J Adv Prosthodont.

2019 Oct;11(5):262-270. 10.4047/jap.2019.11.5.262.

Evaluation of marginal adaptation in three-unit frameworks fabricated with conventional and powder-free digital impression techniques

- Affiliations

-

- 1Private Practice, Calhan Dental Clinic, Denizli, Turkey.

- 2Department of Prosthodontics, Faculty of Dentistry, Erciyes University, Kayseri, Turkey.

- 3Department of Prosthodontics, Faculty of Dentistry, Pamukkale University, Pamukkale, Turkey. sezgis@pau.edu.tr

- KMID: 2462109

- DOI: http://doi.org/10.4047/jap.2019.11.5.262

Abstract

- PURPOSE

The purpose of this in vitro study was to evaluate the marginal misfits of three-unit frameworks fabricated with conventional and digital impressions techniques.

MATERIALS AND METHODS

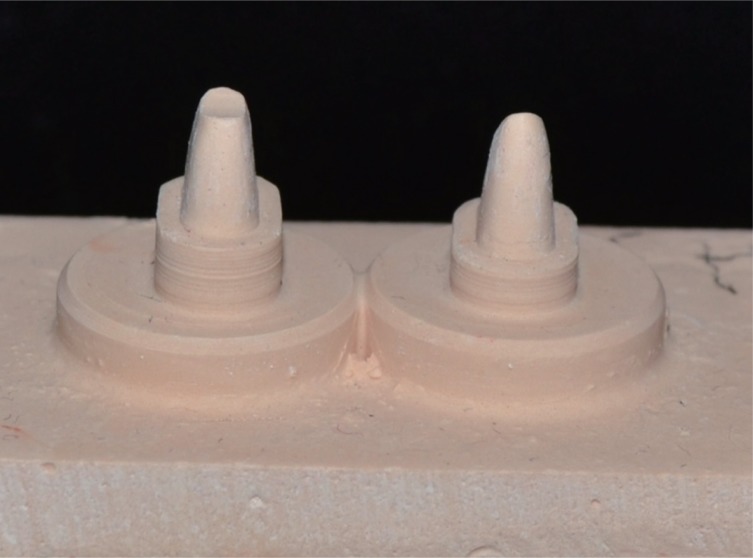

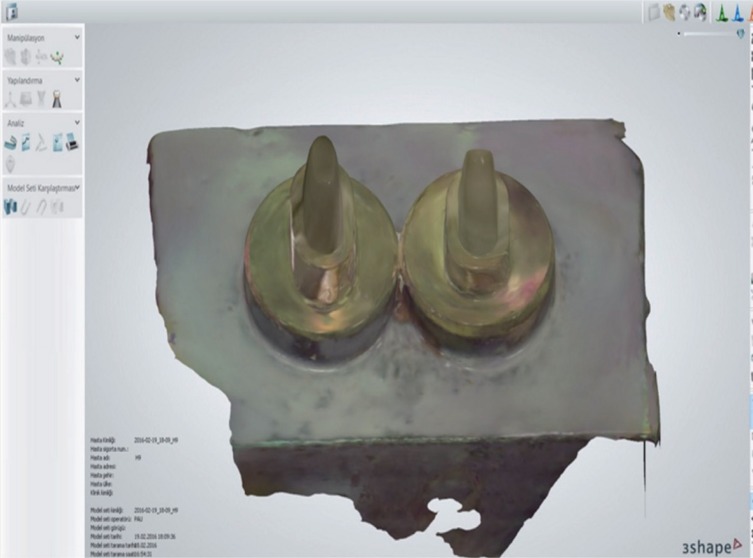

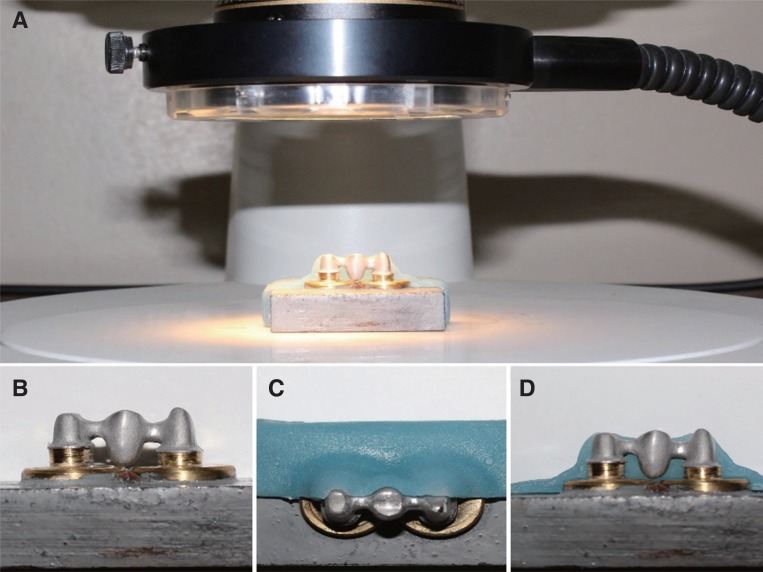

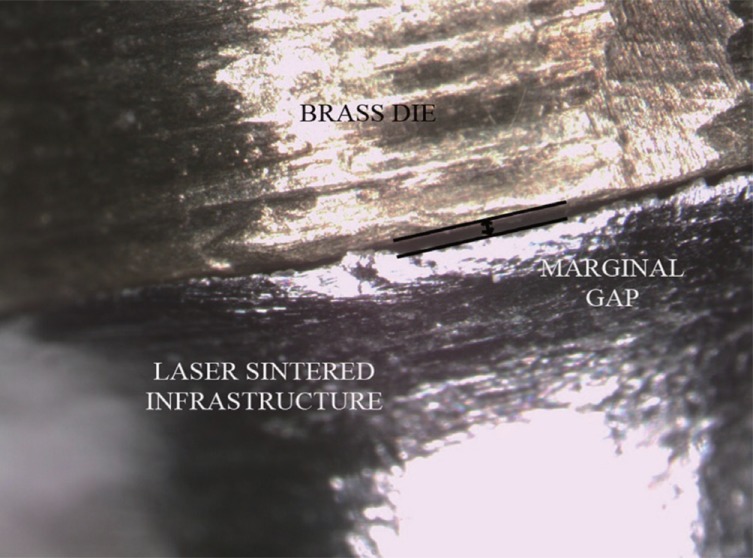

Thirty brass canine and second premolar abutment preparations were fabricated by using a computer numerical control machine and were randomly divided into 3 groups (n=10) as follows: conventional impression group (Group Ci), Cerec Omnicam (Group Cdi), and 3shape TRIOS-3 (Group Tdi) digital impression groups. The laser-sintered metal frameworks were designed and fabricated with conventional and digital impressions. The marginal adaptation was assessed with a stereomicroscope at ×30 magnification. The data were analyzed with 1-way analysis of variances (ANOVAs) and the independent simple t tests.

RESULTS

A statistically significant difference was found between the frameworks fabricated by conventional methods and those fabricated by digital impression methods. Multiple comparison results revealed that the frameworks in Group Ci (average, 98.8 ± 16.43 µm; canine, 93.59 ± 16.82 µm; premolar, 104.10 ± 15.02 µm) had larger marginal misfit values than those in Group Cdi (average, 63.78 ± 14.05 µm; canine, 62.73 ± 13.71 µm; premolar, 64.84 ± 15.06 µm) and Group Tdi (average, 65.14 ± 18.05 µm; canine, 70.64 ± 19.02 µm; premolar, 59.64 ± 16.10 µm) (P=.000 for average; P=.001 for canine; P<.001 for premolar). No statistical difference was found between the marginal misfits of canine and premolar abutment teeth within the same groups (P>.05).

CONCLUSION

The three-unit frameworks fabricated with digital impression techniques showed better marginal fit compared to conventional impression techniques. All marginal misfit values were clinically acceptable.

Keyword

MeSH Terms

Figure

Reference

-

1. Walton TR. The up to 25-year survival and clinical performance of 2,340 high gold-based metal-ceramic single crowns. Int J Prosthodont. 2013; 26:151–160. PMID: 23476910.

Article2. An S, Kim S, Choi H, Lee JH, Moon HS. Evaluating the marginal fit of zirconia copings with digital impressions with an intraoral digital scanner. J Prosthet Dent. 2014; 112:1171–1175. PMID: 24951386.

Article3. Vennerstrom M, Fakhary M, Von Steyern PV. The fit of crowns produced using digital impression systems. Swed Dent J. 2014; 38:101–110. PMID: 25796804.4. Şeker E, Ozcelik TB, Rathi N, Yilmaz B. Evaluation of marginal fit of CAD/CAM restorations fabricated through cone beam computerized tomography and laboratory scanner data. J Prosthet Dent. 2016; 115:47–51. PMID: 26518986.5. Borba M, Cesar PF, Griggs JA, Della Bona Á. Adaptation of all-ceramic fixed partial dentures. Dent Mater. 2011; 27:1119–1126. PMID: 21920595.

Article6. Punj A, Bompolaki D, Garaicoa J. Dental Impression Materials and Techniques. Dent Clin North Am. 2017; 61:779–796. PMID: 28886768.

Article7. Euán R, Figueras-Álvarez O, Cabratosa-Termes J, Oliver-Parra R. Marginal adaptation of zirconium dioxide copings: influence of the CAD/CAM system and the finish line design. J Prosthet Dent. 2014; 112:155–162. PMID: 24445027.

Article8. Dahl BE, Dahl JE, Rønold HJ. Digital evaluation of marginal and internal fit of single-crown fixed dental prostheses. Eur J Oral Sci. 2018; 126:512–517. PMID: 30298624.

Article9. Praça L, Pekamc FC, Regod RO, Radermacherc K, Wolfarta S, Marottia J. Accuracy of single crowns fabricated from ultrasound digital impressions. Dent Mater. 2018; 34:e280–e288. PMID: 30268677.

Article10. Anadioti E, Aquilino SA, Gratton DG, Holloway JA, Denry IL, Thomas GW, Qian F. Internal fit of pressed and computeraided design/computer-aided manufacturing ceramic crowns made from digital and conventional impressions. J Prosthet Dent. 2015; 113:304–309. PMID: 25488521.

Article11. Ahlholm P, Sipilä K, Vallittu P, Jakonen M, Kotiranta U. Digital versus conventional impressions in fixed prosthodontics: A review. J Prosthodont. 2018; 27:35–41. PMID: 27483210.

Article12. Gabor AG, Zaharia C, Stan AT, Gavrilovici AM, Negrutiu ML, Sinescu C. Digital Dentistry-Digital Impression and CAD/CAM system applications. J Interdisciplinary Med. 2017; 2:54–57.13. Ng J, Ruse D, Wyatt C. A comparison of the marginal fit of crowns fabricated with digital and conventional methods. J Prosthet Dent. 2014; 112:555–560. PMID: 24630399.

Article14. Anadioti E, Aquilino SA, Gratton DG, Holloway JA, Denry I, Thomas GW, Qian F. 3D and 2D marginal fit of pressed and CAD/CAM lithium disilicate crowns made from digital and conventional impressions. J Prosthodont. 2014; 23:610–617. PMID: 24995593.

Article15. Abdel-Azim T, Rogers K, Elathamna E, Zandinejad A, Metz M, Morton D. Comparison of the marginal fit of lithium disilicate crowns fabricated with CAD/CAM technology by using conventional impressions and two intraoral digital scanners. J Prosthet Dent. 2015; 114:554–559. PMID: 26100929.

Article16. Schaefer O, Decker M, Wittstock F, Kuepper H, Guentsch A. Impact of digital impression techniques on the adaption of ceramic partial crowns in vitro. J Dent. 2014; 42:677–683. PMID: 24508541.

Article17. Vandeweghe S, Vervack V, Dierens M, De Bruyn H. Accuracy of digital impressions of multiple dental implants: an in vitro study. Clin Oral Implants Res. 2017; 28:648–653. PMID: 27150731.18. Su TS, Sun J. Comparison of marginal and internal fit of 3-unit ceramic fixed dental prostheses made with either a conventional or digital impression. J Prosthet Dent. 2016; 116:362–367. PMID: 27061628.

Article19. Renne W, Wolf B, Kessler R, McPherson K, Mennito AS. Evaluation of the marginal fit of CAD/CAM crowns fabricated using two different chairside CAD/CAM systems on preparations of varying quality. J Esthet Restor Dent. 2015; 27:194–202. PMID: 26177118.

Article20. Haddadi Y, Bahrami G, Isidor F. Accuracy of crowns based on digital intraoral scanning compared to conventional impression-a split-mouth randomised clinical study. Clin Oral Investig. 2019; 23:4043–4050.

Article21. Takeuchi Y, Koizumi H, Furuchi M, Sato Y, Ohkubo C, Matsumura H. Use of digital impression systems with intraoral scanners for fabricating restorations and fixed dental prostheses. J Oral Sci. 2018; 60:1–7. PMID: 29576569.

Article22. Nesse H, Ulstein DM, Vaage MM, Øilo M. Internal and marginal fit of cobalt-chromium fixed dental prostheses fabricated with 3 different techniques. J Prosthet Dent. 2015; 114:686–692. PMID: 26213267.

Article23. Dikbas I, Tanalp J, Tomruk CO, Koksal T. Evaluation of reasons for extraction of crowned teeth: a prospective study at a university clinic. Acta Odontol Scand. 2013; 71:848–856. PMID: 22554248.

Article24. McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971; 131:107–111. PMID: 5283545.

Article25. Ucar Y, Akova T, Akyil MS, Brantley WA. Internal fit evaluation of crowns prepared using a new dental crown fabrication technique: laser-sintered Co-Cr crowns. J Prosthet Dent. 2009; 102:253–259. PMID: 19782828.

Article26. Sakrana AA. In vitro evaluation of the marginal and internal discrepancies of different esthetic restorations. J Appl Oral Sci. 2013; 21:575–580. PMID: 24473725.

Article27. Ortega R, Gonzalo E, Gomez-Polo M, Suárez MJ. Marginal and internal discrepancies of posterior zirconia-based crowns fabricated with three different CAD/CAM systems versus metal-ceramic. Int J Prosthodont. 2015; 28:509–511. PMID: 26340011.

Article28. Zoellner A, Brägger U, Fellmann V, Gaengler P. Correlation between clinical scoring of secondary caries at crown margins and histologically assessed extent of the lesions. Int J Prosthodont. 2000; 13:453–459. PMID: 11203669.29. Keul C, Stawarczyk B, Erdelt KJ, Beuer F, Edelhoff D, Güth JF. Fit of 4-unit FDPs made of zirconia and CoCr-alloy after chairside and labside digitalization-a laboratory study. Dent Mater. 2014; 30:400–407. PMID: 24522150.30. Kocaağaoğlu H, Kılınç Hİ, Albayrak H, Kara M. In vitro evaluation of marginal, axial, and occlusal discrepancies in metal ceramic restorations produced with new technologies. J Prosthet Dent. 2016; 116:368–374. PMID: 27130177.

Article31. Afify A, Haney S, Verrett R, Mansueto M, Cray J, Johnson R. Marginal discrepancy of noble metal-ceramic fixed dental prosthesis frameworks fabricated by conventional and digital technologies. J Prosthet Dent. 2018; 119:307.e1–307.e7. PMID: 29153748.

Article32. Svanborg P, Skjerven H, Carlsson P, Eliasson A, Karlsson S, Ortorp A. Marginal and internal fit of cobalt-chromium fixed dental prostheses generated from digital and conventional impressions. Int J Dent. 2014; 2014:534382. PMID: 24723954.

Article33. Eroğlu Z, Gurbulak AG. Fatigue behavior of zirconia-ceramic, galvano-ceramic, and porcelain-fused-to-metal fixed partial dentures. J Prosthodont. 2013; 22:516–522. PMID: 23735078.

Article34. EOS. Material Data Sheet EOS CobaltChrome SP2 material for EOSINT M 270. No., 2009. (https://www.eos.info/material-m).35. Memarian M, Sadighpour L, Nosratpour R, Fard MJK. Marginal adaptation and internal fit of posterior 3-unit zirconia FPDs fabricated with different CAD/CAM systems. Eur J Prosthodont Restor Dent. 2017; 25:79–85. PMID: 28590093.36. Dureja I, Yadav B, Malhotra P, Dabas N, Bhargava A, Pahwa R. A comparative evaluation of vertical marginal fit of provisional crowns fabricated by computer-aided design/computer-aided manufacturing technique and direct (intraoral technique) and flexural strength of the materials: An in vitro study. J Indian Prosthodont Soc. 2018; 18:314–320. PMID: 30449959.

Article37. Örtorp A1, Jönsson D, Mouhsen A, Vult von Steyern P. The fit of cobalt-chromium three-unit fixed dental prostheses fabricated with four different techniques: a comparative in vitro study. Dent Mater. 2011; 27:356–363. PMID: 21163516.

Article38. Boitelle P, Mawussi B, Tapie L, Fromentin O. A systematic review of CAD/CAM fit restoration evaluations. J Oral Rehabil. 2014; 41:853–874. PMID: 24952991.

Article39. Colpani JT, Borba M, Della Bona A. Evaluation of marginal and internal fit of ceramic crown copings. Dent Mater. 2013; 29:174–180. PMID: 23218747.

Article40. Kenyon BJ, Hagge MS, Leknius C, Daniels WC, Weed ST. Dimensional accuracy of 7 die materials. J Prosthodont. 2005; 14:25–31. PMID: 15733132.

Article41. Corso M, Abanomy A, Di Canzio J, Zurakowski D, Morgano SM. The effect of temperature changes on the dimensional stability of polyvinyl siloxane and polyether impression materials. J Prosthet Dent. 1998; 79:626–631. PMID: 9627890.

Article42. Xu D, Xiang N, Wei B. The marginal fit of selective laser melting-fabricated metal crowns: an in vitro study. J Prosthet Dent. 2014; 112:1437–1440. PMID: 25001421.43. Wankhade S, Sanghavi K, Rajguru V, Lokade J. A comparative evaluation of six commonly used types of die materials for the property of abrasion resistance, at two time intervals: an in vitro study. Int J Prosthodont Restor Dent. 2013; 3:1–6.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Role of span length in the adaptation of implant-supported cobalt chromium frameworks fabricated by three techniques

- Comparison of the fit of cast gold crowns fabricated from the digital and the conventional impression techniques

- Evaluation of marginal and internal gap under model-free monolithic zirconia restoration fabricated by digital intraoral scanner

- Evaluation of marginal and internal gap of three-unit metal framework according to subtractive manufacturing and additive manufacturing of CAD/CAM systems

- Clinical comparison of marginal fit of ceramic inlays between digital and conventional impressions