J Dent Rehabil Appl Sci.

2018 Mar;34(1):1-9. 10.14368/jdras.2018.34.1.1.

On the effect of saline immersion to the removal torque for resorbable blasting media and acid treated implants

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Kyung-pook National University, Daegu, Republic of Korea. sungamcho@gmail.com

- KMID: 2439250

- DOI: http://doi.org/10.14368/jdras.2018.34.1.1

Abstract

- PURPOSE

The purpose of this study is to investigate the effect of the titanium implant soaked in saline after RBM and acid etched surface treatment on the initial osseointegration by comparing the removal torque and the surface analysis compared to the titanium implant with only RBM and acid etched surface treatment.

MATERIALS AND METHODS

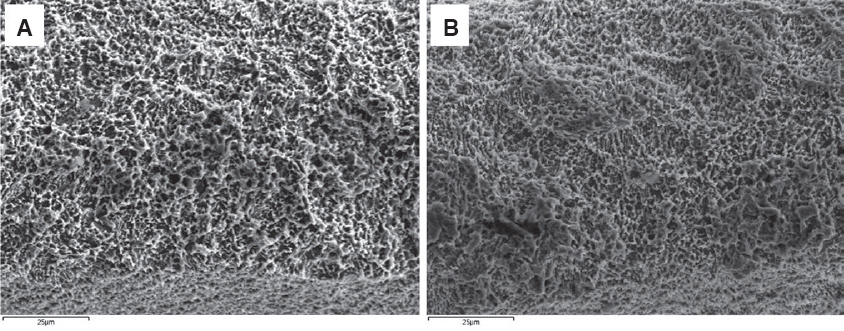

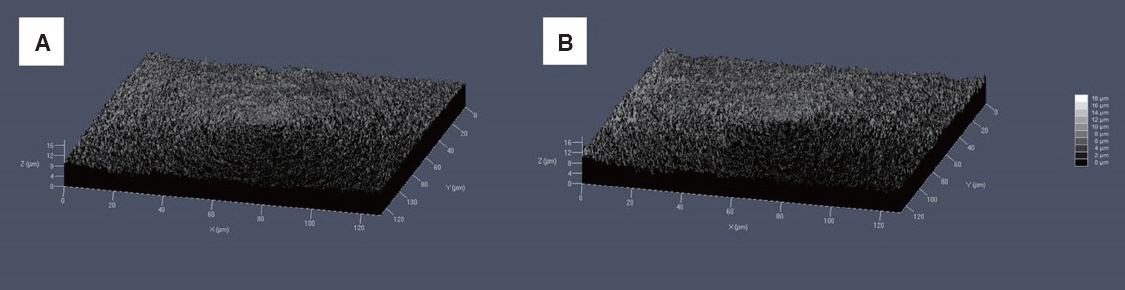

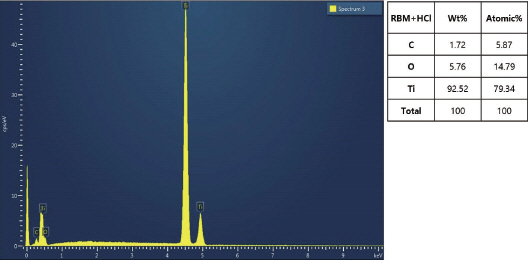

The control group was RBM and acid etched surface treated implants (RBM + HCl), and the test group was implants soaked in saline for 2 weeks after RBM and acid etched surface treatment (RBM + HCl + Sal). The control and test group implants were placed in the left and right tibiae of 10 rabbits, respectively, and at the same time, the insertion torque (ITQ) was measured. After 10 days, the removal torque (RTQ) was measured by exposing the implant site. FE-SEM, EDS, Surface roughness and Raman spectroscopy were performed for the surface analysis of the new implant specimens used in the experiments.

RESULTS

There was significant difference in insertion torque and removal torque between control group and experimental group (P = 0.014 < 0.05). Surface roughness of experimental group is higher than control group.

CONCLUSION

Saline soaking after RBM and acid etched surface treatment of titanium implants were positively affect the initial osseointegration as compared to titanium implants with only RBM and acid etched surface treatment.

Keyword

MeSH Terms

Figure

Reference

-

References

1. Sullivan DY, Sherwood RL, Mai TN. Preliminary results of a multicenter study evaluating a chemically enhanced surface for machined commercially pure titanium implants. J Prosthet Dent. 1997; 78:379–86. DOI: 10.1016/S0022-3913(97)70045-3.2. Mauceri N, Melilli D. Surface treatments for tita-nium implants. Int J Clin Dent. 2015; 8:139–49.3. Svanborg LM, Andersson M, Wennerberg A. Surface characterization of commercial oral implants on the nanometer level. J Biomed Mater Res B Appl Biomater. 2010; 92:462–9. PMID: 19957360.4. Lazzara RJ, Testori T, Trisi P, Porter SS, Weinstein RL. A human histologic analysis of osseotite and machined surfaces using implants with 2 opposing surfaces. Int J Periodontics Restorative Dent. 1999; 19:117–29. PMID: 10635177.5. Cooper LF. A role for surface topography in creating and maintaining bone at titanium endosseous implants. J Prosthet Dent. 2000; 84:522–34. DOI: 10.1067/mpr.2000.111966. PMID: 11105008.6. Wennerberg A, Albrektsson T. Effects of titanium surface topography on bone integration: a systematic review. Clin Oral Implants Res. 2009; 20(Suppl4):172–84. DOI: 10.1111/j.1600-0501.2009.01775.x. PMID: 19663964.7. Le Guéhennec L, Soueidan A, Layrolle P, Amouriq Y. Surface treatments of titanium dental implants for rapid osseointegration. Dent Mater. 2007; 23:844–54. DOI: 10.1016/j.dental.2006.06.025. PMID: 16904738.8. Bagno A, Di Bello C. Surface treatments and roughness properties of Ti-based biomaterials. J Mater Sci Mater Med. 2004; 15:935–49. DOI: 10.1023/B:JMSM.0000042679.28493.7f. PMID: 15448401.9. Piattelli M, Scarano A, Paolantonio M, Iezzi G, Petrone G, Piattelli A. Bone response to machined and resorbable blast material titanium implants: an experimental study in rabbits. J Oral Implantol. 2002; 28:2–8. DOI: 10.1563/1548-1336(2002)028<0002:BRTMAR>2.3.CO;2.10. Müeller WD, Gross U, Fritz T, Voigt C, Fischer P, Berger G, Rogaschewski S, Lange KP. Evaluation of the interface between bone and titanium surfaces being blasted by aluminium oxide or bioceramic particles. Clin Oral Implants Res. 2003; 14:349–56. DOI: 10.1034/j.1600-0501.2003.00791.x. PMID: 12755785.11. Davies JE. Mechanisms of endosseous integration. Int J Prosthodont. 1998; 11:391–401. PMID: 9922731.12. Giavaresi G, Fini M, Cigada A, Chiesa R, Rondelli G, Rimondini L, Torricelli P, Aldini NN, Giardino R. Mechanical and histomorphometric evaluations of titanium implants with different surface treatments inserted in sheep cortical bone. Biomaterials. 2003; 24:1583–94. DOI: 10.1016/S0142-9612(02)00548-3.13. Zhao G, Schwartz Z, Wieland M, Rupp F, GeisGerstorfer J, Cochran DL, Boyan BD. High surface energy enhances cell response to titanium substrate microstructure. J Biomed Mater Res A. 2005; 74:4958. DOI: 10.1002/jbm.a.30320.14. Brånemark PI, Adell R, Breine U, Hansson BO, Lindström J, Ohlsson A. Intra-osseous anchorage of dental prostheses. I. Experimental studies. Scand J Plast Reconstr Surg. 1969; 3:81–100. DOI: 10.3109/02844316909036699. PMID: 4924041.15. Carlsson L, Röstlund T, Albrektsson B, Albrektsson T. Removal torques for polished and rough itanium implants. Int J Oral Maxillofac Implants. 1988; 3:214.16. Albrektsson T, Brånemark PI, Hansson HA, Lindström J. Osseointegrated titanium implants. Requirements for ensuring a long-lasting, direct boneto-implant anchorage in man. Acta Orthop Scand. 1981; 52:155–70. DOI: 10.3109/17453678108991776. PMID: 7246093.17. Buser D, Nydegger T, Oxland T, Cochran DL, Schenk RK, Hirt HP, Snétivy D, Nolte LP. Interface shear strength of titanium implants with a sandblasted and acid-etched surface: a biomechanical study in the maxilla of miniature pigs. J Biomed Mater Res. 1999; 45:75–83. DOI: 10.1002/(SICI)1097-4636(199905)45:2<75::AID-JBM1>3.0.CO;2-P.18. Roccuzzo M, Wilson T. A prospective study evaluating a protocol for 6 weeks'loading of SLA implants in the posterior maxilla: one year results. Clin Oral Implants Res. 2002; 13:502–7. DOI: 10.1034/j.1600-0501.2002.130509.x. PMID: 12453127.19. Albrektsson T, Brånemark PI, Eriksson A, Lindström J. The preformed autologous bone graft. An experimental study in the rabbit. Scand J Plast Reconstr Surg. 1978; 12:215–23. DOI: 10.3109/02844317809012997. PMID: 368971.20. Esposito M, Grusovin MG, Maghaireh H, Worthington HV. Interventions for replacing missing teeth: different times for loading dental implants. Cochrane Database Syst Rev. 2013; Mar. 28. 3:CD003878. DOI: 10.1002/14651858.CD003878.pub5.21. Sanz-Sánchez I, Sanz-Martín I, Figuero E, Sanz M. Clinical efficacy of immediate implant loading protocols compared to conventional loading depending on the type of the restoration: a systematic review. Clin Oral Implants Res. 2015; 26:964–82. DOI: 10.1111/clr.12428. PMID: 24917174.22. Buser D, Broggini N, Wieland M, Schenk RK, Denzer AJ, Cochran DL, Hoffmann B, Lussi A, Steinemann SG. Enhanced bone apposition to a chemically modified SLA titanium surface. J Dent Res. 2004; 83:529–33. DOI: 10.1177/154405910408300704. PMID: 15218041.23. Webb K, Hlady V, Tresco PA. Relative impor-tance of surface wettability and charged functional groups on NIH 3T3 fibroblast attachment, spreading, and cytoskeletal organization. J Biomed Mater Res. 1998; 41:422–30. DOI: 10.1002/(SICI)1097-4636(19980905)41:3<422::AID-JBM12>3.0.CO;2-K.24. Hansson S, Norton M. The relation between surface roughness and interfacial shear strength for bone-anchored implants. A mathematical model. J Biomech. 1999; 32:829–36. DOI: 10.1016/S0021-9290(99)00058-5.25. Albrektsson T, Wennerberg A. The impact of oral implants - past and future 1966-2042. J Can Dent Assoc. 2005; 71:327. PMID: 15949251.26. Shalabi MM, Gortemaker A, Van't Hof MA, Jansen JA, Creugers NH. Implant surface roughness and bone healing: a systematic review. J Dent Res. 2006; 85:496–500. DOI: 10.1177/154405910608500603. PMID: 16723643.27. Choi HC, Jung YM, Kim SB. Size effects in the Raman spectra of TiO2 nanoparticles. Vib Spectrosc. 2005; 37:33–8. DOI: 10.1016/j.vibspec.2004.05.006.28. Yokoyama K, Ichikawa T, Murakami H, Miyamoto Y, Asaoka K. Fracture mechanisms of retrieved titanium screw thread in dental implant. Biomater. 2002; 23:2459–65. DOI: 10.1016/S0142-9612(01)00380-5.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Evaluation of bioactivity and osseointegration for ti-6al-4v alloy implant modified by anodic oxidation and cyclic precalcification treatments

- Histologic evaluation and removal torque analysis of nano- and microtreated titanium implants in the dogs

- Removal torque of bicortically stabilized RBM(resorbable blast media) pin implants in rabbit tibia

- Comparison of removal torque of saline-soaking RBM implants and RBM implants in rabbit tibias

- Histologic analysis of resorbable blasting media surface implants retrieved from humans: a report of two cases