J Adv Prosthodont.

2019 Apr;11(2):120-127. 10.4047/jap.2019.11.2.120.

In vivo wear determination of novel CAD/CAM ceramic crowns by using 3D alignment

- Affiliations

-

- 1Department of Prosthodontics, Faculty of Dentistry, Ege University, Izmir, Turkey. a.aladag@gmail.com

- 2Department of Prosthodontics, Faculty of Dentistry, İzmir Katip Çelebi University, Izmir, Turkey.

- KMID: 2444146

- DOI: http://doi.org/10.4047/jap.2019.11.2.120

Abstract

- PURPOSE

To determine wear amount of single molar crowns, made from four different restoratives, and opposing natural teeth through computerized fabrication techniques using 3D image alignment.

MATERIALS AND METHODS

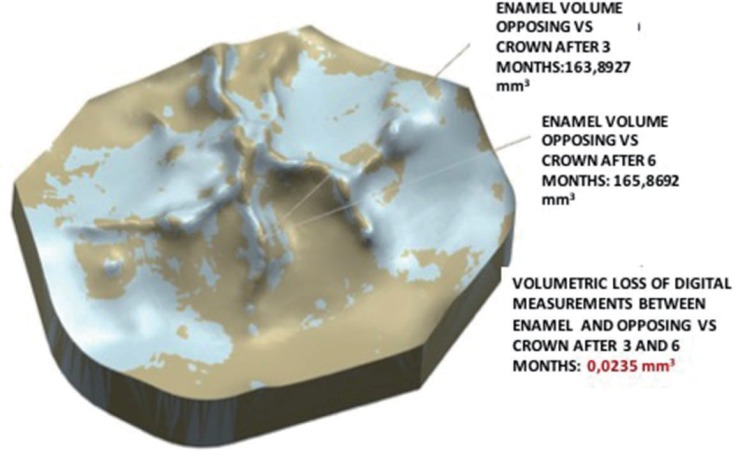

A total of 24 single crowns (N = 24 patients, age range: 18 - 50) were made from lithium disilicate (IPS E-max CAD), lithium silicate and zirconia based (Vita Suprinity CAD), resin matrix ceramic material (Cerasmart, GC), and dual matrix (Vita Enamic CAD) blocks. After digital impressions (Cerec 3D Bluecam, DentsplySirona), the crowns were designed and manufactured (Cerec 3, DentsplySirona). A dual-curing resin cement was used for cementation (Variolink Esthetic DC, Ivoclar). Then, measurement and recording of crowns and the opposing enamel surfaces with the intraoral scanner were made as well as at the third and sixth month follow-ups. All measurements were superimposed with a software (David-Laserscanner, V3.10.4). Volume loss due to wear was calculated from baseline to follow-up periods with Siemens Unigraphics NX 10 software. Statistical analysis was accomplished by Repeated Measures for ANOVA (SPSS 21) at = .05 significance level.

RESULTS

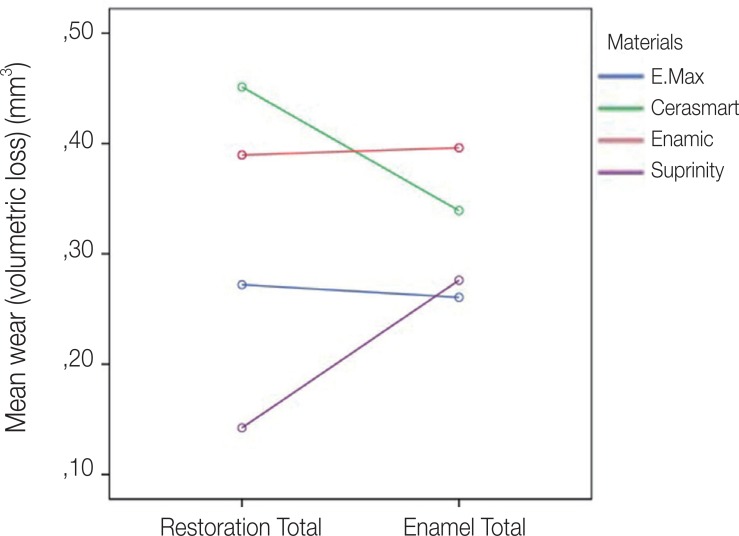

After 6 months, insignificant differences of the glass matrix and resin matrix materials for restoration/enamel wear were observed (P>.05). While there were no significant differences between the glass matrix groups (P>.05), significant differences between the resin matrix group materials (P<.05) were obtained. Although Cerasmart and Enamic were both resin matrix based, they exhibited different wear characteristics.

CONCLUSION

Glass matrix materials showed less wear both on their own and opposing enamel surfaces than resin matrix ceramic materials.

Keyword

MeSH Terms

Figure

Reference

-

1. Strub JR, Rekow ED, Witkowski S. Computer-aided design and fabrication of dental restorations: current systems and future possibilities. J Am Dent Assoc. 2006; 137:1289–1296. PMID: 16946436.2. Lambert H, Durand JC, Jacquot B, Fages M. Dental biomaterials for chairside CAD/CAM: State of the art. J Adv Prosthodont. 2017; 9:486–495. PMID: 29279770.

Article3. Bindl A, Lüthy H, Mörmann WH. Strength and fracture pattern of monolithic CAD/CAM-generated posterior crowns. Dent Mater. 2006; 22:29–36. PMID: 16040113.

Article4. Della Bona A, Corazza PH, Zhang Y. Characterization of a polymer-infiltrated ceramic-network material. Dent Mater. 2014; 30:564–569. PMID: 24656471.

Article5. Leinfelder KF. Indirect posterior composite resins. Compend Contin Educ Dent. 2005; 26:495–503. PMID: 16060379.6. Zhi L, Bortolotto T, Krejci I. Comparative in vitro wear resistance of CAD/CAM composite resin and ceramic materials. J Prosthet Dent. 2016; 115:199–202. PMID: 26460171.7. Oh WS, Delong R, Anusavice KJ. Factors affecting enamel and ceramic wear: a literature review. J Prosthet Dent. 2002; 87:451–459. PMID: 12011863.

Article8. Giordano R. Materials for chairside CAD/CAM-produced restorations. J Am Dent Assoc. 2006; 137:14S–21S.

Article9. Isgrò G, Pallav P, van der Zel JM, Feilzer AJ. The influence of the veneering porcelain and different surface treatments on the biaxial flexural strength of a heat-pressed ceramic. J Prosthet Dent. 2003; 90:465–473. PMID: 14586311.

Article10. Mörmann WH, Bindl A. All-ceramic, chair-side computer-aided design/computer-aided machining restorations. Dent Clin North Am. 2002; 46:405–426. PMID: 12014040.

Article11. Sajewicz E. On evaluation of wear resistance of tooth enamel and dental materials. Wear. 2006; 260:1256–1261.

Article12. Quintas AF, Oliveira F, Bottino MA. Vertical marginal discrepancy of ceramic copings with different ceramic materials, finish lines, and luting agents: an in vitro evaluation. J Prosthet Dent. 2004; 92:250–257. PMID: 15343160.

Article13. Syrek A, Reich G, Ranftl D, Klein C, Cerny B, Brodesser J. Clinical evaluation of all-ceramic crowns fabricated from intraoral digital impressions based on the principle of active wavefront sampling. J Dent. 2010; 38:553–559. PMID: 20381576.

Article14. da Costa JB, Pelogia F, Hagedorn B, Ferracane JL. Evaluation of different methods of optical impression making on the marginal gap of onlays created with CEREC 3D. Oper Dent. 2010; 35:324–329. PMID: 20533633.

Article15. Mou SH, Chai T, Wang JS, Shiau YY. Influence of different convergence angles and tooth preparation heights on the internal adaptation of Cerec crowns. J Prosthet Dent. 2002; 87:248–255. PMID: 11941350.

Article16. Nakamura T, Dei N, Kojima T, Wakabayashi K. Marginal and internal fit of Cerec 3 CAD/CAM all-ceramic crowns. Int J Prosthodont. 2003; 16:244–248. PMID: 12854786.17. Björn AL, Björn H, Grkovic B. Marginal fit of restorations and its relation to periodontal bone level. II. Crowns. Odontol Revy. 1970; 21:337–346. PMID: 5275036.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Marginal fit of the digident CAD/CAM zirconia ceramic crowns

- Comparative fracture strength analysis of Lava and Digident CAD/CAM zirconia ceramic crowns

- Six-year clinical performance of lithium disilicate glass-ceramic CAD-CAM versus metal-ceramic crowns

- Three-dimensional evaluation of the machinability of monolithic CAD/CAM-generated posterior crowns by nano-hybrid ceramic

- A comparison of the fidelity of various zirconia-based all-ceramic crowns fabricated with CAD/CAM systems