J Adv Prosthodont.

2018 Feb;10(1):8-17. 10.4047/jap.2018.10.1.8.

Accuracy and reproducibility of 3D digital tooth preparations made by gypsum materials of various colors

- Affiliations

-

- 1College of Stomatology, Chongqing Medical University, Chongqing, China. soongjl@163.com

- 2Chongqing Key Laboratory for Oral Diseases and Biomedical Sciences, Chongqing, China.

- 3Laboratory for Biomechanics and Mechanobiology of Ministry of Education, School of Biological Science and Medical Engineering, Beihang University, Beijing, China.

- 4Chongqing Municipal Key Laboratory of Oral Biomedical Engineering of Higher Education, Chongqing, China.

- KMID: 2403993

- DOI: http://doi.org/10.4047/jap.2018.10.1.8

Abstract

- PURPOSE

The study aimed to identify the accuracy and reproducibility of preparations made by gypsum materials of various colors using quantitative and semi-quantitative three-dimensional (3D) approach.

MATERIALS AND METHODS

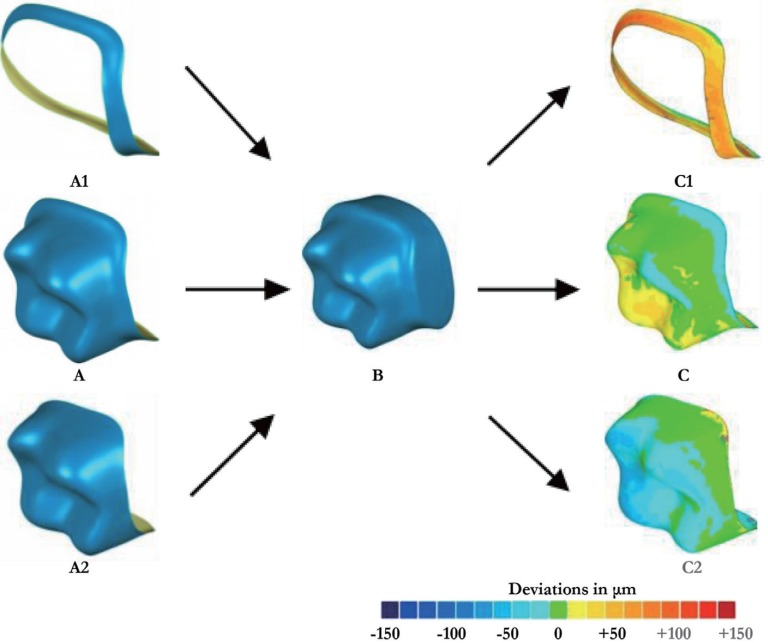

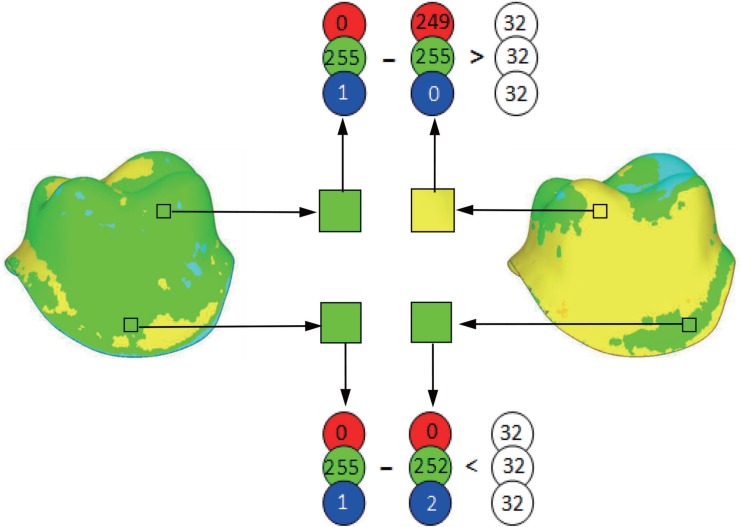

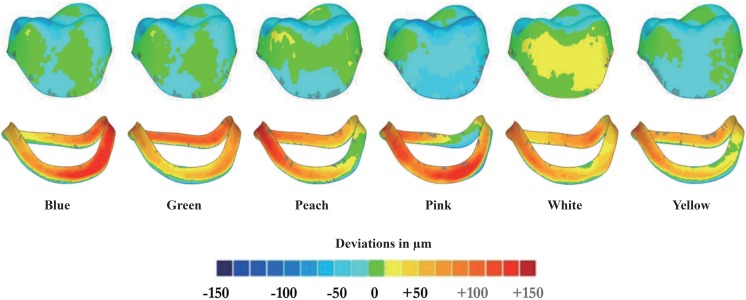

A titanium maxillary first molar preparation was created as reference dataset (REF). Silicone impressions were duplicated from REF and randomized into 6 groups (n=8). Gypsum preparations were formed and grouped according to the color of gypsum materials, and light-scanned to obtain prepared datasets (PRE). Then, in terms of accuracy, PRE were superimposed on REF using the best-fit-algorithm and PRE underwent intragroup pairwise best-fit alignment for assessing reproducibility. Root mean square deviation (RMSD) and degrees of similarity (DS) were computed and analyzed with SPSS 20.0 statistical software (α=.05).

RESULTS

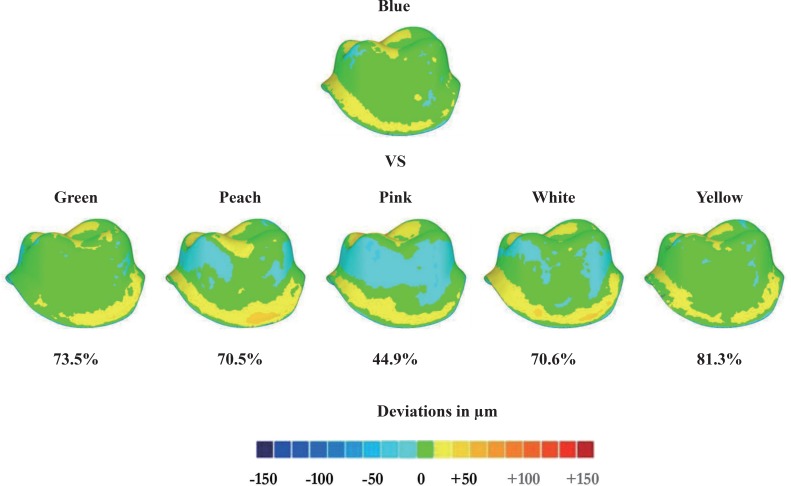

In terms of accuracy, PREs in 3D directions were increased in the 6 color groups (from 19.38 to 20.88 µm), of which the marginal and internal variations ranged 51.36 - 58.26 µm and 18.33 - 20.04 µm, respectively. On the other hand, RMSD value and DS-scores did not show significant differences among groups. Regarding reproducibility, both RMSD and DS-scores showed statistically significant differences among groups, while RMSD values of the 6 color groups were less than 5 µm, of which blue color group was the smallest (3.27 ± 0.24 µm) and white color group was the largest (4.24 ± 0.36 µm). These results were consistent with the DS data.

CONCLUSION

The 3D volume of the PREs was predisposed towards an increase during digitalization, which was unaffected by gypsum color. Furthermore, the reproducibility of digitalizing scanning differed negligibly among different gypsum colors, especially in comparison to clinically observed discrepancies.

MeSH Terms

Figure

Reference

-

1. Kim SY, Lee SH, Cho SK, Jeong CM, Jeon YC, Yun MJ, Huh JB. Comparison of the accuracy of digitally fabricated polyurethane model and conventional gypsum model. J Adv Prosthodont. 2014; 6:1–7. PMID: 24605199.

Article2. Keshvad A, Hooshmand T, Asefzadeh F, Khalilinejad F, Alihemmati M, Van Noort R. Marginal gap, internal fit, and fracture load of leucite-reinforced ceramic inlays fabricated by CEREC inLab and hot-pressed techniques. J Prosthodont. 2011; 20:535–540. PMID: 21806704.

Article3. Eisenburger M, Shellis RP, Addy M. Comparative study of wear of enamel induced by alternating and simultaneous combinations of abrasion and erosion in vitro. Caries Res. 2003; 37:450–455. PMID: 14571125.

Article4. Bartlett DW, Blunt L, Smith BG. Measurement of tooth wear in patients with palatal erosion. Br Dent J. 1997; 182:179–184. PMID: 9134802.

Article5. Azzopardi A, Bartlett DW, Watson TF, Sherriff M. The measurement and prevention of erosion and abrasion. J Dent. 2001; 29:395–400. PMID: 11520587.

Article6. Mehl A, Gloger W, Kunzelmann KH, Hickel R. A new optical 3-D device for the detection of wear. J Dent Res. 1997; 76:1799–1807. PMID: 9372798.

Article7. Pintado MR, Anderson GC, DeLong R, Douglas WH. Variation in tooth wear in young adults over a two-year period. J Prosthet Dent. 1997; 77:313–320. PMID: 9069087.

Article8. Schlueter N, Ganss C, De Sanctis S, Klimek J. Evaluation of a profilometrical method for monitoring erosive tooth wear. Eur J Oral Sci. 2005; 113:505–511. PMID: 16324141.

Article9. McBride J, Christian M. The 3D measurement and analysis of high precision surfaces using con-focal optical methods. IEICE Trans Electron. 2004; 87:1261–1267.10. DeLong R, Pintado MR, Ko CC, Hodges JS, Douglas WH. Factors influencing optical 3D scanning of vinyl polysiloxane impression materials. J Prosthodont. 2001; 10:78–85. PMID: 11512112.

Article11. Heintze SD, Forjanic M, Rousson V. Surface roughness and gloss of dental materials as a function of force and polishing time in vitro. Dent Mater. 2006; 22:146–165. PMID: 16084582.

Article12. Wieland M, Textor M, Spencer ND, Brunette DM. Wavelength-dependent roughness: a quantitative approach to characterizing the topography of rough titanium surfaces. Int J Oral Maxillofac Implants. 2001; 16:163–181. PMID: 11324205.13. Rodriguez JM, Curtis RV, Bartlett DW. Surface roughness of impression materials and dental stones scanned by non-contacting laser profilometry. Dent Mater. 2009; 25:500–505. PMID: 19036424.

Article14. Kim JH, Kim KB, Kim WC, Rhee HS, Lee IH, Kim JH. Influence of various gypsum materials on precision of fit of CAD/CAM-fabricated zirconia copings. Dent Mater J. 2015; 34:19–24. PMID: 25748454.

Article15. Schaefer O, Watts DC, Sigusch BW, Kuepper H, Guentsch A. Marginal and internal fit of pressed lithium disilicate partial crowns in vitro: a three-dimensional analysis of accuracy and reproducibility. Dent Mater. 2012; 28:320–326. PMID: 22265824.

Article16. Schaefer O, Kuepper H, Sigusch BW, Thompson GA, Hefti AF, Guentsch A. Three-dimensional fit of lithium disilicate partial crowns in vitro. J Dent. 2013; 41:271–277. PMID: 23228498.

Article17. Schaefer O, Kuepper H, Thompson GA, Cachovan G, Hefti AF, Guentsch A. Effect of CNC-milling on the marginal and internal fit of dental ceramics: a pilot study. Dent Mater. 2013; 29:851–858. PMID: 23743092.

Article18. Wadhwani CP, Johnson GH, Lepe X, Raigrodski AJ. Accuracy of newly formulated fast-setting elastomeric impression materials. J Prosthet Dent. 2005; 93:530–539. PMID: 15942613.

Article19. Millar BJ, Dunne SM, Robinson PB. The effect of a surface wetting agent on void formation in impressions. J Prosthet Dent. 1997; 77:54–56. PMID: 9029466.

Article20. Cho SH, Schaefer O, Thompson GA, Guentsch A. Comparison of accuracy and reproducibility of casts made by digital and conventional methods. J Prosthet Dent. 2015; 113:310–315. PMID: 25682531.

Article21. Güth JF, Keul C, Stimmelmayr M, Beuer F, Edelhoff D. Accuracy of digital models obtained by direct and indirect data capturing. Clin Oral Investig. 2013; 17:1201–1208.

Article22. Beuer F, Aggstaller H, Edelhoff D, Gernet W, Sorensen J. Marginal and internal fits of fixed dental prostheses zirconia retainers. Dent Mater. 2009; 25:94–102. PMID: 18620749.

Article23. Abdel-Azim T, Rogers K, Elathamna E, Zandinejad A, Metz M, Morton D. Comparison of the marginal fit of lithium disilicate crowns fabricated with CAD/CAM technology by using conventional impressions and two intraoral digital scanners. J Prosthet Dent. 2015; 114:554–559. PMID: 26100929.

Article24. Tsirogiannis P, Reissmann DR, Heydecke G. Evaluation of the marginal fit of single-unit, complete-coverage ceramic restorations fabricated after digital and conventional impressions: A systematic review and meta-analysis. J Prosthet Dent. 2016; 116:328–335. PMID: 27061627.

Article25. Rajan BN, Jayaraman S, Kandhasamy B, Rajakumaran I. Evaluation of marginal fit and internal adaptation of zirconia copings fabricated by two CAD - CAM systems: An in vitro study. J Indian Prosthodont Soc. 2015; 15:173–178. PMID: 26929507.

Article26. Shembesh M, Ali A, Finkelman M, Weber HP, Zandparsa R. An in vitro comparison of the marginal adaptation accuracy of CAD/CAM restorations using different impression systems. J Prosthodont. 2017; 26:581–586. PMID: 26855068.

Article27. Yildiz C, Vanlioğlu BA, Evren B, Uludamar A, Ozkan YK. Marginal-internal adaptation and fracture resistance of CAD/CAM crown restorations. Dent Mater J. 2013; 32:42–47. PMID: 23370869.

Article28. Vanlioglu BA, Evren B, Yildiz C, Uludamar A, Ozkan YK. Internal and marginal adaptation of pressable and computer-aided design/computer-assisted manufacture onlay restorations. Int J Prosthodont. 2012; 25:262–264. PMID: 22545256.29. Alghazzawi TF, Liu PR, Essig ME. The effect of different fabrication steps on the marginal adaptation of two types of glass-infiltrated ceramic crown copings fabricated by CAD/CAM technology. J Prosthodont. 2012; 21:167–172. PMID: 22372838.

Article30. Soares CJ, Martins LR, Fonseca RB, Correr-Sobrinho L, Fernandes Neto AJ. Influence of cavity preparation design on fracture resistance of posterior Leucite-reinforced ceramic restorations. J Prosthet Dent. 2006; 95:421–429. PMID: 16765154.

Article31. Bender IB, Freedland JB. Clinical considerations in the diagnosis and treatment of intra-alveolar root fractures. J Am Dent Assoc. 1983; 107:595–600. PMID: 6579093.

Article32. Schaefer O, Schmidt M, Goebel R, Kuepper H. Qualitative and quantitative three-dimensional accuracy of a single tooth captured by elastomeric impression materials: an in vitro study. J Prosthet Dent. 2012; 108:165–172. PMID: 22944312.

Article33. Phillips S. Report of a special test. NIST Test 2010;681/280055-10, October 8, 2010. accessed November 11, 2011. Available at http://www.geomagic.com/download_file/view/1133/104/.34. Ender A, Mehl A. Accuracy of complete-arch dental impressions: a new method of measuring trueness and precision. J Prosthet Dent. 2013; 109:121–128. PMID: 23395338.

Article35. Ender A, Mehl A. Full arch scans: conventional versus digital impressions-an in-vitro study. Int J Comput Dent. 2011; 14:11–21. PMID: 21657122.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Comparison of the accuracy of digitally fabricated polyurethane model and conventional gypsum model

- A novel 3D scan method to quantify teeth wear

- Comparison on accuracy of porcelain color reproducibility using two colorimeters

- Accuracy of casts produced from conventional and digital workflows: A qualitative and quantitative analyses

- Evaluation of biogeneric design techniques with CEREC CAD/CAM system