J Dent Rehabil Appl Sci.

2020 Sep;36(3):183-195. 10.14368/jdras.2020.36.3.183.

Comparison of flexural strength according to thickness between CAD/CAM denture base resins and conventional denture base resins

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Dankook University, Cheonan, Republic of Korea

- KMID: 2512113

- DOI: http://doi.org/10.14368/jdras.2020.36.3.183

Abstract

- Purpose

The purpose of this study is to compare the flexural strength of CAD/CAM denture base resins with conventional denture base resins based on their thicknesses.

Materials and Methods

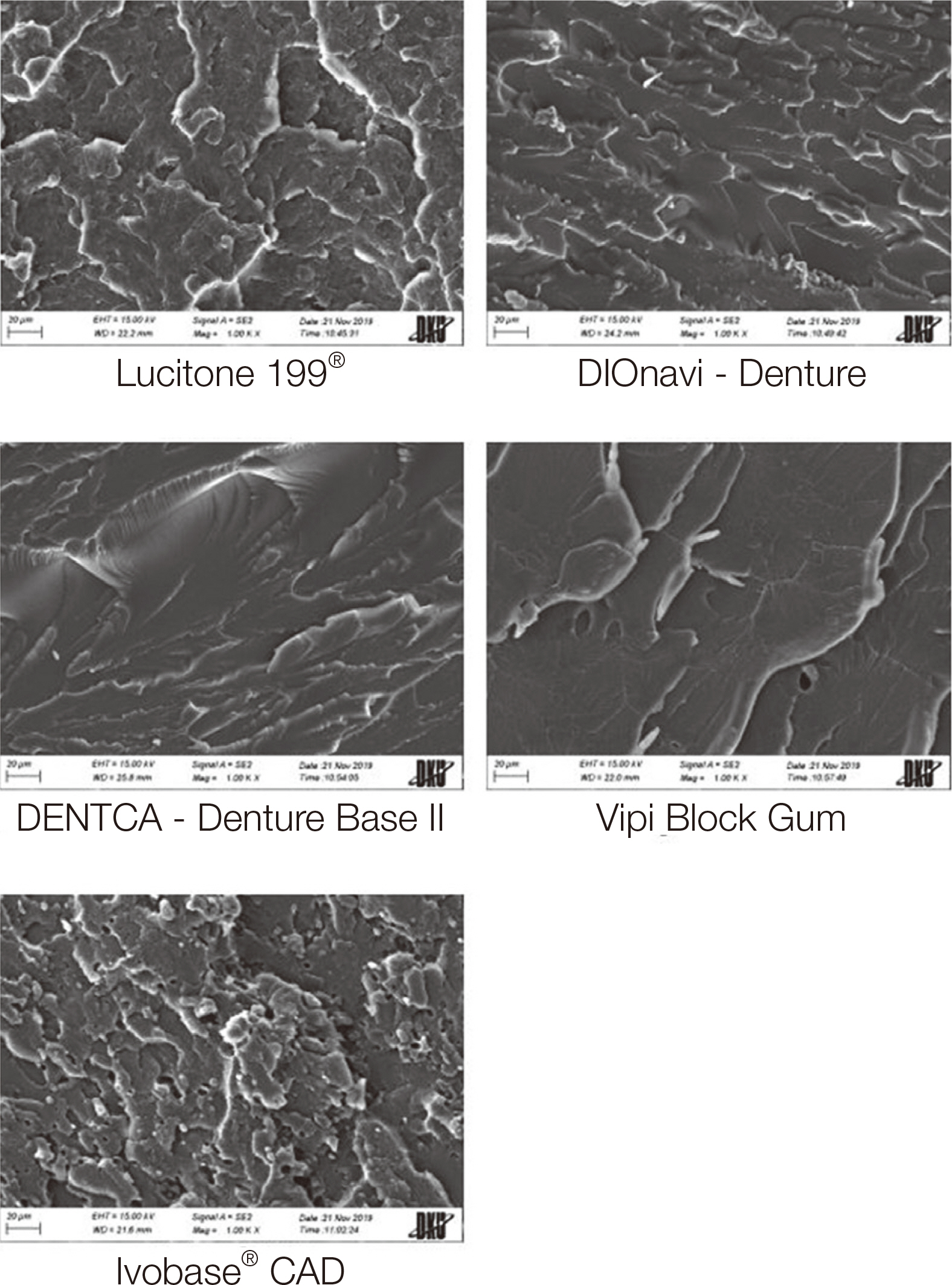

For the conventional denture base resins, Lucitone 199® (C-LC) was used. DIOnavi - Denture (P-DO) and DENTCA Denture Base II (P-DC) were taken for the 3D printing denture base resins. For the prepolymerized PMMA resins, Vipi Block Gum (M-VP) and M-IVoBase® CAD (M-IV) were used. The final dimensions of the specimens were 65.0 mm x 12.7 mm x 1.6 mm / 2.0 mm / 2.5 mm. The 3-point bend test was implemented to measure the flexural strength and flexural modulus. Microscopic evaluation of surface of fractured specimen was conducted by using a scanning electron micro-scope (SEM). After testing the normality of the data, one-way ANOVA was adopted to evaluate the differences among sample groups with a significance level of P = 0.05. The Tukey HSD test was performed for post hoc analysis.

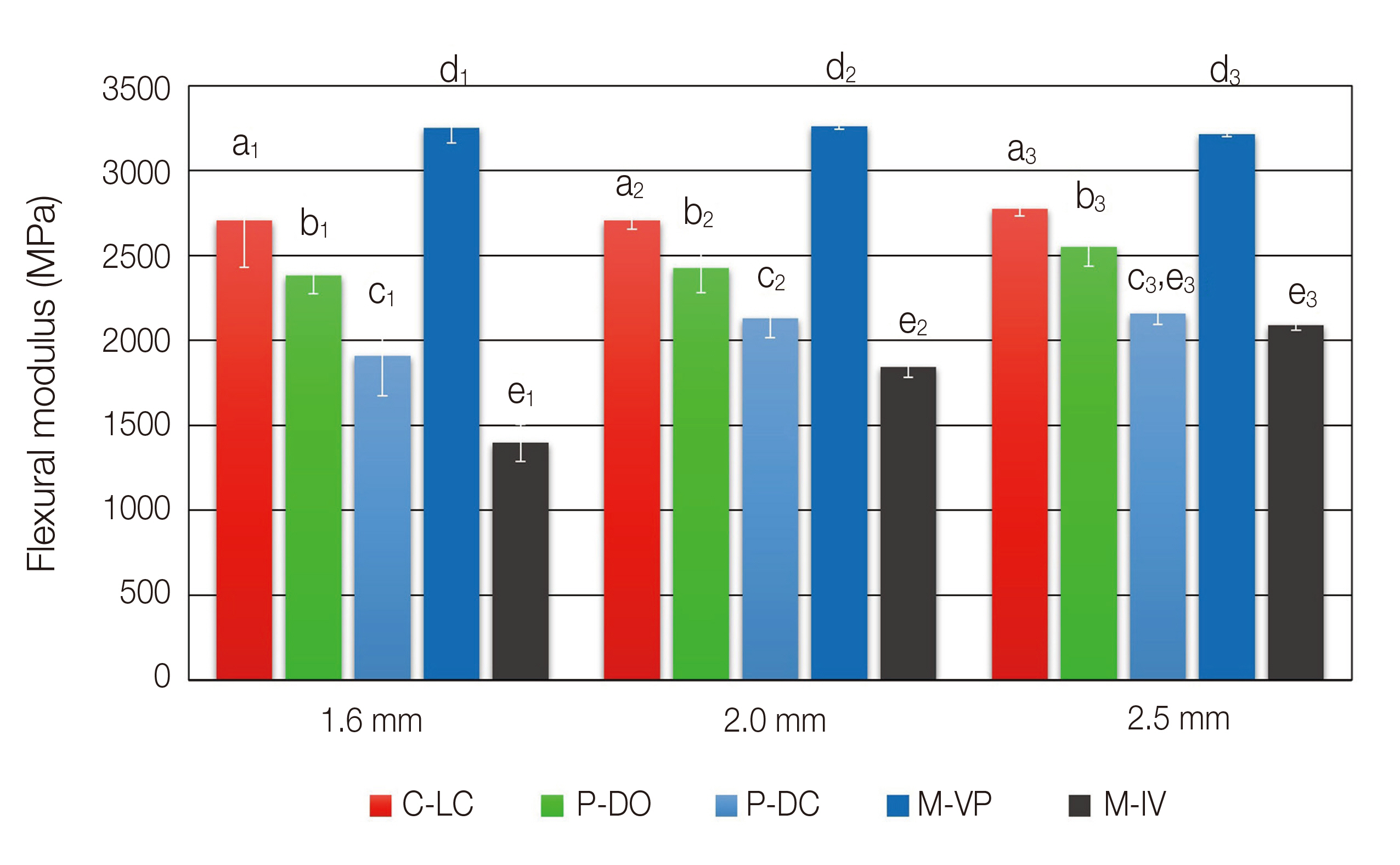

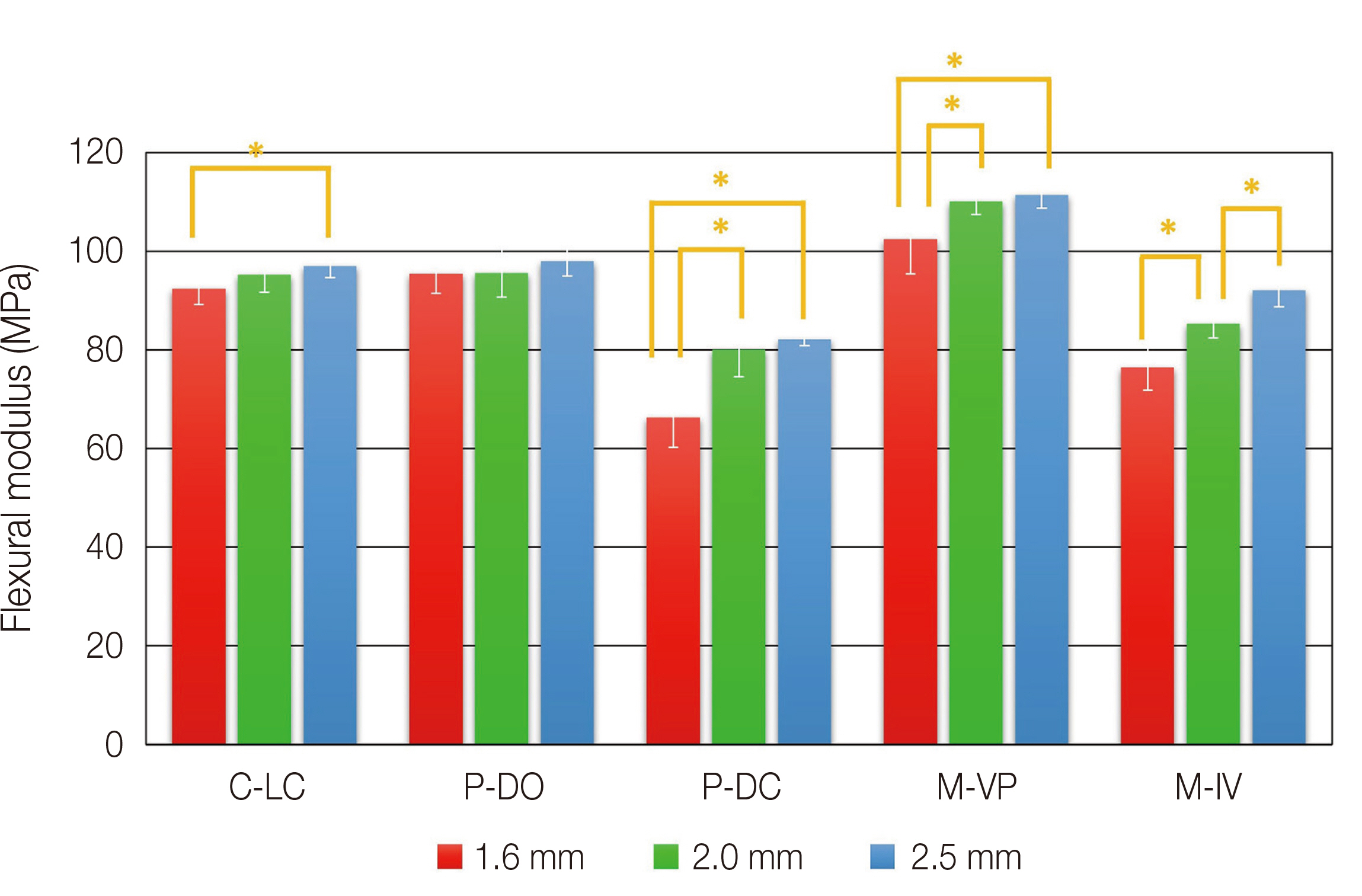

Results

Under the same thicknesses, there are significant differences in flexural strength between CAD/CAM denture base resins and conventional denture base resins except for P-DO and C-LC. M-VP showed higher flexural strength than conventional denture base resins, P-DC and M-IV displayed lower flexural strength than conventional denture base resins. Flexural modulus was highest in M-VP, followed by C-LC, P-DO, P-DC, M-IV, significant differences were found between all materials. In the comparison of flexural strength according to thickness, flexural strength of 2.5 mm was significantly higher than that of 1.6 mm in C-LC. Flexural strength of 2.5 mm and 2.0 mm was significantly higher than that of 1.6 mm in P-DC and M-VP. In M-IV, as the thickness increases, significant increase in flexural strength appeared. SEM analysis illustrates different fracture surfaces of the specimens.

Conclusion

The flexural strength of different CAD/CAM denture base resins used in this study varied according to the composition and properties of each material. The flexural strength of CAD/ CAM denture base resins was higher than the standard suggested by ISO 20795-1:2013 at a thickness of 1.6 mm or more though the thickness decreased. However, for clinical use of dentures with lower thickness, further researches should be done regarding other properties at lower thickness of denture base resins.

Keyword

Figure

Reference

-

References

1. Zarb GA, Fenton AH. 2012. Prosthodontic treatment for edentulous patients. 13th ed. Mosby/Elsevier;St. Louis: p. 133. p. 136. p. 140.2. Anusavice KJ, Shen C, Rawls R. 2012. Phillips’ science of dental materials. 12th ed. Saunders/Elsevier;Philadelphia: p. 94. p. 97. p. 480. p. 481. p. 483.3. Ucar Y, Akova T, Aysan I. 2012; Mechanical properties of polyamide versus different PMMA denture base materials. J Prosthodont. 21:173–6. DOI: 10.1111/j.1532-849X.2011.00804.x. PMID: 22372855.4. Darbar UR, Huggett R, Harrison A. 1994; Denture fracture - a survey. Br Dent J. 176:342–5. DOI: 10.1038/sj.bdj.4808449. PMID: 8024869.5. Sasaki H, Hamanaka I, Takahashi Y, Kawaguchi T. 2016; Effect of long-term water immersion or thermal shock on mechanical properties of high-impact acrylic denture base resins. Dent Mater J. 35:204–9. DOI: 10.4012/dmj.2015-291. PMID: 27041009.6. Kim SH, Watts DC. 2004; The effect of reinforcement with woven E-glass fibers on the impact strength of complete dentures fabricated with high-impact acrylic resin. J Prosthet Dent. 91:274–80. DOI: 10.1016/j.prosdent.2003.12.023. PMID: 15060499.7. Infante L, Yilmaz B, McGlumphy E, Finger I. 2014; Fabricating complete dentures with CAD/CAM technology. J Prosthet Dent. 111:351–5. DOI: 10.1016/j.prosdent.2013.10.014. PMID: 24461946.8. John J, Gangadhar SA, Shah I. 2001; Flexural strength of heat-polymerized polymethyl methacrylate denture resin reinforced with glass, aramid, or nylon fibers. J Prosthet Dent. 86:424–7. DOI: 10.1067/mpr.2001.118564. PMID: 11677538.9. Huggett R, Bates JF, Packham DE. 1987; The effect of the curing cycle upon the molecular weight and properties of denture base materials. Dent Mater. 3:107–12. DOI: 10.1016/s0109-5641(87)80040-4. PMID: 3481584.10. El Ghazali S, Glantz PO, Strandman E, Randow K. 1989; On the clinical deformation of maxillary complete dentures. Influence of denture-base design and shape of denture-bearing tissue. Acta Odontol Scand. 47:69–76. DOI: 10.3109/00016358909167305. PMID: 2655371.11. Murakami N, Wakabayashi N, Matsushima R, Kishida A, Igarashi Y. 2013; Effect of high-pressure polymerization on mechanical properties of PMMA denture base resin. J Mech Behav Biomed Mater. 20:98–104. DOI: 10.1016/j.jmbbm.2012.12.011. PMID: 23455166.12. Kelly E. 1969; Fatigue failure in denture base polymers. J Prosthet Dent. 21:257–66. DOI: 10.1016/0022-3913(69)90289-3. PMID: 5251347.13. Diaz-Arnold AM, Vargas MA, Shaull KL, Laffoon JE, Qian F. 2008; Flexural and fatigue strengths of denture base resin. J Prosthet Dent. 100:47–51. DOI: 10.1016/S0022-3913(08)60136-5. PMID: 18589074.14. Neihart TR, Li SH, Flinton RJ. 1988; Measuring fracture toughness of high-impact poly(methyl methacrylate) with the short rod method. J Prosthet Dent. 60:249–53. DOI: 10.1016/0022-3913(88)90325-3. PMID: 3172010.15. Zappini G, Kammann A, Wachter W. 2003; Comparison of fracture tests of denture base materials. J Prosthet Dent. 90:578–85. DOI: 10.1016/j.prosdent.2003.09.008. PMID: 14668759.16. International Organization for Standardization. 2015. Dentistry - base polymers. Part 1: denture base polymers. ISO 20795-1:2013. ISO;Geneva:17. American Society for Testing and Materials International. Standard test methods for flexural properties of unreinforced plastics and electrical insulating materials. ASTM D790.18. Gharechahi J, Asadzadeh N, Shahabian F, Gharechahi M. 2014; Flexural strength of acrylic resin denture bases processed by two different methods. J Dent Res Dent Clin Dent Prospects. 8:148–52. DOI: 10.5681/joddd.2014.027. PMID: 25346833. PMCID: PMC4206756.19. Neumeier TT, Neumeier H. 2016; Digital immediate dentures treatment: a clinical report of two patients. J Prosthet Dent. 116:314–9. DOI: 10.1016/j.prosdent.2016.01.010. PMID: 27061629.20. Bidra AS, Taylor TD, Agar JR. 2013; Computer-aided technology for fabricating complete dentures: systematic review of historical background, current status, and future perspectives. J Prosthet Dent. 109:361–6. DOI: 10.1016/S0022-3913(13)60318-2. PMID: 23763779.21. Pereyra NM, Marano J, Subramanian G, Qeuk S, Leff D. 2015; Comparison of patient satisfaction in the fabrication of conventional dentures vs. DENTCA (CAD/CAM) dentures: A case report. J N J Dent Assoc. 86:26–33. PMID: 26242110.22. Goodacre CJ, Garbacea A, Naylor WP, Daher T, Marchack CB, Lowry J. 2012; CAD/CAM fabricated complete dentures: concepts and clinical methods of obtaining required morphological data. J Prosthet Dent. 107:34–46. DOI: 10.1016/S0022-3913(12)60015-8. PMID: 22230914.23. Kydd WL. 1960; The comminuting efficiency of varied occlusal tooth form and the associated deformation of the complete denture base. J Am Dent Assoc. 61:465–71. DOI: 10.14219/jada.archive.1960.0203. PMID: 13755561.24. Steinmassl PA, Wiedemair V, Huck C, Klaunzer F, Steinmassl O, Grunert I, Dumfahrt H. 2017; Do CAD/CAM dentures really release less monomer than conventional dentures? Clin Oral Investig. 21:1697–705. DOI: 10.1007/s00784-016-1961-6. PMID: 27704295. PMCID: PMC5442236.25. Aguirre BC, Chen JH, Kontogiorgos ED, Murchison DF, Nagy WW. 2020; Flexural strength of denture base acrylic resins processed by conventional and CAD-CAM methods. J Prosthet Dent. 123:641–6. DOI: 10.1016/j.prosdent.2019.03.010. PMID: 31353106.26. Al-Dwairi ZN, Tahboub KY, Baba NZ, Goodacre CJ. 2020; A comparison of the flexural and impact strengths and flexural modulus of CAD/CAM and conventional heat-cured polymethyl methacrylate (PMMA). J Prosthodont. 29:341–9. DOI: 10.1111/jopr.12926. PMID: 29896904.27. Arslan M, Murat S, Alp G, Zaimoglu A. 2018; Evaluation of flexural strength and surface properties of prepolymerized CAD/CAM PMMA-based polymers used for digital 3D complete dentures. Int J Comput Dent. 21:31–40. PMID: 29610779.28. Steinmassl O, Offermanns V, Stöckl W, Dumfahrt H, Grunert I, Steinmassl PA. 2018; In vitro analysis of the fracture resistance of CAD/CAM denture base resins. Materials (Basal). 11:401. DOI: 10.3390/ma11030401. PMID: 29518022. PMCID: PMC5872980.29. Pacquet W, Benoit A, Hatège-Kimana C, Wulfman C. 2019; Mechanical properties of CAD/CAM denture base resins. Int J Prosthodont. 32:104–6. DOI: 10.11607/ijp.6025. PMID: 30677121.30. McLaughlin JB, Ramos V Jr. 2015; Complete denture fabrication with CAD/CAM record bases. J Prosthet Dent. 114:493–7. DOI: 10.1016/j.prosdent.2015.04.017. PMID: 26139040.31. Gajewski VE, Pfeifer CS, Fróes-Salgado NR, Boaro LC, Braga RR. 2012; Monomers used in resin composites: degree of conversion, mechanical properties and water sorption/solubility. Braz Dent J. 23:508–14. DOI: 10.1590/s0103-64402012000500007. PMID: 23306226.32. Peutzfeldt A. 1997; Resin composites in dentistry: the monomer systems. Eur J Oral Sci. 105:97–116. DOI: 10.1111/j.1600-0722.1997.tb00188.x. PMID: 9151062.33. Ruyter IE, Oysaed H. 1987; Composites for use in posterior teeth: Composition and conversion. J Biomed Mater Res. 21:11–23. DOI: 10.1002/jbm.820210107. PMID: 3558436.34. Lee YS, Choi KK, Park SJ. 2002; Effect of resin matrix on degree of conversion and fracture toughness of dental composites. J Korean Acad Conserv Dent. 27:77–86.35. Peng L, Chen L, Harris BT, Morton D, Lin WS. 2017; Managing complications resulting from limited prosthetic space with a monolithic, multichromatic CAD/CAM implant-retained overdenture. J Prosthet Dent. 118:712–6. DOI: 10.1016/j.prosdent.2017.01.022. PMID: 28456371.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Comparison of shear bond strengths of different types of denture teeth to different denture base resins

- Mechanical properties and biocompatibility of experimental 3D printing denture base resin

- THE CHANGE IN TRANSVERSE STRENGTH OF DENTURE BASE AFTER RELINE PROCEDURE

- Effects of relining materials on the flexural strength of relined thermoplastic denture base resins

- Shear bond strength between CAD/CAM denture base resin and denture artificial teeth when bonded with resin cement