J Dent Rehabil Appl Sci.

2020 Dec;36(4):211-221. 10.14368/jdras.2020.36.4.211.

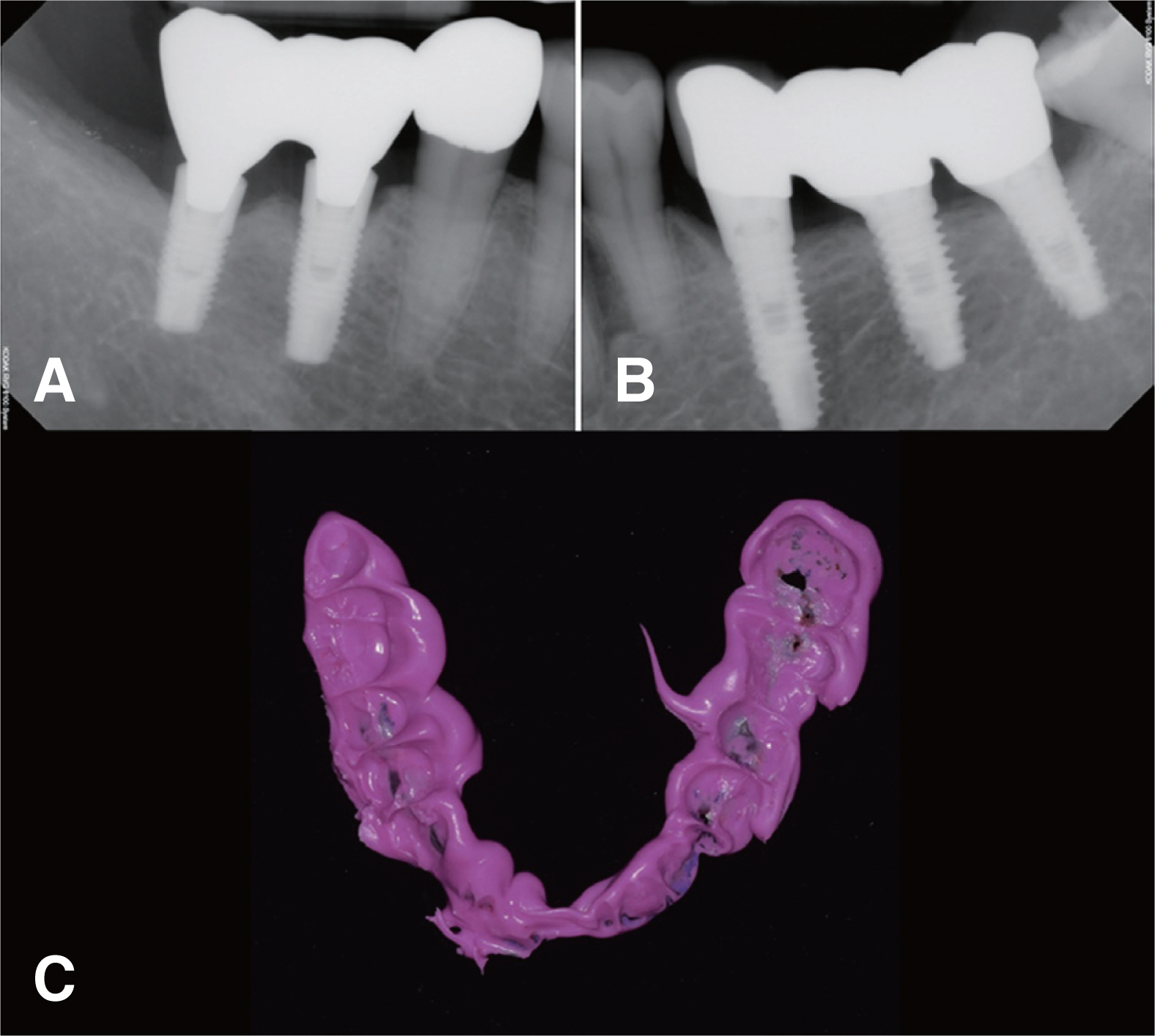

Concept and application of implant connection systems: Part I. Placement and restoration of internal conical connection implant

- Affiliations

-

- 1Department of Prosthodontics and Research Institute of Oral Science, College of Dentistry, Gangneung-Wonju National University, Gangneung, Republic of Korea

- KMID: 2512116

- DOI: http://doi.org/10.14368/jdras.2020.36.4.211

Abstract

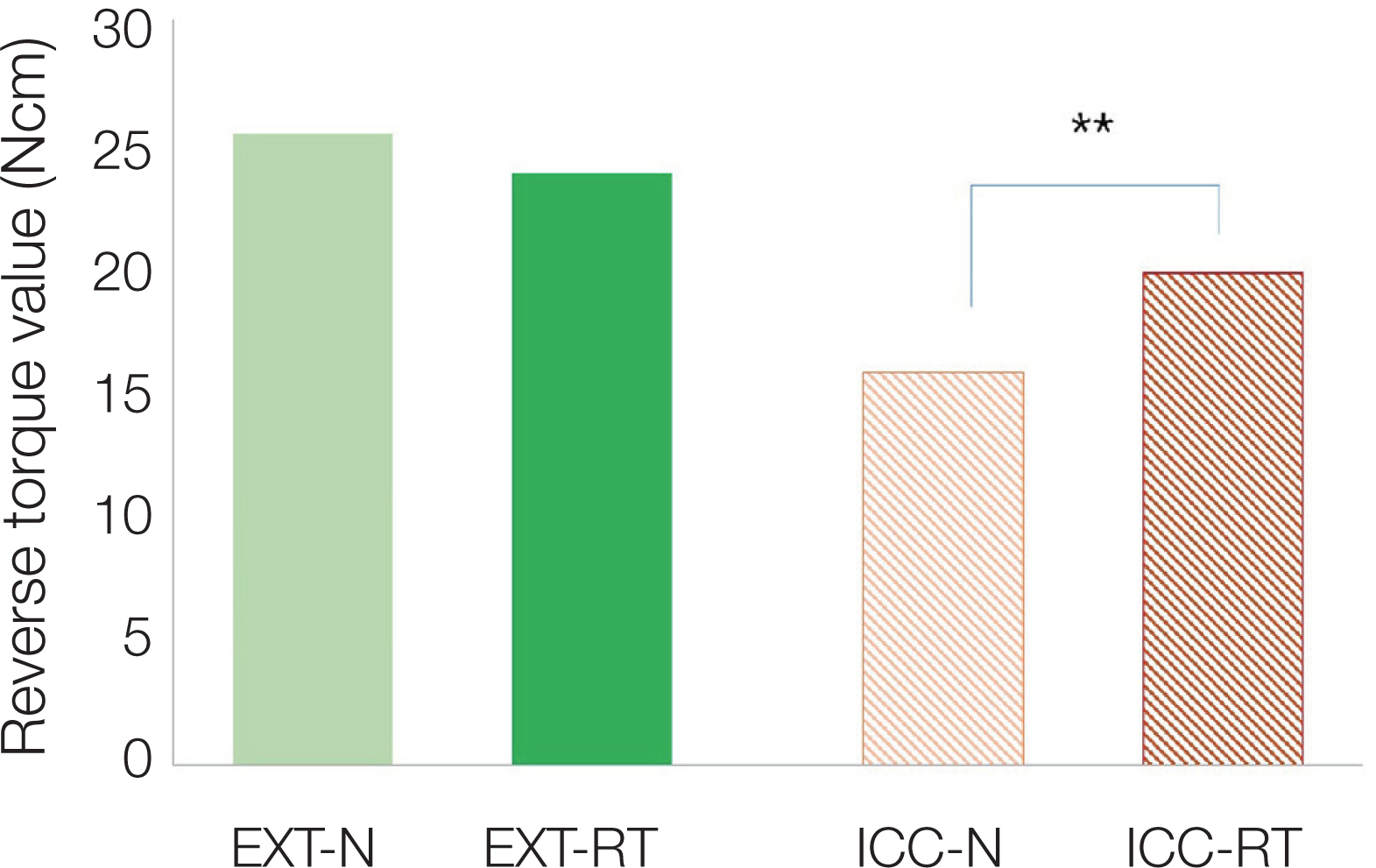

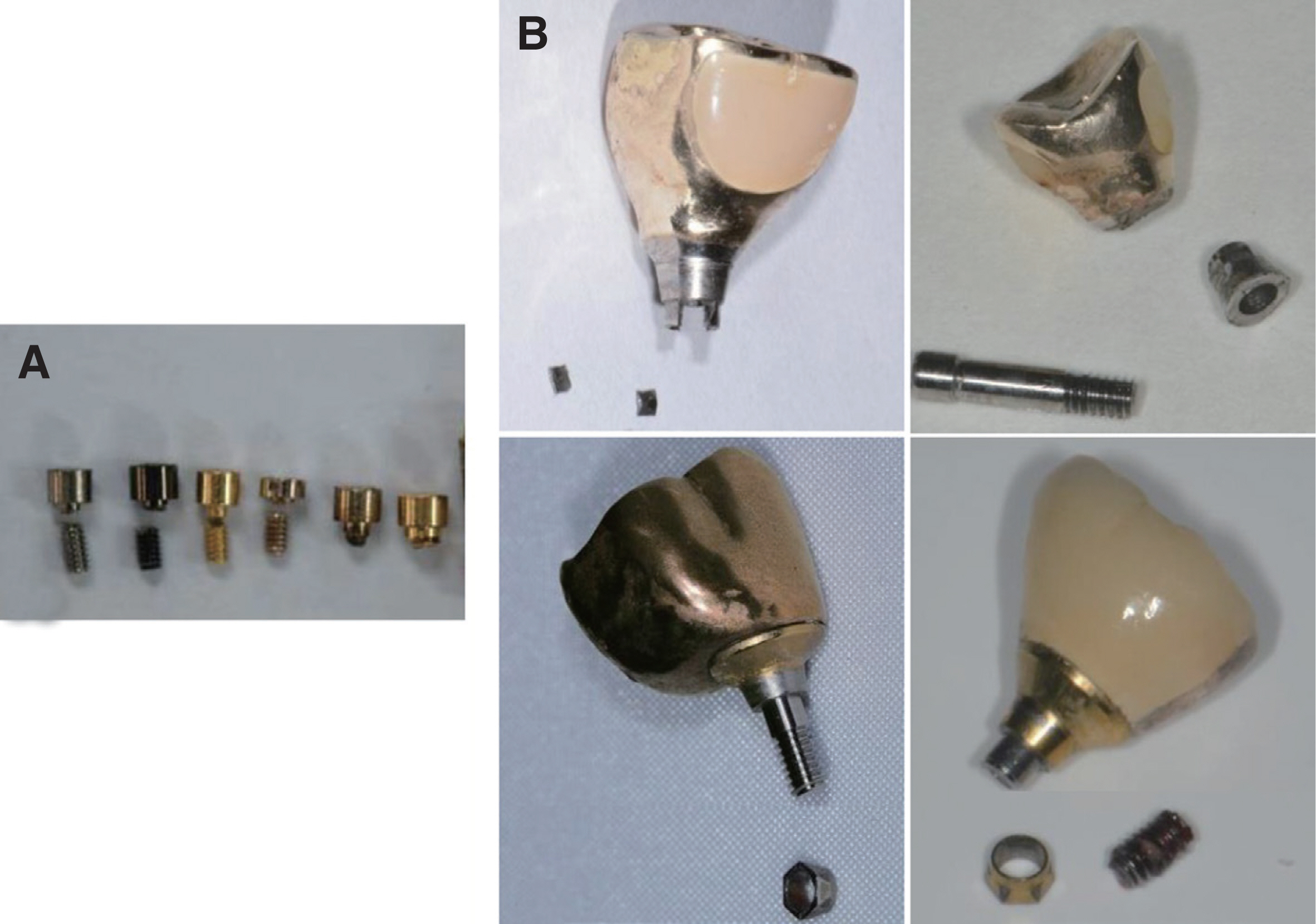

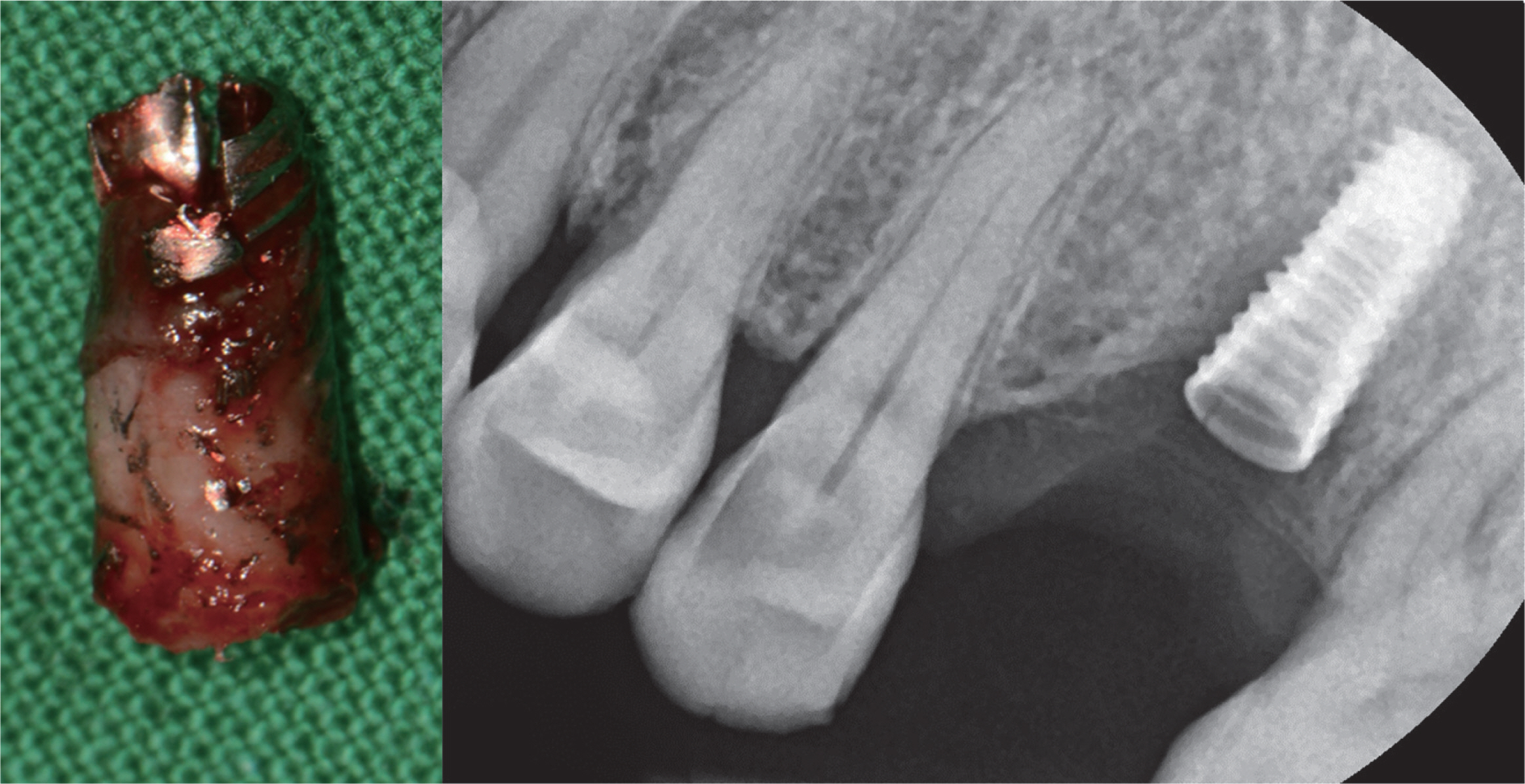

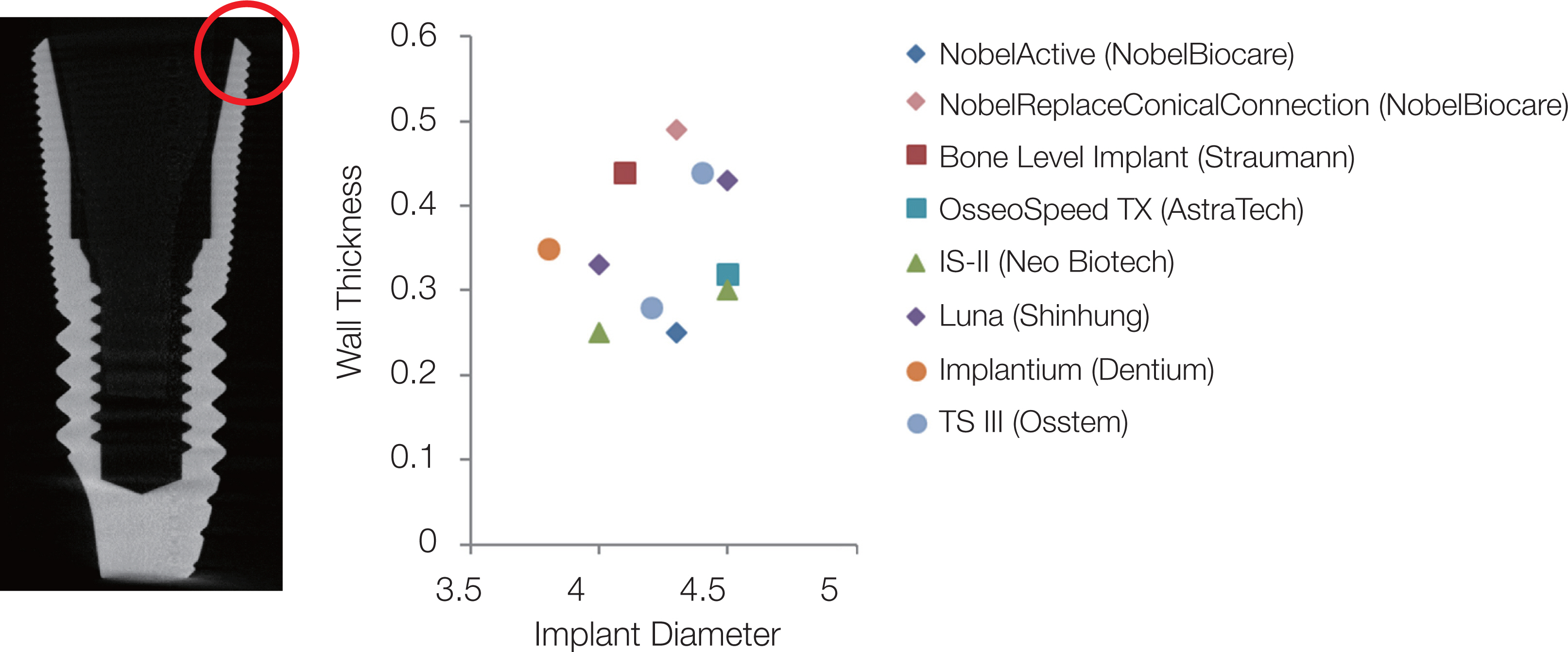

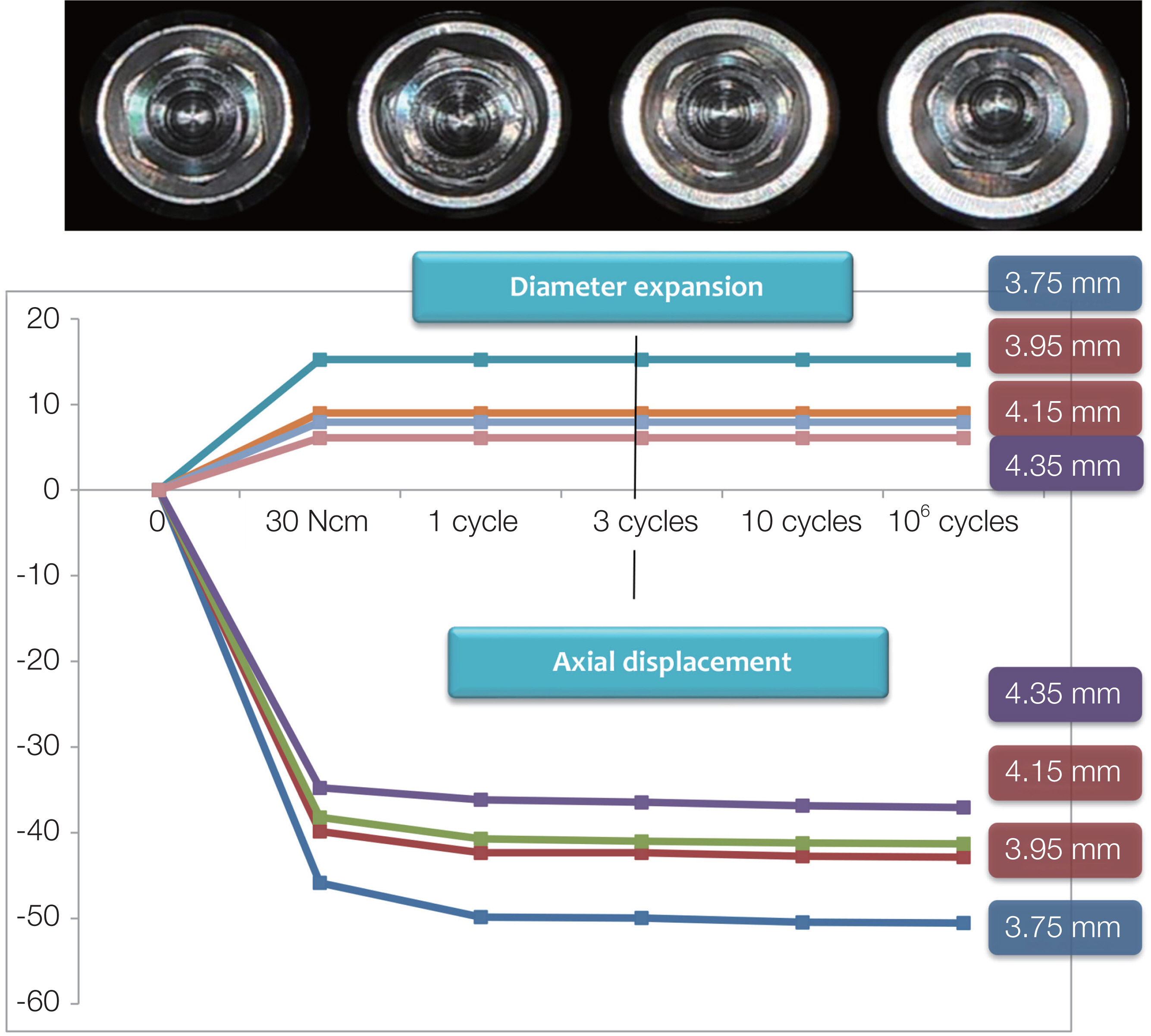

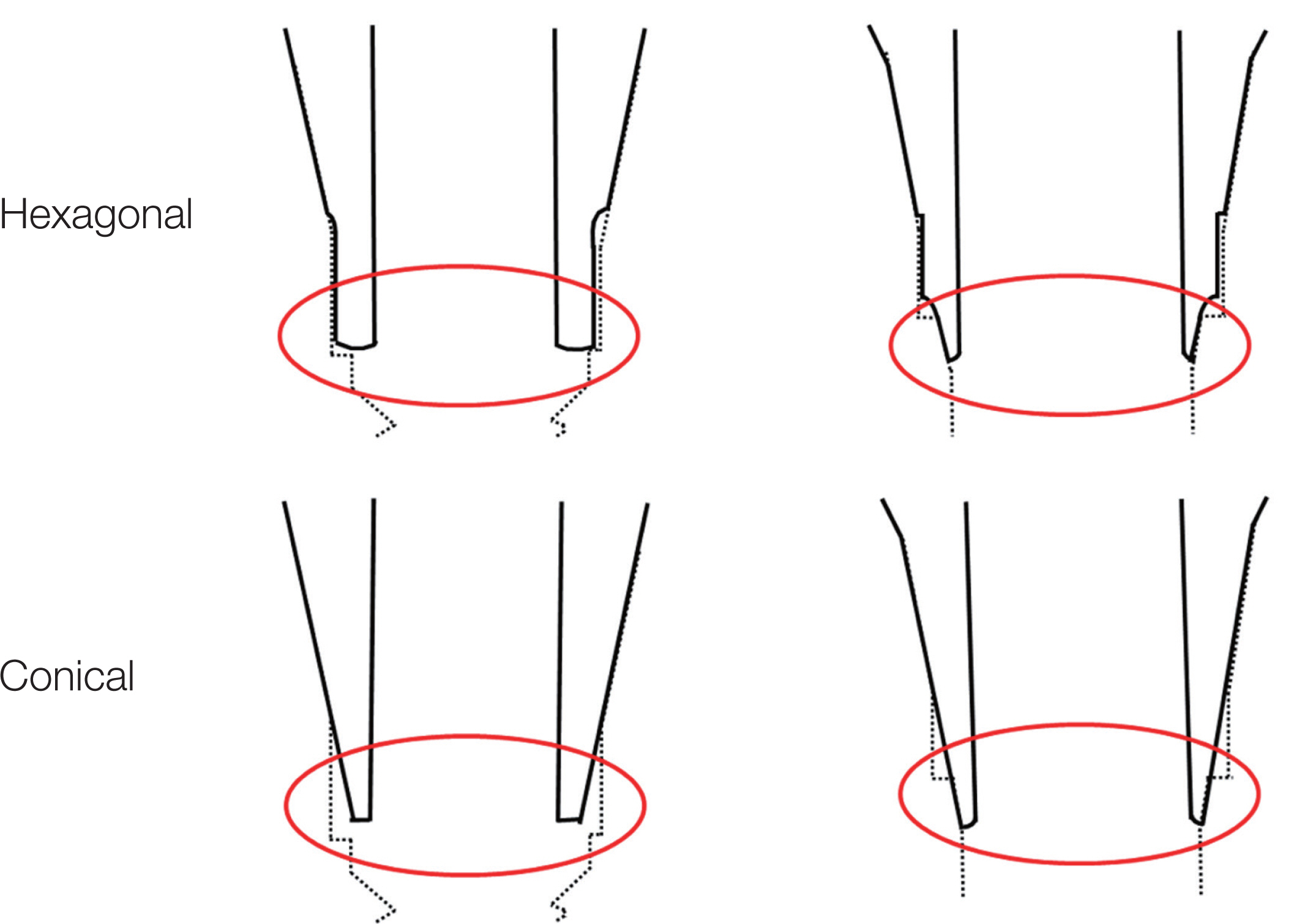

- The typical biomechanical properties of an internal conical connection (ICC) are axial displacement and loss of preload. The axial displacement of an ICC without a vertical stop can cause the loss of preload and a lowered occlusion. The stress of an ICC is concentrated on the contact interface of the abutment and not on the screw, and during placement, it is important to choose a wider coronal wall thickness as much as possible. The ICC should also be placed below the level of the bone crest. During the restoration of an ICC, care should be taken to ensure an appropriate abutment shape and an accurate connection. To get the best clinical results, it is important to select its wall thickness and place it in the appropriate position to restore it adequately.

Figure

Reference

-

References

1. Bonfante EA, Coelho PG. 2016; A critical perspective on mechanical testing of implants and prostheses. Adv Dent Res. 28:18–27. DOI: 10.1177/0022034515624445. PMID: 26927484.2. Sutter F, Weingart D, Mundwiler U, Sutter FJ, Asikainen P. 1994; ITI implants in combination with bone grafts: design and biomechanical aspects. Clin Oral Implants Res. 5:164–72. DOI: 10.1034/j.1600-0501.1994.050307.x. PMID: 7827231.3. Norton MR. 1997; An in vitro evaluation of the strength of an internal conical interface compared to a butt joint interface in implant design. Clin Oral Implants Res. 8:290–8. DOI: 10.1034/j.1600-0501.1997.080407.x. PMID: 9586476.4. Levine RA, Clem DS 3rd, Wilson TG Jr., Higginbottom F, Solnit G. 1999; Multicenter retrospective analysis of the ITI implant system used for single-tooth replacements: results of loading for 2 or more years. Int J Oral Maxillofac Implants. 14:516–20. PMID: 10453666.5. Baggi L, Cappelloni I, Di Girolamo M, Maceri F, Vairo G. 2008; The influence of implant diameter and length on stress distribution of osseointegrated implants related to crestal bone geometry: a threedimensional finite element analysis. J Prosthet Dent. 100:422–31. DOI: 10.1016/S0022-3913(08)60259-0. PMID: 19033026.6. Weng D, Nagata MJ, Bell M, Bosco AF, de Melo LGN, Richter E. 2008; Influence of microgap location and configuration on the periimplant bone morphology in submerged implants. An experimental study in dogs. Clin Oral Implants Res. 19:1141–7. DOI: 10.1111/j.1600-0501.2008.01564.x. PMID: 18983317.7. Weng D, Nagata MJH, Bell M, de Melo LGN, Bosco AF. 2010; Influence of microgap location and configuration on peri-implant bone morphology in nonsubmerged implants: an experimental study in dogs. Int J Oral Maxillofac Implants. 25:540–7. PMID: 20556253.8. Lee JH, Kim DG, Park CJ, Cho LR. 2014; Axial displacements in external and internal implant-abutment connection. Clin Oral Implants Res. 25:e83–9. DOI: 10.1111/clr.12062. PMID: 23088616.9. Seol HW, Heo SJ, Koak JY, Kim SK, Kim SK. 2015; Axial displacement of external and internal implantabutment connection evaluated by linear mixed model analysis. Int J Oral Maxillofac Implants. 30:1387–99. DOI: 10.11607/jomi.3857. PMID: 26574863.10. Braian M, De Bruyn H, Fransson H, Christersson C, Wennerberg A. 2014; Tolerance measurements on internal-and external-hexagon implants. Int J Oral Maxillofac Implants. 29:846–52. DOI: 10.11607/jomi.3242. PMID: 25032764.11. Winkler S, Ring K, Ring JD, Boberick KG. 2003; Implant screw mechanics and the settling effect: overview. J Oral Implantol. 29:242–5. DOI: 10.1563/1548-1336(2003)029<0242:ISMATS>2.3.CO;2. PMID: 14620687.12. Bulaqi HA, Mashhadi MM, Safari H, Samandari MM, Geramipanah F. 2015; Dynamic nature of abutment screw retightening: finite element study of the effect of retightening on the settling effect. J Prosthet Dent. 113:412–9. DOI: 10.1016/j.prosdent.2014.09.017. PMID: 25749092.13. Merz BR, Hunenbart S, Belser UC. 2000; Mechanics of the implant-abutment connection: an 8-degree taper compared to a butt joint connection. Int J Oral Maxillofac Implants. 15:519–26. PMID: 10960985.14. Bozkaya D, Müftü S. 2003; Mechanics of the tapered interference fit in dental implants. J Biomech. 36:1649–58. DOI: 10.1016/S0021-9290(03)00177-5. PMID: 14522206.15. Baixe S, Fauxpoint G, Arntz Y, Etienne O. 2010; Microgap between zirconia abutments and titanium implants. Int J Oral Maxillofac Implants. 25:455–60. PMID: 20556243.16. Teoh SH, Thampuran R, Seah KHW, Goh JCH. 1997; The development of P/M titanium-graphite triphasic composites for biomedical applications. J Mater Sci Ltr. 16:639–41. DOI: 10.1023/A:1018567216717.17. Cho WR, Huh YH, Park CJ, Cho LR. 2015; Effect of cyclic loading and retightening on reverse torque value in external and internal implants. J Adv Prosthodont. 7:288–93. DOI: 10.4047/jap.2015.7.4.288. PMID: 26330975. PMCID: PMC4551784.18. Jeon BS, Kim SK, Lee JJ, Seo JM. 2018; Possibility and limitation of applying occlusal adjustment on implant prosthesis similar to natural teeth. Implantology. 22:162–72. DOI: 10.32542/implantology.20180014.19. Theoharidou A, Petridis HP, Tzannas K, Garefis P. 2008; Abutment screw loosening in single-implant restorations: a systematic review. Int J Oral Maxillofac Implants. 23:681–90. PMID: 18807565.20. Coppedê AR, de Mattos MG, Rodrigues RCS, Ribeiro RF. 2009; Effect of repeated torque/mechanical loading cycles on two different abutment types in implants with internal tapered connections: an in vitro study. Clin Oral Implants Res. 20:624–32. DOI: 10.1111/j.1600-0501.2008.01690.x. PMID: 19281502.21. Piermatti J, Yousef H, Luke A, Mahevich R, Weiner S. 2006; An in vitro analysis of implant screw torque loss with external hex and internal connection implant systems. Implant Dent. 15:427–35. DOI: 10.1097/01.id.0000245440.09464.48. PMID: 17172962.22. Pessoa RS, Muraru L, Júnior EM, Vaz LG, Sloten JV, Duyck J, Jaecques SVN. 2010; Influence of implant connection type on the biomechanical environment of immediately placed implants - CT-based nonlinear, three-dimensional finite element analysis. Clin Implant Dent Relat Res. 12:219–34. DOI: 10.1111/j.1708-8208.2009.00155.x. PMID: 19438946.23. Cho SY, Huh YH, Park CJ, Cho LR. 2016; Three-Dimensional Finite Element Analysis of the Stress Distribution at the Internal Implant-Abutment Connection. Int J Periodontics Restorative Dent. 36:e49–58. DOI: 10.11607/prd.2351. PMID: 27100815.24. Jimbo R, Halldin A, Janda M, Wennerberg A, Vandeweghe S. 2013; Vertical fracture and marginal bone loss of internal-connection implants: a finite element analysis. Int J Oral Maxillofac Implants. 28:e171–6. DOI: 10.11607/jomi.3052. PMID: 23869374.25. Yi Y, Koak JY, Kim SK, Lee SJ, Heo SJ. 2018; Comparison of implant component fractures in external and internal type: A 12-year retrospective study. J Adv Prosthodont. 10:155–62. DOI: 10.4047/jap.2018.10.2.155. PMID: 29713437. PMCID: PMC5917108.26. Cha HS, Kim YS, Jeon JH, Lee JH. 2013; Cumulative survival rate and complication rates of single-tooth implant; focused on the coronal fracture of fixture in the internal connection implant. J Oral Rehabil. 40:595–602. DOI: 10.1111/joor.12065. PMID: 23679929.27. Lee JH, Huh YH, Park CJ, Cho LR. 2016; Effect of the Coronal Wall Thickness of Dental Implants on the Screw Joint Stability in the Internal Implant-Abutment Connection. Int J Oral Maxillofac Implants. 31:1058–65. DOI: 10.11607/jomi.4600. PMID: 27632260.28. Lee JH, Lee W, Huh YH, Park CJ, Cho LR. 2019; Impact of Intentional Overload on Joint Stability of Internal Implant-Abutment Connection System with Different Diameter. J Prosthodont. 28:e649–56. DOI: 10.1111/jopr.12661. PMID: 28872722.29. Parpaiola A, Cecchinato D, Toia M, Bressan E, Speroni S, Lindhe J. 2015; Dimensions of the healthy gingiva and peri-implant mucosa. Clin Oral Implants Res. 26:657–62. DOI: 10.1111/clr.12359. PMID: 24611985.30. Lindhe J, Berglundh T. 1998; The interface between the mucosa and the implant. Periodontol 2000. 17:47–54. DOI: 10.1111/j.1600-0757.1998.tb00122.x. PMID: 10337312.31. Hansson S. 1999; The implant neck: smooth or provided with retention elements. A biomechanical approach. Clin Oral Implants Res. 10:394–405. DOI: 10.1034/j.1600-0501.1999.100506.x. PMID: 10551064.32. Monje A, Galindo-Moreno P, Tözüm TF, Suárez-López del Amo F, Wang H. 2016; Into the Paradigm of Local Factors as Contributors for Peri-implant Disease: Short Communication. Int J Oral Maxillofac Implants. 31:288–92. DOI: 10.11607/jomi.4265. PMID: 27004275.33. Ko KH, Park JH, Cho LR. 2019; Considerations for fabrication of cad-cam abutments: Part I. Selection of titanium block and fabrication process. Implantology. 23:46–58. DOI: 10.32542/implantology.2019005.34. Ko KH, Park JH, Cho LR. 2019; Considerations for fabrication of cad-cam abutments: Part II. Designing abutment. Implantology. 23:112–25. DOI: 10.32542/implantology.2019010.35. Blanco J, Pico A, Caneiro L, Nóvoa L, Batalla P, Martín-Lancharro P. 2018; Effect of abutment height on interproximal implant bone level in the early healing: A randomized clinical trial. Clin Oral Implants Res. 29:108–17. DOI: 10.1111/clr.13108. PMID: 29222809.36. Zabler S, Rack T, Rack A, Nelson K. 2012; Fatigue induced deformation of taper connection in dental titanium implants. Int J Mat Res. 103:207–16. DOI: 10.3139/146.110666.37. Rack T, Zabler S, Rack A, Riesemeier H, Nelson K. 2013; An in vitro pilot study of abutment stability during loading in new and fatigue-loaded conical dental implants using synchrotron-based radiography. Int J Oral Maxillofac Implants. 28:44–50. DOI: 10.11607/jomi.2748. PMID: 23377046.38. Cho SY, Huh YH, Park CJ, Cho LR. 2018; Three-dimensional finite element analysis on stress distribution of internal implant-abutment engagement features. Int J Oral Maxillofac Implants. 33:319–27. DOI: 10.11607/jomi.5789. PMID: 29534119.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Concept and application of implant connection systems: Part II. Placement and restoration of external connection implant and tissue level implant

- Rotational tolerances of a titanium abutment in the as-received condition and after screw tightening in a conical implant connection

- Considerations in implant crestal module to preserve peri-implant tissue

- Influence of abutment materials on the implant-abutment joint stability in internal conical connection type implant systems

- Retrospective study on marginal bone resorption around immediately loaded implants