J Dent Rehabil Appl Sci.

2017 Jun;33(2):114-118. 10.14368/jdras.2017.33.2.114.

The effect of a titanium socket with a zirconia abutment on screw loosening after thermocycling in an internally connected implant: a preliminary study

- Affiliations

-

- 1Department of Prosthodontics, College of Medicine, University of Ulsan, Asan Medical Center, Seoul, Republic of Korea. ljhl11911@hanmail.net

- KMID: 2388017

- DOI: http://doi.org/10.14368/jdras.2017.33.2.114

Abstract

- PURPOSE

The aim of this study was to investigate the effects of a titanium component for the zirconia abutment in the internal connection implant system on screw loosening under thermocycling conditions.

MATERIALS AND METHODS

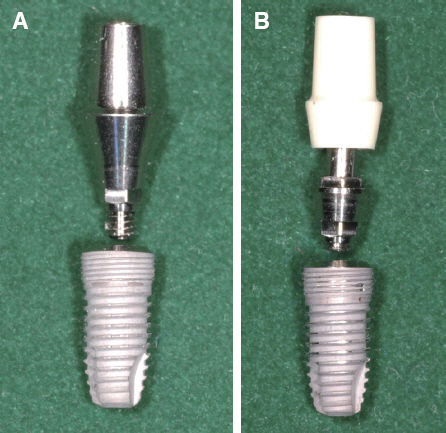

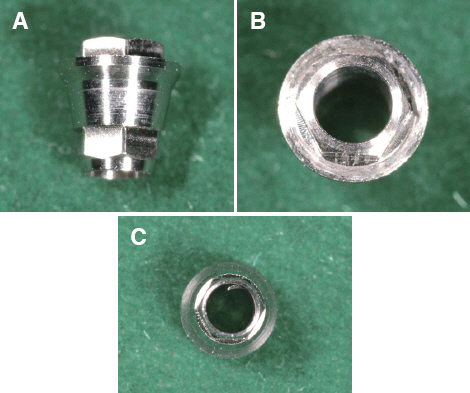

Internal connection titanium abutments and external connection zirconia abutments with titanium sockets were connected respectively to screw-shaped internal connection type titanium implants with 30 Ncm tightening. These implant-screw-abutment assemblies were divided into two groups of five specimens each; titanium abutments as control and zirconia abutments with titanium sockets as experimental group. The specimens were subjected to 2,000 thermocycles in water baths at 5℃ and 55℃, with 60 seconds of immersion at each temperature. The removal torque values (RTVs) of the abutment screws of the specimen were measured before and after thermocycling. RTVs pre- and post-thermocycling were investigated in statistics.

RESULTS

There was not screw loosening identified by tactile and visual inspection in any of the specimens during or after thermocycling. The mean RTV difference for the control group and the experimental group were -1.34 ± 2.53 Ncm and -1.26 ± 2.06 Ncm, respectively. Statistical analysis using an independent t-test revealed that no significant differences were found in the mean RTV difference of the groups (P > 0.05).

CONCLUSION

Within the limitations of this in vitro study, the titanium socket for the zirconia abutment did not show a significant effect on screw loosening under thermal stress compared to the titanium abutment in the internal connection implant.

Keyword

Figure

Cited by 1 articles

-

The effect of heat to remove cement on implant titanium abutment and screw

Hyo-Gyoung Yi, Ki-Sung Gil, Jung-Jin Lee, Seung-Geun Ahn, Jae-Min Seo

J Korean Acad Prosthodont. 2018;56(3):179-187. doi: 10.4047/jkap.2018.56.3.179.

Reference

-

References

1. Yildirim M, Fischer H, Marx R, Edelhoff D. In vivo fracture resistance of implant-supported allceramic restorations. J Prosthet Dent. 2003; 90:32531. DOI: 10.1016/S0022-3913(03)00514-6.2. Apholt W, Bindl A, Lüthy H, Mörmann WH. Flexural strength of Cerec 2 machined and jointed InCeram-Alumina and InCeram-Zirconia bars. Dent Mater. 2001; 17:260–7. DOI: 10.1016/S0109-5641(00)00080-4.3. Garvie RC, Hannink RH, Pascoe RT. Ceramic steel? Nature. 1975; 258:703–4. DOI: 10.1038/258703a0.4. Adatia ND, Bayne SC, Cooper LF, Thompson JY. Fracture resistance of yttria-stabilized zirconia dental implant abutments. J Prosthodont. 2009; 18:1722. DOI: 10.1111/j.1532-849X.2008.00378.x. PMID: 19166544.5. Sailer I, Sailer T, Stawarczyk B, Jung RE, Hämmerle CH. In vitro study of the influence of the type of connection on the fracture load of zirconia abutments with internal and external implant-abutment connections. Int J Oral Maxillofac Implants. 2009; 24:850–8.6. Chun HJ, Yeo IS, Lee JH, Kim SK, Heo SJ, Koak JY, Han JS, Lee SJ. Fracture strength study of internally connected zirconia abutments reinforced with titanium inserts. Int J Oral Maxillofac Implants. 2015; 30:346–50. DOI: 10.11607/jomi.3768. PMID: 25830395.7. Ekelund JA, Lindquist LW, Carlsson GE, Jemt T. Implant treatment in the edentulous mandible:a prospective study on Brånemark system implants over more than 20 years. Int J Prosthodont. 2003; 16:602–8.8. Eckert SE, Meraw SJ, Cal E, Ow RK. Analysis of incidence and associated factors with fractured implants:a retrospective study. Int J Oral Maxillofac Implants. 2000; 15:662–7.9. Taylor TD, Agar JR, Vogiatzi T. Implant prosthodontics:current perspective and future directions. Int J Oral Maxillofac Implants. 2000; 15:66–75.10. Winkler S, Ring K, Ring JD, Boberick KG. Implant screw mechanics and the settling effect:overview. J Oral Implantol. 2003; 29:242–5. DOI: 10.1563/1548-1336(2003)029<0242:ISMATS=2.3.CO;2.11. Halliday D, Resnick R, Walker J. Fundamentals of physics extended. 8th ed. Hoboken: Wiley;2008. p. 586–91.12. McGlumphy EA, Mendel DA, Holloway JA. Implant screw mechanics. Dent Clin North Am. 1998; 42:71–89.13. Burguete RL, Johns RB, King T, Patterson EA. Tightening characteristics for screwed joints in osseointegrated dental implants. J Prosthet Dent. 1994; 71:592–9. DOI: 10.1016/0022-3913(94)90443-X.14. Traini T, Di Iorio D, Caputi S, Degidi M, Iezzi G, Piattelli A. In vitro evaluation of thermomechanic coupling in conical implant-to-abutment joint. Implant Dent. 2007; 16:379–86. DOI: 10.1097/ID.0b013e31815709db. PMID: 18091166.15. Low D, Sumii T, Swain M. Thermal expansion coefficient of titanium casting. J Oral Rehabil. 2001; 28:239–42. DOI: 10.1046/j.1365-2842.2001.00664.x. PMID: 11350579 .

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Removal torque of a two-piece zirconia abutment with a novel titanium component in an internal connection implant system after dynamic cyclic loading

- Comparison of marginal and internal fit of zirconia abutments with titanium abutments in internal hexagonal implants

- Correlation between microleakage and screw loosening at implant-abutment connection

- Alternative Method to Salvage an Internally Damaged Implant using Cast Post

- Zirconia Abutment Fracture in the Anterior Region: Case Series