Korean J Orthod.

2019 Jan;49(1):12-20. 10.4041/kjod.2019.49.1.12.

Surface analysis of metal clips of ceramic self-ligating brackets

- Affiliations

-

- 1Department of Biomedical Engineering, College of Medicine, Kyung Hee University, Seoul, Korea.

- 2Department of Medical Engineering, Graduate School, Kyung Hee University, Seoul, Korea.

- 3Department of Orthodontics, Graduate School, Kyung Hee University, Seoul, Korea.

- 4Department of Orthodontics, School of Dentistry, Kyung Hee University, Seoul, Korea. pkhmate@hanmail.net

- KMID: 2431076

- DOI: http://doi.org/10.4041/kjod.2019.49.1.12

Abstract

OBJECTIVE

The aim of this study was to analyze the surface composition, roughness, and relative friction of metal clips from various ceramic self-ligating brackets.

METHODS

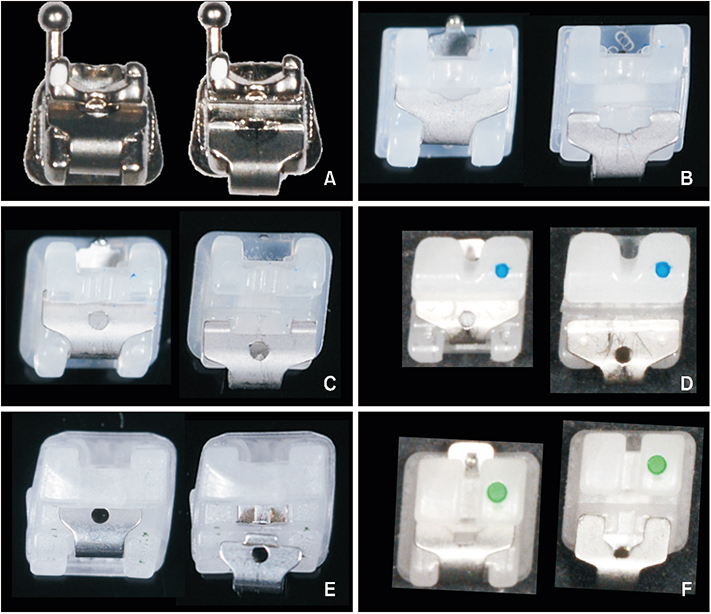

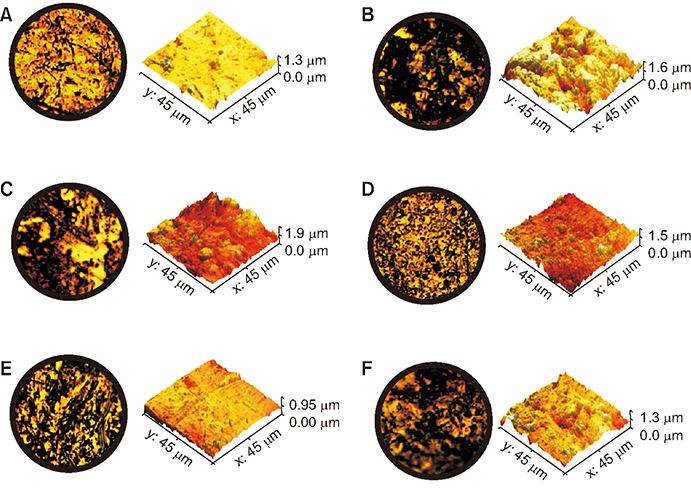

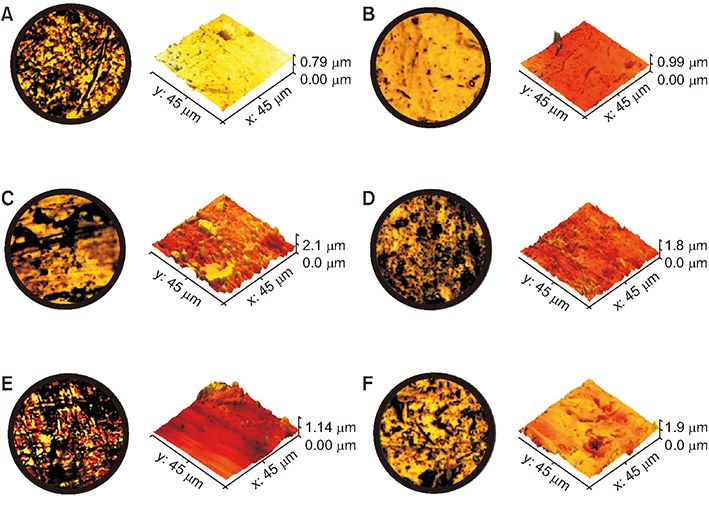

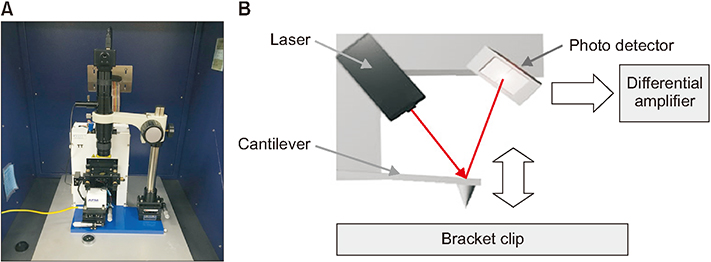

Six kinds of brackets were examined. The control group (mC) consisted of interactive metal self-ligating brackets while the experimental group (CC, EC, MA, QK, and WA) consisted of interactive ceramic self-ligating brackets. Atomic force microscopy-lateral force microscopy and scanning electron microscopy-energy-dispersive X-ray spectroscopy were used to analyze the surface of each bracket clip.

RESULTS

All the clips in the experimental groups were coated with rhodium except for the QK clip. The results showed that the QK clip had the lowest average roughness on the outer surface, followed by the MA, EC, WA, and CC clips. However, the CC clip had the lowest average roughness on the inner surface, followed by the QK, WA, MA, and EC clips. The QK clip also had the lowest relative friction on the outer surface, followed by the MA, EC, CC, and WA clips. Likewise, the CC clip had the lowest relative friction on the inner surface, followed by the QK, WA, MA, and EC clips.

CONCLUSIONS

The surface roughness and relative friction of the rhodium-coated clips were generally higher than those of the uncoated clips.

Figure

Reference

-

1. Carneiro GK, Roque JA, Segundo AS, Suzuki H. Evaluation of stiffness and plastic deformation of active ceramic self-ligating bracket clips after repetitive opening and closure movements. Dental Press J Orthod. 2015; 20:45–50.

Article2. Harradine NW. Self-ligating brackets: where are we now? J Orthod. 2003; 30:262–273.

Article3. Buljan ZI, Ribaric SP, Abram M, Ivankovic A, Spalj S. In vitro oxidative stress induced by conventional and self-ligating brackets. Angle Orthod. 2012; 82:340–345.

Article4. Albuquerque CG, Correr AB, Venezian GC, Santamaria M Jr, Tubel CA, Vedovello SA. Deflection flexural strength effects roughness aesthetic-coated orthodontic wires. Braz Dent J. 2017; 28:40–45.

Article5. Shintcovsk RL, Knop LA, Gandini LG Jr, Martins LP, Pires AS. Comparison surface characteristics and chemical composition of conventional metallic and nickel-free brackets. Braz Oral Res. 2015; 29:DOI: 10.1590/1807-3107BOR-2015.vol29.0022.

Article6. Varma DP, Chidambaram S, Reddy KB, Vijay M, Ravindranath D, Prasad MR. Comparison of galvanic corrosion potential of metal injection molded brackets to that of conventional metal brackets with nickel-titanium and copper nickel-titanium archwire combinations. J Contemp Dent Pract. 2013; 14:488–495.

Article7. Gkantidis N, Zinelis S, Karamolegkou M, Eliades T, Topouzelis N. Comparative assessment of clinical performance of esthetic bracket materials. Angle Orthod. 2012; 82:691–697.

Article8. Pratten DH, Popli K, Germane N, Gunsolley JC. Frictional resistance of ceramic and stainless steel orthodontic brackets. Am J Orthod Dentofacial Orthop. 1990; 98:398–403.

Article9. Bednar JR, Gruendeman GW, Sandrik JL. A comparative study of frictional forces between orthodontic brackets and arch wires. Am J Orthod Dentofacial Orthop. 1991; 100:513–522.

Article10. Saunders CR, Kusy RP. Surface topography and frictional characteristics of ceramic brackets. Am J Orthod Dentofacial Orthop. 1994; 106:76–87.

Article11. Zinelis S, Eliades T, Eliades G, Makou M, Silikas N. Comparative assessment of the roughness, hardness, and wear resistance of aesthetic bracket materials. Dent Mater. 2005; 21:890–894.

Article12. Lee GJ, Park KH, Park YG, Park HK. A quantitative AFM analysis of nano-scale surface roughness in various orthodontic brackets. Micron. 2010; 41:775–782.

Article13. Choi S, Lee S, Cheong Y, Park KH, Park HK, Park YG. Ultrastructural effect of self-ligating bracket materials on stainless steel and superelastic NiTi wire surfaces. Microsc Res Tech. 2012; 75:1076–1083.

Article14. Park KH, Yoon HJ, Kim SJ, Lee GJ, Park HK, Park YG. Surface roughness analysis of ceramic bracket slots using atomic force microscope. Korean J Orthod. 2010; 40:294–303.

Article15. Choi S, Hwang EY, Park HK, Park YG. Correlation between frictional force and surface roughness of orthodontic archwires. Scanning. 2015; 37:399–405.

Article16. Rudge P, Sherriff M, Bister D. A comparison of roughness parameters and friction coefficients of aesthetic archwires. Eur J Orthod. 2015; 37:49–55.

Article17. Misra R, Li J, Cannon GC, Morgan SE. Nanoscale reduction in surface friction of polymer surfaces modified with Sc3 hydrophobin from Schizophyllum commune. Biomacromolecules. 2006; 7:1463–1470.

Article18. Nanjundan K, Vimala G. Evaluation of frictional resistance and surface characteristics after immersion of orthodontic brackets and wire in different chemical solutions: a comparative in vitrostudy. Indian J Dent Res. 2016; 27:513–520.

Article19. Proffit WR, Fields HW, Sarver DM. Contemporary orthodontics. 5th ed. St. Louis: Mosby;2013. p. 370–372.20. Kusy RP. Morphology of polycrystalline alumina brackets and its relationship to fracture toughness and strength. Angle Orthod. 1988; 58:197–203.21. Angolkar PV, Kapila S, Duncanson MG Jr, Nanda RS. Evaluation of friction between ceramic brackets and orthodontic wires of four alloys. Am J Orthod Dentofacial Orthop. 1990; 98:499–506.

Article22. Choi SH, Kang DY, Hwang CJ. Surface roughness of three types of modern plastic bracket slot floors and frictional resistance. Angle Orthod. 2014; 84:177–183.

Article23. Choi S, Park KH, Cheong Y, Kim HK, Park YG, Park HK. Changes in ultrastructure and properties of bracket slots after orthodontic treatment with bicuspid extraction. Scanning. 2011; 33:25–32.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- A comparative study of frictional force in self-ligating brackets according to the bracket-archwire angulation, bracket material, and wire type

- A study on frictional resistance force of orthodontic resin bracket

- Frictional resistance of different ceramic brackets and their relationship to the second order angulation between bracket slot and wire

- Clinical considerations with self-ligating brackets

- A study of the shear bond strength of metal brackets and ceramic brackets and the condition after debonding