J Dent Rehabil Appl Sci.

2022 Jun;38(2):71-80. 10.14368/jdras.2022.38.2.71.

Properties of translucent zirconia and lithium disilicate glass-ceramics: a literature review

- Affiliations

-

- 1Department of Dentistry, Gangneung Asan Hospital, University of Ulsan College of Medicine, Gangneung, Republic of Korea

- 2Department of Prosthodontics and Research Institute of Oral Science, College of Dentistry, Gangneung-Wonju National University, Gangneung, Republic of Korea

- KMID: 2535014

- DOI: http://doi.org/10.14368/jdras.2022.38.2.71

Abstract

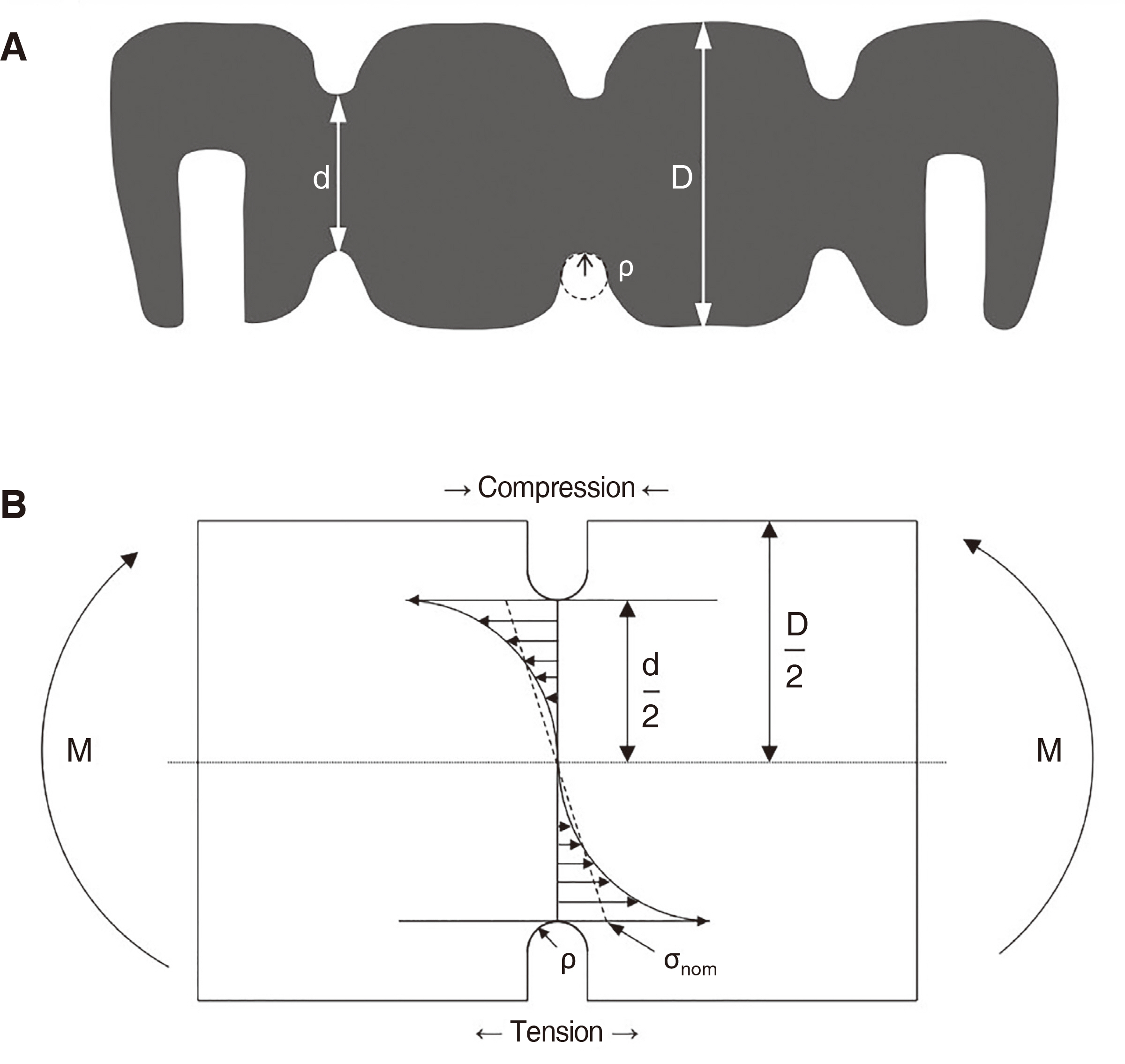

- Although low translucency 3 mol% yttria stabilized tetragonal zirconia polycrystal has excellent mechanical properties, it has limited application as a monolithic prosthesis. To improve these optical limitations, translucent zirconia has improved esthetics due to an increase in the cubic phase; however, it is accompanied by a decrease in mechanical properties simultaneously. Lithium disilicate has improved its mechanical properties through crystal size reduction and various heat treatment methods; therefore, its clinical application range is continuously increasing. Translucent zirconia shows a wide distribution of physical properties depending on the yttria content and lithium disilicate according to the size and density of crystal grains. As a result, the indications for translucent zirconia and lithium disilicate are increasing. Therefore, in this literature review, we intend to examine the rationale behind the material selection criteria in clinical situations and considerations for designing fixed dental prostheses including pontic, in particular, by summarizing recent studies.

Figure

Reference

-

References

1. Ghodsi S, Jafarian Z. 2018; A review on translucent zirconia. Eur J Prosthodont Restor Dent. 26:62–74. DOI: 10.1922/EJPRD_01759Ghodsi13. PMID: 29797847.2. Zhang Y. 2014; Making yttria-stabilized tetragonal zirconia translucent. Dent Mater. 30:1195–203. DOI: 10.1016/j.dental.2014.08.375. PMID: 25193781. PMCID: PMC4167579.

Article3. Sulaiman TA, Abdulmajeed AA, Donovan TE, Ritter AV, Vallittu PK, Närhi TO, Lassila LV. 2015; Optical properties and light irradiance of monolithic zirconia at variable thicknesses. Dent Mater. 31:1180–7. DOI: 10.1016/j.dental.2015.06.016. PMID: 26198027.

Article4. Baldissara P, Wandscher VF, Marchionatti AME, Parisi C, Monaco C, Ciocca L. 2018; Translucency of IPS e.max and cubic zirconia monolithic crowns. J Prosthet Dent. 120:269–75. DOI: 10.1016/j.prosdent.2017.09.007. PMID: 29475752.

Article5. Hallmann L, Ulmer P, Reusser E, Louvel M, Hämmerle C. 2012; Effect of dopants and sintering temperature on microstructure and low temperature degradation of dental Y-TZP-zirconia. J Eur Ceram Soc. 32:4091–104. DOI: 10.1016/j.jeurceramsoc.2012.07.032.

Article6. Nakamura T, Nakano Y, Usami H, Wakabayashi K, Ohnishi H, Sekino T, Yatani H. 2016; Translucency and low-temperature degradation of silica-doped zirconia: A pilot study. Dent Mater J. 35:571–7. DOI: 10.4012/dmj.2015-274. PMID: 27477222.

Article7. Zhang Y, Lawn BR. 2018; Novel zirconia materials in dentistry. J Dent Res. 97:140–7. DOI: 10.1177/0022034517737483. PMID: 29035694. PMCID: PMC5784474.

Article8. Zhang F, Inokoshi M, Batuk M, Hadermann J, Naert I, Van Meerbeek B, Vleugels J. 2016; Strength, toughness and aging stability of highly-translucent Y-TZP ceramics for dental restorations. Dent Mater. 32:e327–37. DOI: 10.1016/j.dental.2016.09.025. PMID: 27697332.

Article9. Stawarczyk B, Ozcan M, Hallmann L, Ender A, Mehl A, Hämmerlet CH. 2013; The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Investig. 17:269–74. DOI: 10.1007/s00784-012-0692-6. PMID: 22358379.

Article10. Bravo-Leon A, Morikawa Y, Kawahara M, Mayo MJ. 2002; Fracture toughness of nanocrystalline tetragonal zirconia with low yttria content. Acta Materialia. 50:4555–62. DOI: 10.1016/S1359-6454(02)00283-5.

Article11. Wang J, Rainforth M, Stevens R. Meriani S, Palmonari C, editors. 1989. The grain size dependence of the mechanical properties in TZP ceramics. Zirconia' 88: Advances in Zirconia Science and Technology. Springer Netherlands;Dordrecht: p. 337–66. DOI: 10.1007/978-94-009-1139-0_31.

Article12. Sulaiman TA. 2020; Materials in digital dentistry-A review. J Esthet Restor Dent. 32:171–81. DOI: 10.1111/jerd.12566. PMID: 31943720.

Article13. Holman CD, Lien W, Gallardo FF, Vandewalle KS. 2020; Assessing flexural strength degradation of new cubic containing zirconia materials. J Contemp Dent Pract. 21:114–8. DOI: 10.5005/jp-journals-10024-2762. PMID: 32381812.

Article14. McLaren EA, Lawson N, Choi J, Kang J, Trujillo C. 2017; New high-translucent cubic-phase-containing zirconia: Clinical and laboratory considerations and the effect of air abrasion on strength. Compend Contin Educ Dent. 38:e13–6. PMID: 28586235.15. Zarone F, Di Mauro MI, Ausiello P, Ruggiero G, Sorrentino R. 2019; Current status on lithium disilicate and zirconia: a narrative review. BMC Oral Health. 19:134. DOI: 10.1186/s12903-019-0838-x. PMID: 31272441. PMCID: PMC6610968. PMID: bfc46b06676d444baad3dcf6a074e8f1. PMID: bfc46b06676d444baad3dcf6a074e8f1.

Article16. Zhang F, Reveron H, Spies BC, Van Meerbeek B, Chevalier J. 2019; Trade-off between fracture resistance and translucency of zirconia and lithium-disilicate glass ceramics for monolithic restorations. Acta Biomater. 91:24–34. DOI: 10.1016/j.actbio.2019.04.043. PMID: 31034947.

Article17. Sulaiman TA, Abdulmajeed AA, Delgado A, Donovan TE. 2020; Fracture rate of 188695 lithium disilicate and zirconia ceramic restorations after up to 7.5 years of clinical service: A dental laboratory survey. J Prosthet Dent. 123:807–10. DOI: 10.1016/j.prosdent.2019.06.011. PMID: 31703926.

Article18. Laksono H. 2007; The clinical potential and limits of the all-ceramic fixed partial denture restorations. Dental Journal. 40:186–92. DOI: 10.20473/j.djmkg.v40.i4.p186-192.

Article19. Mazza LC, Lemos CAA, Pesqueira AA, Pellizzer EP. 2021; Survival and complications of monolithic ceramic for tooth-supported fixed dental prostheses: A systematic review and meta-analysis. J Prosthet Dent. S0022-3913(21)00065-2. DOI: 10.1016/j.prosdent.2021.01.020. PMID: 33745685.

Article20. Garling A, Sasse M, Becker MEE, Kern M. 2019; Fifteenyear outcome of three-unit fixed dental prostheses made from monolithic lithium disilicate ceramic. J Dent. 89:103178. DOI: 10.1016/j.jdent.2019.08.001. PMID: 31394121.

Article21. Reich S, Endres L, Weber C, Wiedhahn K, Neumann P, Schneider O, Rafai N, Wolfart S. 2014; Three-unit CAD/CAM-generated lithium disilicate FDPs after a mean observation time of 46 months. Clin Oral Investig. 18:2171–8. DOI: 10.1007/s00784-014-1191-8. PMID: 24493230.

Article22. Kern M, Sasse M, Wolfart S. 2012; Ten-year outcome of three-unit fixed dental prostheses made from monolithic lithium disilicate ceramic. J Am Dent Assoc. 143:234–40. DOI: 10.14219/jada.archive.2012.0147. PMID: 22383203.

Article23. Makarouna M, Ullmann K, Lazarek K, Boening KW. 2011; Six-year clinical performance of lithium disilicate fixed partial dentures. Int J Prosthodont. 24:204–6. PMID: 21519566.24. Zadeh PN, Lümkemann N, Sener B, Eichberger M, Stawarczyk B. 2018; Flexural strength, fracture toughness, and translucency of cubic/tetragonal zirconia materials. J Prosthet Dent. 120:948–54. DOI: 10.1016/j.prosdent.2017.12.021. PMID: 29807742.

Article25. Lawson NC, Jurado CA, Huang CT, Morris GP, Burgess JO, Liu PR, Kinderknecht KE, Lin CP, Givan DA. 2019; Effect of surface treatment and cement on fracture load of traditional zirconia (3Y), translucent zirconia (5Y), and lithium disilicate crowns. J Prosthodont. 28:659–65. DOI: 10.1111/jopr.13088. PMID: 31145492. PMCID: PMC6642729.

Article26. Yan J, Kaizer MR, Zhang Y. 2018; Load-bearing capacity of lithium disilicate and ultra-translucent zirconias. J Mech Behav Biomed Mater. 88:170–5. DOI: 10.1016/j.jmbbm.2018.08.023. PMID: 30173069. PMCID: PMC6179910.

Article27. Heintze SD, Monreal D, Reinhardt M, Eser A, Peschke A, Reinshagen J, Rousson V. 2018; Fatigue resistance of all-ceramic fixed partial dentures - Fatigue tests and finite element analysis. Dent Mater. 34:494–507. DOI: 10.1016/j.dental.2017.12.005. PMID: 29395474.

Article28. Kim HK. 2020; Optical and mechanical properties of highly translucent dental zirconia. Materials. 13:3395. DOI: 10.3390/ma13153395. PMID: 32751942. PMCID: PMC7435650. PMID: 5291091c6c4543b7bc40eb9cc2ab8670. PMID: 5291091c6c4543b7bc40eb9cc2ab8670.

Article29. Cho YE, Lim YJ, Han JS, Yeo IS, Yoon HI. 2020; Effect of yttria content on the translucency and masking ability of yttria-stabilized tetragonal zirconia polycrystal. Materials. 13:4726. DOI: 10.3390/ma13214726. PMID: 33105902. PMCID: PMC7660169. PMID: e89f00a2a2964cb2906ceca10d7c27d7. PMID: e89f00a2a2964cb2906ceca10d7c27d7.

Article30. Choo SS, Ko KH, Huh YH, Park CJ, Cho LR. 2021; Fatigue resistance of anterior monolithic crowns produced from CAD-CAM materials: An in vitro study. J Prosthet Dent. S0022-3913(21)00568-0. DOI: 10.1016/j.prosdent.2021.09.034. PMID: 34980473.

Article31. Fischer H, Weber M, Eck M, Erdrich A, Marx R. 2004; Finite element and experimental analyses of polymer-based dental bridges reinforced by ceramic bars. J Biomech. 37:289–94. DOI: 10.1016/j.jbiomech.2003.08.013. PMID: 14757447.

Article32. Mahmood DJ, Linderoth EH, Vult von Steyern P. 2011; The influence of support properties and complexity on fracture strength and fracture mode of allceramic fixed dental prostheses. Acta Odont Scand. 69:229–37. DOI: 10.3109/00016357.2010.549508. PMID: 21231816.

Article33. Scherrer SS, de Rijk WG. 1993; The fracture resistance of all-ceramic crowns on supporting structures with different elastic moduli. Int J Prosthodont. 6:462–7. PMID: 8297457.34. Chun KJ, Choi HH, Lee JY. 2014; Comparison of mechanical property and role between enamel and dentin in the human teeth. J Dent Biomech. 5:1758736014520809. DOI: 10.1177/1758736014520809. PMID: 24550998. PMCID: PMC3924884.

Article35. Elsaka SE, Elnaghy AM. 2016; Mechanical properties of zirconia reinforced lithium silicate glass-ceramic. Dent Mater. 32:908–14. DOI: 10.1016/j.dental.2016.03.013. PMID: 27087687.

Article36. Pereira GKR, Graunke P, Maroli A, Zucuni CP, Prochnow C, Valandro LF, Caldas RA, Bacchi A. 2019; Lithium disilicate glass-ceramic vs translucent zirconia polycrystals bonded to distinct substrates: Fatigue failure load, number of cycles for failure, survival rates, and stress distribution. J Mech Behav Biomed Mater. 91:122–30. DOI: 10.1016/j.jmbbm.2018.12.010. PMID: 30579109.

Article37. Gardell E, Larsson C, von Steyern PV. 2021; Translucent zirconium dioxide and lithium disilicate: A 3-year follow-up of a prospective, practice-based randomized controlled trial on posterior monolithic crowns. Int J Prosthodont. 34:163–72. DOI: 10.11607/ijp.6795. PMID: 33882563.

Article38. Solá-Ruiz MF, Baixauli-López M, Roig-Vanaclocha A, Amengual-Lorenzo J, Agustín-Panadero R. 2021; Prospective study of monolithic zirconia crowns: clinical behavior and survival rate at a 5-year follow-up. J Prosthodont Res. 65:284–90. DOI: 10.2186/jpr.JPR_D_20_00034. PMID: 33041280.

Article39. Ambré MJ, Aschan F, Vult von Steyern P. 2013; Fracture strength of yttria-stabilized zirconium-dioxide (Y-TZP) fixed dental prostheses (FDPs) with different abutment core thicknesses and connector dimensions. J Prosthodont. 22:377–82. DOI: 10.1111/jopr.12003. PMID: 23289522.

Article40. Motta AB, Pereira LC, da Cunha AR, Duda FP. 2008; The influence of the loading mode on the stress distribution on the connector region of metal-ceramic and all-ceramic fixed partial denture. Artif Organs. 32:283–91. DOI: 10.1111/j.1525-1594.2008.00544.x. PMID: 18370942.

Article41. Quinn GD, Studart AR, Hebert C, VerHoef JR, Arola D. 2010; Fatigue of zirconia and dental bridge geometry: Design implications. Dent Mater. 26:1133–6. DOI: 10.1016/j.dental.2010.07.014. PMID: 20813401. PMCID: PMC2967591.

Article42. Lohbauer U, Amberger G, Quinn GD, Scherrer SS. 2010; Fractographic analysis of a dental zirconia framework: a case study on design issues. J Mech Behav Biomed Mater. 3:623–9. DOI: 10.1016/j.jmbbm.2010.07.004. PMID: 20826369. PMCID: PMC3086638.

Article43. Larsson C, Holm L, Lövgren N, Kokubo Y, Vult von Steyern P. 2007; Fracture strength of four-unit Y-TZP FPD cores designed with varying connector diameter. An in-vitro study. J Oral Rehabil. 34:702–9. DOI: 10.1111/j.1365-2842.2007.01770.x. PMID: 17716270.

Article44. Spies BC, Zhang F, Wesemann C, Li M, Rosentritt M. 2020; Reliability and aging behavior of three different zirconia grades used for monolithic four-unit fixed dental prostheses. Dent Mater. 36:e329–39. DOI: 10.1016/j.dental.2020.08.002. PMID: 32948330.

Article45. Takuma Y, Nomoto S, Sato T, Sugihara N. 2013; Effect of framework design on fracture resistance in zirconia 4-unit all-ceramic fixed partial dentures. Bull Tokyo Dent Coll. 54:149–56. DOI: 10.2209/tdcpublication.54.149. PMID: 24334628.

Article46. Murase T, Nomoto S, Sato T, Shinya A, Koshihara T, Yasuda H. 2014; Effect of connector design on fracture resistance in all-ceramic fixed partial dentures for mandibular incisor region. Bull Tokyo Dent Coll. 55:149–55. DOI: 10.2209/tdcpublication.55.149. PMID: 25212560.

Article47. Junker R, Höller M, Yoshida-Anastasova Y, Frank W, Nothdurft FP. 2019; Influence of connector diameter on fracture load of CAD/CAM-processed monolithic lithium disilicate fixed partial dentures. Int J Prosthodont. 32:68–70. DOI: 10.11607/ijp.5955. PMID: 30677115.

Article48. Hamza TA, Attia MA, El-Hossary MM, Mosleh IE, Shokry TE, Wee AG. 2016; Flexural strength of small connector designs of zirconia-based partial fixed dental prostheses. J Prosthet Dent. 115:224–9. DOI: 10.1016/j.prosdent.2015.06.022. PMID: 26547519.

Article49. Plengsombut K, Brewer JD, Monaco EA Jr, Davis EL. 2009; Effect of two connector designs on the fracture resistance of all-ceramic core materials for fixed dental prostheses. J Prosthet Dent. 101:166–73. DOI: 10.1016/S0022-3913(09)60022-6. PMID: 19231568.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Comparative analysis of transmittance for different types of commercially available zirconia and lithium disilicate materials

- Comparison of the translucency of shaded zirconia all-ceramic systems

- Evaluation of marginal fit of 2 CAD-CAM anatomic contour zirconia crown systems and lithium disilicate glass-ceramic crown

- Mechanical Properties Of Reused Lithium Disilicate Glass-Ceramic Of Ips Empress 2 System

- Effect of adhesive luting on the fracture resistance of zirconia compared to that of composite resin and lithium disilicate glass ceramic