J Korean Acad Prosthodont.

2019 Oct;57(4):483-489. 10.4047/jkap.2019.57.4.483.

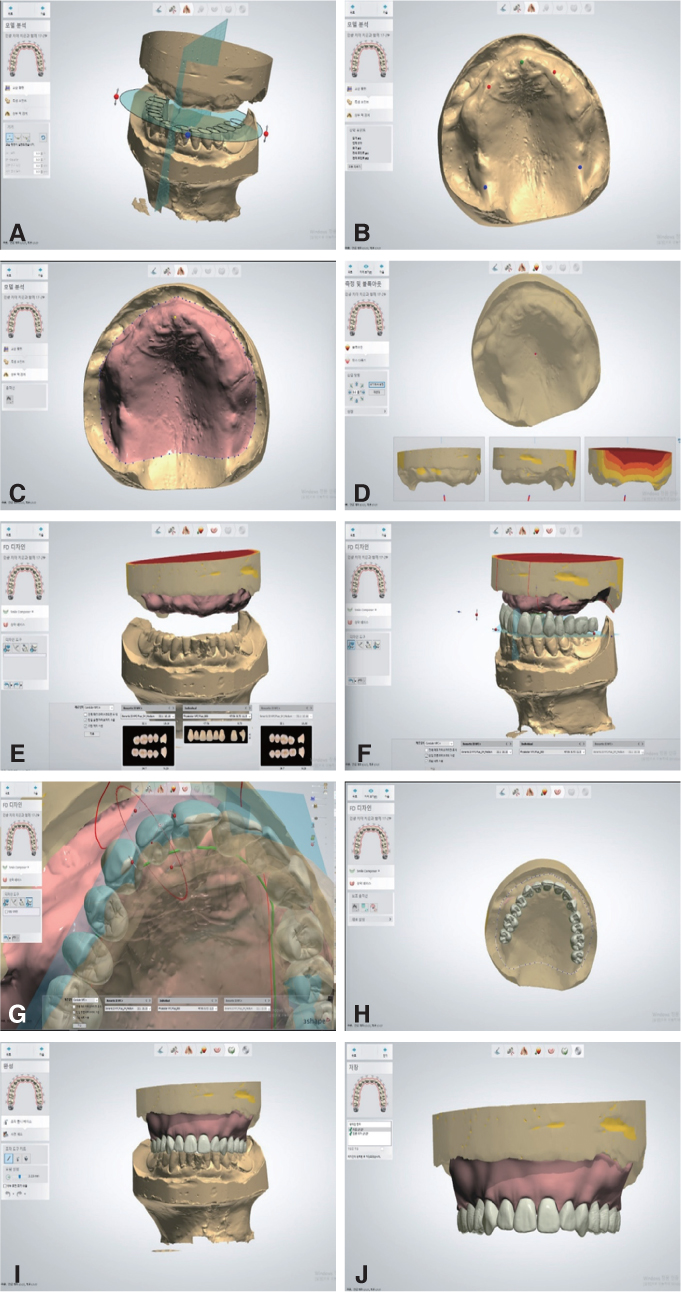

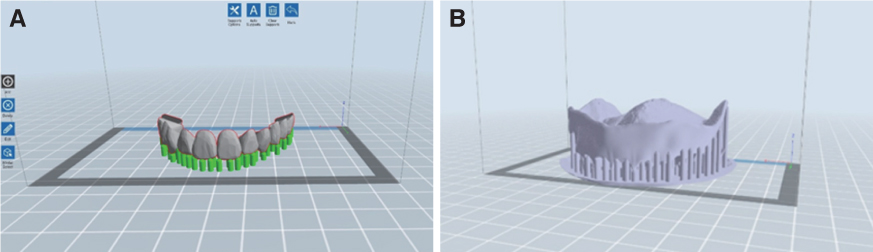

Fabrication of additive manufacturing interim denture and comparison with conventional interim denture: A case report

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Chonnam National University, Gwangju, Republic of Korea. mcnihil@daum.net

- KMID: 2461157

- DOI: http://doi.org/10.4047/jkap.2019.57.4.483

Abstract

- With development of digital dentistry, the 3-dimensional (3D) manufacturing industry using computer-aided design and computer-aided manufacturing (CAD/CAM) has grown dramatically in recent years. Denture fabrication using digital method is also increasing due to the recent development of digital technology in dentistry. The 3D manufacturing process can be categorized into 2 types: subtractive manufacturing (SM) and additive manufacturing (AM). SM, such as milling is based on cutting away from a solid block of materal. AM, such as 3D printing, is based on adding the material layer by layer. AM enables the fabrication of complex structures that are difficult to mill. In this case, additive manufacturing method was applied to the fabrication of the resin-based complete denture to a 80 year-old patient. During the follow-up periods, the denture using digital method has provided satisfactory results esthetically and functionally.

Keyword

MeSH Terms

Figure

Reference

-

1. Maeda Y, Minoura M, Tsutsumi S, Okada M, Nokubi T. A CAD/CAM system for removable denture. Part I: Fabrication of complete dentures. Int J Prosthodont. 1994; 7:17–21.2. Kattadiyil MT, Goodacre CJ, Baba NZ. CAD/CAM complete dentures: a review of two commercial fabrication systems. J Calif Dent Assoc. 2013; 41:407–416.3. Bilgin MS, Erdem A, Aglarci OS, Dilber E. Fabricating complete dentures with CAD/CAM and RP technologies. J Prosthodont. 2015; 24:576–579.

Article4. Wimmer T, Gallus K, Eichberger M, Stawarczyk B. Complete denture fabrication supported by CAD/CAM. J Prosthet Dent. 2016; 115:541–546.

Article5. Goodacre CJ, Garbacea A, Naylor WP, Daher T, Marchack CB, Lowry J. CAD/CAM fabricated complete dentures: concepts and clinical methods of obtaining required morphological data. J Prosthet Dent. 2012; 107:34–46.

Article6. Infante L, Yilmaz B, McGlumphy E, Finger I. Fabricating complete dentures with CAD/CAM technology. J Prosthet Dent. 2014; 111:351–355.

Article7. Park ME, Shin SY. Three-dimensional comparative study on the accuracy and reproducibility of dental casts fabricated by 3D printers. J Prosthet Dent. 2018; 119:861.e1–861.e7.

Article8. Wimmer T, Eichberger M, Lümkemann N, Stawarczyk B. Accuracy of digitally fabricated trial dentures. J Prosthet Dent. 2018; 119:942–947.

Article9. Lo Russo L, Salamini A. Removable complete digital dentures: A workflow that integrates open technologies. J Prosthet Dent. 2018; 119:727–732.

Article10. Inokoshi M, Kanazawa M, Minakuchi S. Evaluation of a complete denture trial method applying rapid prototyping. Dent Mater J. 2012; 31:40–46.

Article11. Kanazawa M, Inokoshi M, Minakuchi S, Ohbayashi N. Trial of a CAD/CAM system for fabricating complete dentures. Dent Mater J. 2011; 30:93–96.

Article12. Yamamoto S, Kanazawa M, Hirayama D, Nakamura T, Arakida T, Minakuchi S. In vitro evaluation of basal shapes and offset values of artificial teeth for CAD/CAM complete dentures. Comput Biol Med. 2016; 68:84–89.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Comparison of digitalized fabrication method for interim removable partial denture: case reports

- Fabrication of complete denture using 3D printing: a case report

- 3D printed interim immediate denture by using the occlusal plane digital transfer method of the POP BOW system in a patient planning to extract upper and lower residual teeth: a case report

- Fabrication of computer-aided design/computer-aided manufacturing complete denture and conventional complete denture: case report

- The case of interim denture applying for thermoforming technique