J Dent Rehabil Appl Sci.

2020 Mar;36(1):41-47. 10.14368/jdras.2020.36.1.41.

Flexural strength and reliability of highly translucent colored zirconia

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Wonkwang University, Iksan, Republic of Korea

- KMID: 2512126

- DOI: http://doi.org/10.14368/jdras.2020.36.1.41

Abstract

- Purpose

The purpose of this study was to evaluate the flexural strength and reliability of highly translucent colored zirconia for all ceramic restoration.

Materials and Methods

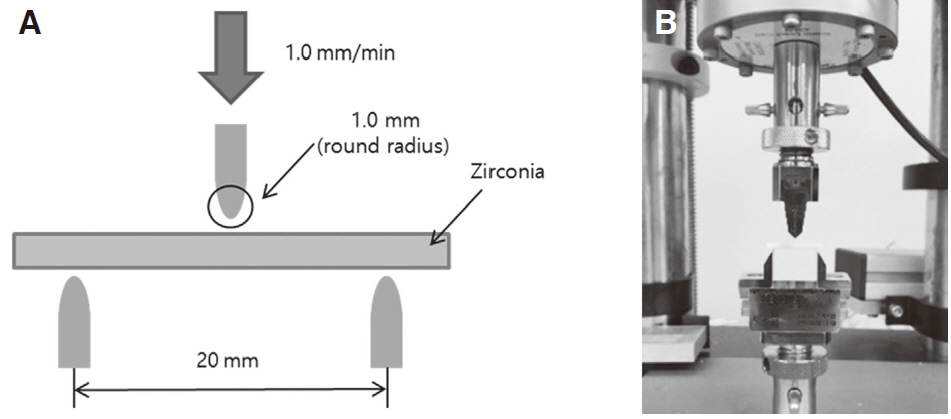

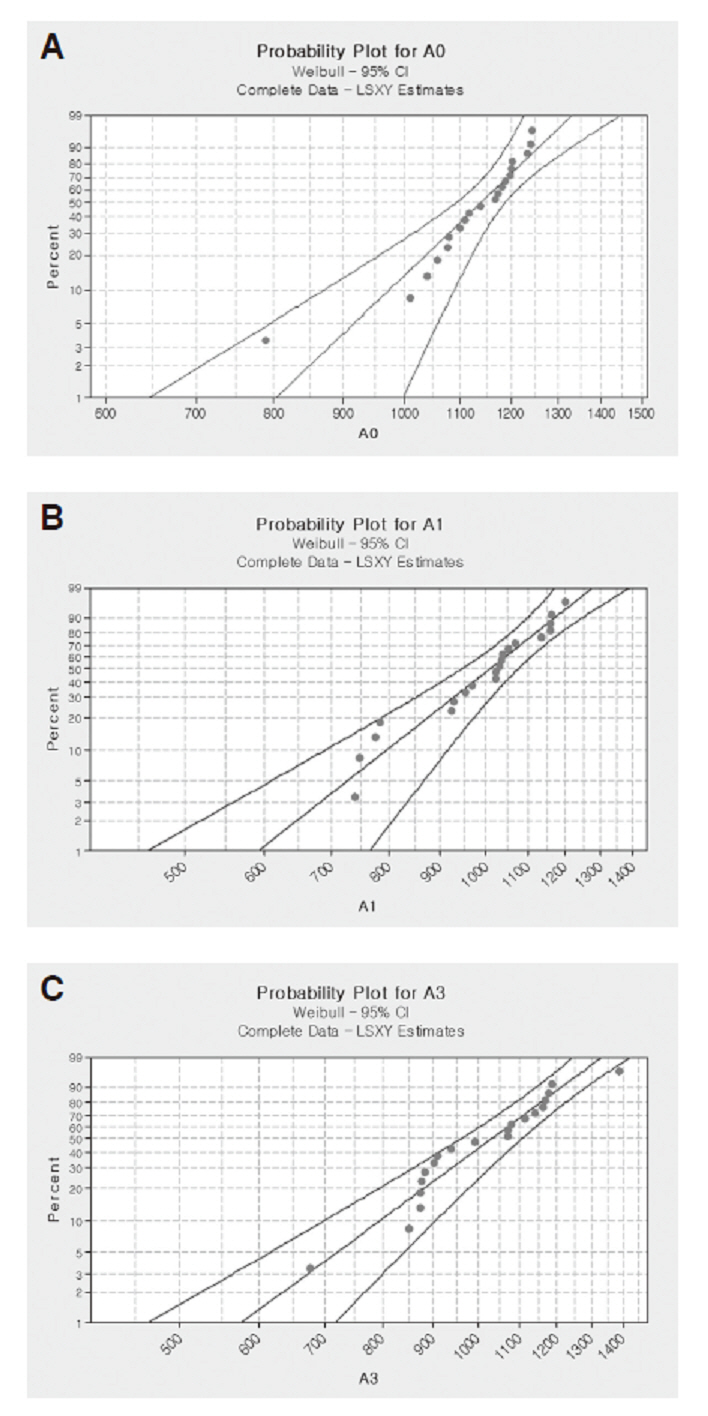

Bar-shaped specimens (25 × 4 × 2.5 mm) were prepared from highly translucent monolithic zirconia. Three experimental groups were set up according to color (shade A0, A1, and A3). For each group, 20 specimens were prepared. Flexural strength was determined using a 3-point flexural test and results were analyzed with one-way ANOVA test. Weibull statistical analysis provided 2 parameter estimates: Weibull modulus and characteristic strength. X-ray diffraction (XRD) analysis was performed.

Results

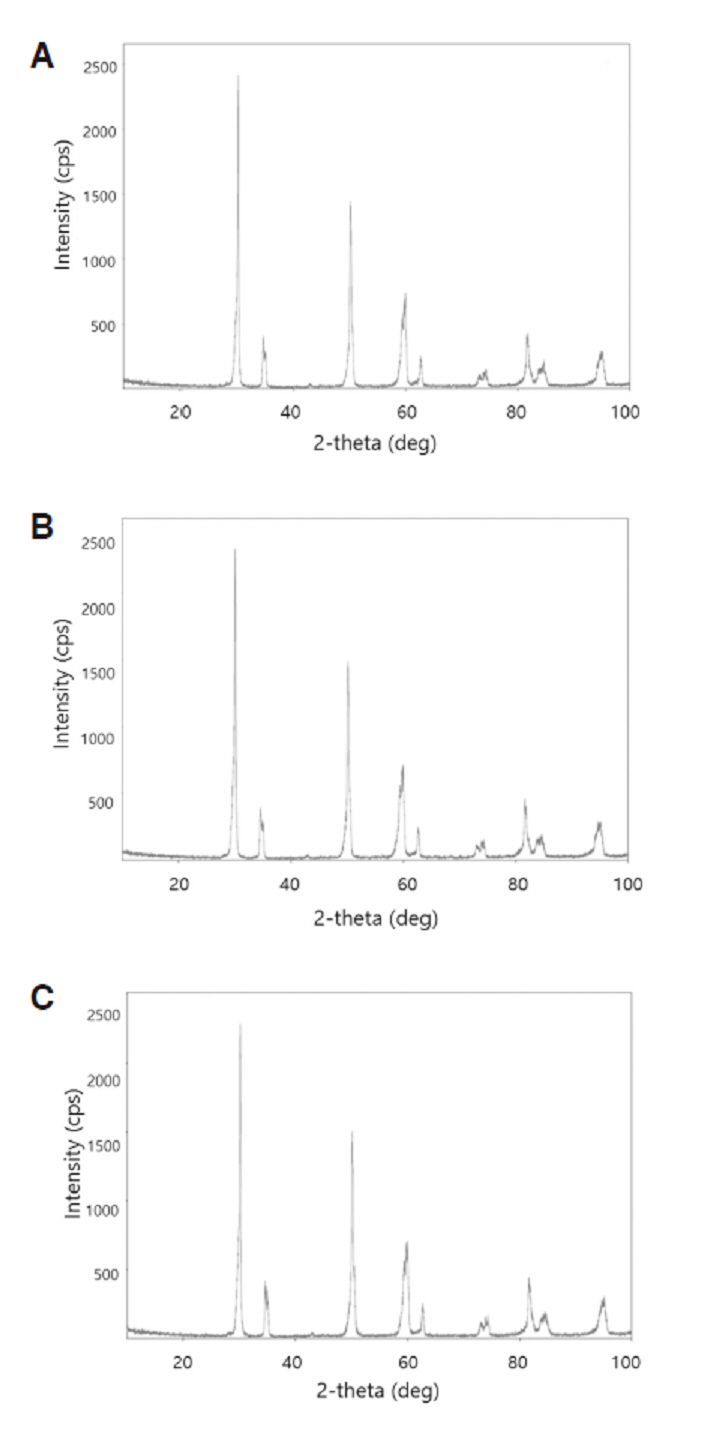

There was statistically significant difference between uncolored (Shade A0) and colored (shade A1 and A3) (P < 0.05), but there was no difference between colored groups (P > 0.05). The uncolored group had higher reliability compared with colored study groups. On x-ray diffraction analysis of each group, typical peaks of tetragonal phase appeared in all groups.

Conclusion

Within the limitations of this in vitro study, coloring highly translucent zirconia had significant effect on flexural strength and reliability. Therefore, clinicians should be careful when using highly translucent colored zirconia to prevent breakage of veneering ceramic and enhance aesthetics.

Keyword

Figure

Reference

-

1. Johansson C, Kmet G, Rivera J, Larsson C, Vult Von Steyern P. 2014; Fracture strength of monolithic all-ceramic crowns made of high translucent yttrium oxide-stabilized zirconium dioxide compared to porcelain-veneered crowns and lithium disilicate crowns. Acta Odontol Scand. 72:145–53. DOI: 10.3109/00016357.2013.822098. PMID: 23865549.2. Kim HK, Kim SH. 2014; Effect of the number of coloring liquid applications on the optical properties of monolithic zirconia. Dent Mater. 30:229–37. DOI: 10.1016/j.dental.2014.04.008. PMID: 24853434.3. Inokoshi M, Shimizu H, Nozaki K, Takagaki T, Yoshihara K, Nagaoka N, Zhang F, Vleugels J, Van Meerbeek B, Minakuchi S. 2018; Crystallographic and morphological analysis of sandblasted highly translucent dental zirconia. Dent Mater. 34:508–18. DOI: 10.1016/j.dental.2017.12.008. PMID: 29325861.4. Kaya G. 2013; Production and characterization of self-colored dental zirconia blocks. Ceram Int. 39:511–7. DOI: 10.1016/j.ceramint.2012.06.056.5. Oh SC, Lee HH, Shin MR, Lee IK. 2007; Flexural strength of various colored and uncolored zirconia ceramics for all-ceramic restoration. J Dent Rehabil Appl Sci. 23:119–30.6. Hjerppe J, Närhi T, Fröberg K, Vallittu PK, Lassila LV. 2008; Effect of shading the zirconia framework on biaxial strength and surface microhardness. Acta Odontol Scand. 66:262–7. DOI: 10.1080/00016350802247123. PMID: 18645687.7. Zhang F, Inokoshi M, Batuk M, Hadermann J, Naert I, Meerbeek BV, Vleugels J. 2016; Strength, toughness and aging stability of highly-translucent Y-TZP ceramics for dental restorations. Dent Mater. 32:e327–37. DOI: 10.1016/j.dental.2016.09.025. PMID: 27697332.8. Zhang Y. 2014; Making yttria-stabilized tetragonal zirconia translucent. Dent Mater. 30:1195–203. DOI: 10.1016/j.dental.2014.08.375. PMID: 25193781. PMCID: PMC4167579.9. International Organization for Standardization. ISO 6872:2008. Dentistry - Ceramic materials. Available from: https://www.iso.org/standard/41385.html (updated 2020 Mar 10).10. Siarampi E, Kontonasaki E, Papadopoulou L, Kantiranis N, Zorba T, Paraskevopoulos KM, Koidis P. 2012; Flexural strength and the probability of failure of cold isostatic pressed zirconia core ceramics. J Prosthet Dent. 108:84–95. DOI: 10.1016/S0022-3913(12)60112-7. PMID: 22867805.11. Garcia Fonseca R, de Oliveira Abi-Rached F, dos Santos Nunes Reis JM, Rambaldi E, Baldissara P. 2013; Effect of particle size on the flexural strength and phase transformation of an airborne-particle abraded yttria-stabilized tetragonal zirconia polycrystal ceramic. J Prosthet Dent. 110:510–4. DOI: 10.1016/j.prosdent.2013.07.007. PMID: 24182897.12. Weibull W. 1951; A statistical distribution function of wide applicability. J Appl Mech. 18:293–7.13. Ritter JE. 1995; Predicting lifetimes of materials and material structures. Dent Mater. 11:142–6. DOI: 10.1016/0109-5641(95)80050-6. PMID: 8621036.14. Kittl P, Diaz G. 1988; Weibull's fracture statistics or probabilistic strength of materials: state of the art. Res Mechanica. 24:99–207.15. Garvie RC, Nicholson PS. 1972; Phase analysis in zirconia systems. J Am Ceram Soc. 55:303–5. DOI: 10.1111/j.1151-2916.1972.tb11290.x.16. Toraya H, Yoshimura M, Somiya S. 1984; Calibration curve for quantitative analysis of the monoclinic-tetragonal ZrO2 system by x-ray diffraction. J Am Ceram Soc. 67:119–21. DOI: 10.1111/j.1151-2916.1984.tb19715.x.17. Guess PC, Schultheis S, Bonfante EA, Coelho PG, Ferencz JL, Silva NR. 2011; All-ceramic systems: laboratory and clinical performance. Dent Clin North Am. 55:333–52. DOI: 10.1016/j.cden.2011.01.005. PMID: 21473997.18. Håff A, Löf H, Gunne J, Sjögren G. 2015; A retrospective evaluation of zirconia-fixed partial dentures in general practices: an up to 13-year study. Dent Mater. 31:162–70. DOI: 10.1016/j.dental.2014.11.009. PMID: 25529500.19. Stefanescu C, Ionita C, Nechita V, Drafta S, Oancea L, Petre A. 2018; Survival rates and complications for zirconia-based fixed dental prostheses in a period up to 10 years: a systematic review. Eur J Prosthodont Restor Dent. 26:54–61. DOI: 10.1922/EJPRD_01681Stefanescu08. PMID: 29517875.20. Tong H, Tanaka CB, Kaizer MR, Zhang Y. 2016; Characterization of three commercial Y-TZP ceramics produced for their high-translucency, high-strength and high surface area. Ceram Int. 42:1077–85. DOI: 10.1016/j.ceramint.2015.09.033. PMID: 26664123. PMCID: PMC4671392.21. Ferrario VF, Sforza C, Zanotti G, Tartaglia GM. 2004; Maximal bite forces in healthy young adults as predicted by surface electromyography. J Dent. 32:451–7. DOI: 10.1016/j.jdent.2004.02.009. PMID: 15240063.22. Guazzato M, Quach L, Albakry M, Swain MV. 2005; Influence of surface and heat treatments on the flexural strength of Y-TZP dental ceramic. J Dent. 33:9–18. DOI: 10.1016/j.jdent.2004.07.001. PMID: 15652163.23. Spyropoulou PE, Kamposiora P, Eliades G, Papavasiliou G, Razzoog ME, Thompson JY, Smith RL, Bayne SC. 2016; Composition, phase analysis, biaxial flexural strength, and fatigue of unshaded versus shaded Procera zirconia ceramic. J Prosthet Dent. 116:269–76. DOI: 10.1016/j.prosdent.2015.08.030. PMID: 27016181.24. Wen N, Yi YF, Zhang WW, Deng B, Shao LQ, Dong LM, Tian JM. 2010; The color of Fe2O3 and Bi2O3 pigmented dental zirconia ceramic. Key Engineering Materials. 434:582–5. DOI: 10.4028/www.scientific.net/KEM.434-435.582.25. Ozer F, Naden A, Turp V, Mante F, Sen D, Blatz MB. 2018; Effect of thickness and surface modifications on flexural strength of monolithic zirconia. J Prosthet Dent. 119:987–93. DOI: 10.1016/j.prosdent.2017.08.007. PMID: 29042115.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of different coloring liquids on the flexural strength of multilayered zirconia

- An experimental study on hydrothermal degradation of cubic-containing translucent zirconia

- Effect of coloring liquids on biaxial flexural strength of monolithic zirconia

- The study of flexural strength of various zirconia ceramics

- Biaxial flexural strength of bilayered zirconia using various veneering ceramics