J Dent Rehabil Appl Sci.

2016 Sep;32(3):246-254. 10.14368/jdras.2016.32.3.246.

Fixed prostheses fabricated by direct metal laser sintering system: case report

- Affiliations

-

- 1Department of Prosthodontics, School of Dentistry, Dankook University, Cheonan, Republic of Korea. syshin@dankook.ac.kr

- KMID: 2357854

- DOI: http://doi.org/10.14368/jdras.2016.32.3.246

Abstract

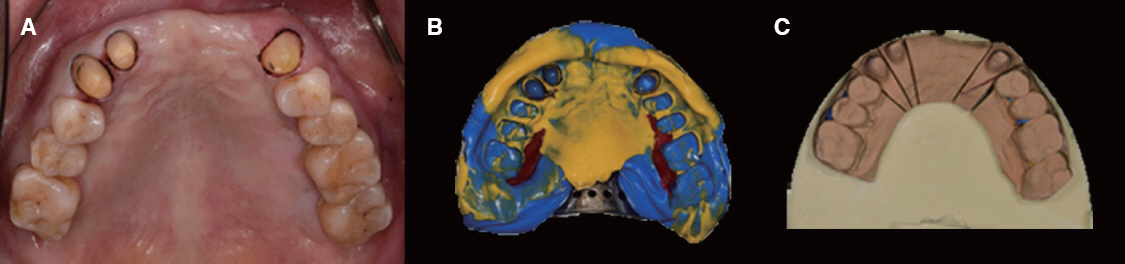

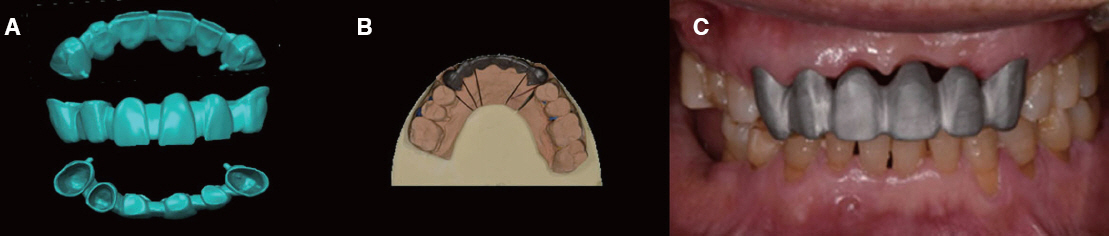

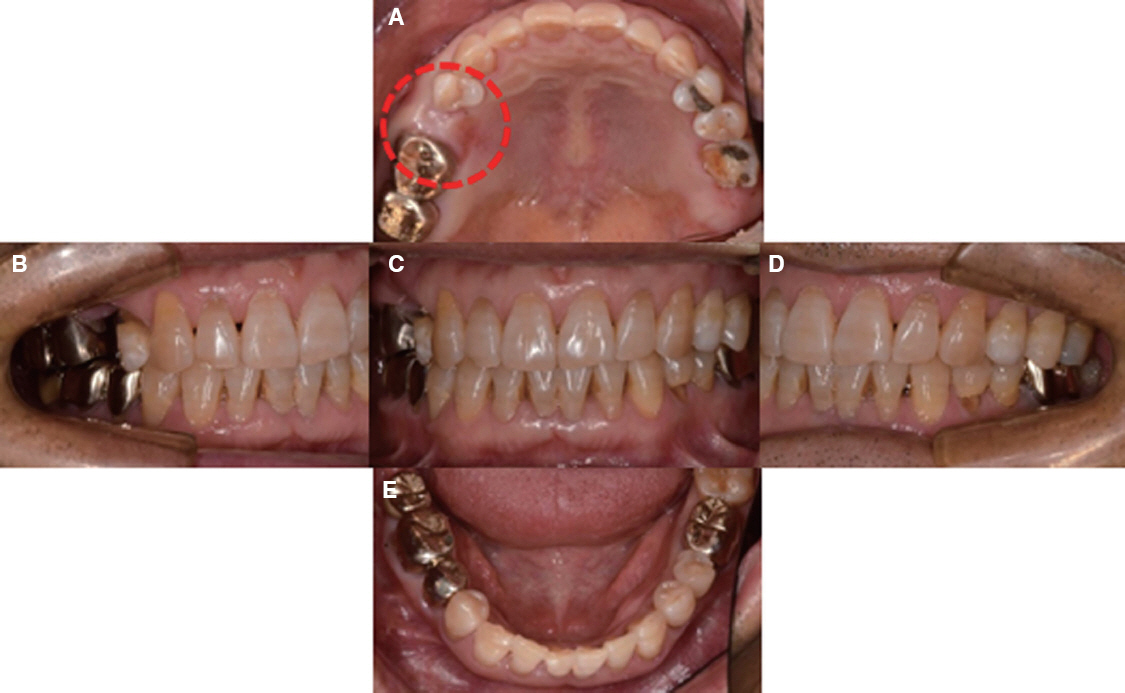

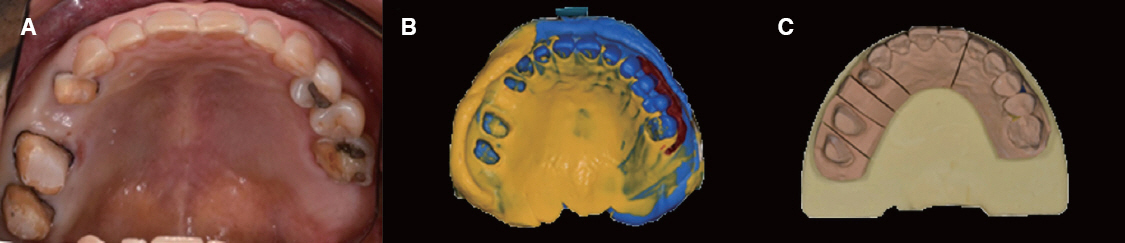

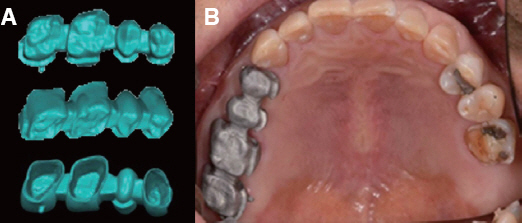

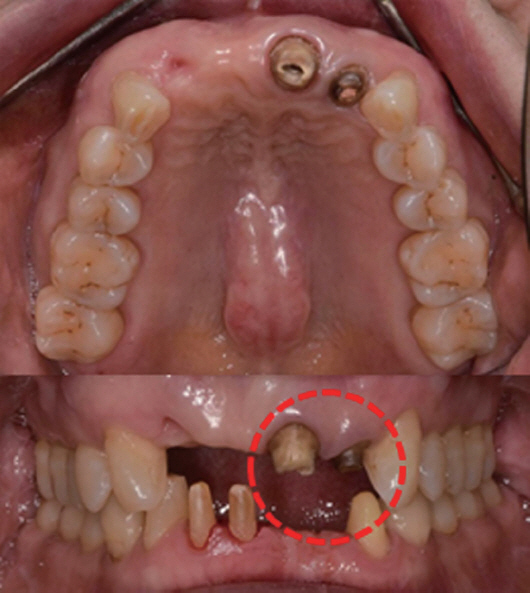

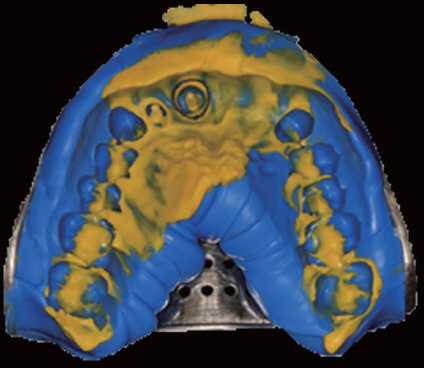

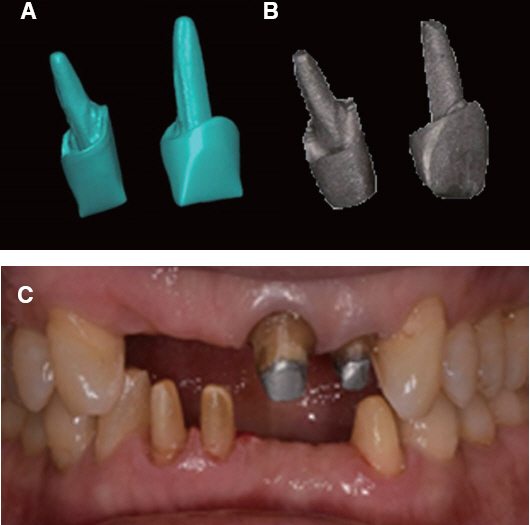

- Nowadays, 3 dimentional (3D) printing, especially Direct Metal Laser Sintering (DMLS) system is used in dentistry. DMLS system has recently been introduced for fabrication metal framework for metal ceramic crowns to overcome the disadvantages of the casting method and computer aided design/computer aided manufacturing (CAD/CAM) milling system. DMLS system uses a high-temperature laser beam to selectively heat a substructure metal powder based on the CAD data with the framework design. A thin layer of the beamed area becomes fused, and the metal framework is completed by laminating these thin layers. Utilizing DMLS system to fabricate fixed prostheses is expected to achieve free-from shaping without mold and limitations from cutting tools, fabricate prostheses with complex geometry, prevent distortion and fabrication defects that inherent to conventional fabrication methods. The purpose of this case report is to demonstrate various fixed prostheses such as long span fixed prostheses, post to achieve satisfactory results in functional and esthetic aspects.

MeSH Terms

Figure

Reference

-

References

1. Abduo J, Lyons K, Swain M. Fit of zirconia fixed partial denture: a systematic review. J Oral Rehabil. 2010; 37:866–76. DOI: 10.1111/j.1365-2842.2010.02113.x. PMID: 20557435.2. Pimenta MA, Frasca LC, Lopes R, Rivaldo E. Evaluation of marginal and internal fit of ceramic and metallic crown copings using x-ray microtomography (micro-CT) technology. J Prosthet Dent. 2015; 114:223–8. DOI: 10.1016/j.prosdent.2015.02.002. PMID: 25882975.3. Miyazaki T, Hotta Y, Kunii J, Kuriyama S, Tamaki Y. A review of dental CAD/CAM: current status and future perspectives from 20 years of experience. Dent Mater J. 2009; 28:44–56. DOI: 10.4012/dmj.28.44. PMID: 19280967.4. Takaichi A, Suyalatu Nakamoto T, Joko N, Nomura N, Tsutsumi Y, Migita S, Doi H, Kurosu S, Chiba A, Wakabayashi N, Igarashi Y, Hanawa T. Microstructures and mechanical properties of Co- 29Cr-6Mo alloy fabricated by selective laser melting process for dental applications. J Mech Behav Biomed Mater. 2013; 21:67–76. DOI: 10.1016/j.jmbbm.2013.01.021. PMID: 23500549.5. Traini T, Mangano C, Sammons RL, Mangano F, Macchi A, Piattelli A. Direct laser metal sintering as a new approach to fabrication of an isoelastic functionally graded material for manufacture of porous titanium dental implants. Dent Mater. 2008; 24:1525–33. DOI: 10.1016/j.dental.2008.03.029. PMID: 18502498.6. Deckard C, Beaman JJ. Process and control issues in selective laser sintering. ASME Prod Eng Div (Publication) PED. 1988; 33:191–7.7. Park JK, Lee WS, Kim HY, Kim WC, Kim JH. Accuracy evaluation of metal copings fabricated by computer-aided milling and direct metal laser sintering systems. J Adv Prosthodont. 2015; 7:122–8. DOI: 10.4047/jap.2015.7.2.122. PMID: 25932310. PMCID: PMC4414942.8. Ayyıldız S, Soylu EH, Ide S, Kılıç S, Sipahi C, Pi kin B, Gökçe HS. Annealing of Co-Cr dental alloy: effects on nanostructure and Rockwell hardness. J Adv Prosthodont. 2013; 5:471–8. DOI: 10.4047/jap.2013.5.4.471. PMID: 24353888. PMCID: PMC3865205.9. Bilgin MS, Erdem A, Dilber E, Ersoy I. Comparison of fracture resistance between cast, CAD/CAM milling, and direct metal laser sintering metal post systems. J Prosthodont Res. 2016; 60:23–8. DOI: 10.1016/j.jpor.2015.08.001. PMID: 26347450.10. Ucar Y, Akova T, Akyil M, Brantley WA. Internal fit evaluation of crowns prepared using a new dental crown fabrication technique: laser-sintered Co–Cr crowns. J Prosthet Dent. 2009; 102:253–9. DOI: 10.1016/S0022-3913(09)60165-7.11. Örtorp A, Jönsson D, Mouhsen A, Vult von Steyern P. The fit of cobalt-chromium three-unit fixed dental prostheses fabricated with four different techniques: a comparative in vitro study. Dent Mater. 2011; 27:356–63. DOI: 10.1016/j.dental.2010.11.015. PMID: 21163516.12. Beuer F, Schweiger J, Edelhoff D. Digital dentistry: an overview of recent developments for CAD/CAM generated restorations. Br Dent J. 2008; 204:505–11. DOI: 10.1038/sj.bdj.2008.350. PMID: 18469768.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Evaluation of marginal discrepancy in metal frameworks fabricated by sintering-based computer-aided manufacturing methods

- Implant-supported prosthetic rehabilitation for the edentulous maxilla using the additive manufacturing technology: A case report

- Comparative clinical study of the marginal discrepancy of fixed dental prosthesis fabricated by the milling-sintering method using a presintered alloy

- DMLS (Direct Metal Laser Sintering) denture repair technique for a removable partial denture: A case report

- Metal-ceramic bond strength between a feldspathic porcelain and a Co-Cr alloy fabricated with Direct Metal Laser Sintering technique