque device on the abutment-implant complex. J Prosthet Dent. 1999. 81:411–7.

Article12.Haack JE., Sakaguchi RL., Sun T., Coffey JP. Elongation and preload stress in dental implant abutment screws. Int J Oral Maxillofac Implants. 1995. 10:529–36.13.Motosh N. Development of design charts for bolts preloaded up to the plastic range. J Eng Ind. 1976. 98:849–51.

Article14.Drago CJ. A clinical study of the efficacy of gold-tite square abutment screws in cemented-retained implant restorations. Int J Oral Maxillofac Implants. 2003. 18:273–8.15.Mezger PR. Creugers NH. Titanium nitride coatings in clinical dentistry. J Dent. 1992. 20:342–4.16.Binon PP. Implants and components: entering the new millenium. Int J Oral Maxillofac Implants. 2000. 15:76–94.17.Choi JU., Jeong CM., Jeon YC., Lim JS., Jeong HC., Eom TG. Influence of tungsten carbide/carbon coating on the preload of implant abutment screws. J Kor Acad Prosthodont. 2006. 44:229–42.18.Weiss EI., Kozak D., Gross MD. Effect of repeated closures on opening torque values in seven abutment-implant systems. J Prosthet Dent. 2000. 84:194–9.

Article19.Bickford JH. An introduction to the design and behavior of bolted joints. 3rd ed.New York: Marcel Dekker 528-2;1995.20.Kim SK., Lee JB., Koak JY., Heo SJ., Lee KR., Cho LR., Lee SS. An abutment screw loosening study of Diamond Like Carbon-coated CP titanium implant. J Oral Rehabil. 2005. 32:346–50.21.Byrne D., Jacobs S., O' connell B., Houston F., Claffey N. Preloads generated with repeated tightening in three types of screws used in dental implant assemblies. J Prosthodont. 2006. 15:164–71.

Article22.Kim HJ., Choe HC., Chung CH. Effect of TiN coating of abutment screw on detorque force. J Kor Acad Prosthodont. 2007. 45:329–38.23.Winkler S., Ring K., Ring JD., Boberick KG. Implant screw mechanics and the settling effect: overview. J Oral Implantol. 2003. 29:242–5.24.Jorneus L., Jemt T., Carlsson L. Loads and designs of screw joints for single crowns supported by osseointegrated implants. Int J Oral Maxillofac Implants. 1992. 7:353–9.25.Sakaguchi RL., Borgersen SE. Nonlinear contact analysis of preload in dental implant screws. Int J Oral Maxillofac Implants. 1995. 10:295–302.26.Binon PP. Implants and components: entering the new millenium. Int J Oral Maxillofac Implants. 2000. 15:76–94.27.Sopwith DG. The distribution of load in screw threads. Proc Inst Mech Eng. 1948. 159:373–83.

Article28.Milic M., Milosavljevic M., Bibic N., Nenadovic T. Mechanical properties of sputtered TiN coatings. Thin Solid Films. 1985. 126:319–23.

Article29.Standlee JP., Caputo AA., Chwu MY., Sun TT. Accuracy of mechanical torque-limiting devices for implant. Int J Oral Maxillofac Implants. 2002. 17:220–4.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Detorque force of TiN-coated abutment screw with various coating thickness after repeated closing and opening

- Surface change and fit of TiN-coated abutment screw after repeated closing and opening

- Effect of TiN coating of abutment screw on detorque force

- Abrasion of abutment screw coated with TiN

- Changes of abutment screw after repeated closing and opening