Korean J Orthod.

2021 Jul;51(4):270-281. 10.4041/kjod.2021.51.4.270.

Effectiveness of medical coating materials in decreasing friction between orthodontic brackets and archwires

- Affiliations

-

- 1Department of Orthodontics, Faculty of Dentistry, Ondokuz Mayıs University, Samsun, Turkey

- 2Department of Orthodontics, Faculty of Dentistry, Kırıkkale University, Kırıkkale, Turkey

- 3Materials Science and Engineering Department, Engineering Faculty, Gebze Technical University, Kocaeli, Turkey

- KMID: 2518520

- DOI: http://doi.org/10.4041/kjod.2021.51.4.270

Abstract

Objective

The aim of this in vitro study was to evaluate the changes in friction between orthodontic brackets and archwires coated with aluminum oxide (Al2O3), titanium nitride (TiN), or chromium nitride (CrN). In addition, the resistance of the coatings to intraoral conditions was evaluated.

Methods

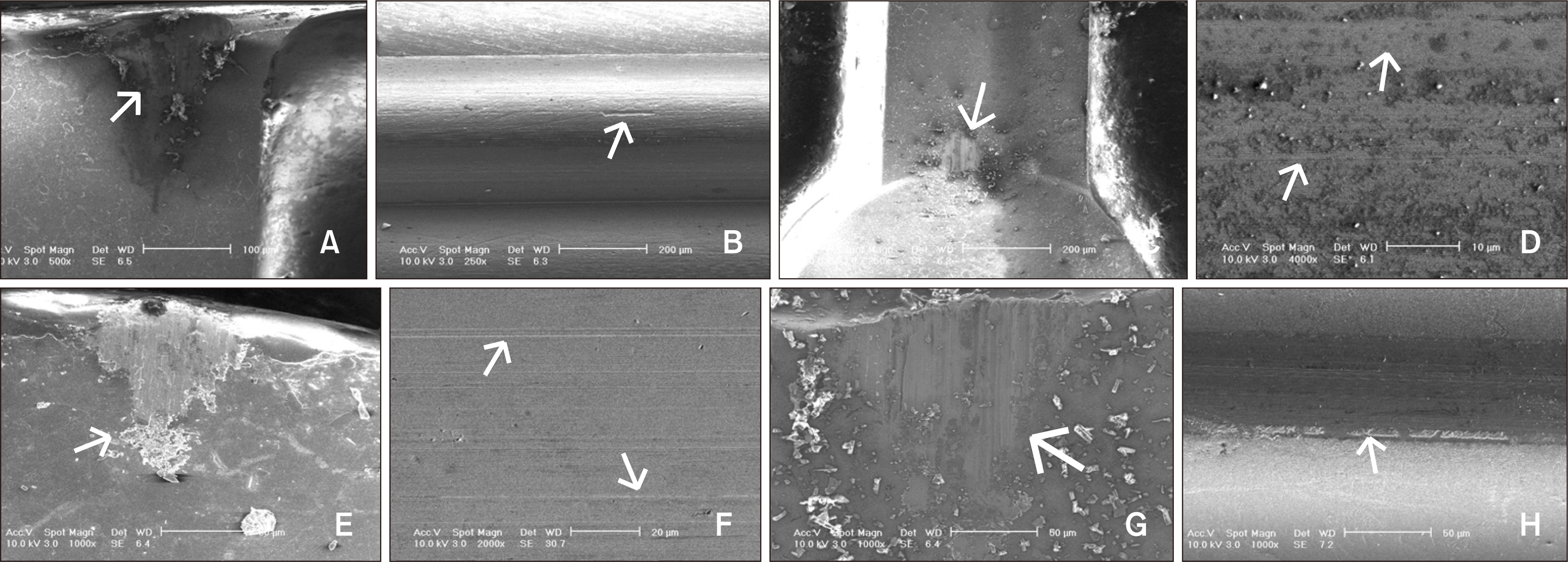

Stainless steel canine brackets, 0.016-inch round nickel–titanium archwires, and 0.019 × 0.025-inch stainless steel archwires were coated with Al2O3 , TiN, and CrN using radio frequency magnetron sputtering. The coated materials were examined using scanning electron microscopy, an X-ray diffractometer, atomic force microscopy, and surface profilometry. In addition, the samples were subjected to thermal cycling and in vitro brushing tests, and the effects of the simulated intraoral conditions on the coating structure were evaluated.

Results

Coating of the metal bracket as well as nickel–titanium archwire with Al2O3 reduced the coefficients of friction (CoFs) for the bracket–archwire combination (p < 0.01). When the bracket and stainless steel archwire were coated with Al2O3 and TiN, the CoFs were significantly lower (0.207 and 0.372, respectively) than that recorded when this bracket–archwire combination was left uncoated (0.552; p < 0.01). The friction, thermal, and brushing tests did not deteriorate the overall quality of the Al2O3 coatings; however, some small areas of peeling were evident for the TiN coatings, whereas comparatively larger areas of peeling were observed for the CrN coatings.

Conclusions

Our findings suggest that the CoFs for metal bracket–archwire combinations used in orthodontic treatment can be decreased by coating with Al2O3 and TiN thin films.

Keyword

Figure

Reference

-

1. Frank CA, Nikolai RJ. 1980; A comparative study of frictional resistances between orthodontic bracket and arch wire. Am J Orthod. 78:593–609. DOI: 10.1016/0002-9416(80)90199-2. PMID: 6935961.

Article2. Kusy RP, Whitley JQ. 1999; Influence of archwire and bracket dimensions on sliding mechanics: derivations and determinations of the critical contact angles for binding. Eur J Orthod. 21:199–208. DOI: 10.1093/ejo/21.2.199. PMID: 10327744.

Article3. Wichelhaus A, Geserick M, Hibst R, Sander FG. 2005; The effect of surface treatment and clinical use on friction in NiTi orthodontic wires. Dent Mater. 21:938–45. DOI: 10.1016/j.dental.2004.11.011. PMID: 15923033.

Article4. Kojima Y, Fukui H. 2005; Numerical simulation of canine retraction by sliding mechanics. Am J Orthod Dentofacial Orthop. 127:542–51. DOI: 10.1016/j.ajodo.2004.12.007. PMID: 15877034.

Article5. Pilon JJ, Kuijpers-Jagtman AM, Maltha JC. 1996; Magnitude of orthodontic forces and rate of bodily tooth movement. An experimental study. Am J Orthod Dentofacial Orthop. 110:16–23. DOI: 10.1016/S0889-5406(96)70082-3. PMID: 8686673.

Article6. Nikolai RJ. 1975; On optimum orthodontic force theory as applied to canine retraction. Am J Orthod. 68:290–302. DOI: 10.1016/0002-9416(75)90237-7. PMID: 1057850.

Article7. Burrow SJ. 2009; Friction and resistance to sliding in orthodontics: a critical review. Am J Orthod Dentofacial Orthop. 135:442–7. DOI: 10.1016/j.ajodo.2008.09.023. PMID: 19361729.

Article8. Mendes K, Rossouw PE. 2003; Friction: validation of manufacturer's claim. Semin Orthod. 9:236–50. DOI: 10.1016/j.sodo.2003.08.004.

Article9. Muguruma T, Iijima M, Brantley WA, Mizoguchi I. 2011; Effects of a diamond-like carbon coating on the frictional properties of orthodontic wires. Angle Orthod. 81:141–8. DOI: 10.2319/052110-276.1. PMID: 20936967.

Article10. Kusy RP, Whitley JQ. 1997; Friction between different wire-bracket configurations and materials. Semin Orthod. 3:166–77. DOI: 10.1016/S1073-8746(97)80067-9. PMID: 9573878.11. Kapur R, Sinha PK, Nanda RS. 1999; Comparison of frictional resistance in titanium and stainless steel brackets. Am J Orthod Dentofacial Orthop. 116:271–4. DOI: 10.1016/S0889-5406(99)70237-4. PMID: 10474098.

Article12. Arici N, Akdeniz BS, Arici S. 2015; Comparison of the frictional characteristics of aesthetic orthodontic brackets measured using a modified in vitro technique. Korean J Orthod. 45:29–37. DOI: 10.4041/kjod.2015.45.1.29. PMID: 25667915. PMCID: PMC4320315.13. Loftus BP, Artun J, Nicholls JI, Alonzo TA, Stoner JA. 1999; Evaluation of friction during sliding tooth movement in various bracket-arch wire combinations. Am J Orthod Dentofacial Orthop. 116:336–45. DOI: 10.1016/S0889-5406(99)70247-7. PMID: 10474108.

Article14. Russell JS. 2005; Current products and practice: aesthetic orthodontic brackets. J Orthod. 32:146–63. DOI: 10.1179/146531205225021024. PMID: 15994990.15. Doshi UH, Bhad-Patil WA. 2011; Static frictional force and surface roughness of various bracket and wire combinations. Am J Orthod Dentofacial Orthop. 139:74–9. DOI: 10.1016/j.ajodo.2009.02.031. PMID: 21195280.

Article16. Cacciafesta V, Sfondrini MF, Ricciardi A, Scribante A, Klersy C, Auricchio F. 2003; Evaluation of friction of stainless steel and esthetic self-ligating brackets in various bracket-archwire combinations. Am J Orthod Dentofacial Orthop. 124:395–402. DOI: 10.1016/S0889-5406(03)00504-3. PMID: 14560269.

Article17. Alfonso MV, Espinar E, Llamas JM, Rupérez E, Manero JM, Barrera JM, et al. 2013; Friction coefficients and wear rates of different orthodontic archwires in artificial saliva. J Mater Sci Mater Med. 24:1327–32. DOI: 10.1007/s10856-013-4887-4. PMID: 23440428.

Article18. Krishnan V, Ravikumar KK, Sukumaran K, Kumar KJ. 2012; In vitro evaluation of physical vapor deposition coated beta titanium orthodontic archwires. Angle Orthod. 82:22–9. DOI: 10.2319/040811-251.1. PMID: 21749248.

Article19. Farronato G, Maijer R, Carìa MP, Esposito L, Alberzoni D, Cacciatore G. 2012; The effect of Teflon coating on the resistance to sliding of orthodontic archwires. Eur J Orthod. 34:410–7. DOI: 10.1093/ejo/cjr011. PMID: 21478301.

Article20. Kang T, Huang SY, Huang JJ, Li QH, Diao DF, Duan YZ. 2015; The effects of diamond-like carbon films on fretting wear behavior of orthodontic archwire-bracket contacts. J Nanosci Nanotechnol. 15:4641–7. DOI: 10.1166/jnn.2015.9788. PMID: 26369091.

Article21. Zuo J, Xie Y, Zhang J, Wei Q, Zhou B, Luo J, et al. 2015; TiN coated stainless steel bracket: tribological, corrosion resistance, biocompatibility and mechanical performance. Surf Coat Technol. 277:227–33. DOI: 10.1016/j.surfcoat.2015.07.009.

Article22. Horiuchi Y, Horiuchi M, Hanawa T, Soma K. 2007; Effect of surface modification on the photocatalysis of Ti-Ni alloy in orthodontics. Dent Mater J. 26:924–9. discussion 73–4. DOI: 10.4012/dmj.26.924. PMID: 18203500.

Article23. De Franco DJ, Spiller RE Jr, von Fraunhofer JA. 1995; Frictional resistances using Teflon-coated ligatures with various bracket-archwire combinations. Angle Orthod. 65:63–72. DOI: 10.1043/0003-3219(1995)065<0063:FRUTLW>2.0.CO;2. PMID: 7726464.24. Neumann P, Bourauel C, Jäger A. 2002; Corrosion and permanent fracture resistance of coated and conventional orthodontic wires. J Mater Sci Mater Med. 13:141–7. DOI: 10.1023/A:1013831011241. PMID: 15348635.25. Muguruma T, Iijima M, Brantley WA, Nakagaki S, Endo K, Mizoguchi I. 2013; Frictional and mechanical properties of diamond-like carbon-coated orthodontic brackets. Eur J Orthod. 35:216–22. DOI: 10.1093/ejo/cjr113. PMID: 21934113.

Article26. Bandeira AM, dos Santos MP, Pulitini G, Elias CN, da Costa MF. 2011; Influence of thermal or chemical degradation on the frictional force of an experimental coated NiTi wire. Angle Orthod. 81:484–9. DOI: 10.2319/042810-232.1. PMID: 21299382.

Article27. Mattox DM. 2010. Handbook of physical vapor deposition (PVD) processing. 2nd ed. Elsevier;Burlington: DOI: 10.1016/B978-0-8155-2037-5.00008-3.28. Zuo J, Keil P, Grundmeier G. 2012; Synthesis and characterization of photochromic Ag-embedded TiO2 nanocomposite thin films by non-reactive RF-magnetron sputter deposition. Appl Surf Sci. 258:7231–7. DOI: 10.1016/j.apsusc.2012.04.054.

Article29. Kuo CG, Hsu CY, Wang SS, Wen DC. 2012; Photocatalytic characteristics of TiO2 films deposited by magnetron sputtering on polycarbonate at room temperature. Appl Surf Sci. 258:6952–7. DOI: 10.1016/j.apsusc.2012.03.142.

Article30. Abraham KS, Jagdish N, Kailasam V, Padmanabhan S. 2017; Streptococcus mutans adhesion on nickel titanium (NiTi) and copper-NiTi archwires: a comparative prospective clinical study. Angle Orthod. 87:448–54. DOI: 10.2319/040516-270.1. PMID: 27849122.

Article31. Cao B, Wang Y, Li N, Liu B, Zhang Y. 2013; Preparation of an orthodontic bracket coated with an nitrogen-doped TiO2-xNy thin film and examination of its antimicrobial performance. Dent Mater J. 32:311–6. DOI: 10.4012/dmj.2012-155. PMID: 23538768.

Article32. Park JB, Kim YK. Bronzino JD, editor. 2000. Metallic biomaterials. The biomedical engineering handbook. 2nd ed. CRC Press;Boca Raton:

Article33. Rahmati M, Mozafari M. 2019; Biocompatibility of alumina-based biomaterials-a review. J Cell Physiol. 234:3321–35. DOI: 10.1002/jcp.27292. PMID: 30187477.

Article34. Kao CT, Ding SJ, Chen YC, Huang TH. 2002; The anticorrosion ability of titanium nitride (TiN) plating on an orthodontic metal bracket and its biocompatibility. J Biomed Mater Res. 63:786–92. DOI: 10.1002/jbm.10484. PMID: 12418025.

Article35. Chung KH, Liu GT, Duh JG, Wang JH. 2004; Biocompatibility of a titanium-aluminum nitride film coating on a dental alloy. Surf Coat Technol. 188-189:745–9. DOI: 10.1016/j.surfcoat.2004.07.050.

Article36. Rahman SU, Ogwu AA. Ahmed W, Phoenix DA, Jackson MJ, Charalambous CP, editors. 2020. Corrosion and Mott-Schottky probe of chromium nitride coatings exposed to saline solution for engineering and biomedical applications. Advances in medical and surgical engineering. Academic Press;London: p. 239–65. DOI: 10.1016/B978-0-12-819712-7.00013-9. PMID: 33184138.

Article37. Pappas MJ, Makris G, Buechel FF. 1995; Titanium nitride ceramic film against polyethylene. A 48 million cycle wear test. Clin Orthop Relat Res. (317):64–70. PMID: 7671497.38. Gil FJ, Solano E, Campos A, Boccio F, Sáez I, Alfonso MV, et al. 1998; Improvement of the friction behaviour of NiTi orthodontic archwires by nitrogen diffusion. Biomed Mater Eng. 8:335–42. PMID: 10081596.39. Kao CT, Guo JU, Huang TH. 2011; Comparison of friction force between corroded and noncorroded titanium nitride plating of metal brackets. Am J Orthod Dentofacial Orthop. 139:594–600. DOI: 10.1016/j.ajodo.2009.06.034. PMID: 21536201.

Article40. Xu JL, Liu F, Wang FP, Yu DZ, Zhao LC. 2009; The corrosion resistance behavior of Al2O3 coating prepared on NiTi alloy by micro-arc oxidation. J Alloy Compd. 472:276–80. DOI: 10.1016/j.jallcom.2008.04.064.

Article41. Liu F, Shimizu T, Yue Q, Xu J, Wang F. 2010; Structure and tribological properties of micro-arc oxidation coatings for reduction of Ni2+ ion release on biomedical NiTi alloy. J Ceram Soc Jpn. 118:357–61. DOI: 10.2109/jcersj2.118.357.

Article42. Jagielski J, Khanna AS, Kucinski J, Mishra DS, Racolta P, Sioshansi P, et al. 2000; Effect of chromium nitride coating on the corrosion and wear resistance of stainless steel. Appl Surf Sci. 156:47–64. DOI: 10.1016/S0169-4332(99)00350-5.

Article43. Drescher D, Bourauel C, Schumacher HA. 1989; Frictional forces between bracket and arch wire. Am J Orthod Dentofacial Orthop. 96:397–404. DOI: 10.1016/0889-5406(89)90324-7. PMID: 2816839.

Article44. Ganss C, Schlueter N, Preiss S, Klimek J. 2009; Tooth brushing habits in uninstructed adults--frequency, technique, duration and force. Clin Oral Investig. 13:203–8. DOI: 10.1007/s00784-008-0230-8. PMID: 18853203.

Article45. Downing A, McCabe JF, Gordon PH. 1995; The effect of artificial saliva on the frictional forces between orthodontic brackets and archwires. Br J Orthod. 22:41–6. DOI: 10.1179/bjo.22.1.41. PMID: 7786865.

Article46. Pratten DH, Popli K, Germane N, Gunsolley JC. 1990; Frictional resistance of ceramic and stainless steel orthodontic brackets. Am J Orthod Dentofacial Orthop. 98:398–403. DOI: 10.1016/S0889-5406(05)81647-6. PMID: 2239837.

Article47. Stannard JG, Gau JM, Hanna MA. 1986; Comparative friction of orthodontic wires under dry and wet conditions. Am J Orthod. 89:485–91. DOI: 10.1016/0002-9416(86)90006-0. PMID: 3459362.

Article48. Kusy RP, Whitley JQ. 2003; Influence of fluid media on the frictional coefficients in orthodontic sliding. Semin Orthod. 9:281–9. DOI: 10.1016/j.sodo.2003.08.007.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Comparison of frictional forces between orthodontic brackets and archwires

- The comparison of the frictional force by the type and angle of orthodontic bracket and the coated or non-coated feature of archwire

- Effect of different combinations of bracket, archwire and ligature on resistance to sliding and axial rotational control during the first stage of orthodontic treatment: An in-vitro study

- Comparison of the frictional characteristics of aesthetic orthodontic brackets measured using a modified in vitro technique

- Friction of calcium phosphate brackets to stainless steel wire