J Korean Acad Prosthodont.

2019 Jul;57(3):211-218. 10.4047/jkap.2019.57.3.211.

Comparative evaluation of marginal and internal fit of metal copings fabricated by various CAD/CAM methods

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Wonkwang University, Iksan, Republic of Korea. pro11@wku.ac.kr

- 2Dental Laboratory, Wonkwang University Dental Hospital, Iksan, Republic of Korea.

- KMID: 2453774

- DOI: http://doi.org/10.4047/jkap.2019.57.3.211

Abstract

- PURPOSE

The purpose of the present study was to compare the accuracy of four different metal copings fabricated by CAD/CAM technology and to evaluate clinical effectiveness.

MATERIALS AND METHODS

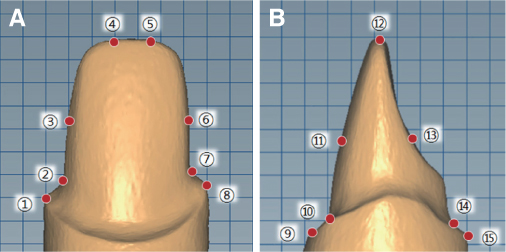

Composite resin tooth of the maxillary central incisor was prepared for a metal ceramic crown and duplicated metal die was fabricated. Then scan the metal die for 12 times to obtain STL files using a confocal microscopy type oral scanner. Metal copings with a thickness of 0.5 mm and a cement space of 50 µm were designed on a CAD program. The Co-Cr metal copings were fabricated by the following four methods: Wax pattern milling & Casting (WM), Resin pattern 3D Printing & casting (RP), Milling & Sintering (MS), Selective laser melting (SLM). Silicone replica technique was used to measure marginal and internal discrepancies. The data was statistically analyzed with One-way analysis of variance and appropriate post hoc test (Scheffe test) (α=.05).

RESULTS

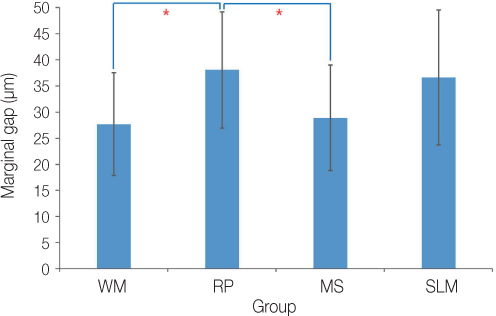

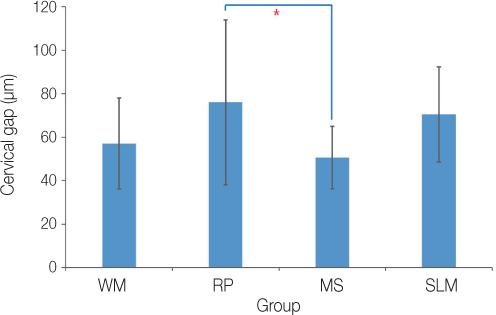

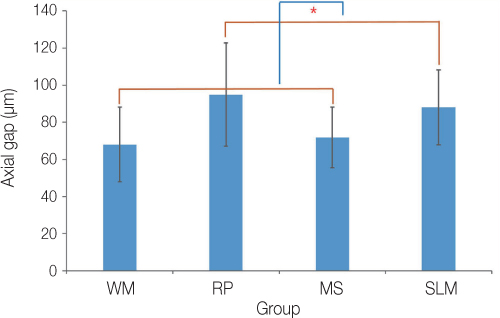

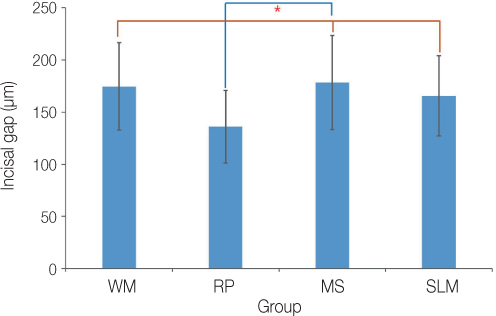

Mean marginal discrepancy was significantly smaller in the Group WM (27.66 ± 9.85 µm) and Group MS (28.88 ± 10.13 µm) than in the Group RP (38.09 ± 11.14 µm). Mean cervical discrepancy was significantly smaller in the Group MS than in the Group RP. Mean axial discrepancy was significantly smaller in the Group WM and Group MS then in the Group RP and Group SLM. Mean incisal discrepancies was significantly smaller in the Group RP than in all other groups.

CONCLUSION

The marginal and axial discrepancies of the Co-Cr coping fabricated by the Wax pattern milling and Milling/Sintering method were better than those of the other groups. The marginal, cervical and axial fit of Co-Cr copings in all groups are within a clinically acceptable range.

MeSH Terms

Figure

Cited by 1 articles

-

Marginal and internal discrepancy of 3-unit fixed dental prostheses fabricated by subtractive and additive manufacturing

Jae-Won Choi

J Korean Acad Prosthodont. 2020;58(1):7-13. doi: 10.4047/jkap.2020.58.1.7.

Reference

-

1. Johnston JF, Dykema RW, Cunningham DM. Porcelain veneers bonded to gold castings-A progress report. J Prosthet Dent. 1958; 8:120–122.

Article2. Kocaağaoğlu H, Kılınç Hİ, Albayrak H, Kara M. In vitro evaluation of marginal, axial, and occlusal discrepancies in metal ceramic restorations produced with new technologies. J Prosthet Dent. 2016; 116:368–374.

Article3. Kane LM, Chronaios D, Sierraalta M, George FM. Marginal and internal adaptation of milled cobalt-chromium copings. J Prosthet Dent. 2015; 114:680–685.

Article4. Kim EH, Lee DH, Kwon SM, Kwon TY. A microcomputed tomography evaluation of the marginal fit of cobalt-chromium alloy copings fabricated by new manufacturing techniques and alloy systems. J Prosthet Dent. 2017; 117:393–399.

Article5. Bidra AS, Taylor TD, Agar JR. Computer-aided technology for fabricating complete dentures: systematic review of historical background, current status, and future perspectives. J Prosthet Dent. 2013; 109:361–366.

Article6. Poggio C, Pigozzo M, Ceci M, Scribante A, Beltrami R, Chiesa M. Influence of different luting protocols on shear bond strength of computer aided design/computer aided manufacturing resin nanoceramic material to dentin. Dent Res J (Isfahan). 2016; 13:91–97.

Article7. Christensen GJ. The state of fixed prosthodontic impressions: room for improvement. J Am Dent Assoc. 2005; 136:343–346.8. Reich S, Wichmann M, Nkenke E, Proeschel P. Clinical fit of allceramic three-unit fixed partial dentures, generated with three different CAD/CAM systems. Eur J Oral Sci. 2005; 113:174–179.

Article9. Chan C, Weber H. Plaque retention on teeth restored with full-ceramic crowns: a comparative study. J Prosthet Dent. 1986; 56:666–671.

Article10. Baig MR, Tan KB, Nicholls JI. Evaluation of the marginal fit of a zirconia ceramic computer-aided machined (CAM) crown system. J Prosthet Dent. 2010; 104:216–227.

Article11. Goldman M, Laosonthorn P, White RR. Microleakage-full crowns and the dental pulp. J Endod. 1992; 18:473–475.

Article12. DeLong R, Pintado MR, Ko CC, Hodges JS, Douglas WH. Factors influencing optical 3D scanning of vinyl polysiloxane impression materials. J Prosthodont. 2001; 10:78–85.

Article13. Seelbach P, Brueckel C, Wöstmann B. Accuracy of digital and conventional impression techniques and workflow. Clin Oral Investig. 2013; 17:1759–1764.

Article14. Lee H, Lee DH, Lee KB. In vitro evaluation methods on adaptation of fixed dental prosthesis. J Dent Rehabil Appl Sci. 2017; 33:63–70.

Article15. Laurent M, Scheer P, Dejou J, Laborde G. Clinical evaluation of the marginal fit of cast crowns-validation of the silicone replica method. J Oral Rehabil. 2008; 35:116–122.

Article16. Wolfart S, Wegner SM, Al-Halabi A, Kern M. Clinical evaluation of marginal fit of a new experimental all-ceramic system before and after cementation. Int J Prosthodont. 2003; 16:587–592.17. Song TJ, Kwon TK, Yang JH, Han JS, Lee JB, Kim SH, Yeo IS. Marginal fit of anterior 3-unit fixed partial zirconia restorations using different CAD/CAM systems. J Adv Prosthodont. 2013; 5:219–225.

Article18. Cho L, Song H, Koak J, Heo S. Marginal accuracy and fracture strength of ceromer/fiber-reinforced composite crowns: effect of variations in preparation design. J Prosthet Dent. 2002; 88:388–395.

Article19. Kale E, Seker E, Yilmaz B, Özcelik TB. Effect of cement space on the marginal fit of CAD-CAM-fabricated monolithic zirconia crowns. J Prosthet Dent. 2016; 116:890–895.

Article20. Holmes JR, Bayne SC, Holland GA, Sulik WD. Considerations in measurement of marginal fit. J Prosthet Dent. 1989; 62:405–408.

Article21. Christensen GJ. Marginal fit of gold inlay castings. J Prosthet Dent. 1966; 16:297–305.

Article22. Hung SH, Hung KS, Eick JD, Chappell RP. Marginal fit of porcelain-fused-to-metal and two types of ceramic crown. J Prosthet Dent. 1990; 63:26–31.

Article23. Kashani HG, Khera SC, Gulker IA. The effects of bevel angulation on marginal integrity. J Am Dent Assoc. 1981; 103:882–885.

Article24. McLean JW. Polycarboxylate cements. Five years’ experience in general practice. Br Dent J. 1972; 132:9–15.

Article25. Jorgensen KD, Esbensen AL. The relationship between the film thickness of zinc phosphate cement and the retention of veneer crowns. Acta Odontol Scand. 1968; 26:169–175.

Article26. Passon C, Lambert RH, Lambert RL, Newman S. The effect of multiple layers of die-spacer on crown retention. Oper Dent. 1992; 17:42–49.27. Grey NJ, Piddock V, Wilson MA. In vitro comparison of conventional crowns and a new all-ceramic system. J Dent. 1993; 21:47–51.

Article28. Iwai T, Komine F, Kobayashi K, Saito A, Matsumura H. Influence of convergence angle and cement space on adaptation of zirconium dioxide ceramic copings. Acta Odontol Scand. 2008; 66:214–218.

Article29. Vojdani M, Torabi K, Farjood E, Khaledi A. Comparison the marginal and internal fit of metal copings cast from wax patterns fabricated by CAD/CAM and conventional wax up techniques. J Dent (Shiraz). 2013; 14:118–129.30. Keul C, Stawarczyk B, Erdelt KJ, Beuer F, Edelhoff D, Güth JF. Fit of 4-unit FDPs made of zirconia and CoCr-alloy after chairside and labside digitalization-a laboratory study. Dent Mater. 2014; 30:400–407.

Article31. Svanborg P, Skjerven H, Carlsson P, Eliasson A, Karlsson S, Ortorp A. Marginal and internal fit of cobalt-chromium fixed dental prostheses generated from digital and conventional impressions. Int J Dent. 2014; 2014:534382.

Article32. Park JM. Comparative analysis on reproducibility among 5 intraoral scanners: sectional analysis according to restoration type and preparation outline form. J Adv Prosthodont. 2016; 8:354–362.

Article33. Imburgia M, Logozzo S, Hauschild U, Veronesi G, Mangano C, Mangano FG. Accuracy of four intraoral scanners in oral implantology: a comparative in vitro study. BMC Oral Health. 2017; 17:92.

Article34. Osman RB, Alharbi N, Wismeijer D. Build angle: Does it influence the accuracy of 3D-printed dental restorations using digital light-processing technology? Int J Prosthodont. 2017; 30:182–188.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Influence of finish line design on the marginal fit of nonprecious metal alloy coping fabricated by 3D printing, milling and casting using CAD-CAM

- Marginal fit of the digident CAD/CAM zirconia ceramic crowns

- Comparison of the fit accuracy of zirconia-based prostheses generated by two CAD/CAM systems

- Accuracy evaluation of metal copings fabricated by computer-aided milling and direct metal laser sintering systems

- The fit of zirconia core fabricated with CAD/CAM system