J Adv Prosthodont.

2015 Feb;7(1):39-46. 10.4047/jap.2015.7.1.39.

Mechanical and interfacial characterization of laser welded Co-Cr alloy with different joint configurations

- Affiliations

-

- 1Department of Biomaterials, School of Dentistry, National and Kapodistrian, University of Athens, Greece. szinelis@dent.uoa.gr

- 2Department of Conservative Dentistry, University of Mosul, Iraq.

- 3Cork University Dental School and Hospital, University College Cork, Ireland.

- 4Department of Dental Technology, Technological Educational Institution of Athens, Greece.

- KMID: 1974889

- DOI: http://doi.org/10.4047/jap.2015.7.1.39

Abstract

- PURPOSE

The mechanical and interfacial characterization of laser welded Co-Cr alloy with two different joint designs.

MATERIALS AND METHODS

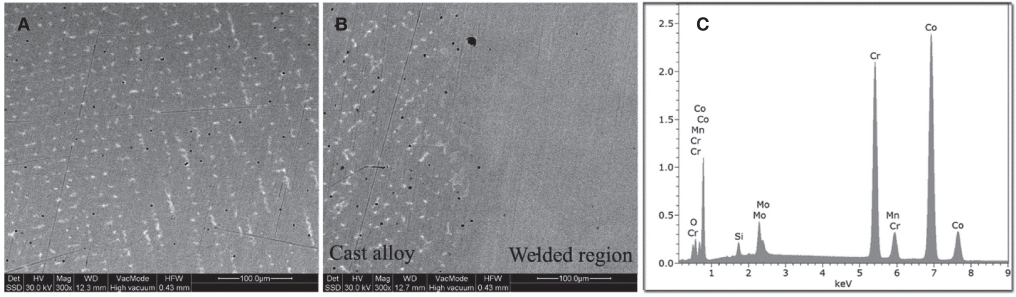

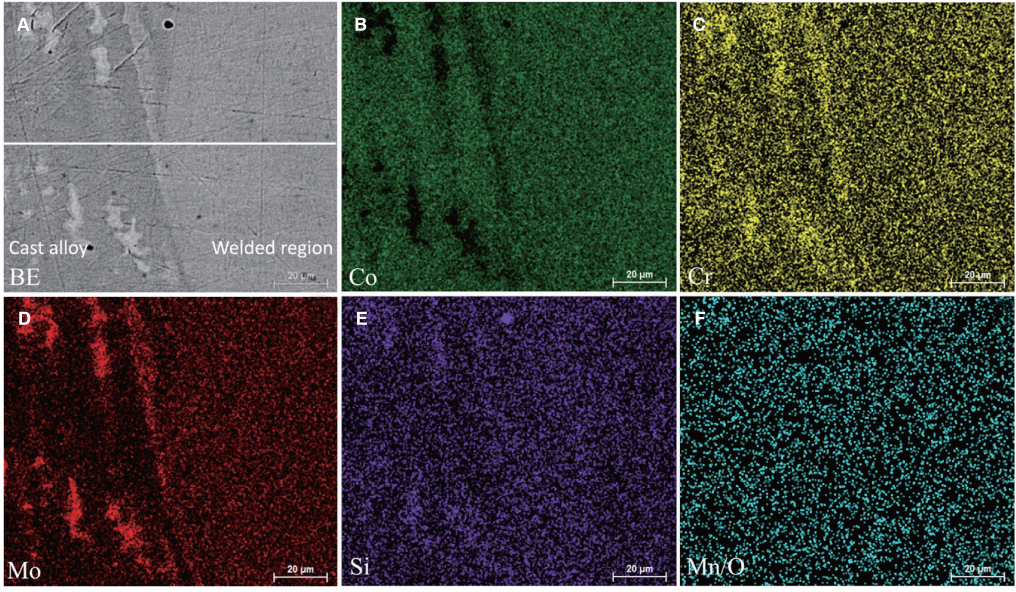

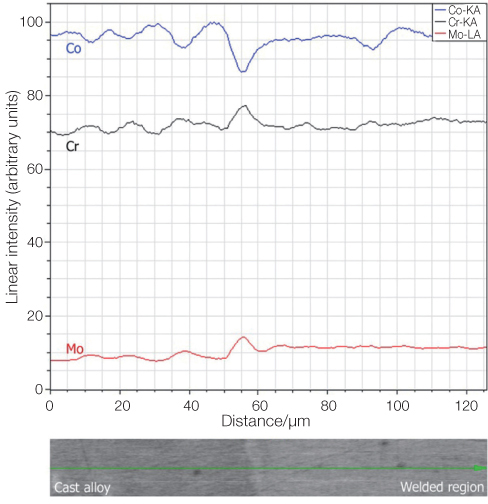

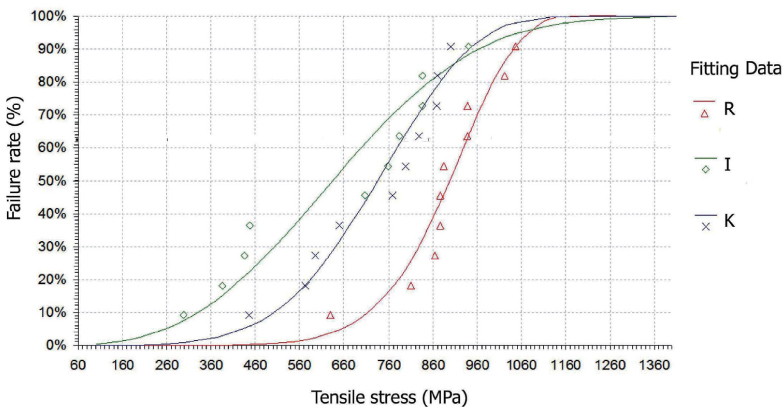

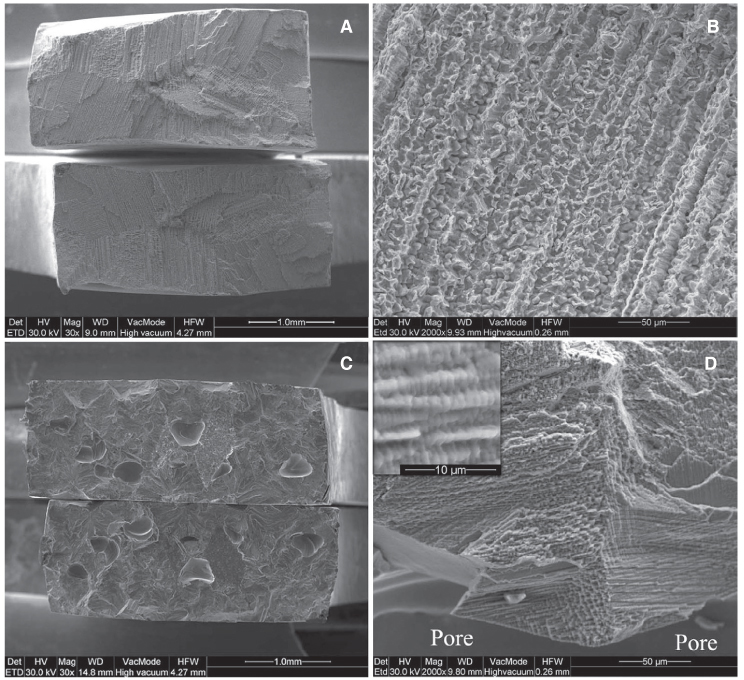

Dumbbell cast specimens (n=30) were divided into 3 groups (R, I, K, n=10). Group R consisted of intact specimens, group I of specimens sectioned with a straight cut, and group K of specimens with a 45degrees bevel made at the one welding edge. The microstructure and the elemental distributions of alloy and welding regions were examined by an SEM/EDX analysis and then specimens were loaded in tension up to fracture. The tensile strength (TS) and elongation (epsilon) were determined and statistically compared among groups employing 1-way ANOVA, SNK multiple comparison test (alpha=.05) and Weibull analysis where Weibull modulus m and characteristic strength sigmaomicron were identified. Fractured surfaces were imaged by a SEM.

RESULTS

SEM/EDX analysis showed that cast alloy consists of two phases with differences in mean atomic number contrast, while no mean atomic number was identified for welded regions. EDX analysis revealed an increased Cr and Mo content at the alloy-joint interface. All mechanical properties of group I (TS, epsilon, m and sigmaomicron) were found inferior to R while group K showed intermediated values without significant differences to R and I, apart from elongation with group R. The fractured surfaces of all groups showed extensive dendritic pattern although with a finer structure in the case of welded groups.

CONCLUSION

The K shape joint configuration should be preferred over the I, as it demonstrates improved mechanical strength and survival probability.

Keyword

MeSH Terms

Figure

Reference

-

1. Ayyıldız S, Soylu EH, Ide S, Kılıç S, Sipahi C, Pişkin B, Gökçe HS. Annealing of Co-Cr dental alloy: effects on nanostructure and Rockwell hardness. J Adv Prosthodont. 2013; 5:471–478.2. Al Jabbari YS. Physico-mechanical properties and prosthodontic applications of Co-Cr dental alloys: a review of the literature. J Adv Prosthodont. 2014; 6:138–145.3. Byrne G. Soldering in prosthodontics-an overview, part I. J Prosthodont. 2011; 20:233–243.4. Yannikakis S, Prombonas A. Improving the fit of implant prosthetics: an in vitro study. Int J Oral Maxillofac Implants. 2013; 28:126–134.5. Barbi FC, Camarini ET, Silva RS, Endo EH, Pereira JR. Comparative analysis of different joining techniques to improve the passive fit of cobalt-chromium superstructures. J Prosthet Dent. 2012; 108:377–385.6. Tiossi R, Rodrigues RC, de Mattos Mda G, Ribeiro RF. Comparative analysis of the fit of 3-unit implant-supported frameworks cast in nickel-chromium and cobalt-chromium alloys and commercially pure titanium after casting, laser welding, and simulated porcelain firings. Int J Prosthodont. 2008; 21:121–123.7. Rocha R, Pinheiro AL, Villaverde AB. Flexural strength of pure Ti, Ni-Cr and Co-Cr alloys submitted to Nd:YAG laser or TIG welding. Braz Dent J. 2006; 17:20–23.8. de Castro GC, de Araújo CA, Mesquita MF, Consani RL, Nóbilo MA. Stress distribution in Co-Cr implant frameworks after laser or TIG welding. Braz Dent J. 2013; 24:147–151.9. Madhan Kumar S, Sethumadhava JR, Anand Kumar V, Manita G. Effects of conventional welding and laser welding on the tensile strength, ultimate tensile strength and surface characteristics of two cobalt-chromium alloys: a comparative study. J Indian Prosthodont Soc. 2012; 12:87–93.10. Zupancic R, Legat A, Funduk N. Tensile strength and corrosion resistance of brazed and laser-welded cobalt-chromium alloy joints. J Prosthet Dent. 2006; 96:273–282.11. Baba N, Watanabe I, Liu J, Atsuta M. Mechanical strength of laser-welded cobalt-chromium alloy. J Biomed Mater Res B Appl Biomater. 2004; 69:121–124.12. Apotheker H, Nishimura I, Seerattan C. Laser-welded vs soldered nonprecious alloy dental bridges: a comparative study. Lasers Surg Med. 1984; 4:207–213.13. Huling JS, Clark RE. Compratative distortion in three-unit fixed prostheses joined by laser welding, conventioanl soldering, or casting in one piece. J Dent Res. 1977; 56:128–134.14. Bertrand C, Le Petitcorps Y, Albingre L, Dupuis V. The laser welding technique applied to the non precious dental alloys procedure and results. Br Dent J. 2001; 190:255–257.15. Baba N, Watanabe I. Penetration depth into dental casting alloys by Nd:YAG laser. J Biomed Mater Res B Appl Biomater. 2005; 72:64–68.16. Al Jabbari YS, Koutsoukis T, Barmpagadaki X, El-Danaf EA, Fournelle RA, Zinelis S. Effect of Nd:YAG laser parameters on the penetration depth of a representative Ni-Cr dental casting alloy. Lasers Med Sci. 2013; DOI10.1007/s10103-013-1502-3.17. Watanabe I, Topham DS. Laser welding of cast titanium and dental alloys using argon shielding. J Prosthodont. 2006; 15:102–107.18. Bertrand C, le Petitcorps Y, Albingre L, Dupuis V. Optimization of operator and physical parameters for laser welding of dental materials. Br Dent J. 2004; 196:413–418. discussion 407.19. Wulfes H. Precision milling and partial denture constructions. 1st ed. Bremen Germany: Academia Dental;2005. p. 133–135.20. Nomoto R, Takayama Y, Tsuchida F, Nakajima H. Non-destructive three-dimensional evaluation of pores at different welded joints and their effects on joints strength. Dent Mater. 2010; 26:e246–e252.21. Watanabe I, Wallace C. Bond strength of gold alloys laser welded to cobalt-chromium alloy. Open Dent J. 2008; 2:109–113.22. Srimaneepong V, Yoneyama T, Kobayashi E, Doi H, Hanawa T. Comparative study on torsional strength, ductility and fracture characteristics of laser-welded alpha+beta Ti-6Al-7Nb alloy, CP Titanium and Co-Cr alloy dental castings. Dent Mater. 2008; 24:839–845.23. Watanabe I, Benson AP, Nguyen K. Effect of heat treatment on joint properties of laser-welded Ag-Au-Cu-Pd and Co-Cr alloys. J Prosthodont. 2005; 14:170–174.24. Simchi A, Pohl H. Effects of laser sintering processing parameters on the microstructure and densification of iron powder. Mater Sci Eng A Struct Mater. 2003; 359:119–128.25. NaBadalung DP, Nicholls JI. Laser welding of a cobalt-chromium removable partial denture alloy. J Prosthet Dent. 1998; 79:285–290.26. Tiossi R, Falcão-Filho H, Aguiar Júnior FA, Rodrigues RC, Mattos Mda G, Ribeiro RF. Modified section method for laser-welding of ill-fitting cp Ti and Ni-Cr alloy one-piece cast implant-supported frameworks. J Oral Rehabil. 2010; 37:359–363.27. Nuñez-Pantoja JM, Vaz LG, Nóbilo MA, Henriques GE, Mesquita MF. Effects of laser-weld joint opening size on fatigue strength of Ti-6Al-4V structures with several diameters. J Oral Rehabil. 2011; 38:196–201.28. Xin XZ, Chen J, Xiang N, Gong Y, Wei B. Surface characteristics and corrosion properties of selective laser melted Co-Cr dental alloy after porcelain firing. Dent Mater. 2014; 30:263–270.29. Dharmar S, Rathnasamy RJ, Swaminathan TN. Radiographic and metallographic evaluation of porosity defects and grain structure of cast chromium cobalt removable partial dentures. J Prosthet Dent. 1993; 69:369–373.30. Al Jabbari YS, Koutsoukis T, Barmpagadaki X, Zinelis S. Metallurgical and interfacial characterization of PFM Co-Cr dental alloys fabricated via casting, milling or selective laser melting. Dent Mater. 2014; 30:e79–e88.31. Quinn JB, Quinn GD. A practical and systematic review of Weibull statistics for reporting strengths of dental materials. Dent Mater. 2010; 26:135–147.32. Takayama Y, Nomoto R, Nakajima H, Ohkubo C. Effects of argon gas flow rate on laser-welding. Dent Mater J. 2012; 31:316–326.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Mechanical properties of laser welded Co-Cr alloy

- Mechanical properties of laser-welded cast titanium and titanium alloy

- MECHANICAL PROPERTIES OF TITANIUM CONNECTORS TREATED BY VARIOUS WELDING TECHNIQUES

- TENSILE STRENGTH OF LASER WELDED-TITANIUM AND GOLD ALLOYS

- Comparison of the mechanical properties and microstructures of fractured surface for Co-Cr alloy fabricated by conventional cast, 3-D printing laser-sintered and CAD/CAM milled techniques