J Korean Assoc Oral Maxillofac Surg.

2018 Apr;44(2):59-65. 10.5125/jkaoms.2018.44.2.59.

Three-dimensional optimization and sensitivity analysis of dental implant thread parameters using finite element analysis

- Affiliations

-

- 1Department of Biomechanical Engineering, Amirkabir University, Tehran, Iran.

- 2Dental Research Center, Research Institute of Dental Sciences, Dental School, Shahid Beheshti University of Medical Sciences, Tehran, Iran. Kadkhodazadehmahdi@yahoo.com

- KMID: 2410581

- DOI: http://doi.org/10.5125/jkaoms.2018.44.2.59

Abstract

OBJECTIVES

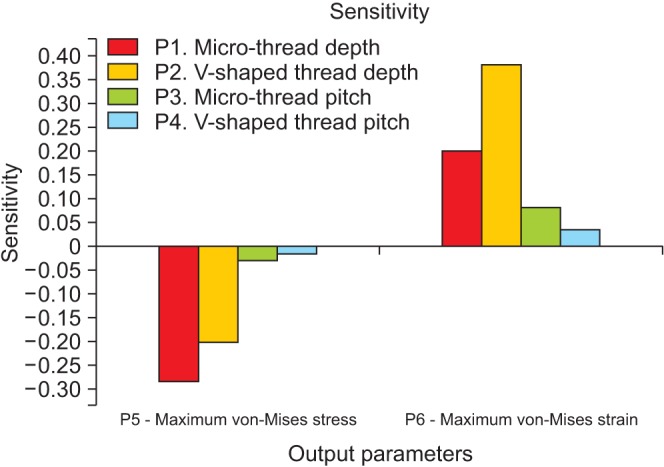

This study aimed to optimize the thread depth and pitch of a recently designed dental implant to provide uniform stress distribution by means of a response surface optimization method available in finite element (FE) software. The sensitivity of simulation to different mechanical parameters was also evaluated.

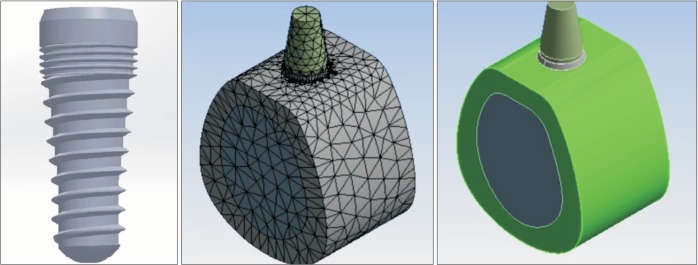

MATERIALS AND METHODS

A three-dimensional model of a tapered dental implant with micro-threads in the upper area and V-shaped threads in the rest of the body was modeled and analyzed using finite element analysis (FEA). An axial load of 100 N was applied to the top of the implants. The model was optimized for thread depth and pitch to determine the optimal stress distribution. In this analysis, micro-threads had 0.25 to 0.3 mm depth and 0.27 to 0.33 mm pitch, and V-shaped threads had 0.405 to 0.495 mm depth and 0.66 to 0.8 mm pitch.

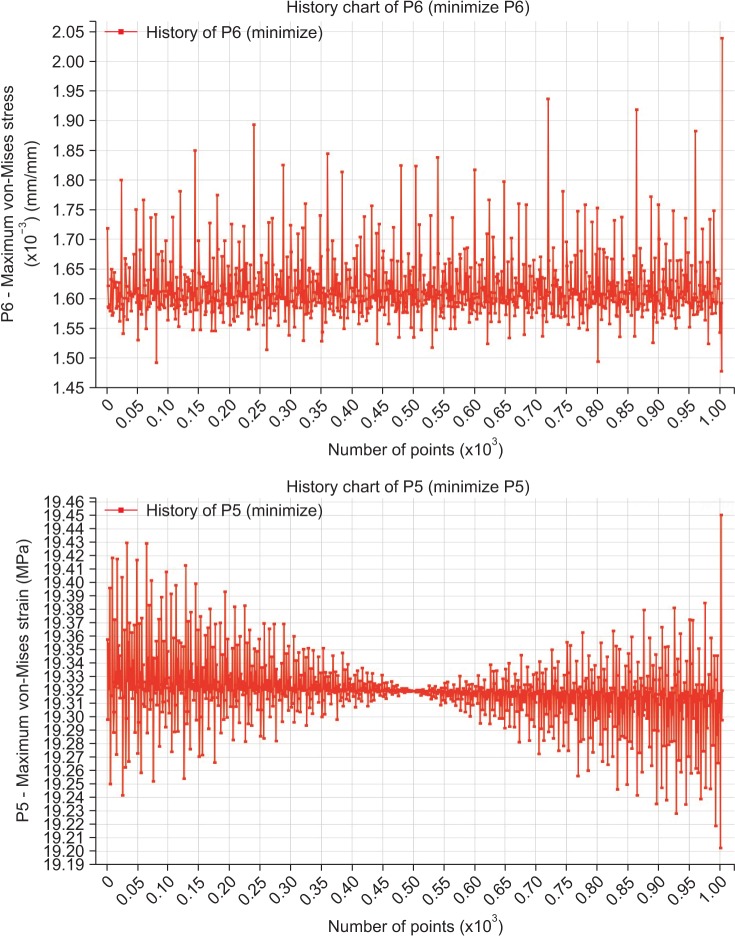

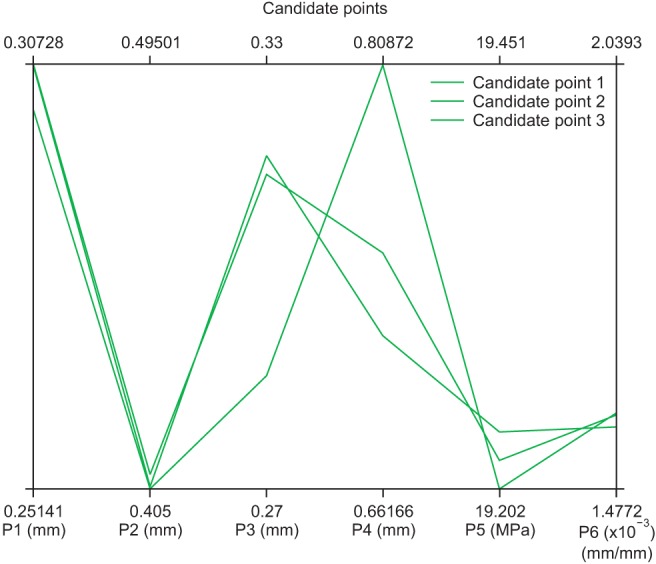

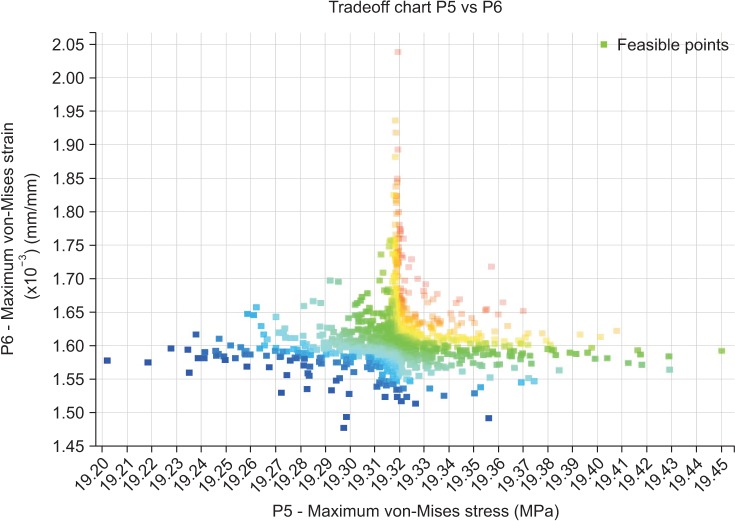

RESULTS

The optimized depth and pitch were 0.307 and 0.286 mm for micro-threads and 0.405 and 0.808 mm for V-shaped threads, respectively. In this design, the most effective parameters on stress distribution were the depth and pitch of the micro-threads based on sensitivity analysis results.

CONCLUSION

Based on the results of this study, the optimal implant design has micro-threads with 0.307 and 0.286 mm depth and pitch, respectively, in the upper area and V-shaped threads with 0.405 and 0.808 mm depth and pitch in the rest of the body. These results indicate that micro-thread parameters have a greater effect on stress and strain values.

Figure

Reference

-

1. Gosavi SP, Dhatrak PN, Narkar KM. Optimisation of dental implant. Int Eng Res J. 2015; 3:4319–4323.2. Brunski JB. Biomaterials and biomechanics in dental implant design. Int J Oral Maxillofac Implants. 1988; 3:85–97. PMID: 3075195.3. Mahajan S, Patil R. Application of finite element analysis to optimizing dental implant. Int Res J Eng Technol. 2016; 3:850–856.4. Kong L, Zhao Y, Hu K, Li D, Zhou H, Wu Z, et al. Selection of the implant thread pitch for optimal biomechanical properties: a three-dimensional finite element analysis. Adv Eng Softw. 2009; 40:474–478.

Article5. Petrie CS, Williams JL. Shape optimization of dental implant designs under oblique loading using the p-version finite element method. J Mech Med Biol. 2002; 3:339.

Article6. Shi L, Li H, Fok AS, Ucer C, Devlin H, Horner K. Shape optimization of dental implants. Int J Oral Maxillofac Implants. 2007; 22:911–920. PMID: 18271372.7. Chang CL, Chen CS, Huang CH, Hsu ML. Finite element analysis of the dental implant using a topology optimization method. Med Eng Phys. 2012; 34:999–1008. PMID: 22770748.

Article8. Shen S, Sun Y, Zhang C, Yang Y, Li Z, Cai X, et al. Bivariate optimization of orthodontic mini-implant thread height and pitch. Int J Comput Assist Radiol Surg. 2015; 10:109–116. PMID: 25159301.

Article9. Hasan I, Rahimi A, Keilig L, Brinkmann KT, Bourauel C. Computational simulation of internal bone remodelling around dental implants: a sensitivity analysis. Comput Methods Biomech Biomed Engin. 2012; 15:807–814. PMID: 21442491.

Article10. Geramizadeh M, Katoozian H, Amir R, Kadkhodazadeh M. Static, dynamic, and fatigue finite element analysis of dental implants with different thread designs. J Long Term Eff Med Implants. 2016; 26:347–355. PMID: 29199621.

Article11. Geramizadeh M, Katoozian H, Amid R, Kadkhodazadeh M. Finite element analysis of dental implants with and without microthreads under static and dynamic loading. J Long Term Eff Med Implants. 2017; 27:25–35. PMID: 29604947.

Article12. Seong WJ, Kim UK, Swift JQ, Heo Y, Hodges JS, Ko CC. Elastic properties and apparent density of human edentulous maxilla and mandible. Int J Oral Maxillofac Surg. 2009; 38:1088–1093. PMID: 19647417.

Article13. Tortorelli DA, Michaleris P. Design sensitivity analysis: overview and review. Inverse Probl Eng. 1994; 1:71–105.

Article14. Kayabaşı O, Yüzbasıoğlu E, Erzincanlı F. Static, dynamic and fatigue behaviors of dental implant using finite element method. Adv Eng Softw. 2006; 37:649–658.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- An optimization of onebody type implant system considering various design parameters

- Three-dimensional finite element analysis of stress distribution for different implant thread slope and implant angulation

- Three-dimentional finite element analysis of stress distribution for different implant thread slope

- studies of Osseointegrated Implant-Models on Stress Distribution

- The Three Dimensional Finite Element Analysis of Stress according to Implant Thread Design under the Axial Load