Korean J Orthod.

2016 Nov;46(6):386-394. 10.4041/kjod.2016.46.6.386.

Bone cutting capacity and osseointegration of surface-treated orthodontic mini-implants

- Affiliations

-

- 1Private Practice, Jeju, Korea.

- 2Department of Orthodontics, School of Dentistry, Wonkwang University, Iksan, Korea. sangkim@wku.ac.kr

- KMID: 2426683

- DOI: http://doi.org/10.4041/kjod.2016.46.6.386

Abstract

OBJECTIVE

The objective of the study was to evaluate the practicality and the validity of different surface treatments of self-drilling orthodontic mini-implants (OMIs) by comparing bone cutting capacity and osseointegration.

METHODS

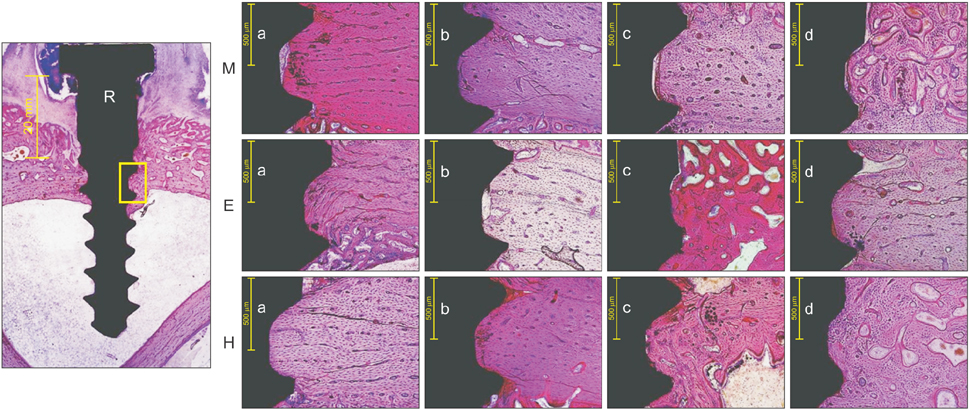

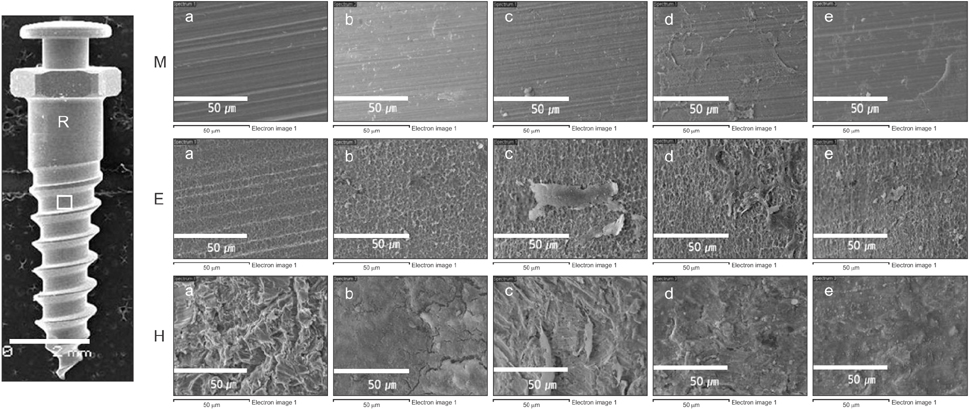

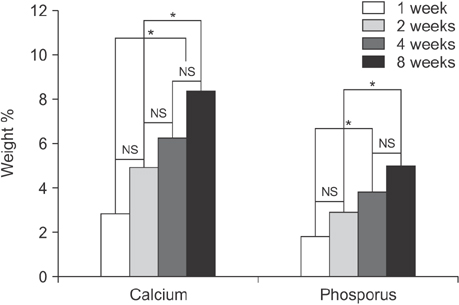

Self-drilling OMIs were surface-treated in three ways: Acid etched (Etched), resorbable blasting media (RBM), partially resorbabla balsting media (Hybrid). We compared the bone cutting capacity by measuring insertion depths into artificial bone (polyurethane foam). To compare osseointegration, OMIs were placed in the tibia of 25 rabbits and the removal torque value was measured at 1, 2, 4, and 8 weeks after placement. The specimens were analyzed by optical microscopy, scanning electron microscopy (SEM), and energy dispersive X-ray spectroscopy (EDS).

RESULTS

The bone cutting capacity of the etched and hybrid group was lower than the machined (control) group, and was most inhibited in the RBM group (p < 0.05). At 4 weeks, the removal torque in the machined group was significantly decreased (p < 0.05), but was increased in the etched group (p < 0.05). In the hybrid group, the removal torque significantly increased at 2 weeks, and was the highest among all measured values at 8 weeks (p < 0.05). The infiltration of bone-like tissue surface was evaluated by SEM, and calcium and phosphorus were detected via EDS only in the hybrid group.

CONCLUSIONS

Partial RBM surface treatment (hybrid type in this study) produced the most stable self-drilling OMIs, without a corresponding reduction in bone cutting capacity.

MeSH Terms

Figure

Cited by 1 articles

-

Repeated injections of botulinum toxin into the masseter muscle induce bony changes in human adults: A longitudinal study

Hwa-Jin Lee, Sung-Jin Kim, Kee-Joon Lee, Hyung-Seog Yu, Hyoung-Seon Baik

Korean J Orthod. 2017;47(4):222-228. doi: 10.4041/kjod.2017.47.4.222.

Reference

-

1. Reynders R, Ronchi L, Bipat S. Mini-implants in orthodontics: a systematic review of the literature. Am J Orthod Dentofacial Orthop. 2009; 135:564.e1–564.e19.

Article2. Miyawaki S, Koyama I, Inoue M, Mishima K, Sugahara T, Takano-Yamamoto T. Factors associated with the stability of titanium screws placed in the posterior region for orthodontic anchorage. Am J Orthod Dentofacial Orthop. 2003; 124:373–378.

Article3. Lim HJ, Eun CS, Cho JH, Lee KH, Hwang HS. Factors associated with initial stability of miniscrews for orthodontic treatment. Am J Orthod Dentofacial Orthop. 2009; 136:236–242.

Article4. Kuroda S, Yamada K, Deguchi T, Hashimoto T, Kyung HM, Takano-Yamamoto T. Root proximity is a major factor for screw failure in orthodontic anchorage. Am J Orthod Dentofacial Orthop. 2007; 131:4 Suppl. S68–S73.

Article5. Lee YK, Kim JW, Baek SH, Kim TW, Chang YI. Root and bone response to the proximity of a mini-implant under orthodontic loading. Angle Orthod. 2010; 80:452–458.

Article6. Poggio PM, Incorvati C, Velo S, Carano A. "Safe zones": a guide for miniscrew positioning in the maxillary and mandibular arch. Angle Orthod. 2006; 76:191–197.7. Lim SA, Cha JY, Hwang CJ. Insertion torque of orthodontic miniscrews according to changes in shape, diameter and length. Angle Orthod. 2008; 78:234–240.

Article8. Kim JW, Baek SH, Kim TW, Chang YI. Comparison of stability between cylindrical and conical type mini-implants. Mechanical and histological properties. Angle Orthod. 2008; 78:692–698.

Article9. Chen Y, Shin HI, Kyung HM. Biomechanical and histological comparison of self-drilling and self-tapping orthodontic microimplants in dogs. Am J Orthod Dentofacial Orthop. 2008; 133:44–50.

Article10. Yu W, Kyung HM. Torque and mechanical failure of orthodontic micro-implant influenced by implant design parameters. Korean J Orthod. 2007; 37:171–181.11. Mo SS, Kim SH, Kook YA, Jeong DM, Chung KR, Nelson G. Resistance to immediate orthodontic loading of surface-treated mini-implants. Angle Orthod. 2010; 80:123–129.

Article12. Kim SH, Lee SJ, Cho IS, Kim SK, Kim TW. Rotational resistance of surface-treated mini-implants. Angle Orthod. 2009; 79:899–907.

Article13. Le Guéhennec L, Soueidan A, Layrolle P, Amouriq Y. Surface treatments of titanium dental implants for rapid osseointegration. Dent Mater. 2007; 23:844–854.

Article14. Heidemann W, Gerlach KL, Gröbel KH, Köllner HG. Drill Free Screws: a new form of osteosynthesis screw. J Craniomaxillofac Surg. 1998; 26:163–168.

Article15. Park HS, Jeong SH, Kwon OW. Factors affecting the clinical success of screw implants used as orthodontic anchorage. Am J Orthod Dentofacial Orthop. 2006; 130:18–25.

Article16. Chen CH, Chang CS, Hsieh CH, Tseng YC, Shen YS, Huang IY, et al. The use of microimplants in orthodontic anchorage. J Oral Maxillofac Surg. 2006; 64:1209–1213.

Article17. Chen Y, Kyung HM, Zhao WT, Yu WJ. Critical factors for the success of orthodontic mini-implants: A systematic review. Am J Orthod Dentofacial Orthop. 2009; 135:284–291.

Article18. Morais LS, Serra GG, Muller CA, Andrade LR, Palermo EF, Elias CN, et al. Titanium alloy mini-implants for orthodontic anchorage: immediate loading and metal ion release. Acta Biomater. 2007; 3:331–339.

Article19. Blumenthal NC, Cosma V. Inhibition of apatite formation by titanium and vanadium ions. J Biomed Mater Res. 1989; 23:A1 Suppl. 13–22.

Article20. Johansson CB, Han CH, Wennerberg A, Albrektsson T. A quantitative comparison of machined commercially pure titanium and titanium-aluminum-vanadium implants in rabbit bone. Int J Oral Maxillofac Implants. 1998; 13:315–321.21. Shah FA, Trobos M, Thomsen P, Palmquist A. Commercially pure titanium (cp-Ti) versus titanium alloy (Ti6Al4V) materials as bone anchored implants - Is one truly better than the other? Mater Sci Eng C Mater Biol Appl. 2016; 62:960–966.

Article22. Kim SC, Kim HY, Lee SJ, Kim CM. Influence of surface treatment on the insertion pattern of self-drilling orthodontic mini-implants. Korean J Orthod. 2011; 41:268–279.

Article23. Carlsson L, Röstlund T, Albrektsson B, Albrektsson T. Removal torques for polished and rough titanium implants. Int J Oral Maxillofac Implants. 1988; 3:21–24.24. Roberts WE, Helm FR, Marshall KJ, Gongloff RK. Rigid endosseous implants for orthodontic and orthopedic anchorage. Angle Orthod. 1989; 59:247–256.25. Johansson C, Albrektsson T. Integration of screw implants in the rabbit: a 1-year follow-up of removal torque of titanium implants. Int J Oral Maxillofac Implants. 1987; 2:69–75.26. Heidemann W, Terheyden H, Louis Gerlach K. Analysis of the osseous/metal interface of drill free screws and self-tapping screws. J Maxillofac Surg. 2001; 29:69–74.

Article27. Bjursten LM, Emanuelsson L, Ericson LE, Thomsen P, Lausmaa J, Mattsson L, et al. Method for ultrastructural studies of the intact tissue-metal interface. Biomaterials. 1990; 11:596–601.

Article28. Roberts WE. Bone tissue interface. J Dent Educ. 1988; 52:804–809.

Article29. Kim YJ, Cho IH. On the bone tissue reaction to implants with different surface treatment methods. J Korean Acad Prosthodont. 2007; 45:71–84.30. Wennerberg A, Ektessabi A, Albrektsson T, Johansson C, Andersson B. A 1-year follow-up of implants of differing surface roughness placed in rabbit bone. Int J Oral Maxillofac Implants. 1997; 12:486–494.31. Choi SH, Kim SJ, Lee KG, Sung SJ, Chun YS, Hwang CJ. Stress distributions in peri-miniscrew areas from cylindrical and tapered miniscrews inserted at different angles. Korean J Orthod. 2016; 46:189–198.

Article32. Hong SB, Kusnoto B, Kim EJ, BeGole EA, Hwang HS, Lim HJ. Prognostic factors associated with the success rates of posterior orthodontic miniscrew implants: A subgroup meta-analysis. Korean J Orthod. 2016; 46:111–126.

Article33. Oh EJ, Nguyen TD, Lee SY, Jeon YM, Bae TS, Kim JG. Enhanced compatibility and initial stability of Ti6Al4V alloy orthodontic miniscrews subjected to anodization, cyclic precalcification, and heat treatment. Korean J Orthod. 2014; 44:246–253.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effects of surface treatment on the osseointegration potential of orthodontic mini-implant

- Effect of cutting flute length and shape on insertion and removal torque of orthodontic mini-implants

- Influence of surface treatment on the insertion pattern of self-drilling orthodontic mini-implants

- The effect of dental orthopedic force to implants on bone tissue before complete osseointegration

- The effect of early loading on the direct bone-to-implant surface contact of the orthodontic osseointegrated titanium implant